Modern vehicles are experiencing a fundamental transformation in how they stop. If you’ve driven a hybrid, electric vehicle, or recent high-performance car, you’ve likely experienced brake-by-wire technology without realizing it. This electronic braking system represents one of the most significant advances in automotive safety and efficiency since the introduction of anti-lock brakes.

Brake-by-wire technology replaces the direct mechanical connection between your brake pedal and the braking components with an electronic control system. When you press the brake pedal in a brake-by-wire equipped vehicle, sensors detect your input and send electronic signals to actuators that apply the brakes. This might sound concerning at first—no direct connection to your brakes?—but the technology includes extensive redundancy and fail-safe mechanisms that make it as safe or safer than traditional hydraulic systems.

The driving force behind brake-by-wire adoption is the rise of hybrid and electric vehicles. These vehicles use regenerative braking to recover energy during deceleration, converting kinetic energy back into electricity stored in the battery. Traditional hydraulic-only brake systems can’t seamlessly blend regenerative and friction braking—they need electronic mediation to coordinate between the electric motor acting as a generator and the conventional brake calipers. Beyond energy recovery, brake-by-wire enables advanced safety features like automatic emergency braking, adaptive cruise control, and the precise control required for autonomous driving systems.

There are three main types of brake-by-wire systems currently in production or development. Electronic parking brakes have become commonplace since the early 2000s, replacing hand brake levers with push-button activation. Electro-hydraulic brakes (EHB) represent the most common implementation for service brakes, combining electronic control with hydraulic actuation and maintaining a mechanical backup connection. Electro-mechanical brakes (EMB), which would eliminate hydraulic fluid entirely using electric motors at each wheel, remain in development due to regulatory and technical challenges.

This comprehensive guide explains how brake-by-wire systems function, their extensive safety mechanisms, performance advantages, and maintenance requirements. Whether you’re a professional technician working with these systems, an automotive enthusiast interested in emerging technologies, or a vehicle owner wanting to understand your car’s braking system, you’ll gain detailed insights into this transformative technology.

Safety Note: Brake-by-wire systems are safety-critical technologies requiring specialized diagnostic equipment and training. This article is educational only—all brake system repairs and diagnostics should be performed by qualified technicians with appropriate training and manufacturer-specific tools. Never attempt to diagnose or repair brake-by-wire systems without proper certification.

What Are Brake-by-Wire Systems?

Brake-by-wire systems control vehicle braking through electronic means rather than a direct mechanical connection between the brake pedal and the braking components. The fundamental concept is straightforward: sensors detect your brake pedal input, an electronic control unit processes this information and determines the appropriate braking force, and actuators apply that force to the brakes at each wheel. This electronic mediation creates opportunities for enhanced performance, safety features, and integration with electric propulsion systems that traditional hydraulic-only brakes cannot provide.

To understand brake-by-wire, it helps to compare it with traditional hydraulic braking systems. In a conventional setup, pressing the brake pedal pushes a rod into the master cylinder, which generates hydraulic pressure that travels through brake lines to brake calipers at each wheel. The harder you push the pedal, the more hydraulic pressure is created, and the more braking force is applied. This direct mechanical and hydraulic linkage provides immediate feedback—you can feel the road conditions and brake system response through the pedal. In a brake-by-wire system, the pedal position and force are measured by sensors, converted to electronic signals, processed by a control computer, and then actuators create the braking force. The pedal feel you experience is artificially generated by a simulator to match the familiar feel of traditional brakes.

Three Main Brake-by-Wire System Types

Current brake-by-wire technology exists in three distinct forms, each with different levels of integration and commercial deployment.

Electronic Parking Brakes (EPB) represent the most widespread brake-by-wire implementation. Since the early 2000s, electronic parking brakes have increasingly replaced traditional hand brake levers and foot-operated parking brakes. Instead of pulling a lever that mechanically tensions cables connected to the rear brakes, you press a button that sends an electronic signal to electric motors integrated into the rear brake calipers. These motors turn lead screws that push the brake pistons to clamp the pads against the rotors. EPBs offer several advantages: they automatically release when you accelerate (no more forgetting to disengage the parking brake), they integrate with hill start assist to prevent rollback, they provide automatic hold functionality in stop-and-go traffic, and they simplify vehicle design by eliminating mechanical linkages and cables. Most importantly, EPBs proved that electronically controlled braking could be safe and reliable, paving the way for more extensive brake-by-wire implementation.

