Modern vehicles have undergone a quiet revolution in steering technology. If you’ve driven a car built after 2010, you’ve likely experienced electronic power steering (EPS) without even realizing it. This electric-based system has rapidly replaced traditional hydraulic power steering, becoming the industry standard across passenger vehicles from compact cars to full-size SUVs.

The transition from hydraulic to electric power steering began in earnest during the 1990s, though the technology existed much earlier. Toyota pioneered early adoption with the 1990 MR2’s electro-hydraulic system, but fully electric systems gained momentum in the 2000s as automakers pursued fuel efficiency improvements. The benefits proved compelling: EPS systems deliver approximately 1 mpg better fuel economy compared to hydraulic systems, eliminate the need for power steering fluid maintenance, and enable advanced driver assistance features like lane-keeping and automatic parking.

Understanding how EPS works helps you make informed decisions about vehicle maintenance, diagnose potential issues, and communicate effectively with service professionals. Whether you’re a DIY enthusiast looking to understand your vehicle better, a professional mechanic refining your diagnostic skills, or simply curious about automotive technology, this guide breaks down the components, operation, and practical considerations of electronic power steering systems.

One critical safety advantage: even if the EPS system fails, you retain the ability to steer manually. The steering effort increases significantly, but mechanical control remains intact—an important fail-safe that distinguishes modern steering from purely electronic “drive-by-wire” systems. To appreciate how revolutionary EPS is, it helps to understand what it replaced. Hydraulic power steering systems used engine-driven pumps that operated constantly, consuming power regardless of whether you were actively steering. EPS eliminates this parasitic loss entirely.

EPS System Components

Electronic power steering relies on four main components working together to provide variable steering assistance. Each plays a specific role in detecting driver input, calculating the appropriate response, and delivering precisely calibrated assistance.

Electric Motor

The electric motor is the muscle of the EPS system, replacing the hydraulic pump and actuator of traditional systems. Most modern EPS applications use brushless DC motors for their reliability and efficiency. These motors typically deliver between 400 and 1,200 watts of power depending on vehicle size and weight—compact cars need less assistance than full-size trucks.

