Have you ever wondered what keeps your car from rolling away when parked on a hill? Or why mechanics call it both a parking brake and an emergency brake? The answer reveals one of your vehicle’s most underutilized yet critical safety systems.

The parking brake is far more than just a hill-parking tool. While most drivers only think about it when facing steep inclines, this mechanical braking system serves multiple essential functions—from protecting your transmission to providing emergency stopping power when hydraulic brakes fail. Understanding how it works helps you use it properly and recognize when it needs service.

In this comprehensive guide, you’ll learn exactly how parking brake systems work, when to use them (spoiler: every time you park), and how to identify common problems before they become safety hazards. We’ll cover both traditional cable-operated systems and modern electronic parking brakes, explain proper maintenance procedures, and clarify when professional service is necessary.

Safety Note: Parking brake systems are safety-critical components. While understanding how they work helps with informed decision-making, repairs involving brake cables, adjustment mechanisms, or electronic actuators should be performed by qualified technicians. This article provides educational information to help you recognize issues and communicate effectively with service professionals.

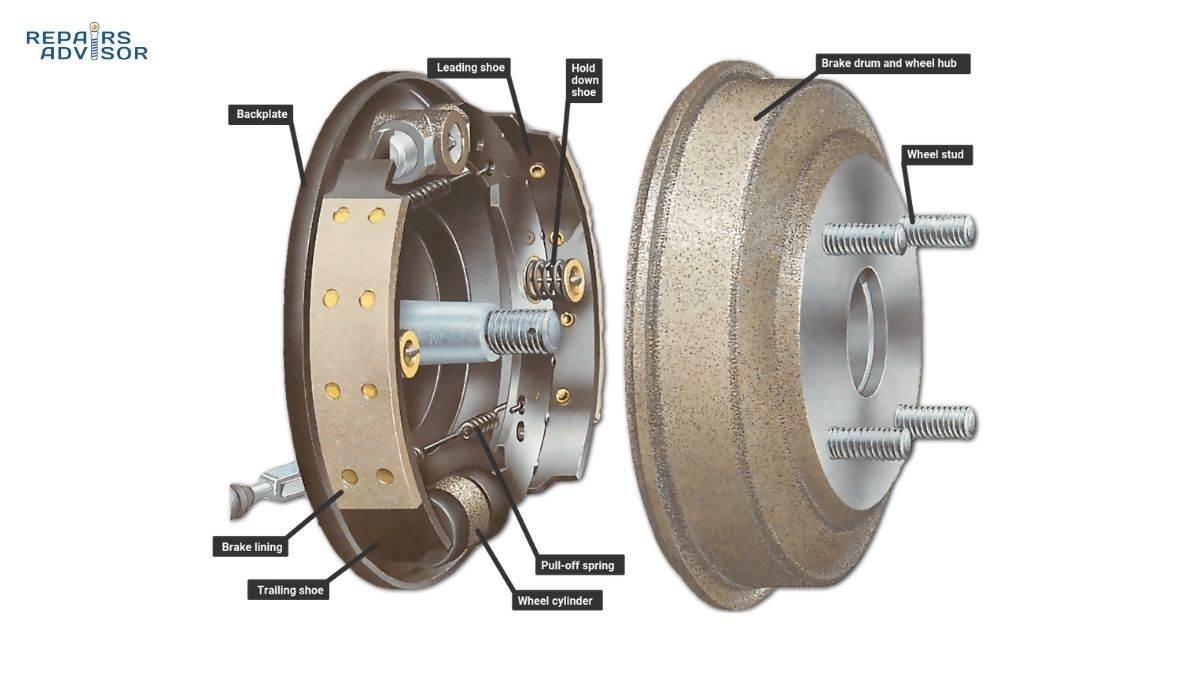

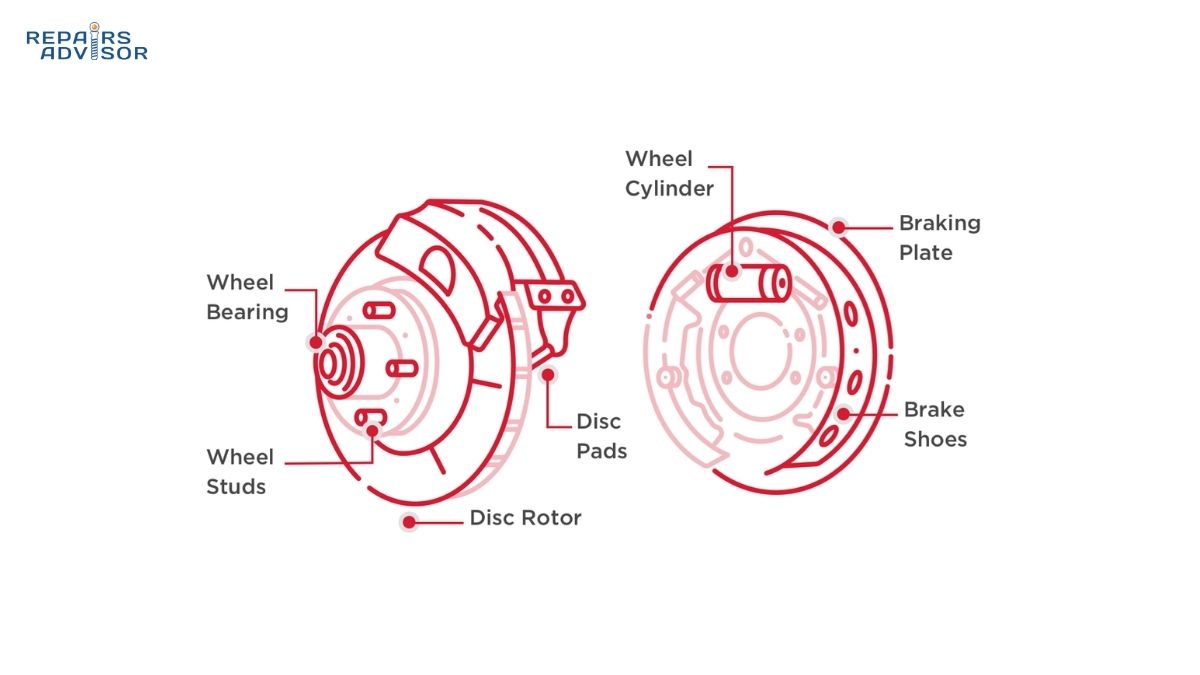

Before diving into parking brakes specifically, it helps to understand the broader brake system context. The disc brake system uses hydraulic pressure to squeeze brake pads against rotors, while drum brakes push shoes outward against drum interiors. The parking brake integrates with these systems but operates through purely mechanical means.