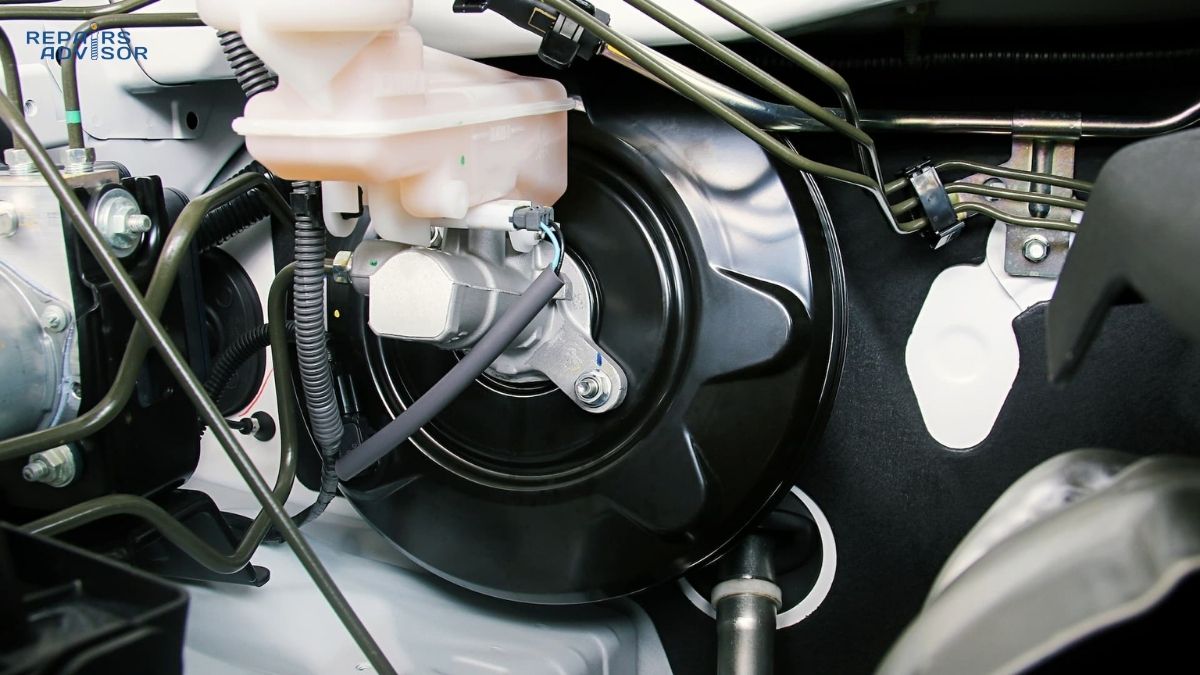

Electro-Hydraulic Brakes (EHB) combine electronic control with hydraulic actuation, representing a hybrid approach that has found substantial adoption in modern vehicles. In an EHB system, an electric motor drives a hydraulic pump to generate brake pressure based on electronic commands from the brake control computer. Two prominent examples demonstrate this technology: the Bosch iBooster uses an electric motor to assist or replace the traditional vacuum booster, providing faster pressure build-up and enabling regenerative braking blending; the Continental MKC1 system, first implemented in the Alfa Romeo Giulia and Stelvio, integrates the master cylinder, hydraulic pump, and ABS components into a single compact unit. A critical safety feature of EHB systems is that they maintain a mechanical backup connection—if the electronics fail, a valve opens to create a direct hydraulic path from the brake pedal to the calipers, allowing the driver to stop the vehicle through manual pedal pressure, albeit with significantly increased effort.

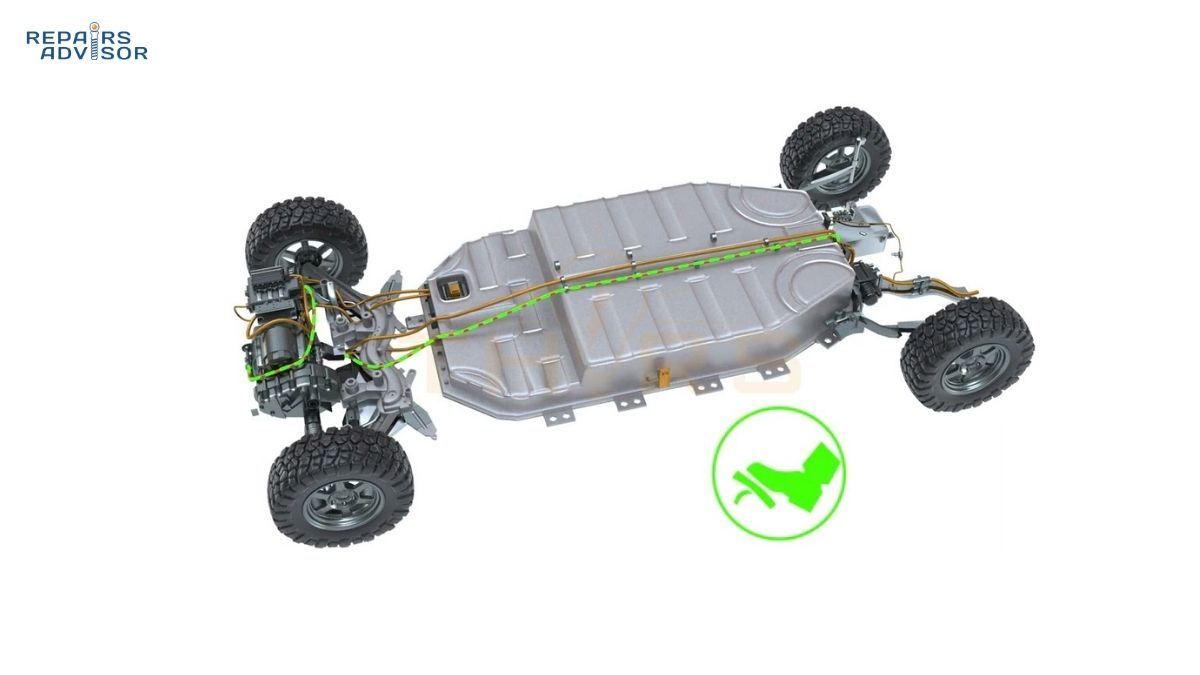

Electro-Mechanical Brakes (EMB) represent the future vision of fully electric brake actuation without any hydraulic fluid. In an EMB system, electric motors at each brake caliper would directly apply clamping force to the brake pads. This “dry” braking system offers compelling advantages: elimination of hydraulic fluid (no more corrosive, environmentally harmful brake fluid), significant weight reduction by removing hydraulic lines and the master cylinder, complete design flexibility in component placement, simplified manufacturing with fewer parts, and potentially enhanced performance with even faster response times. However, as of 2024, EMB systems have not been successfully commercialized in production passenger vehicles. The challenges are substantial: electric motors powerful enough yet compact enough for caliper integration, sufficient electrical power to ensure fail-operational capability, meeting rigorous safety standards including ISO 26262 Level D requirements, and gaining regulatory approval for a system with no mechanical backup. Research continues, and EMB systems may appear in production vehicles within the next decade as electric motors, power electronics, and battery technology continue advancing.

The key distinction between brake-by-wire and traditional systems lies in the electronic mediation of braking commands. Traditional systems provide a direct, proportional connection: more pedal force equals more braking force. Brake-by-wire systems interpret your input and can modify the response based on numerous factors including vehicle speed, road conditions detected by wheel slip sensors, integration with regenerative braking, coordination with stability control systems, and automatic interventions from safety features. This electronic intelligence enables capabilities impossible with purely mechanical systems, though it requires extensive redundancy and fail-safe mechanisms to ensure safety.

How Brake-by-Wire Systems Work: Step-by-Step Operation

Understanding the complete operational cycle of a brake-by-wire system reveals the sophisticated coordination between sensors, computers, and actuators that happens in milliseconds every time you touch the brake pedal.

Step 1: Pedal Input Detection and Signal Processing

The braking process begins the instant your foot contacts the brake pedal. Unlike a traditional brake pedal mechanically connected to a master cylinder, a brake-by-wire pedal is equipped with dual redundant sensors measuring two key parameters: position and force. The pedal position sensor tracks how far you’ve pushed the pedal, typically across a range of 0 to 100 millimeters, providing information about your braking intent and urgency. Simultaneously, the pedal force sensor measures how hard you’re pushing, detecting the pressure you’re applying. These measurements happen continuously at extremely high sampling rates—100 to 1000 times per second—ensuring the system has real-time data with minimal latency.

