Modern engine management systems represent one of the most sophisticated technological advances in automotive engineering. These complex networks of sensors, actuators, and electronic control units work together to optimize engine performance, reduce emissions, and improve fuel economy while maintaining smooth operation across all driving conditions.

Safety Notice: Engine management system diagnosis requires professional-grade scan tools and technical knowledge. While intermediate DIY enthusiasts can perform basic maintenance, electrical diagnostics should be left to qualified technicians to prevent damage to expensive components.

Why Engine Management Systems Are Critical for Engine Performance

The engine management system serves as the brain of your vehicle’s powerplant, continuously monitoring and adjusting dozens of parameters to maintain optimal combustion. Without this precise control, modern engines would suffer from poor performance, excessive emissions, and premature component failure.

Primary Functions of Engine Management

Fuel Delivery Control: The ECU precisely calculates the exact amount of fuel needed for each combustion cycle based on inputs from multiple sensors. This calculation occurs thousands of times per minute, adjusting for changing conditions like throttle position, engine load, and ambient temperature.

Ignition Timing Optimization: Advanced timing maps stored in the ECU determine the optimal spark timing for maximum power and efficiency while preventing engine knock. The system can advance or retard timing in real-time based on feedback from knock sensors and other inputs.

Emissions Control: Modern engine management systems integrate with exhaust aftertreatment components like catalytic converters and oxygen sensors to maintain stoichiometric air-fuel ratios and minimize harmful emissions.

Closed-Loop Control: The system continuously monitors its own performance through feedback sensors, making real-time adjustments to maintain optimal operation. This closed-loop approach ensures consistent performance despite changing conditions.

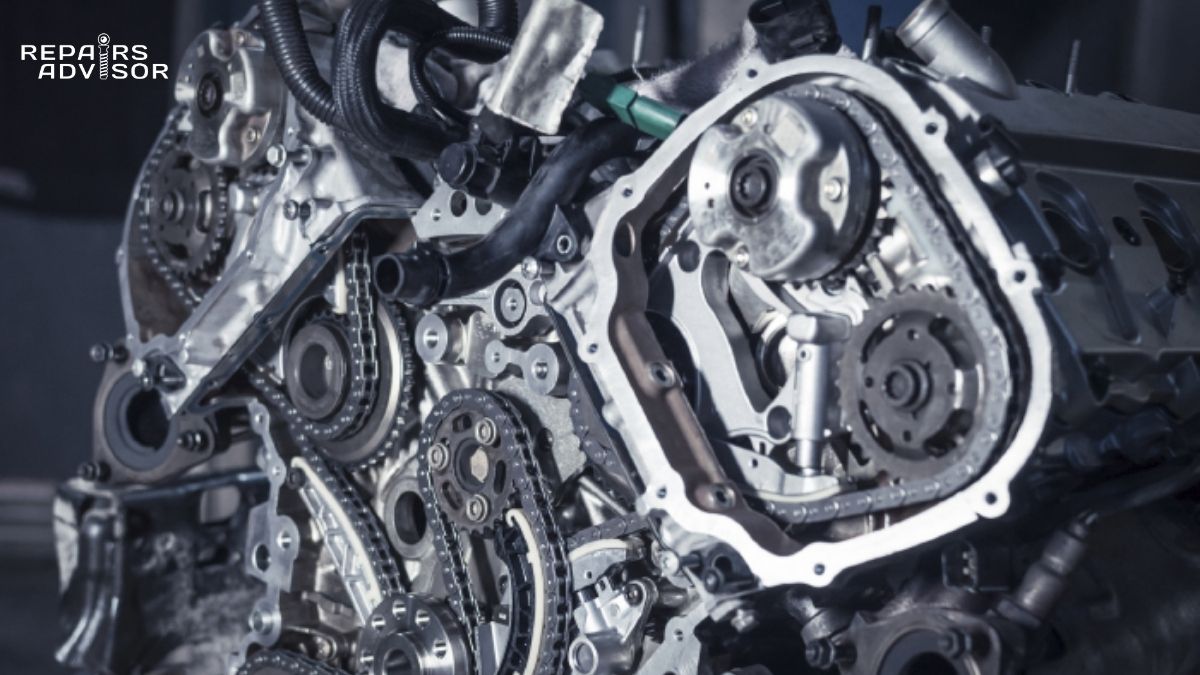

Engine Management System Parts and Construction Explained

Understanding the major components of an engine management system helps appreciate the complexity and precision required for modern engine operation.

