Engine timing systems are the precision choreographers of your vehicle’s powerplant, orchestrating the precise coordination between your engine’s intake, compression, combustion, and exhaust cycles. Whether your engine uses a timing chain, timing belt, or advanced variable valve timing technology, these systems ensure optimal performance, fuel efficiency, and emissions control across all operating conditions.

⚠️ Safety Notice: Engine timing system work involves precise procedures and specialized tools. Incorrect timing can cause severe engine damage. Beginners should focus on understanding operation principles, while timing adjustments and component replacement should be performed by experienced technicians with proper equipment.

Why Engine Timing Systems Are Critical for Engine Performance

Engine timing systems serve as the central nervous system of your engine’s valve train, controlling when intake and exhaust valves open and close relative to piston position and crankshaft rotation. This precise synchronization directly impacts engine power output, fuel economy, emissions compliance, and component longevity.

Primary Functions of Engine Timing Systems

Valve Event Coordination: The timing system ensures intake valves open precisely when pistons create maximum vacuum during the intake stroke, optimizing air-fuel mixture entry. Similarly, exhaust valves open at the optimal moment during the exhaust stroke to efficiently expel combustion gases while maintaining proper back-pressure for scavenging.

Combustion Chamber Sealing: Proper timing ensures both intake and exhaust valves remain fully closed during compression and combustion strokes, maintaining optimal compression ratios and preventing pressure loss that would reduce power output and efficiency.

Dynamic Timing Optimization: Modern variable valve timing systems adjust cam timing based on engine speed, load, and temperature conditions. This allows engines to maintain optimal performance characteristics across their entire operating range, from idle efficiency to high-RPM power delivery.

Component Protection: Accurate timing prevents valve-to-piston interference on interference engines, where pistons travel into the valve pocket area at top dead center. Even minor timing errors can result in catastrophic internal damage requiring complete engine rebuilding.

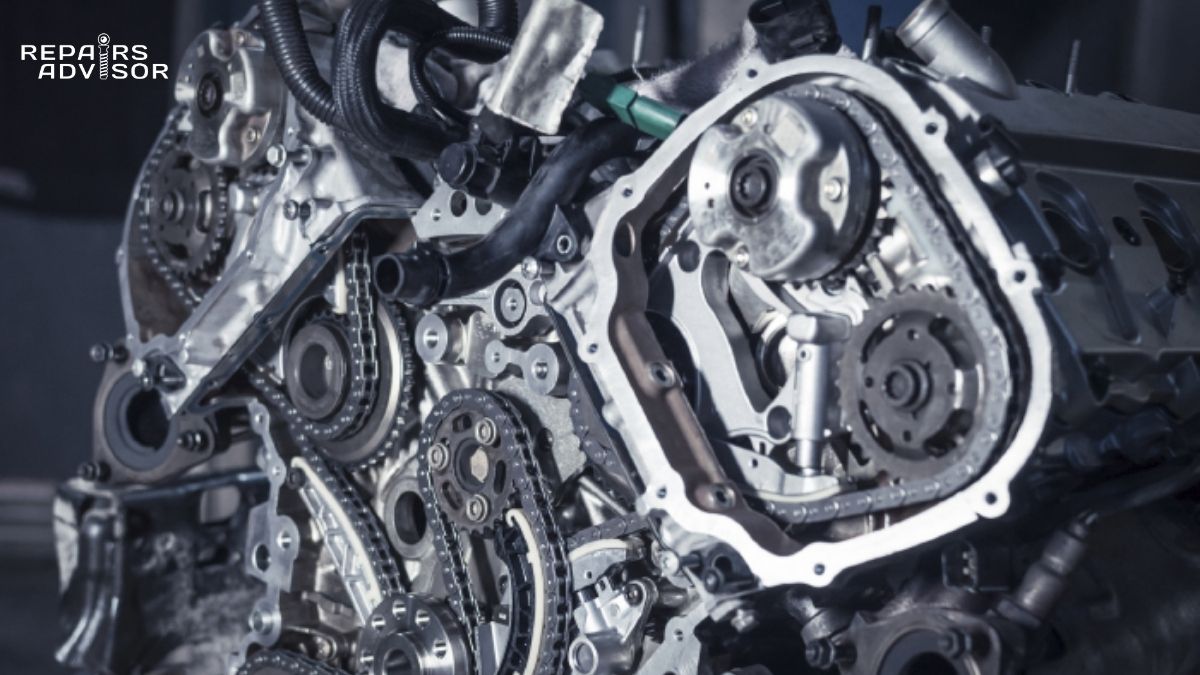

Engine Timing System Parts and Construction Explained

Modern engine timing systems integrate mechanical, hydraulic, and electronic components to achieve precise valve timing control under all operating conditions.