Why Parking Brakes Are Critical for Vehicle Safety

The Parking Pawl Limitation

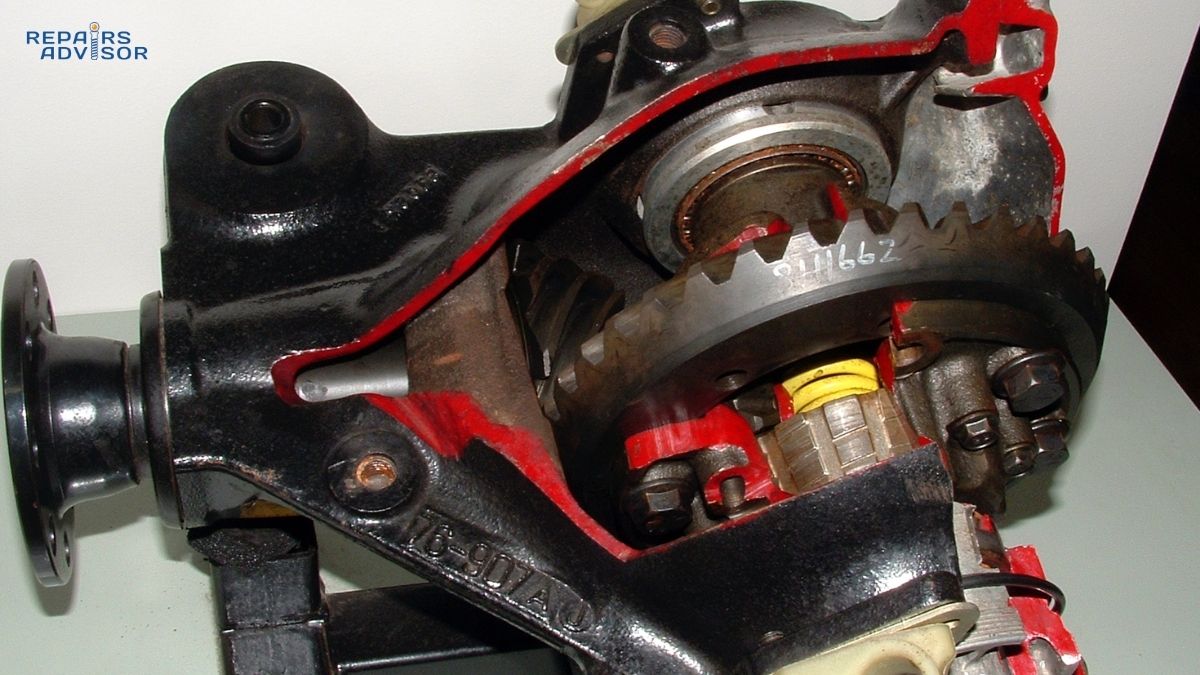

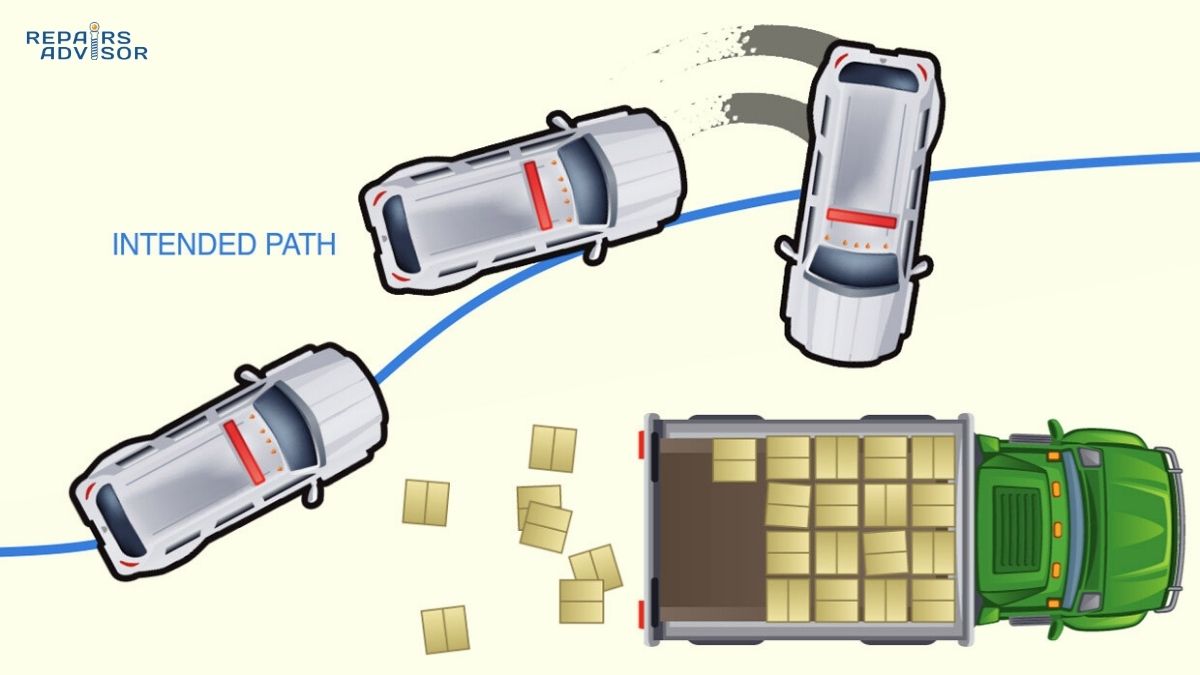

When you shift your automatic transmission into “Park,” a small metal pin called a parking pawl engages with gears in the transmission. This pawl is designed to hold your vehicle stationary, but it has significant limitations that most drivers never consider.

The parking pawl is a relatively small component carrying your vehicle’s entire weight. On inclines, the pawl experiences extreme stress that accelerates wear and can lead to failure. A broken or worn parking pawl can result in unexpected vehicle movement—a dangerous situation that causes thousands of accidents annually. Worse, parking pawl replacement requires transmission disassembly, costing anywhere from $800 to $2,500.

Consider the physics: a 4,000-pound vehicle parked on a 15-degree slope places approximately 1,000 pounds of force on that single small pin. Repeatedly parking on hills without engaging the parking brake significantly reduces parking pawl life expectancy from the typical 150,000 miles down to 80,000 miles or less.

The Two Essential Functions

The parking brake provides two distinct safety functions that work independently of your primary hydraulic brake system.

Primary Function – Parking Security: The parking brake provides mechanical holding power independent of the transmission. This dual-system approach distributes forces between the transmission and the brake system, creating redundancy. If one system fails, the other maintains vehicle security. This is particularly critical when parking on inclines where gravity constantly pulls the vehicle downward.

Secondary Function – Emergency Stopping: Although many vehicles label it as an “emergency brake,” this secondary function has important limitations. The parking brake operates only on rear wheels, which have reduced traction during emergency braking due to forward weight transfer. It provides significantly less stopping power than your primary hydraulic brake system. However, in the rare event of complete hydraulic brake failure, the parking brake can bring your vehicle to a controlled stop when applied gradually.

The Department of Transportation mandates that parking brakes must hold a vehicle on a specified incline and provide emergency stopping capability within defined distances—all with the force that can be applied by someone with minimal strength. These requirements ensure the system works for all drivers, regardless of physical capability.

Parking Brake Parts and Construction

Understanding parking brake components helps you recognize potential issues and appreciate how the system works. Modern vehicles use either traditional mechanical cable systems or newer electronic parking brakes.

Mechanical Parking Brake Components

Traditional cable-operated parking brakes have been used for over a century, and their basic design remains remarkably effective.

