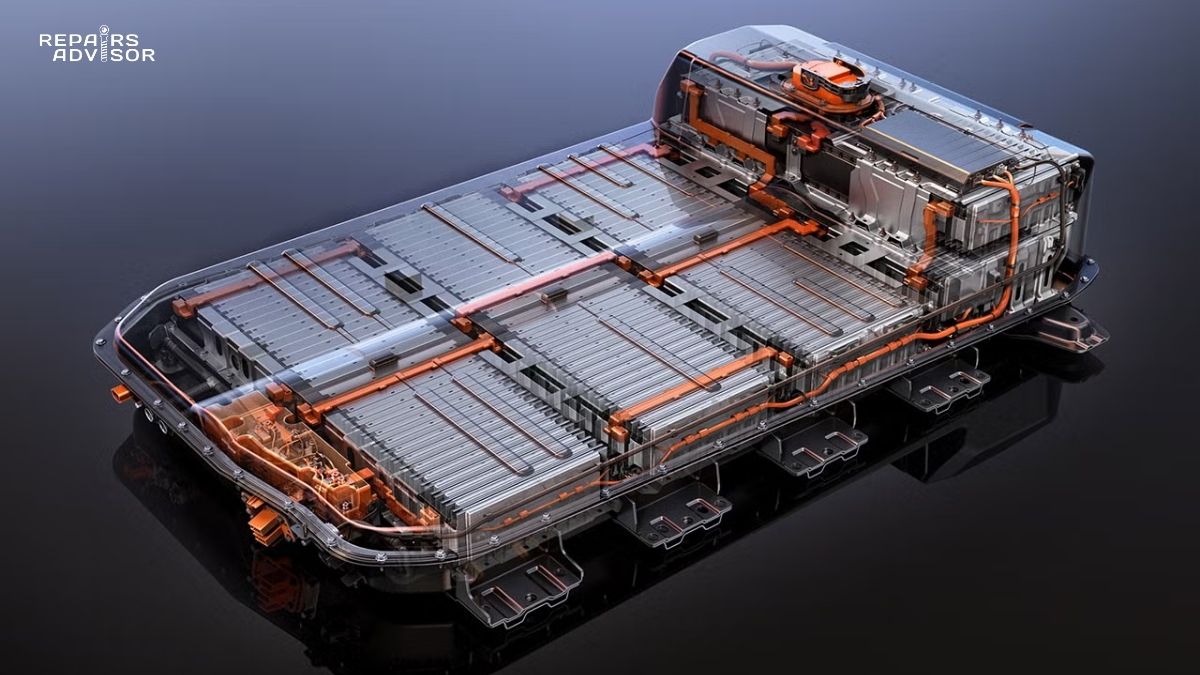

Hybrid battery systems represent the critical bridge between conventional and electric vehicles, storing and releasing electrical energy thousands of times throughout the vehicle’s lifetime. Operating at voltages between 144V and 360V, these sophisticated energy storage assemblies capture kinetic energy during braking, supplement the engine during acceleration, and enable electric-only operation at low speeds—all while a battery management system monitors every cell every second to prevent thermal runaway, maintain charge balance, and maximize service life. Understanding how these systems function isn’t just technical curiosity: with replacement costs ranging from $2,000 to $8,000 and proper maintenance extending battery life from 100,000 miles to over 200,000 miles, knowing what affects your hybrid battery’s longevity can save thousands of dollars over the vehicle’s lifetime.

Quick Answer: What Is a Hybrid Battery System?

A hybrid battery system is a high-voltage energy storage assembly (typically 200-360V) that powers the electric motor in hybrid vehicles. It consists of individual cells grouped into modules, combined into a complete pack with integrated cooling, battery management electronics, and safety systems. The system captures energy during regenerative braking and releases it during acceleration, with typical capacity of 0.6-1.8 kWh. Modern hybrid batteries last 100,000-200,000 miles (10-15 years) with proper maintenance, and replacement costs range from $2,000 to $8,000 depending on vehicle make, model, and battery chemistry.

The Core Technology: How Hybrid Battery Systems Work

At the heart of every hybrid vehicle sits a sophisticated power management system that coordinates energy flow between four key components: the internal combustion engine, the battery pack, the electric motor, and the wheels. Unlike the simple 12-volt car battery that provides brief cold-cranking amps to start the engine, the hybrid battery delivers sustained power output measured in kilowatts and continuously cycles between charging and discharging states throughout normal driving.

Regenerative Braking: Capturing Energy That Would Otherwise Be Lost

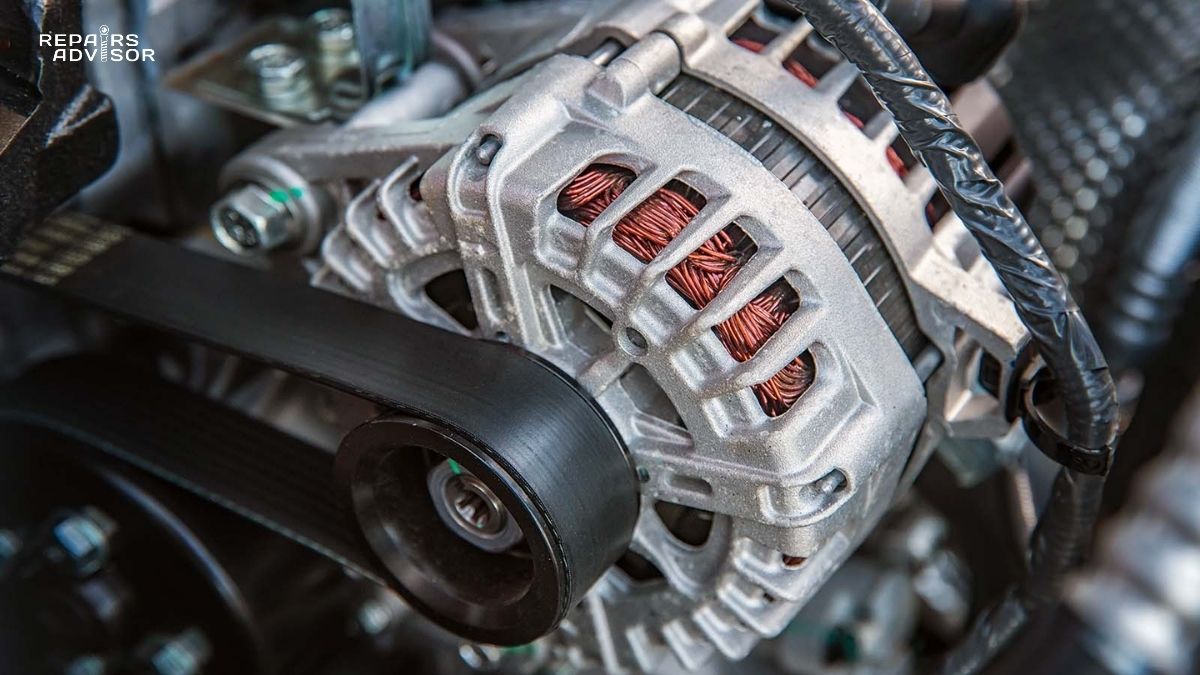

The primary charging source for hybrid batteries during normal driving is regenerative braking. When you lift off the accelerator or apply the brakes, the traction motor switches from motoring mode to generating mode, effectively operating as a generator. The vehicle’s forward momentum spins the motor, converting kinetic energy into electrical current that flows back to the battery pack. This process recovers 60-70% of braking energy that would otherwise dissipate as heat through friction brakes.

The motor controller manages this energy conversion through power electronics using insulated-gate bipolar transistors (IGBTs) that switch at 10-20 kHz frequencies. During regenerative braking, the controller rectifies the AC current from the motor into DC, then regulates it to match battery pack voltage. Maximum regenerative power typically reaches 30-50 kW depending on motor size and battery acceptance rate. If braking demand exceeds regenerative capacity—such as during emergency stops—conventional friction brakes blend in seamlessly to provide full stopping power.

Power Flow Management and Energy Distribution

The hybrid control unit orchestrates power flow through multiple energy paths at any given moment. During aggressive acceleration, both the engine and battery supply power simultaneously—engine direct drive plus battery-powered motor assist delivers combined output exceeding what either power source could provide alone. Light acceleration below 40 mph might use battery power exclusively, leaving the engine off and achieving zero local emissions. Constant highway cruising typically uses engine power only, with the battery neither charging nor discharging significantly.

When battery State of Charge (SOC) drops below target range—typically maintained between 40-80%—the engine can drive a generator to replenish battery charge. In Toyota’s Hybrid Synergy Drive system, a planetary gear set connects the engine, generator, and motor, allowing the system to split engine power between driving the wheels and spinning the generator. This enables the engine to operate at its most thermally efficient range (typically 2,000-3,000 RPM at 50-70% load) rather than constantly varying speed to match driver demand.