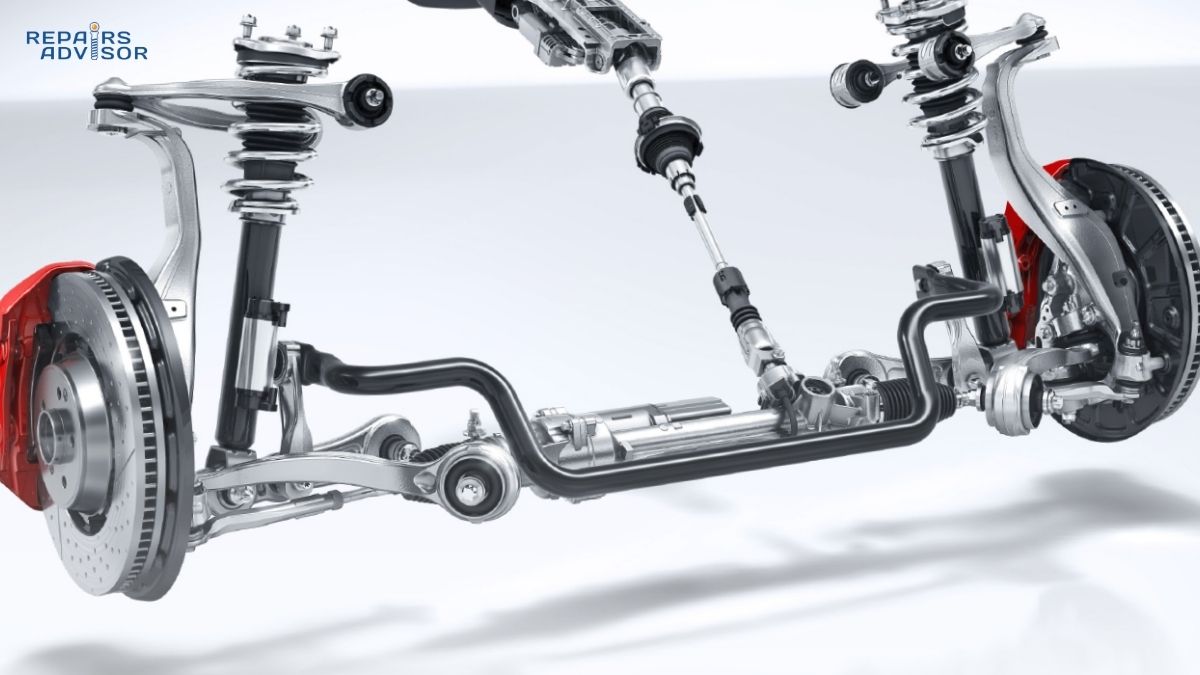

The motor connects to the steering system through reduction gearing, most commonly a worm gear mechanism. This configuration multiplies the motor’s torque output while converting rotational motion into the linear force needed to move the rack and pinion steering assembly. Some systems use ball-screw mechanisms instead, which engage a spiral cut machined into the outside of the steering rack.

For beginners, think of the electric motor as doing the heavy lifting that your arm muscles would otherwise handle. When you turn the steering wheel, the motor “helps” push or pull the steering rack in the direction you want to go. Crucially, this motor only operates when you’re actively steering—when driving straight, it consumes zero power. This on-demand operation is what delivers the fuel efficiency advantage over hydraulic systems.