Control Mechanisms: The control mechanism varies by vehicle design. Hand lever types, located between the front seats, are pulled upward to engage with 3-7 clicks being typical for proper adjustment. Foot pedal types feature a small pedal positioned left of the other pedals that’s pressed downward to engage. Older vehicles may have stick lever types mounted under the dashboard that pull outward. All include a release button or lever to disengage the brake.

Steel Cable Assembly: The cable assembly is the heart of the mechanical parking brake. The primary cable connects the control mechanism to an equalizer bar, while secondary cables branch in a Y-shaped configuration from the equalizer to each rear brake. The cable sheath provides protective outer housing with dry lubricant inside to ensure smooth operation. Modern cables use stainless steel inner wire to resist corrosion, though cheaper aftermarket cables may use standard steel that corrodes more quickly.

The adjustment mechanism consists of threaded nuts that allow cable tension adjustment as components wear. Proper adjustment is critical—too loose and the brake won’t hold, too tight and the brake drags continuously, causing premature wear and reduced fuel economy.

Equalizer Bar: This often-overlooked component distributes force equally to both rear wheels, ensuring balanced brake application. The equalizer prevents one-sided brake engagement that could cause the vehicle to shift position when parked.

Rear Brake Integration: How the parking brake connects to your rear brakes depends on whether you have disc or drum brakes.

For drum brake systems, the cable connects directly to a brake shoe lever. These systems use the same brake shoes as the hydraulic system but with separate actuation mechanisms. Mechanical advantage through lever geometry increases holding force—a 40-pound pull on the parking brake lever can generate 400-600 pounds of shoe-to-drum pressure.

For disc brake systems, three different designs exist. The most common is the drum-in-hat design, where a small drum brake is cast inside the rear rotor hub. This separate mechanism uses dedicated brake shoes for parking function and is also called a “banksia brake.” The caliper-integrated design uses a corkscrew mechanism inside the brake caliper to mechanically push the piston into brake pads. Less commonly, some high-performance vehicles use a separate small cable-actuated caliper exclusively for parking brake function.

Quality variations matter significantly for longevity. OEM cables feature factory-spec materials with proper sheath lubrication and typically last 7-10 years. Premium aftermarket cables use stainless steel construction with quality sheaths and last 5-7 years. Budget cables may lack proper lubrication and are prone to binding, often requiring replacement after just 2-4 years.

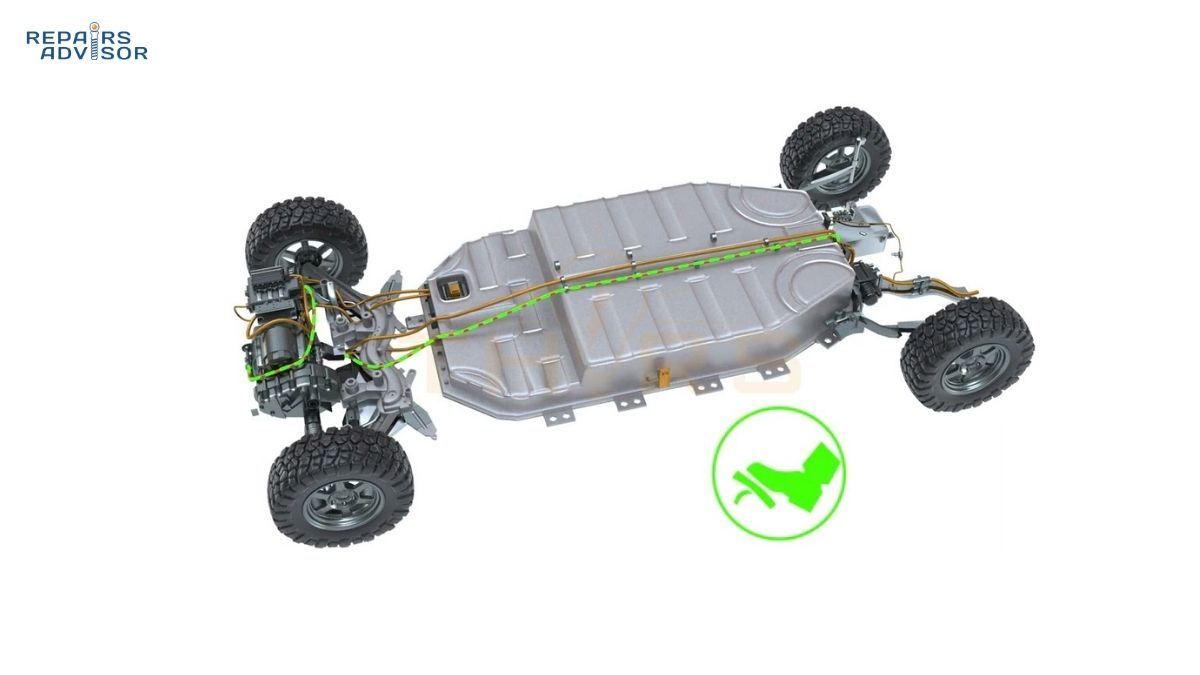

Electronic Parking Brake Systems

Electronic parking brakes (EPB) represent the modern evolution of parking brake technology. First introduced in 2001 on the BMW 7 Series, these systems replace mechanical cables with electric motors and electronic control.