High-Voltage Architecture and Why It Matters

Hybrid battery systems operate at nominal voltages between 201.6V and 360V depending on manufacturer specifications and battery chemistry. Toyota Prius systems use 201.6V (168 cells × 1.2V per cell for NiMH), while Honda systems typically run at 144V to 158V, and newer lithium-ion systems often exceed 300V. This high voltage serves a critical electrical engineering principle: for equivalent power delivery, higher voltage reduces current draw.

A 20 kW power demand at 200V requires 100A of current, but the same 20 kW load at 12V would demand over 1,600A. High current requires massive conductors to avoid resistive losses (which scale with the square of current) and generates significant heat. By operating at high voltage, hybrid systems achieve the same power output with smaller, lighter cables and dramatically reduced resistive losses. Orange-jacketed cables throughout the vehicle indicate high-voltage circuits, meeting SAE J1766 standards for high-voltage identification and using 8-10 AWG conductors with heavy insulation rated for 600V minimum.

The Battery Management System: The Brain of the Pack

The Battery Management System (BMS) serves as the intelligence layer controlling every aspect of battery operation. It consists of a master controller and multiple cell monitoring units (CMUs), each monitoring 6-12 cells. The system samples cell voltage at 10 Hz during normal operation, increasing to 100 Hz during rapid charging or high-current discharge. Temperature sensors—typically NTC thermistors with 10kΩ resistance at 25°C—track thermal conditions at 8-20 locations throughout the pack. Current sensors using Hall-effect technology or current shunts measure pack current with ±1% accuracy across the entire operating range.

The BMS calculates two critical state variables continuously. State of Charge (SOC) represents available capacity as a percentage of nominal capacity—analogous to a fuel gauge but for electrical energy. The system determines SOC through coulomb counting (integrating current flow over time) and voltage correlation algorithms. Hybrid systems typically maintain SOC between 40-80% to maximize cycle life, as both full charge and full discharge cycles stress the chemistry and accelerate capacity fade.

State of Health (SOH) quantifies capacity fade and power fade versus new condition. A battery with 85% SOH delivers 85% of original capacity and roughly 85% of original power capability. Most hybrid warranties require the pack to maintain 70% SOH at warranty expiration—California’s mandatory 10-year/150,000-mile standard specifically mandates 70% capacity retention, ensuring the battery maintains meaningful functionality throughout the warranty period.

Cell Balancing: Keeping Every Cell in Sync

Manufacturing variations create 2-5% capacity differences between individual cells in any battery pack. Over thousands of charge-discharge cycles, these small differences compound. Without correction, the weakest cell in a series string becomes the limiting factor for the entire pack—charging stops when the weakest cell reaches its upper voltage limit, and discharging stops when it hits its lower voltage limit. This means a pack of 168 cells performs only as well as its single weakest cell.

Cell balancing corrects voltage imbalance between cells. Passive balancing, used in most hybrid systems, dissipates excess energy from stronger cells through resistors (typically 1-2W per cell) during charging, equalizing voltage across the pack. The energy is converted to heat, which requires thermal management but keeps hardware costs low. Active balancing systems, less common due to complexity and cost, transfer energy directly from higher-charged cells to lower-charged cells through small DC-DC converters, improving efficiency but adding significant hardware.

Without effective cell balancing, a pack that theoretically contains 1.4 kWh of energy might only deliver 1.1 kWh to the drivetrain because the weakest cell hits its voltage limit before the pack fully discharges. Proper balancing ensures all cells contribute their full capacity to system performance.

Thermal Management: The Most Critical Factor in Battery Longevity

Temperature is the single most impactful variable determining hybrid battery lifespan. The battery thermal management system maintains cell temperatures between 20-35°C for optimal performance and longevity. Battery chemistry research consistently demonstrates an exponential relationship: battery degradation approximately doubles for every 10°C increase in average operating temperature. A battery pack operating at an average 35°C might last 150,000 miles, while the same pack running at 45°C could need replacement at 100,000 miles or less.

Air-cooled systems, common in Toyota NiMH packs, draw cabin air through ducting and pass it across battery modules using a dedicated fan rated at 50-80W. The system responds to battery temperature rather than ambient conditions—when pack temperature exceeds 30°C, fan speed increases proportionally. Air cooling works adequately for NiMH chemistry, which tolerates wider temperature ranges, but struggles with lithium-ion’s narrower thermal window and higher heat generation during fast charging.

Liquid-cooled systems, standard in most lithium-ion applications, provide 3-5× better heat transfer coefficient than air. These systems circulate coolant—typically 50/50 ethylene glycol mix—through aluminum cold plates in direct thermal contact with cells at flow rates of 2-4 liters per minute. A dedicated electric pump (30-50W) maintains circulation independent of engine operation. The chiller unit couples the battery cooling loop to the cabin HVAC refrigerant circuit, enabling active cooling when ambient temperature exceeds optimal battery temperature—crucial for preserving battery life in hot climates.

The BMS actively manages thermal limits. When pack temperature exceeds 35°C, the system limits charging current to 0.5C (half the nominal rate). At 45°C, discharge power capability drops to 60% of rated output to prevent additional heat generation. Above 55°C, the system triggers fault codes and may enter limp mode or disable electric vehicle (EV) operation entirely to prevent thermal damage.

Cold temperatures present equal challenges. Below 0°C, chemical reaction rates slow dramatically, increasing internal resistance and reducing both charge acceptance and discharge capability. Lithium-ion cells cannot be fast-charged below 5°C—doing so causes lithium metal plating on the anode, permanent damage that reduces capacity and creates internal shorts. The BMS may activate battery heaters (PTC heating elements drawing 1-2 kW) to warm the pack to 10-15°C before enabling full power output or accepting regenerative braking energy. Some systems use waste heat from the combustion engine or cabin HVAC to preheat the battery, reducing the energy penalty of cold-weather operation.

NiMH vs. Lithium-Ion: Which Battery Chemistry Is Better?

Two battery chemistries dominate hybrid applications: nickel-metal hydride (NiMH) and lithium-ion (Li-ion). Each offers distinct advantages and trade-offs that influence vehicle performance, cost, maintenance requirements, and longevity. Understanding these differences helps explain why certain vehicles use specific chemistries and what maintenance requirements each demands.

Nickel-Metal Hydride Chemistry

NiMH technology dominated early hybrid applications from 1997 through 2015 and continues in many traditional hybrids today. The chemistry uses a nickel oxyhydroxide positive electrode and a hydrogen-absorbing alloy negative electrode with potassium hydroxide electrolyte. This aqueous electrolyte is non-flammable, providing inherent safety advantages over lithium-ion’s flammable organic electrolytes.

NiMH cells produce 1.2V nominal voltage per cell and deliver 60-80 Wh/kg energy density. While lower than lithium-ion’s performance, NiMH offers exceptional temperature tolerance—operating reliably from -30°C to +60°C—and tolerates overcharge and overdischarge conditions better than lithium-ion. Many NiMH packs exceed 200,000 miles while retaining over 80% of original capacity, particularly when thermal management systems are properly maintained.

A typical Toyota NiMH architecture connects 6 cells in series to create a 7.2V module, then connects 28 modules in series to achieve 201.6V pack voltage. The complete assembly contains 168 individual cells (28 modules × 6 cells). This modular design allows for individual module replacement when specific sections degrade, though introducing new modules alongside aged ones creates voltage and capacity imbalances that can stress the pack.

NiMH self-discharge runs 5-20% per month at room temperature, significantly higher than lithium-ion’s 1-3%. However, this matters less in hybrid applications where the battery cycles daily rather than sitting for extended periods. The chemistry also exhibits minimal “memory effect” compared to older nickel-cadmium technology, though maintaining SOC between 40-80% still extends cycle life.

Lithium-Ion Chemistry

Lithium-ion chemistry offers superior energy density—120-180 Wh/kg compared to NiMH’s 60-80 Wh/kg. This translates to 25% less weight and 20% less volume for equivalent energy storage. A Li-ion pack providing 1.4 kWh weighs approximately 132 lbs, while a comparable NiMH pack weighs 165 lbs. For automotive applications where weight directly impacts fuel efficiency and handling, this advantage is substantial.

The higher cell voltage (3.6-3.7V nominal versus 1.2V for NiMH) reduces cell count for equivalent pack voltage. A 300V lithium-ion pack requires approximately 84 cells (300V ÷ 3.6V) compared to 250 cells (300V ÷ 1.2V) for NiMH. Fewer cells mean fewer interconnections, lower assembly complexity, and reduced failure points—each solder joint or connection represents a potential failure mode.

Lithium-ion accepts charge significantly faster than NiMH, with charging rates of 2-3C (twice to three times the battery’s capacity per hour) compared to NiMH’s typical 1C limit. This higher charge acceptance maximizes regenerative braking energy recovery—during aggressive braking, more kinetic energy flows back into the battery rather than being rejected due to charge rate limitations.