Redundancy is built in from the very first measurement. The system uses two independent pedal position sensors and two independent force sensors, each generating analog voltage signals proportional to the measured value. These analog signals are converted to digital data that can be processed by the electronic control unit. Before sending this data forward, the system performs validation: it compares readings from the redundant sensors, checks that the values are within expected ranges, and rejects any outliers that indicate a sensor malfunction. If one sensor fails, the system continues operating using the healthy sensor while alerting the driver through a warning light. This dual-sensor architecture ensures that a single sensor failure won’t compromise braking capability.

Step 2: Electronic Control Unit (ECU) Processing and Decision Making

Once validated pedal data reaches the brake control ECU via the vehicle’s CAN bus communication network, sophisticated algorithms calculate the appropriate braking response. The ECU doesn’t simply translate pedal position to braking force—it considers multiple inputs and system states to optimize braking performance and safety.

The brake control ECU processes pedal position, rate of change of pedal position (how quickly you’re pushing), pedal force applied, current vehicle speed from wheel speed sensors, individual wheel speeds for slip detection, driver-selected mode (Sport, Comfort, Eco), and integration requirements with ADAS systems like automatic emergency braking or adaptive cruise control. In hybrid and electric vehicles, the ECU must also determine the optimal split between regenerative braking (using the electric motor as a generator) and friction braking (conventional brake pads and rotors). During light to moderate braking, the system may use regenerative braking exclusively to maximize energy recovery. As braking force increases or vehicle speed drops below the effective regenerative braking range (typically 5-7 mph), the system seamlessly transitions to or blends in friction braking.

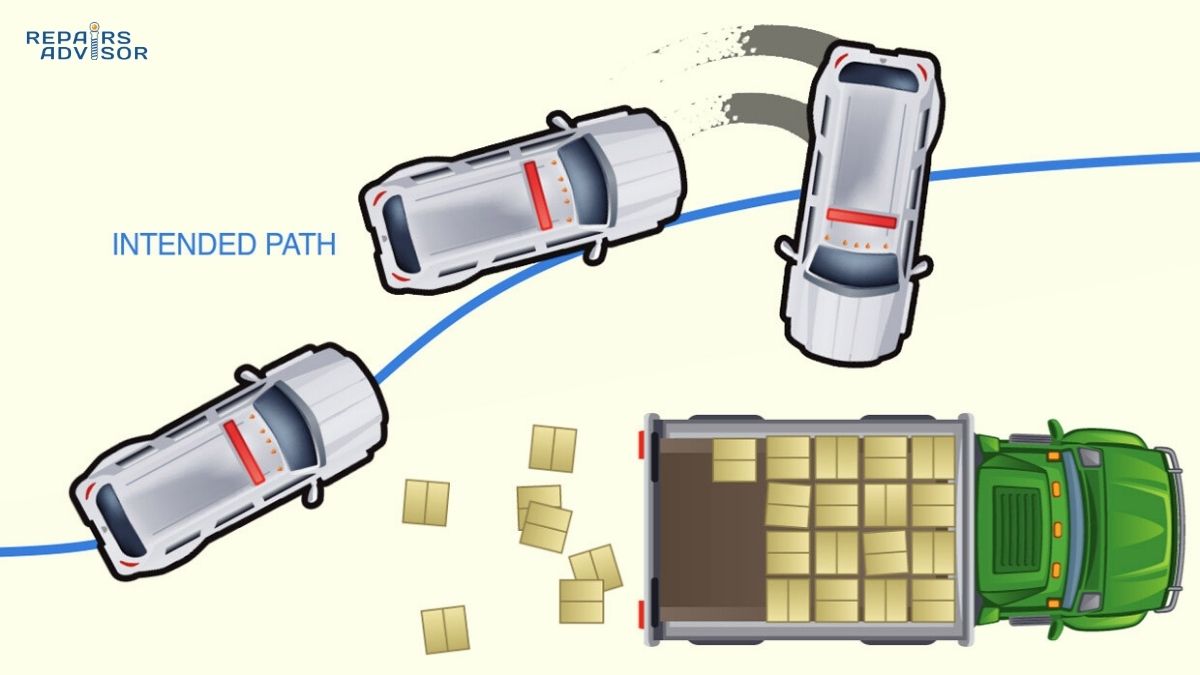

The ECU also processes inputs from stability control systems. If the electronic stability control system detects that the vehicle is beginning to slide or lose directional stability, it can command individual wheel brake interventions that override or supplement the driver’s pedal input. Similarly, traction control integration allows the system to apply brakes to spinning wheels independently. This entire decision-making process happens within 10 to 50 milliseconds—fast enough that the driver perceives instantaneous response.

Step 3: Actuator Command and Brake Application

After calculating the target braking force for each wheel, the ECU sends commands to brake actuators. The specific actuator type and operation depends on whether the system uses electro-hydraulic or electro-mechanical architecture.

In electro-hydraulic brake-by-wire systems like the Bosch iBooster, an electric motor assists or replaces the traditional vacuum booster. When you press the brake pedal in a conventional system, a vacuum booster multiplies your pedal force before it reaches the master cylinder. The iBooster replaces this vacuum assistance with an electric motor that drives the master cylinder piston based on electronic commands. This electric actuation is significantly faster than vacuum-assisted systems, capable of building pressure at rates exceeding 200 bar per second—nearly twice as fast as conventional systems. This rapid pressure build-up reduces stopping distances, particularly in emergency braking situations.

The Continental MKC1 system takes integration further by combining the master cylinder, electric pump, and ABS hydraulic control unit into a single compact assembly. When the brake ECU commands braking, the integrated electric pump generates hydraulic pressure that flows through electronically controlled valves to each wheel’s brake caliper. This architecture allows independent pressure control at each wheel, enabling precise brake force distribution that optimizes stopping performance and vehicle stability.

For electronic parking brakes, small electric motors integrated into the rear brake calipers turn lead screws when you activate the parking brake button. These motors provide sufficient force to clamp the brake pads against the rotors with enough pressure to hold the vehicle on a steep grade. The electronic parking brake system can also be integrated with automatic hold and hill start assist features, automatically applying the parking brake when you come to a complete stop and releasing it when you press the accelerator.

The independent control capability of brake-by-wire systems enables advanced anti-lock braking functionality. When wheel speed sensors detect that a wheel is beginning to lock up during heavy braking, the system can rapidly pulse hydraulic pressure to that specific wheel at rates of 10 to 15 cycles per second, preventing lock-up while maintaining maximum braking force. This rapid modulation happens faster and more precisely than traditional ABS systems that use a single hydraulic control unit for all wheels.