Two EPB Design Types: Cable-pull EPB systems use an electric motor to pull a traditional parking brake cable, with a button replacing the lever or pedal. This simpler design makes retrofitting easier and is found on mid-range vehicles. Motor-on-caliper (MoC) EPB systems integrate an electric motor into each rear brake caliper, with computer control via the vehicle’s CAN bus network. This more sophisticated design provides direct mechanical actuation without cables and is used on premium vehicles.

EPB Components and Features: The control button, mounted on the dashboard or center console, replaces the traditional lever. An electronic control unit manages motor operation and safety monitoring, while actuator motors—either servo motors for cable-pull designs or caliper-integrated motors for MoC systems—provide the mechanical force. Position sensors monitor engagement status, and the entire system integrates with the vehicle’s 12V electrical system.

Advanced EPB features include automatic engagement when the engine turns off, automatic release when the accelerator is pressed, hill-hold function that prevents rollback when starting from a stop, emergency brake assist that provides stopping power if applied while moving, and service mode that allows caliper retraction for brake pad replacement. These features represent significant convenience improvements over traditional mechanical systems, though they also introduce additional complexity and potential failure points.

The electronic stability control system often integrates with EPB systems to provide coordinated vehicle dynamics management.

How Parking Brakes Work: Step-by-Step Operation

Mechanical Cable System Operation

Understanding the mechanical sequence reveals why proper adjustment and maintenance matter so much.

Step 1: Driver Engagement – When you pull the parking brake lever, press the pedal, or pull the stick lever, the control mechanism rotates a quadrant gear or cable attachment point. This initial movement takes up any slack in the primary cable. A ratcheting mechanism locks the control in the engaged position, typically providing 3-7 clicks. Proper adjustment requires 3-5 clicks for full engagement—fewer clicks indicate over-tightening, while more clicks suggest the brake needs adjustment.

Step 2: Cable Force Transmission – The primary cable pulls on the equalizer bar, which converts the single cable pull into equal force on both secondary cables. These secondary cables route along the vehicle undercarriage to each rear wheel, with the cable sheaths providing smooth sliding action while protecting the inner wire from contaminants, road debris, and moisture. The Y-shaped cable configuration ensures simultaneous rear brake application, critical for stable parking on slopes.

Step 3: Brake Shoe/Pad Engagement – For drum brake systems, the cable pulls a lever arm attached to the brake shoe assembly, which mechanically forces brake shoes outward against the drum interior. This shoe-to-drum contact creates friction that holds the wheel stationary. The self-energizing effect inherent in drum brake design enhances holding power without requiring hydraulic fluid—this is purely mechanical force.

For disc brake systems with drum-in-hat design, the cable pulls an actuating lever inside the drum assembly, forcing small brake shoes to press against the interior drum surface cast into the rotor. This separate parking brake mechanism operates independently of the main caliper, providing reliable holding power with lower force than hydraulic brakes but sufficient for parking applications.

For disc brake systems with caliper-integrated parking brakes, the cable pulls a lever that rotates a threaded spindle in a corkscrew mechanism. The rotating spindle pushes the caliper piston outward mechanically, forcing the brake pad against the rotor. Typical parking brake force represents only 20-30% of full hydraulic brake force, but this is adequate for holding a parked vehicle.

Step 4: Mechanical Lock-Up – The ratcheting mechanism in the control lever or pedal maintains tension indefinitely. Cable tension keeps brake shoes or pads in contact with friction surfaces, and this mechanical engagement persists without requiring power or hydraulic pressure. The system remains engaged even if the vehicle loses electrical power or suffers complete hydraulic system failure.

Step 5: Release Mechanism – To release the parking brake, first press the brake pedal (required by safety interlocks on many vehicles), then press the release button on lever-type controls or pull the release lever on pedal-type controls. The ratchet mechanism disengages, return springs pull brake shoes or pads away from friction surfaces, cable tension releases, and the control returns to its rest position.

Electronic Parking Brake Operation

Electronic systems operate quite differently from mechanical cables, though they achieve the same end result.

Step 1: Electronic Activation – When you press the EPB button, the electronic control unit receives the signal and verifies vehicle conditions including stopped status, gear position, and brake pedal status. Safety checks must complete before motor activation begins, preventing engagement while driving unless the emergency brake function is intentionally activated.