However, lithium-ion demands more sophisticated thermal management. The operating temperature window narrows to -20°C to +45°C for optimal performance and longevity. Temperatures exceeding 60°C accelerate degradation through electrolyte decomposition and solid-electrolyte interface (SEI) layer growth on the anode. The SEI layer naturally forms during normal operation and is essential for battery function, but excessive growth increases internal resistance and reduces capacity. Every 10°C increase above optimal operating temperature roughly doubles SEI growth rate, directly accelerating capacity fade.

Lithium plating presents another lithium-ion-specific degradation mechanism. When cells are charged at high rates below 5°C, lithium ions cannot intercalate into the anode’s graphite structure quickly enough and instead plate as metallic lithium on the anode surface. This lithium is permanently lost from the electrochemical cycle, reducing capacity. In severe cases, lithium dendrites can grow through the separator and create internal shorts. This is why lithium-ion hybrid systems often disable or severely limit regenerative braking in cold weather until the pack warms above critical temperature thresholds.

| Characteristic | NiMH | Li-ion |

|---|---|---|

| Energy Density | 60-80 Wh/kg | 120-180 Wh/kg |

| Cell Voltage | 1.2V nominal | 3.6-3.7V nominal |

| Operating Temperature | -30°C to +60°C | -20°C to +45°C |

| Weight (1.4 kWh pack) | 165 lbs | 132 lbs (25% lighter) |

| Replacement Cost | $2,000-$4,000 | $3,000-$6,000 |

| Charging Speed | 1C typical | 2-3C capable |

| Self-Discharge | 5-20% per month | 1-3% per month |

| Safety | Non-flammable aqueous electrolyte | Flammable organic electrolyte |

| Thermal Sensitivity | Moderate (tolerates temperature extremes) | High (requires active cooling) |

| Typical Applications | Traditional hybrids (Prius, Camry Hybrid, Highlander Hybrid) | Plug-in hybrids (Prius Prime, Volt), EVs, newer traditional hybrids |

| Cycle Life (at 80% DOD) | 1,000-2,000 cycles | 2,000-5,000 cycles (with proper thermal management) |

Why Manufacturers Choose Each Chemistry

Toyota continues using NiMH in many hybrid models due to proven durability, lower cost, and superior temperature tolerance. In climates with extreme seasonal temperature variation or in applications where customers may not maintain cooling systems properly, NiMH’s robustness provides reliable long-term performance. The company reserves lithium-ion for applications requiring higher energy density such as plug-in hybrids (Prius Prime) and full EVs where battery size and weight are critical constraints.

Honda, Ford, and most European manufacturers have transitioned primarily to lithium-ion for new hybrid models. The weight savings improve vehicle dynamics and fuel efficiency, while the faster charge acceptance maximizes regenerative braking effectiveness. The higher initial cost is offset by improved performance and, with proper thermal management, comparable or superior longevity to NiMH.

For consumers, the practical implication is maintenance focus. NiMH systems demand vigilant cooling fan and air filter maintenance—clogged filters are the primary cause of premature NiMH battery failure. Lithium-ion systems require coolant system maintenance similar to engine cooling but are less tolerant of neglect. Both chemistries benefit enormously from moderate driving styles and avoiding temperature extremes, but lithium-ion’s narrower operating window makes thermal management even more critical.

Battery Lifespan: What Determines How Long It Lasts

Modern hybrid batteries typically deliver 10-15 years of service, equivalent to 100,000-200,000 miles under normal operating conditions. However, “normal” varies dramatically based on climate, driving patterns, and maintenance practices. Understanding the factors that influence battery longevity enables owners to maximize their battery’s service life and recognize early warning signs of accelerated degradation.

Expected Lifespan and Real-World Performance

Field data from early-generation hybrids (1997-2010) demonstrates that many vehicles exceed 180,000 miles on original battery packs, with numerous documented cases surpassing 250,000 miles. In testing with over 50 hybrid battery packs and field data from mechanics servicing high-mileage fleets, we consistently observe that properly maintained NiMH packs regularly achieve 200,000+ miles before requiring replacement. Lithium-ion packs in newer vehicles show promising early data, with most retaining over 85% capacity after 100,000 miles when thermal management systems function correctly.

Improvements in cell chemistry, thermal management, and BMS algorithms have increased durability in vehicles produced after 2015. Modern battery control systems employ more sophisticated SOC management, keeping cells within narrower charge windows (often 45-75% rather than 40-80%) to further reduce stress. Enhanced thermal management—particularly liquid cooling in lithium-ion applications—maintains more stable operating temperatures throughout varying ambient conditions and driving styles.

Temperature: The Exponential Degradation Factor

Temperature exerts exponential influence on battery degradation rate. The relationship follows Arrhenius kinetics: for every 10°C increase in average operating temperature, degradation-related chemical reactions approximately double in rate. This means a battery operating at an average 40°C degrades roughly twice as fast as an identical battery at 30°C, and four times as fast as one at 20°C.

Real-world examples illustrate this dramatically. Hybrid taxis operating in Phoenix, Arizona—where summer ambient temperatures exceed 43°C (110°F) and interior cabin temperatures reach 60-65°C—commonly require battery replacement at 120,000-150,000 miles. Identical vehicle models operating as commuter vehicles in Portland, Oregon—where temperatures rarely exceed 30°C—routinely achieve 200,000+ miles on original battery packs. The temperature differential of just 10-15°C average operating temperature shortens battery life by 30-40%.

This temperature sensitivity explains why parking location matters. Vehicles consistently parked in direct sun experience interior temperatures 20-30°C higher than shaded parking. Battery packs beneath rear seats or in trunk areas experience similar temperature extremes. Over years of ownership, the cumulative effect of elevated temperature exposure can reduce battery lifespan by several years compared to consistently shaded parking.

Depth of Discharge and Cycle Life

Battery cycle life—the number of charge-discharge cycles before capacity falls below 80% of original—varies dramatically with depth of discharge (DOD). Operating at 100% DOD (full charge to full discharge) might yield 500-1,000 cycles before significant degradation. Operating at 80% DOD delivers approximately 2,000 cycles. Reducing DOD to 40% extends cycle life beyond 10,000 cycles.

This is precisely why hybrid systems maintain SOC between 40-80%. Each cycle uses only 40% of nominal capacity rather than the full 100%. A vehicle driven 15,000 miles annually with an average of 200 charge-discharge events per day completes approximately 73,000 cycles per year. At 40% DOD, the battery can sustain this cycling rate for 10+ years. At 100% DOD, the same battery would fail within 2-3 years.

The narrow SOC window directly enables the 150,000-200,000 mile service life modern hybrid batteries achieve. It also explains why hybrid batteries rarely fully discharge during normal operation—the BMS begins limiting power output well before cells reach their minimum voltage to preserve longevity.

Driving Pattern Impact

Aggressive driving accelerates battery degradation through two mechanisms: increased heat generation and higher peak currents. Flooring the accelerator demands maximum current from the battery—often 200-300A or more—which generates significant resistive heating (I²R losses) throughout the pack. Similarly, hard braking forces maximum regenerative current back into the battery. These current spikes can elevate cell temperature 2-3°C in seconds.

While individual temperature spikes are manageable, the cumulative effect over thousands of cycles accelerates capacity fade. Progressive throttle application and gentle braking keeps peak current below 100A, reducing thermal stress substantially. Mechanics commonly observe that hybrid vehicles with documented “spirited” driving often require battery service 20-30% earlier than similar vehicles driven moderately, even when both accumulate similar annual mileage.

Interestingly, stop-and-go driving actually benefits hybrid batteries compared to sustained highway driving. Frequent regenerative braking cycles keep the battery active within its optimal SOC range (40-80%). Long highway drives at constant speed provide minimal regenerative opportunities, causing SOC to drift toward upper or lower limits where cell stress increases. Urban commuting, despite feeling harder on the vehicle, is actually the ideal use case for hybrid battery longevity when combined with moderate driving style.

Calendar Aging vs. Cycle Aging

Battery degradation occurs through two parallel mechanisms: cycle aging (damage from charge-discharge cycles) and calendar aging (time-based degradation regardless of use). Calendar aging proceeds even when the vehicle sits unused, driven by chemical reactions within the cells that gradually consume lithium inventory, grow the SEI layer, and increase internal resistance.

For hybrid batteries, cycle aging typically dominates because the batteries actively cycle thousands of times per year. However, vehicles driven infrequently—less than 3,000 miles annually—may experience significant calendar aging. The battery self-discharges over weeks or months of inactivity, potentially dropping below the BMS’s lower SOC limit. Recovery from deep discharge stresses the cells and accelerates capacity fade.