Step 4: Brake Application and Pedal Feel Simulation

As the actuators apply braking force to the calipers, the brake pads clamp against the spinning rotors, generating friction that converts the vehicle’s kinetic energy into thermal energy. This is the same fundamental braking action that occurs in traditional systems, but the feel you experience through the brake pedal is artificially generated rather than directly transmitted from the hydraulic system.

The pedal feel simulator is a critical component that maintains driver confidence and control. This device—which may be hydraulic or electromechanical depending on the system design—creates resistance against your foot that mimics the feel of a conventional brake pedal. The simulator provides progressive resistance as you push deeper into the pedal, creates the familiar firmness that drivers expect, maintains consistent feel regardless of brake temperature or regenerative braking blend, and can be adjusted based on the selected drive mode (firmer in Sport, softer in Comfort).

Throughout the braking event, the system continuously monitors actual brake pressure at each wheel using pressure sensors in the hydraulic circuits. The ECU compares actual pressure to target pressure and makes real-time adjustments to the actuator commands to achieve precise brake force. This closed-loop control ensures consistent braking performance across varying conditions including brake temperature, pad wear state, road surface conditions, and vehicle load.

Step 5: Regenerative Braking Integration in Hybrids and EVs

One of the primary drivers for brake-by-wire adoption is seamless regenerative braking integration in hybrid and electric vehicles. During deceleration, the electric motor that normally propels the vehicle can operate in reverse as a generator, converting kinetic energy back into electrical energy stored in the battery. This energy recovery improves overall vehicle efficiency and can extend brake component life by reducing reliance on friction braking.

The brake-by-wire system manages the complex coordination between regenerative and friction braking. During light to moderate braking at highway speeds, the system may use regenerative braking exclusively, with the electric motor providing all the deceleration force. The driver experiences normal brake pedal feel through the simulator while no hydraulic pressure is applied to the brake calipers. As braking force demand increases beyond what the electric motor can provide (typically around 0.3g deceleration), the system begins blending in friction braking, adding hydraulic pressure to the calipers while maintaining regenerative braking. The transition is imperceptible to the driver—the brake pedal feel remains linear and consistent.

At low speeds below approximately 5 to 7 mph, regenerative braking becomes ineffective as the electric motor’s generator function produces minimal power at low rotational speeds. The brake-by-wire system smoothly transitions to full friction braking as the vehicle approaches a stop. During emergency braking when maximum deceleration is required, the system immediately applies full friction brake pressure, overriding the regenerative braking priority to achieve the shortest possible stopping distance.

This sophisticated blending capability can recover substantial energy—up to 30% of energy consumption in city driving conditions—while providing the driver with brake pedal feel and response indistinguishable from a conventional vehicle. The system achieves this through predictive algorithms that anticipate the need for friction braking based on pedal rate, vehicle speed, and battery charge state, minimizing any delay in friction brake engagement.

Step 6: Brake Release and System Reset

When you release the brake pedal, sensors detect the reduced pedal position and force. The brake control ECU commands the actuators to release pressure, and hydraulic pressure in the brake lines drops to zero. In the brake calipers, the square-section rubber seals that surround the pistons provide automatic retraction. During brake application, these seals stretch slightly as the pistons extend. When pressure releases, the seals elastically return to their original shape, pulling the pistons back approximately 0.005 to 0.010 inches. This small retraction creates a clearance gap between the brake pads and rotors, eliminating drag and allowing the wheels to rotate freely.

The system returns to standby mode, with all sensors actively monitoring and ready to detect the next brake application. The continuous monitoring includes checking all sensor values for plausibility, verifying actuator functionality through periodic self-tests, maintaining communication with other vehicle systems via the CAN bus, and ensuring redundant power supplies are charged and ready. This constant vigilance ensures that the brake-by-wire system can respond instantly to any braking demand.

Brake-by-Wire Safety Systems and Redundancy

The most common concern about brake-by-wire technology is safety: what happens if the electronics fail? The answer lies in multiple layers of redundancy and fail-safe mechanisms designed according to the stringent ISO 26262 functional safety standard.

ISO 26262 Functional Safety Standard Compliance

Brake-by-wire systems must comply with ISO 26262, the international standard for functional safety of electrical and electronic systems in road vehicles. Brake-by-wire is classified as ASIL D (Automotive Safety Integrity Level D), the highest safety integrity level, requiring fail-operational capability. This means the system must continue providing adequate braking performance even when components fail. The standard mandates systematic safety analysis throughout the development process, extensive testing and validation, redundancy at multiple system levels, and continuous monitoring with fault detection and response.

Meeting ASIL D requirements means that brake-by-wire systems undergo far more rigorous safety analysis and testing than typical automotive components. Every potential failure mode must be identified, analyzed for its impact on safety, and addressed through design measures, redundancy, or fail-safe mechanisms.

Triple-Layer Redundancy Architecture

Brake-by-wire systems employ redundancy at three critical levels: sensors, power supplies, and actuators with communication networks.

Sensor Redundancy ensures that critical measurements remain available even if individual sensors fail. The brake pedal uses dual position sensors and dual force sensors, with each pair consisting of independent sensors using different physical mounting or measurement principles. The system compares readings from redundant sensors every cycle, and if readings differ beyond acceptable tolerances, sophisticated voting algorithms determine which sensor is faulty and isolate it from the control system. The system continues operating using the healthy sensor while illuminating a warning light to alert the driver. Similarly, each wheel has redundant speed sensors, and hydraulic circuits include multiple pressure sensors that cross-check each other. Yaw rate and lateral acceleration sensors used for stability control also employ redundancy.

Power Supply Redundancy guarantees that brake actuators have electrical power even if the vehicle’s primary electrical system fails. Brake-by-wire systems typically include dual power sources—the main battery plus a backup battery or high-capacity capacitor bank dedicated to the brake system. Separate power circuits feed critical brake components, with voltage monitoring that automatically switches to backup power if the primary source drops below safe operating voltage. The backup power system must provide sufficient energy for multiple full-force brake applications, typically enough to bring the vehicle to a safe stop from highway speed even with complete alternator and main battery failure. Capacitor banks can deliver high current for rapid pressure build-up in emergency braking situations.