Electronic Control Unit (ECU)

The ECU serves as the central processing hub, containing powerful microprocessors that execute millions of calculations per second. Modern ECUs feature multiple processor cores, extensive memory for fuel and timing maps, and sophisticated input/output circuits capable of handling analog and digital signals from numerous sensors.

Construction Elements: High-speed processors, flash memory for calibration storage, RAM for real-time calculations, input conditioning circuits, output driver circuits, and robust connectors designed for harsh automotive environments.

Primary Sensor Network

Mass Air Flow (MAF) Sensor: Located in the air intake system, MAF sensors measure the actual mass of air entering the engine. This critical input allows the ECU to calculate precise fuel requirements for optimal combustion.

Manifold Absolute Pressure (MAP) Sensor: MAP sensors monitor intake manifold pressure, providing load information that helps determine fuel and timing requirements. Some systems use both MAF and MAP sensors for enhanced accuracy.

Throttle Position Sensor (TPS): Throttle position sensors communicate driver intent to the ECU, enabling rapid response to throttle changes and proper fuel delivery matching.

Temperature Monitoring Systems

Engine Coolant Temperature (ECT) Sensor: Coolant temperature sensors provide critical thermal information that affects fuel delivery, ignition timing, and emission control strategies. Cold engines require different calibrations than fully warmed engines.

Intake Air Temperature (IAT) Sensor: This sensor monitors incoming air temperature, allowing the ECU to compensate for density changes that affect combustion quality and power output.

Timing and Position Sensors

Crankshaft Position Sensor (CKP): Crankshaft position sensors provide essential timing reference signals that synchronize fuel injection and ignition events with engine rotation.

Camshaft Position Sensor (CMP): Camshaft position sensors enable cylinder identification in sequential fuel injection systems and provide feedback for variable valve timing systems.

How Engine Management Systems Work: Step-by-Step Operation

The operation of a modern engine management system involves complex real-time processing that occurs in precisely timed cycles synchronized with engine rotation.

Data Acquisition Phase

The process begins with continuous sensor monitoring. The ECU samples inputs from all sensors hundreds of times per second, converting analog signals to digital values and processing digital communications from intelligent sensors.

Signal Processing: Raw sensor signals undergo filtering and conditioning to remove electrical noise and ensure accuracy. The ECU validates sensor readings against expected ranges and may substitute calculated values if sensors fail.

Calculation and Decision Making

Using stored calibration maps and real-time sensor data, the ECU calculates optimal fuel delivery, ignition timing, and other parameters for current operating conditions.

Fuel Calculation: The ECU determines base fuel requirements using air flow measurements, then applies corrections for temperature, barometric pressure, engine warm-up status, and feedback from exhaust oxygen sensors.

Ignition Timing Calculation: Base timing maps provide starting values that are modified based on knock sensor feedback, engine temperature, load conditions, and fuel quality adaptations.

Output Control Phase

The ECU generates precisely timed control signals for fuel injectors, ignition coils, and other actuators. These signals must be delivered with microsecond precision to maintain proper engine operation.

Fuel Injection Control: Modern systems use sequential injection, where each cylinder receives fuel at the optimal time in its cycle. The ECU controls injection duration and timing with extreme precision.

Ignition System Control: The ECU triggers ignition coils at precisely calculated moments, adjusting timing for each cylinder individually in advanced systems.

Feedback and Adaptation

The system continuously monitors results through feedback sensors and adapts its control strategies accordingly. This adaptive capability allows the engine to maintain optimal performance despite component wear and changing conditions.

Short-Term Adaptations: Immediate adjustments based on oxygen sensor feedback and knock detection maintain optimal combustion in real-time.

Long-Term Learning: The ECU stores adaptation values in memory, learning from driving patterns and component variations to improve performance over time.

Engine Management System Location and Access Guide

Understanding the physical layout of engine management components helps with maintenance and troubleshooting activities.

ECU Location and Access

Most engine control units are located in protected areas within the engine compartment or passenger cabin. Common locations include the firewall area, inside the air cleaner housing, or under the dashboard.

Intermediate DIY Access: ECU replacement typically requires connector removal and may involve programming or coding procedures. While physically accessible, ECU service should be performed by qualified technicians with appropriate diagnostic equipment.