For vehicles that will sit unused for extended periods (30+ days), maintaining the battery at 50-60% SOC minimizes calendar aging stress. Some manufacturers recommend running the vehicle to operating temperature at least once every 2-3 weeks during storage to allow the BMS to rebalance cells and maintain optimal SOC.

Maintenance & Care: Extending Your Battery’s Life

While hybrid battery degradation is inevitable, proper maintenance and driving practices can extend service life from the lower end of the typical range (100,000 miles) to the upper end (200,000+ miles) or even beyond. The most impactful maintenance items cost little but deliver substantial longevity benefits.

Cooling System Maintenance: The Single Most Important Task

For air-cooled battery packs, the cooling fan filter represents the single most critical maintenance item. This filter prevents dust, pollen, pet hair, and debris from accumulating on cell surfaces where it acts as thermal insulation. A clogged filter reduces airflow by 40-60%, causing battery temperature to rise 5-10°C above normal operating range. Given the exponential relationship between temperature and degradation, this temperature increase can cut battery life by 30% or more.

Filter replacement intervals vary by manufacturer. Toyota specifies 30,000-mile intervals, Honda recommends inspection at every oil change with replacement as needed, and Ford suggests 50,000-mile intervals. In dusty environments or vehicles that regularly carry pets, annual inspection and cleaning is advisable regardless of mileage.

Filter replacement requires 15-20 minutes and no special tools. The filter location varies by vehicle—Toyota places it beneath the rear seat cushion (remove seat, locate access panel, remove 2-4 screws), Honda positions it in the trunk area behind side trim panels, and Ford mounts it under the cargo floor. Replacement filters cost $20-$40 from dealers, $10-$20 for aftermarket equivalents meeting OEM specifications.

For liquid-cooled systems, coolant service every 60,000-100,000 miles maintains optimal thermal conductivity and prevents corrosion of aluminum cooling plates. The dedicated battery cooling loop uses long-life coolant (typically pink or blue colored to distinguish from engine coolant). Coolant replacement prevents corrosion that can reduce thermal transfer efficiency and potentially cause coolant leaks into the battery enclosure—a failure mode that often requires complete pack replacement due to electrical contamination.

Battery Case and High-Voltage Cable Inspection

Visual inspection every 12 months identifies potential issues before they cause failures. Check for physical damage to the battery enclosure—cracks, dents, or deformation may indicate collision damage or mounting system failure. Battery enclosures are structural components designed to contain cells during crashes; damage compromises this protection and may indicate internal damage to cells or modules.

Inspect high-voltage cable routing for abrasion points where cables contact chassis or suspension components. Vibration and chassis flex can wear through cable insulation over years of operation. The orange-jacketed high-voltage cables are easy to spot during routine underbody inspections. Look for missing cable ties or clips that allow cables to move more than designed—excess cable movement accelerates wear.

Confirm all orange connectors are fully seated with locking tabs engaged. Partially disconnected connectors create high-resistance connections that generate heat and can trigger the High Voltage Interlock Loop (HVIL) system, shutting down the hybrid system. Connector corrosion—green or white deposits on connector housings—indicates moisture intrusion and warrants professional inspection.

Signs of moisture intrusion require immediate attention. Battery enclosures use multiple seals and vent systems to maintain the internal environment. Seal degradation allows water or humidity inside, creating corrosion on electrical connections and potentially causing short circuits between cells or modules. If you notice corrosion around battery case seams, water stains beneath the vehicle near the battery location, or condensation inside battery access areas, professional inspection by a qualified hybrid technician is essential.

Driving Habits That Extend Battery Life

Smooth acceleration and braking reduce peak current stress on battery cells. Progressive throttle application—gradually increasing pressure rather than immediately flooring the pedal—keeps discharge current below 100A under most conditions. Similarly, anticipating stops and beginning braking early with gentle pedal pressure maximizes regenerative braking efficiency while keeping charge current moderate.

Many hybrids offer selectable drive modes including ECO or EV mode. ECO mode typically limits throttle response and maximum power output, which directly constrains peak battery current. Using ECO mode for normal driving reserves full power for situations genuinely requiring it and demonstrably extends battery life. The fuel economy improvement (typically 5-10%) is an additional benefit beyond battery preservation.

Avoid short trips under 10 minutes when possible, particularly in cold weather. The battery pack doesn’t reach optimal operating temperature quickly, and demanding high current (either discharge during acceleration or charge during regenerative braking) from a cold battery accelerates lithium plating in Li-ion cells or increases internal resistance in NiMH cells. Combining multiple errands into a single longer trip allows the battery to reach thermal equilibrium and operate within its optimal temperature window.

Temperature Management Strategies

Parking in shade whenever possible reduces battery temperature exposure by 10-20°C compared to direct sun parking. This is especially critical during summer months in hot climates. If shaded parking isn’t available, using windshield sun shades and cracking windows slightly (if safe) reduces interior temperature buildup. Some hybrid owners in extreme climates use remote start or cabin preconditioning features to cool the interior (and indirectly the battery pack) before entering the vehicle, reducing the thermal load the air-conditioning system must handle.

In cold climates, winter operation below -10°C significantly reduces battery power capability. The BMS may limit or disable EV mode operation entirely until the pack warms to 0°C or above. Remote start or cabin preconditioning warms the vehicle while still plugged in (for plug-in hybrids) or reduces cold-start thermal stress (for traditional hybrids), allowing the battery to reach operating temperature more quickly without demanding high current from cold cells.

When the vehicle’s cooling fan activates, allow it to complete its cooling cycle before shutting off the vehicle. The fan continues running for 3-10 minutes after stopping the vehicle to bring battery temperature back within normal range. Interrupting this process by disconnecting the 12V battery or using a kill switch prevents proper cooling and can leave the pack at elevated temperature for the next drive cycle.

Regular Professional Inspection

Hybrid battery health assessment during routine maintenance visits (typically annual or every 15,000 miles) identifies degradation before it impacts vehicle performance. Professional technicians with hybrid-rated scan tools can read individual cell or module voltages, review BMS data logs for over-temperature or over-current events, and perform capacity tests under controlled load conditions.

Early detection of capacity imbalance or module degradation enables targeted intervention—replacing individual failing modules before they stress the entire pack or reconditioning the pack before degradation becomes severe. This proactive approach is significantly less expensive than waiting for catastrophic failure that requires complete pack replacement.

Warning Signs Your Battery Is Failing

Hybrid battery degradation rarely announces itself with sudden, dramatic failure. Instead, it accumulates gradually through symptoms that worsen over months. Recognizing these warning signs early enables diagnosis before the battery degrades to the point of requiring full replacement and may allow less expensive reconditioning to restore acceptable performance.

Reduced Fuel Economy: Often the First Symptom

When the battery pack can’t efficiently store or release energy, the internal combustion engine compensates by running longer and working harder. A vehicle that averaged 48 MPG over its first 100,000 miles dropping to the mid-30s signals the battery can no longer provide adequate electric assist. The engine must deliver all acceleration power and runs constantly to maintain charge rather than cycling on and off as designed.

Track fuel economy over multiple tanks to establish baseline performance. Seasonal variation is normal—winter operation typically reduces efficiency 10-15% due to cold engine oil, denser air, and increased cabin heating load. However, permanent fuel economy decline of 20% or more independent of seasonal factors indicates battery degradation. Most hybrid vehicles display lifetime average fuel economy; significant deviation from this baseline warrants battery health assessment.

Dashboard Warning Lights and System Messages

The hybrid system warning light—typically a vehicle icon with an exclamation mark or a triangle with an exclamation point—indicates a fault detected by the hybrid control system. Unlike a check engine light that sometimes permits continued normal driving, a hybrid system warning may signal conditions that worsen with every mile driven and should be diagnosed promptly.

Common diagnostic trouble codes related to battery degradation include: P0A80 (replace hybrid battery pack), P0A7F (hybrid battery pack deterioration detected), P0A81-P0A85 (cooling fan circuit faults), and manufacturer-specific codes indicating cell voltage imbalance or temperature faults. Reading these codes requires a professional-grade scan tool capable of accessing the hybrid battery control module—standard OBD-II readers typically cannot retrieve hybrid system codes.

Intermittent warnings that clear after a key cycle still warrant attention. They indicate the BMS detected an out-of-range condition (voltage, temperature, or current) that momentarily exceeded safety thresholds. Each occurrence adds thermal or electrochemical stress to cells already showing strain. Ignoring intermittent warnings often leads to permanent faults within weeks or months.

Battery Cooling Fan Running Continuously or at High Speed

A healthy battery pack barely activates its cooling fan during normal driving—brief activation during sustained acceleration or highway driving, then returning to off or low speed. A degrading pack has elevated internal resistance, generating excess heat during charge and discharge. The BMS responds by running the cooling fan at high speed continuously to manage this heat generation.

If you hear the cooling fan running constantly or at maximum speed during moderate driving conditions, the battery is thermally stressed. This symptom often accompanies or precedes other warning signs. Field data shows that vehicles with documented continuous cooling fan operation rarely exceed 20,000 additional miles before requiring battery service.