Actuator and Communication Redundancy provides multiple pathways for brake force generation. Most systems use dual hydraulic circuits, typically split front/rear or diagonally, so that failure of one circuit still provides braking on at least two wheels. Some advanced systems include redundant brake actuators—for example, a Bosch system might combine an iBooster electric brake booster with a separate ESP (Electronic Stability Program) hydraulic control unit. If the iBooster fails, the ESP unit can independently generate brake pressure on all four wheels. The communication networks use redundant CAN bus channels or higher-reliability protocols like FlexRay that guarantee message delivery. Time-triggered protocols ensure critical brake commands are processed within strict time windows, typically within 400 milliseconds from fault detection to full backup system activation.

Fail-Safe Mechanical Backup

The ultimate safety feature in electro-hydraulic brake-by-wire systems is the retention of a mechanical connection as a final fallback. This “push-through” capability ensures that even if all electronic systems fail simultaneously—an extremely unlikely scenario given the redundancy layers—the driver can still stop the vehicle.

In normal operation, a valve in the hydraulic circuit remains closed, isolating the brake pedal from the hydraulic lines to the calipers. All brake pressure comes from the electronic actuators. If the system detects a complete electronic failure, this valve automatically opens, creating a direct hydraulic path from the brake pedal to the brake calipers. The driver’s pedal force is transmitted through the master cylinder, generating hydraulic pressure that flows to the calipers just like a traditional brake system.

The catch is that this emergency mode lacks power assistance—there’s no vacuum booster or electric motor to multiply your pedal force. You must push the brake pedal significantly harder, potentially with both feet in an emergency, to generate sufficient pressure. Pedal travel also increases substantially compared to normal operation. However, this mechanical backup provides adequate braking force to safely stop the vehicle, even if the driver must exert considerably more effort. This fail-safe mechanism has proven reliable across millions of vehicles and decades of operation.

Fault Detection, Diagnostics, and Warning Systems

Brake-by-wire systems include extensive self-monitoring capabilities that continuously verify system health. The brake control ECU performs real-time plausibility checks, comparing sensor values against expected ranges and checking for logical consistency. For example, if the pedal position sensor shows rapid movement but the force sensor shows no change, the system recognizes a fault. Stored fault codes allow technicians to diagnose specific component failures using manufacturer scan tools.

When faults are detected, the system operates in degraded modes with progressively increasing warning visibility. Minor faults that don’t affect immediate braking capability might log a code without illuminating warning lights, allowing diagnosis at the next service visit. Moderate faults that activate redundant systems illuminate the amber brake warning light, indicating the system is operating with reduced redundancy. Major faults that significantly compromise braking performance illuminate the red brake warning light and may activate audible warnings, requiring immediate attention.

The system is designed for fail-operational behavior—it continues providing braking capability even with faults, though potentially at reduced performance levels. Only in the extremely unlikely event of multiple simultaneous failures does the system revert to the mechanical backup mode.

Testing, Validation, and Durability

Before any brake-by-wire system reaches production, it undergoes exhaustive testing that far exceeds typical automotive component validation. Manufacturers perform millions of simulated brake cycles to verify durability over a vehicle’s lifetime—typically validated for 15 years and 150,000 miles of operation. Environmental testing confirms functionality across temperature extremes from -40°C to +85°C, through humidity, salt spray, and vibration exposure. Electromagnetic compatibility testing ensures the system resists interference from other vehicle systems, nearby vehicles, and external sources like radar and radio transmissions.

Safety validation includes extensive fault injection testing where engineers deliberately introduce failures—sensor faults, actuator failures, power interruptions, communication errors—and verify that the system responds appropriately through redundancy activation or fail-safe modes. Crash testing verifies high-voltage safety in hybrid and EV applications, ensuring that brake system components don’t present electrical hazards in collision scenarios.

The result of this rigorous development and testing process is brake-by-wire systems that match or exceed the safety record of traditional hydraulic brakes while enabling capabilities impossible with purely mechanical systems.

Brake-by-Wire Advantages and Benefits

Beyond the safety features built into brake-by-wire systems, this technology delivers substantial performance, efficiency, and design benefits that are driving widespread adoption across the automotive industry.

Performance Advantages

Faster Response Time represents one of the most significant performance improvements. Electronic signals propagate at nearly the speed of light, while hydraulic fluid pressure travels at the speed of sound in the fluid. In practice, brake-by-wire systems can build pressure at rates exceeding 200 bar per second, compared to approximately 120 bar per second in high-performance vacuum-assisted systems. This faster response translates to measurably shorter stopping distances—typically 3 to 8 feet shorter from 60 mph in emergency braking situations. Every foot of reduced stopping distance can mean the difference between a near-miss and a collision, making this performance advantage particularly valuable for automatic emergency braking systems that must respond to threats within fractions of a second.

Individual Wheel Control enables precision brake force distribution impossible with traditional systems. Each wheel’s brake can be controlled independently with millisecond-level response time, allowing the system to optimize brake force distribution based on real-time wheel slip detection, adjust braking to compensate for uneven road surfaces or varying tire grip, implement torque vectoring for enhanced handling and cornering performance, and provide more effective ABS modulation with faster cycling and finer pressure control. This wheel-independent control particularly benefits electronic stability control, which relies on selective brake application to individual wheels to correct oversteer or understeer conditions. The faster, more precise control available with brake-by-wire significantly enhances ESC effectiveness.

Adjustable Pedal Feel allows manufacturers to tune brake pedal characteristics for different driving scenarios and customer preferences. Through the pedal feel simulator, the system can provide a firmer, more responsive pedal in Sport mode that gives drivers immediate feedback and a sense of performance capability; a progressive, softer pedal in Comfort mode that makes city driving and parking more pleasant; or an optimized pedal feel in Eco mode that encourages smooth, efficient braking. Unlike traditional brake systems where pedal feel varies with brake temperature (longer pedal travel when hot), brake pad wear (gradually increasing travel), and brake fade (reduced firmness), brake-by-wire maintains consistent pedal feel regardless of these conditions. The simulator can compensate for these physical changes, presenting the driver with uniform pedal characteristics throughout the life of the brake components.

Integration Advantages for Hybrid and Electric Vehicles

Regenerative Braking Blending stands as perhaps the most compelling advantage for hybrid and electric vehicles. Without brake-by-wire, seamlessly coordinating regenerative and friction braking is extremely difficult. The system must switch between or blend two fundamentally different braking mechanisms—an electric motor acting as a generator versus hydraulic calipers squeezing brake pads—while maintaining linear, predictable pedal feel for the driver.