Professional Considerations: Modern ECUs contain vehicle-specific calibrations and security protocols that require specialized tools for replacement or programming.

Sensor Accessibility

Easy Access Sensors: Components like throttle bodies and some temperature sensors are typically accessible for cleaning and basic maintenance by intermediate DIY enthusiasts.

Moderate Access Sensors: MAF sensors and oxygen sensors require more involved procedures but remain within the capabilities of experienced DIY mechanics with proper tools.

Professional Service Sensors: Crankshaft and camshaft position sensors often require significant disassembly and timing procedures that are best left to professional technicians.

Diagnostic Access Points

OBD-II Connector: All modern vehicles provide standardized diagnostic access through the OBD-II port, typically located under the dashboard. This connection allows scan tools to communicate with the engine management system for trouble code retrieval and live data monitoring.

Advanced Diagnostics: Professional-level diagnostics may require manufacturer-specific scan tools capable of bi-directional testing and advanced programming functions.

Maintenance and Service Considerations

Proper maintenance of engine management systems ensures reliable operation and prevents costly component failures.

Regular Maintenance Items

Air Filter Service: Clean air filters are essential for accurate MAF sensor readings and overall system performance. Replace filters according to manufacturer recommendations or when visibly contaminated.

Fuel System Maintenance: Quality fuel and regular fuel system cleaning help prevent injector fouling that can affect fuel delivery accuracy and engine performance.

Diagnostic Procedures

Scan Tool Usage: Regular diagnostic scans can identify developing problems before they cause driveability issues. Intermediate DIY enthusiasts should invest in quality OBD-II scan tools capable of reading manufacturer-specific codes.

Sensor Testing: Professional diagnosis often requires oscilloscope testing and live data analysis to verify proper sensor operation and signal quality.

Common Issues and Solutions

Sensor Contamination: MAF sensors and throttle bodies can accumulate deposits that affect operation. Regular cleaning with appropriate solvents can restore proper function.

Electrical Problems: Corroded connectors and damaged wiring harnesses are common causes of engine management issues. Visual inspection and electrical testing help identify these problems.

Software Updates: Manufacturers occasionally release ECU software updates that improve performance or address known issues. These updates require professional equipment and procedures.

Integration with Vehicle Systems

Modern engine management systems don’t operate in isolation but integrate closely with other vehicle systems for optimal performance and efficiency.

Transmission Integration

The engine management system communicates with transmission control modules to coordinate shift timing, torque delivery, and efficiency optimization. This integration is particularly important in vehicles with continuously variable transmissions and hybrid powertrains.

Climate Control Integration

Engine thermal management affects both performance and cabin comfort. The ECU coordinates with climate control systems to manage cooling fan operation, warm-up strategies, and thermal load balancing.

Safety System Integration

Modern vehicles integrate engine management with safety systems like electronic stability control and traction control. The ECU can reduce engine torque output when these systems detect loss of vehicle control.

Hybrid and Electric Integration

In hybrid vehicles, engine management systems coordinate with electric motor controllers and battery management systems to optimize power delivery and efficiency. This integration requires sophisticated energy management strategies and seamless transitions between power sources.

Troubleshooting and Professional Support

Engine management system problems can manifest in various ways, from reduced performance to complete no-start conditions.

Diagnostic Approach

Initial Assessment: Start with scan tool diagnosis to retrieve stored trouble codes and review live data parameters. Compare readings to known good values and manufacturer specifications.

Systematic Testing: Follow logical diagnostic procedures, testing sensors and actuators individually while considering system interactions and dependencies.

When to Seek Professional Help

Complex Electrical Issues: Intermittent problems, communication errors, and multiple system failures typically require professional diagnosis with advanced equipment.

Programming Requirements: ECU replacement, software updates, and security system relearning procedures require manufacturer-specific tools and procedures available only to professional technicians.

Safety-Critical Systems: Any issues affecting emissions control, safety systems, or drivability should be diagnosed and repaired by qualified professionals to ensure proper operation and compliance with regulations.

Information for reference only: Engine management systems are complex and safety-critical. Always consult manufacturer service procedures and professional guidance for diagnosis and repair procedures.

For additional technical support and comprehensive repair procedures, visit our help center or contact our technical support team at [email protected] for detailed manual recommendations specific to your vehicle’s engine management system.