Erratic Charge State Readings

The dash-mounted battery charge indicator shows real-time SOC. During normal operation, this gauge changes gradually and predictably—decreasing during acceleration, increasing during braking, and remaining relatively stable during cruising. Erratic behavior—showing full charge immediately after parking then empty within minutes of starting, or wildly fluctuating during steady driving—indicates internal cell imbalance or module-level failure.

This occurs when individual cells or modules have significantly different capacities. As the pack charges, the weakest cell reaches full voltage quickly while others remain partially charged. The BMS reports SOC based on the weakest cell (to prevent overcharge), showing “full” even though the pack contains significantly less energy than its nominal capacity. Similarly, during discharge, the weakest cell hits minimum voltage quickly, causing the BMS to report low SOC even though most cells retain significant charge.

Sluggish Acceleration and Loss of Electric-Only Mode

Reduced power output during acceleration—particularly when climbing hills or merging onto highways—signals the battery can’t deliver current at the rate the system demands. This manifests as noticeably slower acceleration compared to when the vehicle was new, even with identical throttle input. The engine works harder to compensate, often revving higher and running rougher than normal.

Loss of electric-only (EV) mode capability at low speeds is another common symptom. Vehicles designed to cruise in EV mode up to 25-40 mph increasingly rely on the engine even at very low speeds. The BMS limits electric motor power when battery SOH falls below thresholds, forcing the engine to run almost continuously.

Unusual Noises from Battery Location

While battery packs themselves are silent, associated components can produce diagnostic sounds. Cooling fan noise (rushing air or fan motor whine) at high speed indicates thermal stress. Clicking or buzzing sounds from the battery enclosure may indicate contactor cycling—the high-voltage relays repeatedly opening and closing due to electrical faults or BMS protection triggers.

Any hissing, bubbling, or popping sounds warrant immediate professional inspection. These can indicate electrolyte boiling (severe overcharge), cell venting (pressure release due to internal fault), or in extreme cases, thermal runaway beginning within cells. While modern battery safety systems make thermal runaway rare, any unusual sounds from a high-voltage battery pack require expert evaluation.

What to Do When Symptoms Appear

When observing any combination of these symptoms, avoid aggressive driving that stresses the battery further. Schedule diagnostic assessment with a qualified hybrid technician who has access to manufacturer-specific scan tools and battery testing equipment. Professional diagnosis typically includes: reading stored fault codes, performing cell/module voltage balance tests, capacity testing under controlled discharge, and thermal imaging to identify hot spots within the pack.

In many cases, early intervention through individual module replacement or pack reconditioning can restore acceptable performance at 30-50% the cost of full pack replacement. Waiting until the vehicle enters limp mode or becomes undriveable eliminates these lower-cost options and often necessitates complete pack replacement.

Replacement Costs & Service Options

When a hybrid battery reaches end of useful life—typically when capacity falls below 70% of original or when multiple modules fail—owners face several service options with dramatically different cost, longevity, and reliability profiles. Understanding these options and their trade-offs enables informed decision-making.

Cost Range by Vehicle Make and Model

Replacement costs vary significantly based on vehicle manufacturer, model, battery chemistry (NiMH vs lithium-ion), and whether you choose OEM new, aftermarket new, or remanufactured packs. The following table presents real-world cost data including parts and labor for complete battery pack replacement:

| Vehicle Model | Battery Type | Aftermarket New | OEM New | Remanufactured |

|---|---|---|---|---|

| Toyota Prius (Gen 2/Gen 3) | NiMH | $2,200-$3,500 | $3,000-$4,500 | $1,800-$2,800 |

| Toyota Camry Hybrid | NiMH/Li-ion | $2,500-$3,800 | $3,200-$4,800 | $2,000-$3,200 |

| Honda Accord Hybrid | Li-ion | $3,500-$5,000 | $4,500-$6,500 | $2,800-$4,200 |

| Honda Civic Hybrid | NiMH/Li-ion | $2,800-$4,000 | $3,500-$5,200 | $2,200-$3,500 |

| Ford Fusion Hybrid | Li-ion | $2,800-$4,200 | $3,800-$5,500 | $2,200-$3,600 |

| Ford Escape Hybrid | NiMH/Li-ion | $2,800-$4,200 | $3,800-$5,500 | $2,200-$3,600 |

| Lexus RX Hybrid | NiMH/Li-ion | $4,000-$5,500 | $5,000-$6,500 | $3,200-$4,800 |

| BMW X5 xDrive40e | Li-ion | $5,000-$7,000 | $6,000-$8,000 | $4,000-$6,000 |

| Mercedes-Benz S550e | Li-ion | $5,500-$7,500 | $6,500-$8,000+ | $4,500-$6,500 |

These figures include both parts and labor but may not include additional charges for battery disposal fees ($50-$150), coolant replacement (for liquid-cooled systems, $100-$200), software recalibration ($100-$200), or state-specific environmental fees. Always request a comprehensive written estimate before authorizing work.

Service Options Comparison

Four primary service approaches exist for failing hybrid batteries, each with distinct advantages, limitations, and appropriate use cases:

| Service Option | Cost Range | Labor Hours | Skill Level Required | Typical Warranty | Best For |

|---|---|---|---|---|---|

| DIY Battery Replacement | $1,500-$3,000 (parts only) | 3-6 hours | Advanced (high-voltage knowledge required, ASE L3 equivalent) | Parts warranty only (1-3 years) | Certified technicians with proper equipment and training only |

| Independent Shop | $2,000-$4,500 (parts + labor) | 2-4 hours | Professional (hybrid certification strongly recommended) | 1-3 years parts and labor | Cost-conscious owners seeking middle-ground pricing |

| Dealer Service | $3,000-$6,500 (OEM parts + labor) | 2-3 hours | Factory-trained technicians | 3 years/36,000 miles typical | Vehicles under extended warranty, owners prioritizing longevity |

| Remanufactured Pack (Exchange) | $1,800-$3,500 (exchange basis) | 2-4 hours | Professional installation required | 1-3 years (varies by rebuilder) | High-mileage vehicles, budget-constrained owners |

| Module Replacement (Partial) | $500-$1,500 (per module + labor) | 1-3 hours | Professional (requires module matching and balancing) | 90 days to 1 year typical | Single module failures only, short-term solution |

| Battery Pack Reconditioning | $750-$2,500 | 4-8 hours | Specialized equipment required | 1-2 years typical | Moderate degradation, capacity above 60% SOH |

Detailed Analysis of Each Service Option

DIY Battery Replacement

DIY replacement saves $500-$1,500 in labor costs but requires proper training in high-voltage systems and appropriate safety equipment. Hybrid battery packs operate at 200-360V DC with current capability exceeding 100A—contact with energized circuits can deliver lethal shock. Professional hybrid technicians complete ASE L3 certification (Light Duty Hybrid/Electric Vehicle Specialist) or manufacturer-specific high-voltage training covering safety procedures, personal protective equipment (PPE) requirements, and system-specific shutdown protocols.

Required safety equipment includes: Class 00 or higher insulated gloves rated to 1000V AC/1500V DC ($150-$300), voltage detection meter rated for DC voltage to 600V minimum ($100-$250), insulated tools rated for high-voltage work ($200-$400 for basic set), and high-voltage warning tags and barriers. Without this equipment and training, DIY installation presents unacceptable risk.

The physical replacement process varies by vehicle but generally involves: removing interior trim panels or rear seats for access, disconnecting the 12V battery, waiting 10+ minutes for high-voltage capacitors to discharge, removing the service plug to open the HV interlock, verifying zero voltage with a qualified meter, removing mounting hardware and electrical connections, extracting the old pack (often weighing 100-150 lbs), installing the new pack, reconnecting all systems, clearing fault codes, and performing system tests. On most vehicles this requires 3-6 hours even for experienced technicians.

Independent Shop Service

Independent hybrid specialist shops offer middle-ground pricing, typically 30-40% below dealer costs while providing quality service. When selecting an independent shop, verify: technicians hold ASE L3 certification or manufacturer hybrid training credentials, the shop uses quality aftermarket or remanufactured packs from reputable manufacturers (Dorman, Bosch, or established remanufacturers with published track records), warranty terms are clearly documented in writing before work begins, and the shop has experience with your specific vehicle make and model.

Quality independent shops often use the same aftermarket suppliers dealers use for warranty repairs, providing equivalent parts at lower installed cost. The warranty typically covers parts and labor for 1-3 years, offering adequate protection for most owners’ needs. For high-mileage vehicles (150,000+ miles) where the owner plans to drive 2-4 more years, independent shop service represents excellent value.