Core Mechanical Components

Timing Chains: Steel roller chains connect the crankshaft to camshaft sprockets, providing durable power transmission with minimal stretch over time. Modern timing chains feature improved metallurgy and precision manufacturing that extends service intervals to 100,000+ miles in many applications. Chain systems typically include primary chains (crankshaft to intermediate shaft) and secondary chains (intermediate shaft to camshafts) in complex configurations.

Timing Belts: Reinforced rubber belts with fiber or steel reinforcement provide quiet operation and precise timing control. Belt-driven systems require more frequent replacement intervals (typically 60,000-105,000 miles) but offer advantages in noise reduction and manufacturing cost. Timing belt systems often drive additional components like water pumps and oil pumps.

Sprockets and Pulleys: Precisely machined components transfer rotational motion between the crankshaft and camshafts at the correct 2:1 ratio (crankshaft rotates twice for each camshaft rotation). Sprocket tooth profiles and timing marks ensure accurate initial timing during assembly and service procedures.

Tension and Guide Systems

Chain Tensioners: Hydraulic or spring-loaded tensioners maintain proper chain tension throughout the engine’s operating range, compensating for thermal expansion and gradual chain stretch over time. Modern hydraulic tensioners use engine oil pressure for consistent tension control and often include ratcheting mechanisms to prevent timing chain slack during engine off cycles.

Chain Guides: Fixed and pivoting guides control chain path and prevent excessive vibration that could cause premature wear or timing variations. Upper guides typically mount to the cylinder head, while lower guides attach to the engine block, creating a controlled chain pathway that maintains proper sprocket engagement.

Belt Tensioners: Spring-loaded or hydraulic tensioners maintain optimal belt tension to prevent slippage while avoiding excessive stress that could cause premature belt failure. Many modern systems include automatic tensioning that adjusts for belt stretch and thermal conditions throughout the service interval.

Advanced Variable Timing Components

Cam Phasers: Hydraulic actuators mounted between timing chain sprockets and camshafts allow continuous adjustment of cam timing relative to crankshaft position. These systems typically provide 15-50 degrees of timing adjustment range, enabling optimization for different engine operating conditions.

VVT Solenoids: Electronically controlled oil flow valves direct hydraulic pressure to cam phasers based on engine management system commands. These solenoids respond to inputs from crankshaft position sensors, camshaft position sensors, and various engine load sensors.

Oil Control Valves: Precision valves regulate oil flow and pressure to variable timing actuators, ensuring accurate timing response under all engine operating conditions. These components require clean oil and proper pressure for reliable operation.

How Engine Timing Systems Work: Step-by-Step Operation

Engine timing systems operate through precise mechanical coordination between rotating assemblies, with modern systems adding electronic control for dynamic optimization.

Basic Mechanical Timing Operation

Crankshaft Drive: The crankshaft’s rotation provides the primary drive force through timing sprockets or pulleys. As the crankshaft completes two full rotations (720 degrees), each camshaft completes one rotation (360 degrees), maintaining the 2:1 drive ratio essential for proper four-stroke engine operation.

Power Transmission: Timing chains or belts transfer crankshaft rotation to camshaft sprockets or pulleys with minimal backlash and precise timing relationship. Chain systems provide direct mechanical connection, while belt systems may include intermediate tensioning systems to maintain proper drive characteristics.

Valve Event Sequencing: As camshafts rotate, their lobes actuate rocker arms or direct-acting mechanisms that open and close intake and exhaust valves at precisely timed intervals. The shape and timing of cam lobes determine valve duration, lift characteristics, and overlap timing between intake and exhaust events.