Brake-by-wire systems accomplish this complex coordination transparently. During light to moderate braking at highway speeds, the system may use regenerative braking exclusively, with the electric motor providing all deceleration while the hydraulic brakes remain inactive. As braking force demand increases, the system seamlessly adds friction braking without any perceptible transition or change in pedal feel. The energy recovery from regenerative braking can be substantial—up to 30% of total energy consumption in city driving with frequent stops and starts. This recovered energy directly extends the vehicle’s electric range.

Beyond efficiency, regenerative braking integration significantly extends brake component life. In many hybrid and electric vehicles, brake pads and rotors can last 100,000 miles or more because friction braking handles only a portion of total braking events. This longevity reduces maintenance costs and environmental impact from brake dust and worn components.

Advanced Safety Features become more effective and reliable with brake-by-wire systems. Features like automatic emergency braking require the ability to automatically command full braking force within milliseconds of detecting a collision threat. Brake-by-wire’s fast response time and precise pressure control optimize AEB performance. Adaptive cruise control benefits from smooth, modulated brake applications that maintain comfortable following distances without jerky braking. Hill start assist and automatic hold functions, which prevent the vehicle from rolling backward on slopes or in traffic, integrate naturally with electronic parking brake systems. These features rely on the brake system responding to computer commands rather than driver input, making brake-by-wire essential infrastructure for advanced driver assistance systems.

Packaging and Design Benefits

Space and Weight Savings provide tangible benefits for vehicle designers and owners. Eliminating the vacuum brake booster saves 4 to 6 kilograms while freeing up valuable engine bay space. The vacuum booster is a bulky component mounted on the firewall, and its removal creates opportunities for better crash structure design, more efficient packaging of other components, or additional crumple zone space. Smaller hydraulic components become possible because the system doesn’t need to accommodate direct pedal force transmission. Flexible actuator placement—brake-by-wire actuators don’t need to be mounted on the firewall near the brake pedal—allows designers to position components where they best fit the vehicle architecture. This flexibility particularly benefits electric vehicles where traditional engine bay space is being reimagined for battery packaging, electric motors, and power electronics.

Manufacturing Efficiency improvements benefit automakers and ultimately vehicle buyers through reduced costs. Brake line routing becomes simpler with fewer hard lines and connections. The same brake-by-wire components can be used for both left-hand-drive and right-hand-drive vehicles without modification, eliminating the need for mirror-image parts and reducing inventory complexity. Easier assembly with fewer mechanical linkages and adjustments reduces production time. The overall reduction in mechanical parts (fewer cables, springs, levers, linkages) lowers material costs and potential failure points.

Future-Enabling Capabilities

Looking forward, brake-by-wire provides essential infrastructure for emerging vehicle technologies. Autonomous vehicles require precise brake control without human input, making brake-by-wire mandatory for Levels 3, 4, and 5 automation. The system enables vehicle-to-vehicle communication where cooperative braking between multiple vehicles could optimize traffic flow and safety. Predictive maintenance becomes possible as the system monitors brake component condition, actuator performance, and system response characteristics, potentially alerting drivers to required service before failures occur. Full electro-mechanical brake systems, once commercialized, could eliminate hydraulic fluid entirely—removing a toxic, corrosive fluid from vehicles and simplifying manufacturing with dry brake assemblies.

Common Applications and Vehicle Examples

Brake-by-wire technology has progressed from specialized applications to mainstream adoption, particularly in hybrid and electric vehicles where regenerative braking integration is essential.

Hybrid and Electric Vehicles

The overwhelming majority of hybrid and electric vehicles use brake-by-wire systems for regenerative braking integration. Toyota and Lexus pioneered widespread brake-by-wire adoption, beginning with the original Prius in 1997. The sophisticated regenerative braking system in the Prius seamlessly blends electric motor and friction braking, setting the standard that other manufacturers have followed. Today, nearly all Toyota and Lexus hybrids including the Camry Hybrid, RAV4 Hybrid, Highlander Hybrid, and Lexus RX Hybrid use advanced brake-by-wire systems. General Motors implemented brake-by-wire in the Chevrolet Volt extended-range electric vehicle and the Bolt EV pure electric vehicle. The Chevrolet Corvette C8 Stingray represents an interesting application—despite being a conventional gasoline-powered car, it uses brake-by-wire for enhanced performance and integration with advanced driver assistance features.

Ford employs brake-by-wire across its hybrid and electric lineup, including the Fusion Hybrid, Escape Hybrid, Mustang Mach-E, and F-150 Lightning. The system in the F-150 Lightning must handle the unique challenges of a full-size pickup truck, including heavy payload capacity and trailer towing, while still providing smooth regenerative braking and precise control. Tesla uses brake-by-wire in all its vehicles—Model S, Model 3, Model X, and Model Y—with sophisticated software that enables features like one-pedal driving where aggressive regenerative braking can bring the vehicle to a complete stop without touching the brake pedal in many situations.

European manufacturers have also embraced the technology. Audi uses brake-by-wire in its e-tron electric SUV family, e-tron GT sedan, and Q4 e-tron, with systems that blend regenerative and friction braking to maximize range. Porsche implemented brake-by-wire in the Taycan electric sports sedan and plug-in hybrid versions of the Cayenne SUV. The Taycan’s system must deliver the precise brake feel and performance expected in a sports car while maximizing regenerative energy recovery. For vehicle-specific repair information and service procedures for these models, you can explore detailed manuals at Toyota Repair Manuals, Ford Repair Manuals, Chevrolet Repair Manuals, and Tesla Repair Information.

Performance Vehicle Applications

Brake-by-wire isn’t limited to efficiency-focused hybrids and EVs. Performance vehicles have adopted the technology for its precision control and integration with track-focused features. The Alfa Romeo Giulia and Stelvio earned distinction as the first production vehicles to feature the Continental MKC1 brake-by-wire system. These performance-oriented vehicles benefit from consistent brake pedal feel during aggressive driving, faster brake pressure build-up in emergency stops, and integration with advanced stability control systems that enhance handling dynamics.

The Chevrolet Corvette C8, as mentioned earlier, represents a fascinating case of brake-by-wire in a traditional internal combustion performance car. The mid-engine Corvette uses brake-by-wire to enable launch control, precise brake-based torque vectoring that enhances corner exit acceleration, integration with the Performance Traction Management system, and automatic emergency braking with pedestrian detection. The system maintains the firm, responsive pedal feel that sports car drivers expect while enabling electronic features that enhance both performance and safety.