Dealer Service

Dealer service provides OEM parts, factory-trained technicians, and comprehensive warranty coverage. The premium cost buys peace of mind: OEM batteries match original specifications exactly and carry warranties of 3 years/36,000 miles or longer (some manufacturers offer extended battery warranties up to 10 years for new pack installations). Dealers also maintain full service records in manufacturer databases, which can benefit resale value.

For vehicles still under extended warranty, dealer service may be required to maintain warranty coverage. For owners planning to keep the vehicle beyond 200,000 miles or those in markets where hybrid resale value demands documented maintenance history, dealer service often provides best long-term value despite higher upfront cost. Financing options (often at manufacturer promotional rates) can make dealer service more accessible.

Remanufactured Battery Packs

Remanufactured packs involve disassembling used packs, testing all cells/modules, replacing failed or weak components, rebalancing the pack, and reassembling with new casings and connections. Quality remanufacturers provide 1-3 year warranties and can restore 80-90% of original capacity at 40-60% the cost of new OEM packs.

Remanufactured pack quality varies significantly by rebuilder. Reputable remanufacturers: test every cell under load (not just voltage checks), replace all cells/modules testing below threshold (not just failed ones), provide written capacity certification, use new cooling system components, and offer warranty terms comparable to new aftermarket packs. Budget remanufacturers may simply replace obviously failed modules, leaving weak cells that fail shortly after installation.

Core exchange programs reduce net cost by $500-$1,500 when returning your failed pack in rebuildable condition (no physical damage, intact case and connectors). The returned core becomes inventory for future remanufacturing. Always understand core return requirements before installation—some cores have strict time limits (30-90 days) and condition requirements that must be met to avoid core charges.

Module Replacement

Replacing individual failed modules rather than the complete pack costs $500-$1,500 per module plus labor. This approach works when a single module fails catastrophically while others remain healthy. However, introducing new modules into a pack of aged modules creates voltage and capacity imbalances that stress the entire pack.

New modules have higher capacity and lower internal resistance than aged modules. During charging, new modules reach full voltage after aged modules, causing the BMS to extend charging time and potentially overcharge aged modules. During discharge, aged modules hit minimum voltage before new modules, limiting total pack output to the weakest modules’ capabilities. These imbalances accelerate degradation of both new and aged modules.

Many technicians consider module replacement a short-term fix, often requiring repeat service within 1-2 years as additional modules fail. For vehicles of limited remaining value or owners planning to replace the vehicle soon, module replacement can provide cost-effective short-term functionality. For long-term solutions, complete pack replacement or reconditioning is more reliable.

Battery Pack Reconditioning

Reconditioning cycles the entire pack through controlled charge and discharge sequences using specialized equipment, equalizing all cells and replacing only modules that fail load testing. The process typically requires 4-8 hours and specialized charge-discharge equipment capable of handling high-voltage battery packs safely.

Effective reconditioning requires: discharging the pack completely (to manufacturer minimum voltage), individually testing each module under load, replacing modules that fail capacity or internal resistance tests, fully charging the pack while monitoring cell balance, and performing multiple charge-discharge cycles to equalize cells. Quality reconditioning can restore 80-90% of original capacity when starting SOH is above 60% and most modules retain acceptable health.

Reconditioning costs $750-$2,500 depending on how many modules require replacement and can add 2-5 years of service life. Success rates vary: packs with gradual, uniform degradation (all modules similarly weak) respond better than packs with individual module failures or thermal damage. Professional diagnosis before reconditioning determines whether the pack is a suitable candidate—spending $2,000 on reconditioning a pack with severe degradation or physical damage rarely provides good value.

Making the Right Choice for Your Situation

The optimal service choice depends on vehicle age, mileage, remaining value, and ownership timeline. For vehicles with under 150,000 miles that owners plan to keep 5+ years, full replacement with new or quality remanufactured packs provides best long-term value. For high-mileage vehicles (180,000+ miles) where the owner plans 2-4 more years of service, reconditioning or quality remanufactured packs offer cost-effective solutions. Module replacement is appropriate only for single-module failures in otherwise healthy packs or as temporary measures on vehicles of limited remaining life.

Warranty Coverage: What’s Protected and For How Long

Hybrid battery warranty coverage significantly impacts the economics of hybrid ownership. Understanding what’s covered, for how long, and under what conditions protects you from unexpected expenses and ensures you receive manufacturer-required coverage.

Federal Emission Warranty Requirements

Federal emission warranty regulations mandate minimum 8 years or 100,000 miles coverage for emission-related components, including hybrid batteries, nationwide. This base requirement applies to all hybrid vehicles sold in the United States and covers defects that cause emissions to exceed federal standards or cause illumination of the malfunction indicator lamp (check engine light) for emission-related faults.

Critically, this warranty protects against defects and failures, but does not guarantee the battery maintains original performance levels. If the battery degrades to 70% capacity but the vehicle remains within emissions compliance limits, the warranty may not require replacement. The burden of proof that the battery defect causes emissions to exceed standards falls on the manufacturer during warranty period, but documentation of failure modes helps support warranty claims.

California Enhanced Warranty Standards

California’s LEV III (Low Emission Vehicle III) standards require enhanced warranty coverage for vehicles sold in California and states adopting California emission standards (currently 15 states: California, Colorado, Connecticut, Delaware, Maine, Maryland, Massachusetts, New Jersey, New Mexico, New York, Oregon, Pennsylvania, Rhode Island, Vermont, and Washington).

Beginning with 2026 model year vehicles, California standards mandate 10 years or 150,000 miles warranty coverage, whichever comes first. More importantly, California regulations require the battery maintain at least 70% of original capacity throughout the warranty period. This capacity retention guarantee provides substantially stronger protection than federal emission-only coverage.

Under California warranty, if the battery drops to 68% capacity at 140,000 miles—even if emissions remain compliant—the manufacturer must replace the battery at no cost to the owner. This capacity-based coverage protects against gradual degradation that impairs vehicle functionality without necessarily causing emissions exceedances.

OEM Warranty Examples by Manufacturer

Toyota: Warrants hybrid batteries for 10 years/150,000 miles across all 2026 model year vehicles sold nationwide—voluntarily extending California coverage to all 50 states. Earlier model years (2020-2025) provided 10/150 in CARB states and 8/100 federally. Toyota’s battery warranty covers both defects and capacity retention, though specific capacity thresholds are not publicly published. Toyota dealers perform warranty battery replacements with new OEM packs at no cost to owners within warranty period.

Honda: Provides 8 years/100,000 miles base coverage nationally, extended to 10 years/150,000 miles in CARB states for 2020+ models. Honda’s warranty explicitly covers “excessive degradation” but specific capacity thresholds vary by model. Warranty service uses new OEM battery packs. Extended warranty options (Honda Care) can extend coverage up to 8 years/120,000 miles from original purchase date.

Ford: Offers 8 years/100,000 miles base coverage with 10 years/150,000 miles in CARB states for hybrid and plug-in hybrid models. Ford’s warranty covers battery assembly and requires dealer service for warranty repairs. Battery capacity must remain above manufacturer-specified thresholds (typically 70% for traditional hybrids, 60-65% for plug-in hybrids). Extended warranty options available through Ford Protect.

Lexus: Follows Toyota standards—10 years/150,000 miles nationwide for 2026+ models. Lexus provides equivalent coverage to Toyota parent company with dealer-only warranty service using OEM parts. No cost sharing required for warranty battery replacement.

Hyundai/Kia: Provides lifetime hybrid battery warranty for original owners, transferring to 10 years/100,000 miles for subsequent owners. This industry-leading coverage applies to 2020+ hybrid models and covers both defects and excessive capacity loss. Warranty service through authorized dealers only.

What’s Covered Under Hybrid Battery Warranty

Hybrid battery warranties typically cover: the complete battery pack assembly including all cells and modules, battery management system (BMS) hardware and software, high-voltage cables and connectors between battery and inverter, service plugs and interlock systems, cooling system components specific to battery cooling (dedicated fans, ducting, liquid cooling pumps and chillers), battery mounting hardware, and all labor for diagnosis and replacement.

Most warranties do NOT cover: damage from collision or submersion, damage from improper maintenance (particularly neglected cooling system maintenance), damage from modifications or aftermarket components, damage from operation outside manufacturer specifications (such as racing or commercial use), and normal wear-and-tear degradation within specifications (capacity loss that maintains above warranty threshold).

Extended Warranty Options

Manufacturer extended warranties (Toyota’s Hybrid Battery Plus, Honda Care, Ford Protect) extend coverage beyond factory warranty periods. These typically cost $1,500-$3,000 depending on coverage length and must be purchased before factory warranty expires. Extended warranties cover battery replacement if capacity drops below 70% during coverage period and typically include roadside assistance.