Variable Timing System Operation

Electronic Control Integration: The engine control unit monitors engine speed, load, temperature, and throttle position to determine optimal cam timing for current operating conditions. Throttle position sensors, MAP sensors, and other inputs provide real-time feedback for timing adjustments.

Hydraulic Actuation: VVT solenoids receive electronic commands and direct engine oil flow to cam phasers or other variable timing actuators. Oil pressure creates the force necessary to advance or retard cam timing against spring pressure and combustion loads.

Continuous Adjustment: Modern systems can adjust cam timing continuously within their operating range, providing optimized valve events for idle stability, part-throttle fuel economy, and maximum power output. Some advanced systems adjust intake and exhaust cam timing independently for maximum flexibility.

Feedback and Correction: Camshaft position sensors provide continuous feedback to the engine control unit, enabling closed-loop timing control that compensates for system tolerances, wear, and changing operating conditions.

System Integration and Coordination

Multi-Camshaft Coordination: Dual overhead cam engines typically include separate timing drives for intake and exhaust camshafts, with some systems providing independent variable timing control for each camshaft. This allows optimization of valve overlap timing, intake charging effects, and exhaust gas retention strategies.

Accessory Drive Integration: Many timing systems also drive essential engine accessories including water pumps, oil pumps, and fuel injection pumps. This integration requires careful consideration of drive ratios and component placement to ensure reliable operation of all engine systems.

Engine Timing System Location and Access Guide

Engine timing systems are typically located at the front of the engine, behind the main accessory drive components, requiring systematic disassembly for inspection and service.

Component Access Procedures

External Access Points: Timing covers provide access to timing components while protecting them from contamination. These covers may be single-piece or multi-section designs, with gasket sealing systems that require careful attention during removal and installation to prevent oil leaks.

Upper Chain/Belt Access: The upper portion of timing systems is typically accessible after removing valve covers, cooling system components, and upper timing covers. This area provides access to chain guides, tensioners, and camshaft sprockets for inspection and service.

Crankshaft Access: Lower timing components require access to the crankshaft pulley and lower timing covers. This often involves supporting the engine and removing front motor mounts to provide adequate working clearance for component removal.

Service Access Considerations

Interference Engine Precautions: Engines with interference designs require absolute precision during timing component service to prevent valve-to-piston contact. Proper locking tools and timing procedures are essential for safe component replacement.

Specialized Tool Requirements: Timing system service typically requires specific holding tools, tensioning devices, and timing equipment unique to each engine design. Generic tools may not provide adequate precision or safety margins for proper service procedures.

Multiple System Coordination: Modern engines often integrate timing system service with other major components including water pumps, front engine seals, and accessory drives. This integration can affect service intervals and repair procedures.

Professional Service Recommendations

Timing Belt Replacement: Belt-driven systems require periodic replacement based on time and mileage intervals. This service typically includes tensioner replacement, sprocket inspection, and often includes related components like water pumps to maximize service value and reliability.

Chain System Inspection: While timing chains generally last longer than belts, they require periodic inspection for stretch, guide wear, and tensioner operation. Early detection of timing system wear can prevent more extensive engine damage.

Variable Timing System Maintenance: VVT systems require clean oil and proper pressure for reliable operation. Regular oil changes using manufacturer-specified oil grades are essential for preventing timing system problems and maintaining optimal engine performance.

Related Engine Performance Resources

For comprehensive understanding of related engine systems that work closely with timing components:

- How Camshafts and Valve Systems Work – Complete valve train operation

- How Variable Valve Timing Works – Advanced timing optimization

- How Crankshaft Position Sensors Work – Timing reference systems

- How Engine Management Systems Work – Electronic timing control

- How Ignition Systems Work – Spark timing coordination

Professional Consultation: For timing system diagnosis, component replacement, or performance modifications, consult qualified automotive technicians with engine-specific training and proper diagnostic equipment.

This information is provided for educational reference only. Always consult manufacturer specifications and professional guidance for timing system service procedures. Repairs Advisor provides technical manuals and information – timing system work should be performed by experienced professionals with proper tools and safety procedures.