Step 2: Motor Engagement – For cable-pull type EPB systems, the electric motor rotates to wind cable around a drum or pull the cable taut. Force sensors monitor cable tension, and the motor stops when target tension is reached, typically 400-600 pounds. For motor-on-caliper type systems, the ECU sends commands to both rear caliper motors via the CAN bus network. Each motor activates independently, with threaded spindle mechanisms pushing pistons into brake pads. Position sensors confirm engagement completion.

Step 3: Holding and Monitoring – EPB systems actively monitor engagement status during parking. If sensors detect slippage, motors automatically re-engage to maintain holding force. A dashboard indicator light confirms engaged status, and the system maintains engagement through electronic control without driver intervention.

Step 4: Release Process – When you press the EPB button or press the accelerator on vehicles with auto-release, the ECU commands motor reversal. Motors retract pistons or release cable tension as position sensors confirm full release and the indicator light extinguishes.

Emergency Brake Function – If you pull and hold the EPB button while moving, the system activates emergency braking mode. The ECU modulates rear brake pressure using an anti-lock braking algorithm to prevent wheel lock. This provides progressive brake application rather than full emergency stopping power. Warning chimes and lights alert the driver to this unusual condition.

The integration between EPB systems and ABS demonstrates how modern brake systems work together for maximum safety.

When and How to Use Your Parking Brake

Always Use It—Here’s Why

Automotive experts and manufacturers universally recommend engaging the parking brake every time you park, regardless of whether you drive an automatic or manual transmission or whether you’re parking on flat ground or a slope.

Benefits of Regular Use: Using the parking brake every time you park reduces stress on the transmission by 70-90%, extending parking pawl life from the typical 100,000 miles to 200,000 miles or more. This simple habit prevents expensive transmission repairs that can cost thousands of dollars.

Regular cable movement prevents rust buildup and maintains smooth cable action, keeping brake shoes and pads from binding. Cables that sit unused for long periods develop internal corrosion that eventually causes seizure, requiring complete cable replacement.

If your parked vehicle is struck by another car, the engaged parking brake helps prevent movement and reduces the severity of secondary collisions. This added security also reduces rollaway risk from parking pawl failure—a critical safety factor that becomes more important as vehicles age.

Perhaps most importantly, habitual use creates muscle memory. When engaging the parking brake becomes automatic, you ensure it’s engaged when truly needed, such as on hills or during emergencies. Many rollaway accidents occur because drivers who rarely use their parking brake forget to engage it in the one situation where it’s critically needed.

Proper Engagement Sequence: For maximum transmission protection, follow this specific sequence. Come to a complete stop with your foot brake, then engage the parking brake FIRST while still holding the foot brake. Next, shift to Park for automatics or into gear for manuals. Finally, release the foot brake last.

This sequence is crucial because it puts vehicle weight on the parking brake rather than the parking pawl. If you shift to Park before engaging the parking brake, the pawl takes the full load, defeating the purpose of using the parking brake to protect the transmission.

When to Use for Emergency Stopping: Only use the parking brake as an emergency brake if your hydraulic brake system fails completely. If this rare situation occurs, apply the brake gradually, not suddenly, to prevent wheel lock and loss of control. Pull the lever progressively or press the pedal slowly, and expect longer stopping distance since only rear wheels are braking. Modern EPB systems automatically modulate pressure to prevent lock-up when used for emergency braking.

When NOT to Use: Avoid using the parking brake in freezing or icy conditions when moisture in the cable sheath or brake mechanism can freeze solid. A frozen parking brake may not release, potentially requiring towing or professional service to free it. If you must park in freezing conditions immediately after a car wash, consider using wheel chocks instead of the parking brake.

Never use the parking brake for “drifting” or stunt driving. This causes excessive brake wear, damages the cable and mechanism, and creates unsafe vehicle dynamics that can lead to loss of control and accidents.

Understanding how the brake booster and other hydraulic components work helps you appreciate why the mechanical parking brake provides such important backup protection.

Common Parking Brake Problems and Solutions

Mechanical Parking Brake Issues

Parking Brake Won’t Engage or Hold: If your parking brake lever pulls up too easily with many clicks (more than 7), your vehicle rolls when the parking brake is engaged on an incline, or there’s no resistance when pulling the lever, you’re experiencing engagement failure.

Common causes include stretched cables that create excessive slack due to normal wear over time, improper adjustment where shoes are too far from the drum or cable tension is insufficient, worn brake shoes or pads with insufficient material thickness for proper contact, or broken cables where strand failure prevents force transmission.

Professional solutions include cable adjustment for $80-$150, cable replacement for $150-$400 depending on configuration complexity, brake shoe replacement including parking brake shoes for $200-$400, or drum-in-hat brake service for $250-$450.

Parking Brake Won’t Release (Stuck): Symptoms include a lever that won’t lower or pedal that won’t release, vehicle that won’t move or moves with resistance, burning smell from rear brakes, or parking brake warning light that stays illuminated.