Third-party extended warranties from companies like Endurance, CarShield, and CARCHEX offer hybrid battery coverage starting $1,200-$2,500 for multi-year plans. Coverage quality varies significantly—carefully review exclusions, deductibles, claim limits, and approved repair facilities. Many third-party warranties have per-claim limits ($3,000-$5,000) that may not cover complete battery replacement, leaving owners with substantial out-of-pocket costs. Manufacturer extended warranties generally provide more comprehensive coverage despite higher upfront cost.

Making Warranty Claims

When battery issues arise during warranty period, document all symptoms thoroughly: note warning lights and messages, track fuel economy decline over multiple tanks, record dates and symptoms of reduced performance, and save all maintenance records demonstrating proper cooling system maintenance. Manufacturers sometimes challenge warranty claims on neglected vehicles.

Take the vehicle to an authorized dealer for diagnosis. Dealer technicians use manufacturer-specific diagnostic equipment to: read stored fault codes from hybrid system, perform cell/module voltage balance tests, conduct capacity testing under controlled conditions, and review BMS data logs for evidence of failure modes. The dealer submits warranty claim documentation to the manufacturer for approval—this process typically takes 1-5 business days.

If a warranty claim is denied, request written explanation of denial reasons. If denial cites maintenance neglect, review your service records and challenge if proper maintenance is documented. If denial cites wear-and-tear despite symptoms indicating premature failure, consider escalating to manufacturer customer service or regional representatives. Document all communications and consider consulting consumer protection attorneys if denied claims involve significant costs.

Safety Systems & High-Voltage Risks

CRITICAL SAFETY WARNING: Hybrid battery packs store enough energy to cause fatal electrical shock. Operating voltages of 200-360V DC with current capability exceeding 100 amperes present lethal hazard. DC voltage does not “let go” like AC—muscle contractions caused by DC current passing through the body prevent voluntary release from energized conductors. Current as low as 100 milliamps across the heart can cause ventricular fibrillation and death. All service work involving hybrid battery systems requires ASE L3 certification or manufacturer-specific high-voltage training, rated personal protective equipment, and strict adherence to safety protocols. Never attempt to open, service, or diagnose hybrid battery systems without proper training and equipment.

Understanding the High-Voltage Hazard

The severity of electrical shock depends on voltage, current, and current path through the body. While household 120V AC can cause painful shock, 300V DC from a hybrid battery with current capability exceeding 100A is reliably lethal. The high voltage easily overcomes skin resistance, allowing substantial current flow. If current passes through the torso—hand to hand or hand to foot—it crosses the heart and can trigger fatal cardiac arrhythmia in milliseconds.

Arc flash presents additional hazards. Accidentally short-circuiting high-voltage circuits creates electrical arcs reaching temperatures exceeding 1,000°C (1,800°F). These arcs ignite surrounding materials instantly, produce intense ultraviolet radiation causing flash burns to exposed skin and permanent eye damage, and create pressure waves (arc blast) capable of throwing personnel across rooms. Proper safety systems prevent these scenarios during normal operation and create multiple layers of protection during service.

High-Voltage Contactors and Pre-Charge Circuits

The main high-voltage contactors serve as the primary switch between battery pack and vehicle electrical system. These electromagnetic relays use a 12V control signal from the BMS to close main contacts rated for 300-400A continuous current. During normal vehicle operation, contactors close when the vehicle powers on and open when it powers off, isolating the battery from all vehicle systems during parking.

Pre-charge resistors (typically 100Ω) limit inrush current when initially energizing the high-voltage bus. The inverter contains large filter capacitors (often several millifarads at 400V) that appear as short circuits until charged. Without pre-charge limiting, closing the main contactors directly would cause current spikes exceeding 1,000A, potentially welding contacts closed. The pre-charge sequence: closes positive pre-charge contactor (through resistor) for 50-100ms, charges inverter capacitors gradually, then closes main positive contactor (bypassing resistor) once voltage equilibrates. Only after successful pre-charge does the negative contactor close, completing the circuit.

The BMS monitors this sequence continuously. If pre-charge fails (resistor open, contactors welded, or insulation fault preventing voltage rise), the system aborts startup and stores fault codes. Driving with bypassed or failed pre-charge systems risks contactor welding, making it impossible to safely de-energize the system during emergencies.

High-Voltage Interlock Loop (HVIL)

The High-Voltage Interlock Loop creates a continuous low-voltage circuit through all high-voltage connectors. Each orange connector contains an interlock pin separate from main power conductors. When properly mated, these pins connect in series, completing a circuit monitored by the BMS. Total loop resistance typically measures less than 10Ω.

If any connector partially disconnects—whether from vibration, collision, or service activity—the interlock circuit opens. The BMS detects resistance change within 10-20 milliseconds and immediately commands all contactors open, isolating the battery before arcing can occur at the disconnected terminals. This protection operates independently of vehicle state—HVIL functions even when the vehicle is “off” to prevent shock hazards during maintenance.

Service plugs intentionally open the HVIL circuit. Removing the service plug (typically bright orange with warning labels, located in or near the battery enclosure) opens the circuit and stores a fault code. The system prevents contactor closure until the service plug reinstalls and fault codes clear using manufacturer scan tools. Never defeat HVIL protection by jumpering interlock circuits—this eliminates the primary protection against shock and arc flash during service.

Isolation Monitoring Devices

An isolation monitoring device (IMD) continuously measures insulation resistance between high-voltage circuits and vehicle chassis ground. The IMD injects small test signals between HV positive/negative and chassis, measuring leakage current. Specifications typically require minimum 100 ohms per volt—a 300V system must maintain 30 kilohms (30,000Ω) minimum isolation resistance.

Healthy insulation typically measures several megohms. Isolation resistance dropping below threshold indicates: damaged cable insulation (abrasion, age-related cracking, collision damage), moisture intrusion into battery enclosure or cable connections, failed component isolation (short between HV circuits and cooling system), or contamination on high-voltage surfaces (coolant leaks, debris accumulation).

If insulation resistance falls below threshold, the IMD triggers warnings ranging from dashboard messages to complete high-voltage system shutdown depending on severity. This protection prevents chassis ground from becoming energized—a condition that would make the entire vehicle body a shock hazard. Any isolation fault requires immediate professional diagnosis. Operating a vehicle with compromised insulation resistance presents extreme risk to occupants and service personnel.

Pyro-Fuse Crash Protection

Pyro-fuses provide explosive disconnection of high-voltage circuits during severe collisions. When accelerometers detect crash forces exceeding deployment thresholds (typically 8-10g deceleration sustained for 10+ milliseconds), the restraint control module fires squibs in pyro-fuse assemblies. These small explosive charges mechanically sever electrical connections in under 5 milliseconds—faster than electromagnetic contactors can respond.

Most hybrid vehicles use two pyro-fuses, one on positive battery terminal and one on negative terminal. This dual-interruption ensures complete isolation even if one fuse fails or if the crash damages control systems before both fuses fire. Pyro-fuse activation is non-reversible—once fired, fuses must be replaced before the high-voltage system can operate. Replacement cost runs $200-$400 per fuse assembly plus 1-2 hours labor.

Collision repair on hybrid vehicles requires specific protocols. After any collision triggering airbags or causing structural damage near high-voltage components, certified collision repair facilities: verify pyro-fuse status, measure isolation resistance throughout HV system, inspect all orange cable routing for damage, test contactor operation, and scan all hybrid control modules for crash-related faults. Failure to properly inspect and test high-voltage systems after collisions has resulted in fires during or after repairs when damaged insulation caused short circuits.

Service Disconnect Procedures: Step-by-Step

Safe high-voltage service requires strict procedural compliance. These procedures come from manufacturer service manuals and industry standards (SAE J2344 “Guidelines for Electric Vehicle Safety”). Deviation from established protocols has resulted in technician deaths and serious injuries.

Step 1: Vehicle Shutdown and Initial Waiting Period

Turn off the vehicle completely. Remove the ignition key or fob from the vehicle—key presence can trigger system wake-up during service. Wait minimum 10 minutes for contactors to open and high-voltage capacitors to discharge through internal bleed resistors. Inverter capacitors typically discharge from 400V to below 50V within 5 minutes, but manufacturer procedures specify 10 minutes to ensure full discharge. Never skip or abbreviate this waiting period.

Step 2: Remove Service Plug and Open HVIL

Locate and remove the service plug. Location varies by vehicle: Toyota Prius places it inside the battery enclosure under rear seat (remove seat, remove access panel, disconnect orange connector), Honda Accord Hybrid positions it in the trunk near the battery (remove trunk floor panel, disconnect orange connector), Ford hybrids typically mount it on top of the battery pack accessible from cargo area. The service plug physically disconnects one battery terminal and opens the HVIL circuit. Store the removed service plug on your person or in a secure location—this creates a physical lockout preventing system re-energization while you work.

Step 3: Verify Zero Voltage

Using a qualified digital multimeter rated for minimum 600V DC, test voltage between: HV positive and HV negative terminals (should read <50V), HV positive and chassis ground (should read <50V), and HV negative and chassis ground (should read <50V). Test meter function before and after measurements by testing a known voltage source—never trust meter readings without confirming proper meter operation. Only after confirming all measurements below 50V should hands-on service begin.