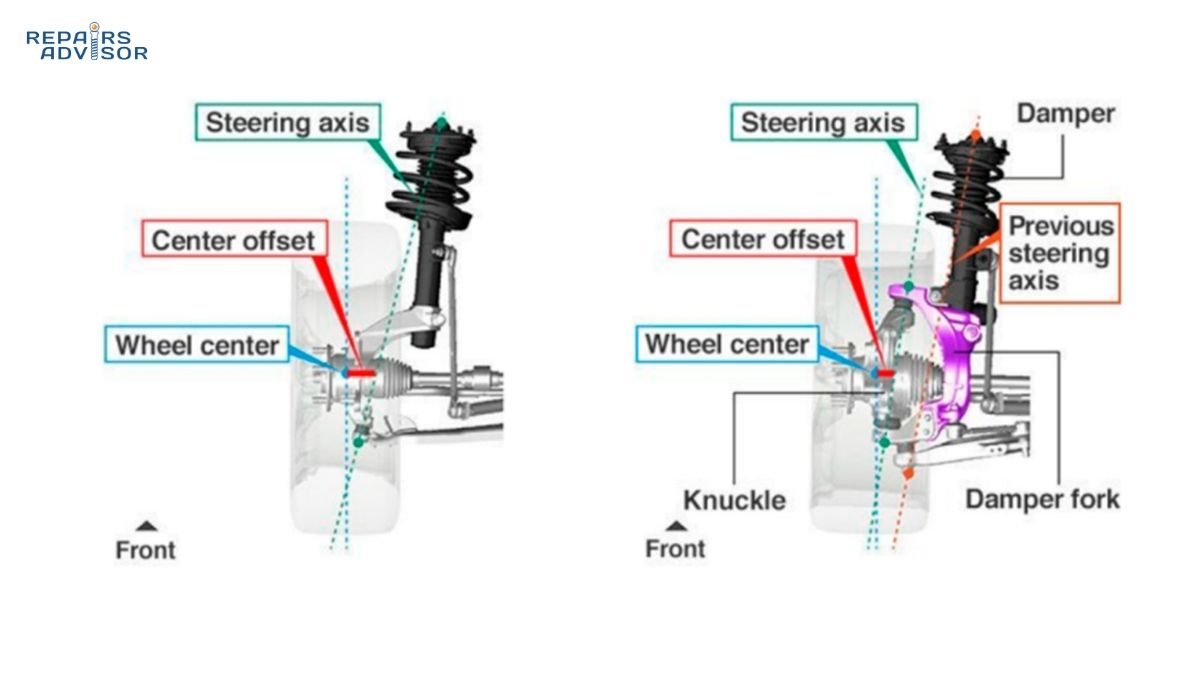

Motor placement varies by system type. In column-assist configurations, the motor mounts directly to the steering column. Pinion-assist systems place the motor on the pinion shaft of the steering rack. Rack-assist designs integrate the motor directly with the rack assembly. Each configuration offers different trade-offs in terms of packaging, performance characteristics, and vehicle application.

Torque Sensor (Steering Force Sensor)

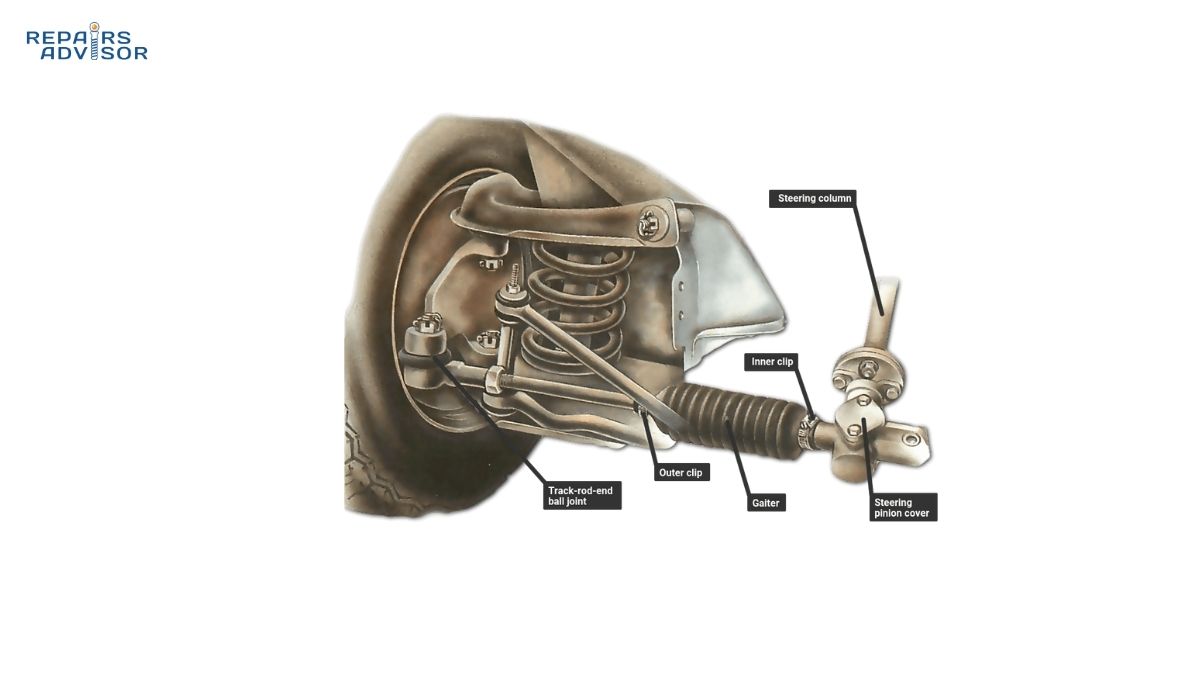

The torque sensor measures how much force you’re applying to the steering wheel, providing the primary input that determines how much electric assistance the system delivers. This sensor typically mounts on or inside the steering rack, connected to the pinion gear, though some systems integrate it into the steering column.

At its core, the torque sensor uses a torsion bar—a precisely calibrated metal shaft that twists slightly under load. When you turn the steering wheel, the input shaft and output shaft (connected by the torsion bar) rotate at slightly different rates. The amount of twist correlates directly to the steering force you’re applying.