Commercial Vehicle Implementation

Heavy-duty trucks and buses have used Electronic Braking Systems (EBS)—essentially brake-by-wire for air brake systems—since the 1990s. In commercial vehicles, EBS provides electronic control of compressed air brake actuation, coordination between tractor and trailer braking via ISO 11992 communication protocol, integration with stability control systems designed for high center-of-gravity vehicles, and reduced brake lag compared to traditional air brake systems. The technology has proven extremely reliable in commercial applications with millions of miles of operation, providing additional confidence in passenger vehicle brake-by-wire safety.

Autonomous and Semi-Autonomous Vehicle Requirements

As vehicles incorporate higher levels of automation, brake-by-wire becomes mandatory infrastructure. Level 2 systems (partial automation with adaptive cruise control and lane-keeping) require automated brake control. Levels 3, 4, and 5 (conditional, high, and full automation) are impossible without precise computer-controlled braking. Autonomous vehicles must be able to execute emergency stops, perform smooth brake modulations for passenger comfort, coordinate braking with steering for obstacle avoidance, and operate safely even with component failures—all requirements that brake-by-wire systems are specifically designed to meet.

The widespread adoption across vehicle types and manufacturers demonstrates that brake-by-wire has matured from experimental technology to proven, reliable automotive infrastructure that enables both current and future vehicle capabilities.

Maintenance and Diagnostic Considerations

While brake-by-wire systems are designed for reliability and longevity, they require specialized knowledge and equipment for service and diagnosis. Understanding maintenance requirements and recognizing warning signs helps ensure these safety-critical systems remain functional.

Maintenance Requirements and Service Intervals

Electronic System Diagnostics represent the most significant departure from traditional brake service. Generic OBD-II scan tools that can read basic fault codes are insufficient for brake-by-wire diagnostics. These systems require manufacturer-specific diagnostic software that can access brake control module data, retrieve detailed fault codes with specific failure mode information, perform active tests of actuators and solenoids, monitor real-time sensor data during brake application, and calibrate sensors after replacement or service. Professional technicians need factory scan tools or equivalent professional-grade diagnostic equipment, often costing thousands of dollars and requiring annual software subscriptions.

The CAN bus communication network that connects brake system components must also be testable. Technicians need equipment to verify signal integrity, detect communication errors, identify network resistance issues, and confirm proper termination. Without this diagnostic capability, intermittent electronic faults can be nearly impossible to isolate and repair.

Hydraulic System Service in brake-by-wire vehicles follows similar schedules to traditional systems but requires electronic procedures. Brake fluid remains hygroscopic (absorbing moisture from air) and should be replaced every 2 to 3 years regardless of mileage. Most brake-by-wire systems specify DOT 4 or DOT 5.1 brake fluid due to their higher boiling points—essential for systems that may generate higher pressures and temperatures. Bleeding brake-by-wire systems requires electronic activation of the brake actuators to purge all air from the system. The brake control module must cycle actuators through specific sequences to ensure complete bleeding. Manual bleeding without electronic activation typically leaves air trapped in actuator assemblies, resulting in soft pedal feel and potentially reduced braking performance.

After brake fluid service, pressure sensor calibration may be required. The system must learn the zero-pressure baseline and maximum pressure values to accurately control brake force. This calibration requires a scan tool and following specific manufacturer procedures.

Sensor Calibration becomes necessary after replacing certain brake system components. Pedal position sensors typically require calibration after replacement so the system knows the exact physical pedal positions corresponding to minimum and maximum braking. Wheel speed sensors must be verified for proper air gap and signal quality—while they may not require active calibration, they need testing to ensure correct operation. Pressure sensors in hydraulic circuits need calibration to establish accurate pressure readings. The steering angle sensor, which feeds information to stability control systems that work in conjunction with brake-by-wire, requires calibration after wheel alignment or steering component replacement. These calibration procedures are vehicle-specific and require manufacturer diagnostic tools.

Warning Signs and Symptoms of System Problems

Recognizing early warning signs of brake-by-wire issues allows prompt professional attention before problems escalate. Warning Light Illumination is the most obvious indicator. The amber brake warning light indicates a fault that has activated redundant systems—the brakes still function but with reduced redundancy. The red brake warning light or BRAKE message indicates a significant fault requiring immediate attention. The electronic parking brake warning light signals EPB malfunction. A flashing brake warning light often indicates an active, severe fault. Never ignore brake warning lights—they indicate safety-critical system problems.

Pedal Feel Changes can indicate developing issues even before warning lights appear. A brake pedal that suddenly feels softer or requires more travel may indicate hydraulic fluid loss, air in the system, or actuator malfunction. Conversely, an unusually firm or hard pedal could signal actuator failure or system operating in fail-safe mode. Inconsistent pedal feel—sometimes normal, sometimes different—often indicates intermittent electronic faults. Vibration or pulsation different from normal ABS operation could indicate mechanical issues in calipers or rotors. Any significant change in brake pedal feel warrants immediate professional inspection.

Unusual Noises during normal, non-ABS braking require investigation. Grinding, squealing, or clicking sounds during brake application could indicate pad wear (grinding), electronic actuator cycling (clicking), or component looseness. Motor whining or buzzing when pressing the brake pedal might indicate actuator motor problems or abnormal hydraulic pump operation. Electronic parking brake motor sounds when the parking brake isn’t being applied suggest EPB actuator issues.

Reduced Regenerative Braking in hybrid and electric vehicles often presents as decreased electric-only range, more frequent friction brake engagement (you can sometimes hear or feel the transition), or the tachometer or power meter showing less generator operation during braking. While reduced regenerative braking can result from battery state of charge (a full battery can’t accept more energy), persistent reduction suggests brake-by-wire system problems affecting the regenerative blending function.

Increased Pedal Effort beyond normal variation could indicate the system has entered fail-safe mode, activating the mechanical backup path where power assist is lost. This condition requires immediate attention—while the vehicle can still be stopped, it indicates significant system faults that have exhausted redundant systems.

Professional Service Requirements and DIY Limitations

This point cannot be overemphasized: brake-by-wire diagnosis and repair require specialized professional service. These are not DIY-friendly systems. Professional service is mandatory because brake-by-wire systems are safety-critical with no room for error. Modern brake-by-wire systems require manufacturer-specific scan tools costing $3,000 to $10,000 or more, technician training and certification on specific brake-by-wire systems, knowledge of system-specific failure modes and diagnostic procedures, and proper calibration equipment and procedures.

Many brake-by-wire repairs also require software updates or reprogramming. After replacing control modules, actuators, or sensors, the system may need initialization procedures or programming to function correctly. Only dealer-level or professional shops with manufacturer access can perform these software procedures.