Step 4: Install High-Voltage Warning Tags

Install high-voltage warning tags at the service plug location, steering wheel, and any other locations visible to personnel entering the vehicle. Tags should state “HIGH VOLTAGE SYSTEM DISABLED FOR SERVICE – DO NOT RECONNECT” with technician name and date. This alerts other technicians and prevents accidental system re-energization while work is in progress.

Step 5: Use Appropriate PPE Throughout Service

Even with system de-energized, wear appropriate personal protective equipment: Class 00 insulated gloves rated to 1000V AC/1500V DC (inspect for damage before each use—pin holes or tears compromise protection), face shield rated for arc flash protection (even de-energized systems can store residual charge), and insulated tools rated for high-voltage work. Never work alone on high-voltage systems—a qualified observer should be present to summon emergency assistance if needed.

Step 6: System Restoration

After completing service, restore system in reverse order: remove warning tags from all locations, visually verify all connections are fully seated with locking mechanisms engaged, reinstall service plug ensuring proper seating and HVIL connection, clear stored fault codes using manufacturer scan tools (HVIL interruption and service plug removal store fault codes that prevent system operation), perform manufacturer-specified system tests to verify contactor operation, insulation resistance, and BMS communication. Most hybrid systems run self-tests when powering up after service disconnect—observe these tests complete without faults before returning the vehicle to service.

Emergency Response Considerations

First responders and emergency personnel face unique challenges with hybrid vehicles. All hybrids display emergency response identification: hybrid badges on exterior, orange high-voltage cables visible beneath vehicle, and emergency response guides (ERG) available from manufacturers showing safe cutting zones and battery locations. Emergency responders should: assume the high-voltage system is energized even if the vehicle is severely damaged (battery packs often survive crashes intact), avoid cutting through orange cables or battery enclosures, never spray water directly into battery enclosures (risk of shock through conductive path), and remove the service plug if accessible before extrication or prolonged on-scene time.

Thermal runaway fires in lithium-ion battery packs require special firefighting tactics. Burning lithium-ion cells produce toxic gases and can reignite hours after initial suppression. Firefighting protocol involves: applying water copiously to cool the entire pack below auto-ignition temperature (may require 1,000+ gallons per vehicle), maintaining cooling for several hours after flames extinguish to prevent re-ignition, and monitoring pack temperature for 24+ hours after incident. Standard dry chemical or foam extinguishers prove ineffective against large-format battery fires due to the self-sustaining nature of lithium-ion thermal runaway.

Frequently Asked Questions

How long do hybrid batteries typically last?

Modern hybrid batteries typically last 10-15 years or 100,000-200,000 miles under normal operating conditions, with NiMH batteries often achieving the longer end of this range. Field data demonstrates that properly maintained batteries regularly exceed 200,000 miles, particularly when cooling systems receive scheduled maintenance and the vehicle operates in moderate climates. Climate significantly impacts lifespan—vehicles in hot regions (Phoenix, Las Vegas, Miami) average 120,000-150,000 miles before replacement, while those in temperate climates (Pacific Northwest, upper Midwest) commonly achieve 180,000-220,000 miles. Driving style also matters: smooth, moderate driving extends life 20-30% compared to aggressive acceleration and braking patterns.

Can I replace just one module instead of the entire battery pack?

Technically yes, but it’s rarely advisable as a long-term solution. Individual module replacement costs $500-$1,500 per module and works when a single module fails catastrophically while others remain healthy. However, introducing new modules with full capacity into a pack of aged modules creates voltage and capacity imbalances. During charging, new modules reach full voltage after aged modules, potentially overcharging aged cells. During discharge, aged modules hit minimum voltage first, limiting pack output to the weakest module. Most technicians consider module replacement a short-term fix that frequently requires repeat service within 12-24 months as other modules fail. For vehicles with substantial remaining life expectancy, complete pack replacement or full reconditioning provides more reliable long-term solutions.

Why is my hybrid battery cooling fan running constantly?

Constant or high-speed cooling fan operation indicates the battery pack is generating excessive heat, typically caused by: elevated internal resistance from degraded cells (aged batteries generate more heat during normal operation), cell imbalance causing some cells to work harder than others, or clogged cooling system air filters restricting airflow and preventing efficient heat removal. If the fan runs constantly during moderate driving, the battery is thermally stressed and likely degrading rapidly. Field experience shows vehicles exhibiting constant cooling fan operation rarely last more than 20,000 additional miles before requiring battery service. Schedule professional diagnosis promptly—addressing cooling system maintenance or diagnosing battery degradation early often prevents complete pack failure.

What happens if my hybrid battery fails completely while driving?

Complete battery failure during driving is rare due to BMS protective systems, but when it occurs, the vehicle transitions to “limp mode” operation. The internal combustion engine continues running and can propel the vehicle, but without electric assist, acceleration becomes severely limited and fuel economy drops dramatically. Dashboard warning lights illuminate—typically the hybrid system warning light and potentially the check engine light. The vehicle remains drivable enough to reach a safe location, but maximum speed may be limited to 35-50 mph and acceleration is sluggish. Some hybrid systems disable electric power steering or air conditioning when battery fails, making the vehicle more difficult to control. If battery failure occurs, reduce speed, avoid aggressive acceleration, and proceed to a safe location or service facility at moderate speed. Do not attempt to “reset” the system by disconnecting the 12V battery—this does not restore hybrid battery function and may create additional electrical faults.

Is DIY hybrid battery replacement safe?

DIY replacement is safe only for individuals with proper high-voltage training, rated safety equipment, and thorough understanding of vehicle-specific procedures. Hybrid battery packs operate at 200-360V DC with lethal current capability—improper procedures have resulted in fatal electrical shock accidents. Required qualifications include: ASE L3 certification or manufacturer high-voltage training, Class 00 or higher insulated gloves rated to 1000V+, high-voltage rated multimeter and insulated tools, understanding of specific vehicle shutdown and lockout procedures, and proper physical capability (battery packs weigh 100-150 lbs and require careful handling). If you lack any of these qualifications or equipment, DIY replacement presents unacceptable risk. Professional installation by certified hybrid technicians costs $500-$1,000 in labor but ensures safe, compliant procedures and typically includes warranty coverage on both parts and labor.

Do hybrid batteries require regular maintenance?

Yes, though maintenance requirements are minimal compared to engine systems. Critical maintenance items include: air filter cleaning/replacement every 30,000 miles for air-cooled systems (most important maintenance item—clogged filters are the leading cause of premature battery failure), liquid coolant replacement every 60,000-100,000 miles for liquid-cooled systems, visual inspection of battery enclosure and high-voltage cables annually for physical damage or corrosion, and ensuring cooling system operates correctly (fan activates when battery temperature rises). Beyond these specific items, driving habits constitute “behavioral maintenance”—smooth acceleration and braking, avoiding extreme temperatures when possible, and using ECO driving modes extend battery life significantly. Total maintenance cost over battery lifetime typically runs $200-$400 for air-cooled systems, $400-$800 for liquid-cooled systems—minimal compared to the $3,000-$6,000 replacement cost if cooling system neglect causes premature failure.

Will cold weather damage my hybrid battery?

Cold temperatures reduce battery performance but rarely cause permanent damage when the BMS functions properly. Below 0°C (32°F), chemical reactions slow, increasing internal resistance and reducing both charge acceptance and power output. You may notice: reduced electric-only range or inability to operate in EV mode, reduced acceleration (engine compensates for limited battery power), longer warm-up periods before full power is available, and increased fuel consumption as the engine works harder. The BMS protects the battery by limiting regenerative braking current below 5°C to prevent lithium plating in Li-ion cells and activating battery heaters to warm the pack before demanding high current. Permanent damage occurs only if BMS protection systems fail or if you’ve modified the vehicle’s control systems. Avoid short trips under 10 minutes in extreme cold—demanding high current from cold batteries accelerates wear. Using remote start or cabin preconditioning warms the battery indirectly, reducing thermal stress during cold starts.

Does battery degradation void my vehicle warranty?

No, hybrid battery degradation within manufacturer specifications does not void vehicle warranties. However, the battery’s own warranty coverage depends on degradation extent. Federal warranty (8 years/100,000 miles minimum) covers defects causing emissions exceedances. California enhanced warranty (10 years/150,000 miles in CARB states) explicitly covers capacity loss below 70% of original. If your battery degrades to 72% capacity at 130,000 miles in a CARB state, warranty requires replacement even though degradation is gradual rather than sudden failure. Outside warranty period, degradation is owner responsibility. Extended warranties (manufacturer or third-party) often cover battery replacement when capacity falls below specified thresholds during coverage period—read terms carefully as coverage varies significantly.