The most common cause in winter is frozen brake components where ice forms in the cable sheath or brake mechanism. Seized cables due to corrosion from lack of use or water intrusion also frequently cause this problem. A rusted bell crank or lever with corroded pivot points prevents release, as do broken return springs that can’t retract shoes or pads. Sometimes drivers pull the lever too hard, damaging the ratchet mechanism.

Temporary solutions for stuck brakes include warming the vehicle with the engine running if the brake is frozen, carefully rocking the vehicle forward and backward to break the brake free if safe to do so, or releasing and re-applying several times to free binding. Never drive with the brake dragging—this can cause severe damage. Call for service instead.

Professional solutions include cable lubrication and adjustment for $100-$200, cable replacement for $150-$400, bell crank or lever repair for $80-$150, return spring replacement for $100-$250, or complete parking brake system overhaul for $400-$800.

Poor Adjustment (Improper Engagement): If your parking brake takes only 2 clicks or fewer to engage (too tight), takes 8 or more clicks to engage (too loose), drags when released, or engages unevenly with one side engaging before the other, the adjustment is incorrect.

Causes include incorrectly positioned cable adjustment nuts, automatic adjuster failure in drum brake systems, or lacking guide pin lubrication in disc brake calipers. Professional service typically costs $80-$150 for proper adjustment.

Electronic Parking Brake Issues

EPB Warning Light or Message: Dashboard EPB warning lights, messages saying “Parking Brake Malfunction” or “Service Required,” or EPB buttons that won’t engage or release all indicate electronic system problems.

Common causes include electrical issues like faulty wiring, blown fuses, or connector corrosion. Failed actuator motors, whether servo motors or caliper motors, prevent operation. Sensor malfunctions including position sensors or brake fluid level sensors trigger warnings. Low brake fluid causes the system to detect insufficient fluid and prevent operation. Worn brake pads trigger sensors that detect excessive wear. Sometimes simple software glitches cause temporary ECU errors.

Safe DIY diagnostic steps include checking brake fluid level and topping off if low, turning the vehicle off and restarting to reset temporary glitches, checking for blown fuses related to the EPB system, and verifying brake pads aren’t excessively worn.

Professional solutions include diagnostic scanning for $80-$150, actuator motor replacement for $300-$800 per wheel, sensor replacement for $150-$400, software update or calibration for $100-$200, or complete EPB module replacement for $800-$1,500.

EPB Noise (Grinding, Clicking): Grinding sounds when the EPB engages or releases, clicking or buzzing from rear wheels, or unusual motor sounds all indicate mechanical problems within the EPB system.

Common causes include worn brake pads creating metal-to-metal contact, debris in the caliper mechanism, failing actuator motor bearings, or dry caliper threads and spindles. Professional service typically costs $200-$600 depending on the cause.

EPB Won’t Enter Service Mode: If you cannot retract rear calipers for brake pad replacement, the EPB system requires a specialized scan tool to command service mode. Professional service is mandatory for this issue.

A critical safety warning: never attempt to work on rear brakes with EPB systems without proper scan tools and training. Attempting to compress EPB calipers without entering service mode can damage actuator motors and cost $800 or more per caliper to repair.

For additional context on related systems, see how traction control integrates with modern brake systems.

Parking Brake Maintenance and Adjustment

Maintenance Schedule

Regular parking brake maintenance prevents problems before they become safety hazards. Visual cable inspections should occur every 6 months, looking for fraying, corrosion, or damage. Functional testing monthly ensures the brake engages and releases properly and holds the vehicle on an incline. Professional inspection should occur annually or during any brake service. Note that cable lubrication is not recommended on modern sealed systems, as lubricants can actually attract dirt and accelerate wear.

Service is needed when lever engagement changes (more or fewer clicks than normal), when the vehicle rolls with the parking brake engaged, when the brake doesn’t release smoothly, when visible cable damage or corrosion appears, or after approximately 50,000 miles of use.

Cable Adjustment Basics

Warning: Parking brake adjustment requires technical knowledge and proper tools. Improper adjustment can cause brake drag, leading to fuel economy loss and premature wear, or insufficient holding power, creating serious safety risks. This information is educational—professional service is recommended for actual adjustment work.

Access adjustment points vary by vehicle. Most commonly, the adjustment point is under the vehicle at the equalizer bar. Some vehicles have adjustment points inside the cabin at the lever base, while older vehicles may adjust through a brake drum access hole.

Proper adjustment targets 3-5 clicks for full engagement on most vehicles. The brake should provide sufficient force to hold the vehicle on a 30% grade while producing no brake drag when released.

Common mistakes include over-tightening which causes brake drag and overheating, estimating adjustment rather than using specific click counts, adjusting cables without first checking shoe or pad wear, and lubricating cables which attracts dirt and accelerates wear.