For hybrid and electric vehicles, brake-by-wire service adds high-voltage safety considerations. Technicians must be trained in high-voltage system safety, able to properly de-energize high-voltage systems before brake work, and equipped with insulated tools and personal protective equipment. Improper procedures around high-voltage brake systems can result in electric shock hazards or system damage.

DIY Maintenance Limitations are significant. The only brake-by-wire maintenance typically appropriate for DIY enthusiasts is visual inspection of brake pads and rotors for wear (from outside the wheel), verification that no brake fluid leaks are present, and checking that warning lights function during the key-on bulb check. Even these simple checks should prompt professional service if issues are found—don’t attempt repairs without proper tools and knowledge.

If you experience any brake warning lights, changes in pedal feel, unusual noises, or other symptoms, have the vehicle inspected by a qualified professional immediately. Don’t delay brake system service—these components directly affect your safety and the safety of others on the road.

Conclusion

Brake-by-wire systems represent a fundamental transformation in how vehicles translate driver input into stopping power. By replacing direct mechanical connections with electronic mediation, these systems enable capabilities that were impossible with traditional hydraulic-only brakes. From seamless regenerative braking in hybrids and electric vehicles to faster response times that reduce stopping distances, from precise individual wheel control that enhances stability to the computer-commanded braking required for autonomous vehicles, brake-by-wire has become essential automotive infrastructure.

The three types of brake-by-wire systems—electronic parking brakes now commonplace on modern vehicles, electro-hydraulic brakes that combine electronic control with hydraulic actuation, and the future vision of fully electro-mechanical brakes—each serve specific applications and offer distinct advantages. Electro-hydraulic systems have proven particularly successful, achieving widespread adoption across hybrid, electric, and high-performance vehicles while maintaining the safety reassurance of mechanical backup connections.

Safety concerns that initially surrounded brake-by-wire technology have been thoroughly addressed through extensive redundancy and fail-safe mechanisms. Triple-layer redundancy in sensors, power supplies, and actuators ensures that single-point failures don’t compromise braking capability. ISO 26262 Level D compliance mandates fail-operational design where the system continues functioning despite faults. The retention of mechanical backup connections in electro-hydraulic systems provides ultimate fail-safe capability even in the extremely unlikely event of total electronic failure. Decades of reliable operation across millions of vehicles, from Toyota Priuses to commercial trucks, demonstrate that properly designed brake-by-wire systems meet or exceed the safety record of traditional brakes.

The performance and efficiency advantages drive continued adoption. Faster pressure build-up reduces stopping distances in emergencies. Independent wheel control enhances ABS and stability control effectiveness. Adjustable pedal feel allows customization for driving modes. For hybrid and electric vehicles, transparent regenerative braking blending can recover up to 30% of energy in city driving while extending brake component life beyond 100,000 miles. These tangible benefits explain why brake-by-wire is rapidly becoming standard equipment rather than optional technology.

Addressing Lingering Concerns

Despite the proven track record, some drivers remain skeptical of electronic braking. These concerns are understandable—brakes are literally life-safety systems—but they should be contextualized against the reality of modern automotive technology. Your vehicle likely already uses electronic throttle control (no cable connecting the accelerator pedal to the engine), electronic stability control (computer-controlled brake interventions without driver input), and numerous other electronically mediated systems. Brake-by-wire undergoes far more rigorous safety analysis and testing than most vehicle components precisely because braking is so critical.

The mechanical backup connection in electro-hydraulic systems means you’re never truly relying solely on electronics. If every electronic component failed simultaneously—an scenario made vanishingly unlikely by redundancy layers—you could still stop the vehicle through direct pedal pressure. This fail-safe architecture provides genuine safety assurance beyond marketing claims.

When to Seek Professional Service

Given the complexity and safety-critical nature of brake-by-wire systems, professional service is non-negotiable. Seek immediate professional inspection if you experience:

- Any brake warning light illumination, amber or red

- Changes in brake pedal feel including increased travel, unusual softness or firmness, or inconsistent response

- Unusual noises during normal braking (grinding, clicking, buzzing, motor sounds)

- Electronic parking brake malfunctions or warning messages

- Reduced regenerative braking performance in hybrids or EVs

- Any condition that increases your braking distance or requires unusual pedal force

Don’t delay brake system service hoping problems will resolve themselves—brake issues typically worsen over time and can compromise your safety. All brake-by-wire diagnosis, repair, and maintenance must be performed by qualified technicians with appropriate training, manufacturer-specific diagnostic equipment, and access to service procedures. This includes brake fluid changes, sensor replacements, actuator service, software updates, and any troubleshooting beyond visual inspection.

For hybrid and electric vehicles, brake-by-wire service requires additional high-voltage safety training and procedures that only certified technicians should perform. The combination of high-voltage electrical systems and hydraulic brake systems creates unique hazards that demand professional expertise.

Looking to the Future

Brake-by-wire technology continues evolving. Fully electro-mechanical brake systems, once commercialized, will eliminate hydraulic fluid entirely while reducing weight and simplifying manufacturing. Integration with vehicle-to-vehicle communication could enable cooperative braking where multiple vehicles coordinate deceleration for optimal traffic flow and safety. Advanced algorithms may enable predictive maintenance that alerts drivers to required brake service before components fail. As autonomous vehicles progress from current Level 2 systems to higher automation levels, brake-by-wire will become even more sophisticated and capable.

For most drivers, brake-by-wire operates transparently—you press the brake pedal and the vehicle stops smoothly and predictably, just as it always has. The sophisticated technology working behind the scenes enhances your safety through faster response, precise control, and integration with advanced safety features while enabling the energy efficiency critical to hybrid and electric vehicles. Understanding this technology helps you appreciate the engineering achievement it represents and reinforces the importance of professional service when issues arise.

For vehicle-specific brake system information and professional service procedures, explore our comprehensive collection of repair manuals organized by brand at Automotive Repair Manuals. You can also learn more about related brake system components in our technical articles on disc brake systems, ABS technology, and electronic stability control.

Final Safety Reminder: Brake-by-wire systems are complex, safety-critical technologies requiring specialized knowledge and equipment. This article provides educational information only. All brake system diagnosis, repair, and maintenance must be performed by qualified technicians with appropriate training, manufacturer-specific tools, and access to factory service procedures. Never attempt to diagnose or repair brake-by-wire systems without proper certification and equipment. Your safety and the safety of others depends on properly functioning brakes—always prioritize professional service for brake system work.