Some vehicles use self-adjusting systems where cable length automatically adjusts at the lever or pedal, maintaining consistent pedal travel throughout brake shoe life. These systems still require manual adjustment if wheel brake service is performed. The reset procedure is specific to each vehicle model and often requires removing a lockout pin.

Electronic Parking Brake Maintenance

EPB systems require professional scan tools for service mode, and you cannot compress rear calipers without electronic commands. Brake pad replacement requires entering maintenance mode, and system recalibration is necessary after pad replacement. Software updates may be needed periodically as manufacturers release improvements.

Typical EPB service costs include brake pad replacement with EPB service for $250-$500, EPB calibration for $100-$200, or cable replacement for cable-pull EPB systems for $200-$500.

Preventive Maintenance Tips

Use the parking brake regularly to prevent corrosion and binding. Avoid excessive force when engaging, as this damages the ratchet mechanism. Check operation monthly by testing engagement, release, and proper holding. Have cables inspected annually for fraying, corrosion, and damage. Address warning lights immediately to prevent minor issues from becoming major failures. If you must wash your car before freezing temperatures, avoid using the parking brake afterward.

For comprehensive brake system information, see the complete vehicle braking system category.

Safety Considerations and Professional Service

When Professional Service Is Mandatory

Always consult a professional for parking brake cable replacement, which requires vehicle lifting with proper support, critical cable routing through suspension and undercarriage components, and essential proper tension adjustment for safe operation.

Electronic parking brake service always requires specialized scan tools, involves high-current electrical systems requiring specific training, and mandates software calibration after any service work.

Brake shoe or pad replacement involving parking brake integration requires proper adjustment, involves drum brake springs under dangerous tension, and needs EPB service mode for caliper retraction on electronic systems.

Professional parking brake diagnosis is essential because distinguishing between parking brake issues, hydraulic brake problems, and wheel bearing failures requires expertise and specialized equipment. Professional inspection prevents misdiagnosis and unnecessary repairs.

DIY Boundaries

Experienced DIYers can safely perform visual cable inspection looking for damage and corrosion, functional testing of engagement, holding power, and release, and brake fluid level checks.

DIY work is not recommended for cable adjustment due to precision requirements, cable replacement due to routing complexity, any EPB service work since specialized tools are mandatory, brake drum or rotor removal affecting the parking brake, or parking brake shoe replacement.

Safety Classifications

According to automotive service standards, the parking brake system rates as SAFETY-2, indicating moderate complexity. Adjustment is DIY-friendly for experienced technicians with proper knowledge and tools, but replacement and major service require professional service.

The parking brake is a critical safety system. Improper service can result in vehicle rollaway, brake failure, or accidents causing injury or death. When in doubt, consult a qualified technician who specializes in brake systems.

For professional service information, repair manual databases include comprehensive parking brake service procedures for qualified technicians. For DIY enthusiasts, these manuals provide the technical understanding to recognize issues early and communicate effectively with service professionals. You can find detailed service information organized by vehicle brand, such as Ford repair manuals, covering specific parking brake procedures for your vehicle.

Conclusion: The Overlooked Safety Essential

The parking brake is far more than an occasional hill-parking tool—it’s a fundamental safety system that protects your transmission, provides emergency stopping capability, and prevents dangerous vehicle rollaway situations that cause thousands of accidents and injuries every year.

The key takeaways are clear and actionable. Use the parking brake every time you park, even on flat surfaces, to prevent transmission wear and maintain system functionality. Engage it before shifting to Park—this sequence protects your parking pawl and extends transmission life by tens of thousands of miles. Don’t ignore warning signs like unusual engagement, strange noises, or dashboard warning lights, as these require immediate attention. Regular use prevents problems because the parking brake that gets used rarely is the one most likely to fail when needed. Finally, respect the complexity of the system—while understanding how it works is valuable, professional service ensures safety and proper operation.

Modern electronic parking brakes represent the future of this essential system, offering convenience features like automatic engagement, hill-hold assist, and integrated electronic brake management. However, the fundamental purpose—keeping your vehicle securely stationary—remains unchanged since the earliest automobiles over a century ago.

Whether you drive a classic car with a traditional hand lever or a modern vehicle with an electronic button, make the parking brake an integral part of your driving routine. This simple habit protects your vehicle, your wallet through reduced transmission wear, and most importantly, the safety of everyone around your parked car.

Take action this week by testing your parking brake on a gentle slope to verify it holds properly. Make engagement part of your parking routine, engaging it before shifting to Park. Schedule professional inspection if you notice any performance changes, unusual noises, or warning lights. Consider obtaining repair manual documentation for your specific vehicle’s parking brake system to better understand its operation and maintenance requirements.

Understanding your vehicle’s complete brake system helps you appreciate how each component contributes to safety. The parking brake works alongside hydraulic brake fluid, calipers, rotors, and electronic control systems to provide comprehensive stopping and holding power under all conditions.