Measuring this twist requires sophisticated sensing technology. Most modern systems use non-contact magnetic sensors. A magnetic ring attaches to the torsion bar, and Hall-effect sensors detect changes in the magnetic field as the bar twists. This generates dual analog signals that mirror each other—when one voltage increases, the other decreases. The electronic control unit monitors both signals to determine steering direction and effort while also verifying sensor integrity.

For professionals, it’s worth noting that these are typically five-volt reference sensors operating between 0.25 and 4.75 volts. Voltages outside this range indicate sensor malfunction and will trigger diagnostic trouble codes. When you turn the steering wheel right, Signal 1 voltage increases while Signal 2 decreases; left turns reverse this pattern. The ECU uses this inverse relationship to rationalize inputs and detect faults.

Contact-type torque sensors exist in some applications, using wipers and voltage dividers attached to the torsion bar, but non-contact magnetic designs have become standard due to their superior reliability and lack of wear components.

Electronic Control Unit (ECU/PSCM)

The Power Steering Control Module serves as the brain of the EPS system, processing inputs from multiple sensors and calculating the precise amount of steering assistance required at any given moment. This isn’t a simple on-off switch—the ECU performs complex real-time calculations dozens of times per second to deliver smooth, natural-feeling steering assistance.

The ECU receives data from several sources. The torque sensor provides steering direction and effort information. Vehicle speed data arrives through the CAN (Controller Area Network) bus, typically from the ABS module or engine control unit. The system also monitors motor temperature (calculated based on current draw and operating time) and steering tuning parameters programmed during vehicle calibration.

Using this information, the ECU references assist curves—preprogrammed relationships between vehicle speed, steering torque, and motor assistance. At low speeds (parking lot maneuvering), the system provides maximum assistance for effortless turning. As vehicle speed increases, assistance decreases progressively to provide better road feel and stability. A lane change at highway speeds requires far less assistance than a tight parking maneuver, and the ECU adjusts accordingly.

Integration with other vehicle systems represents a key advantage of EPS over hydraulic steering. The control module communicates with electronic stability control (ESC), anti-lock braking systems (ABS), and advanced driver assistance systems (ADAS). When ESC detects loss of traction, it can instantaneously command steering torque adjustments to help maintain vehicle control. Lane-keeping systems and adaptive cruise control rely on the ECU’s ability to control steering input without driver intervention.

For those interested in the deeper technical aspects of how these control algorithms work, our article on EPS control systems covers torque overlay, damping control, and fail-operational modes in detail.

Steering Angle Sensor

While the torque sensor measures how hard you’re turning the steering wheel, the steering angle sensor tracks the wheel’s position—how far you’ve turned from center and in which direction. This information is critical for stability control, traction control, and ADAS features.

Most steering angle sensors use optical encoder technology. An LED illuminates a code wheel with alternating transparent and opaque segments arranged in multiple tracks. Photodiodes on the opposite side detect the light patterns as the wheel rotates, generating digital signals that indicate absolute steering wheel position, typically accurate to within one degree.

The multi-track design allows the sensor to determine absolute position even after power loss—when you start the vehicle, the system immediately knows where the steering wheel is positioned. This differs from simpler relative position sensors that need to be “trained” to find center position.

Calibration of the steering angle sensor becomes necessary after certain repairs or service procedures. Wheel alignment adjustments, steering component replacement, or even battery disconnection on some vehicles can cause the sensor to lose its reference point. Professional recalibration using a scan tool ensures the sensor correctly reports zero degrees when the vehicle is tracking straight. Failure to recalibrate can result in stability control malfunctions, the steering wheel being off-center when driving straight, or the vehicle pulling to one side.

Modern automotive ECUs increasingly rely on steering angle data for calculations beyond just power steering assistance, making this sensor a critical component of the broader vehicle control network.

Types of EPS Systems

Electronic power steering systems are classified into four main types based on where the electric motor is positioned and how it applies force to the steering system. Each configuration offers distinct advantages for different vehicle applications.

Column-Assist EPS (C-EPS)

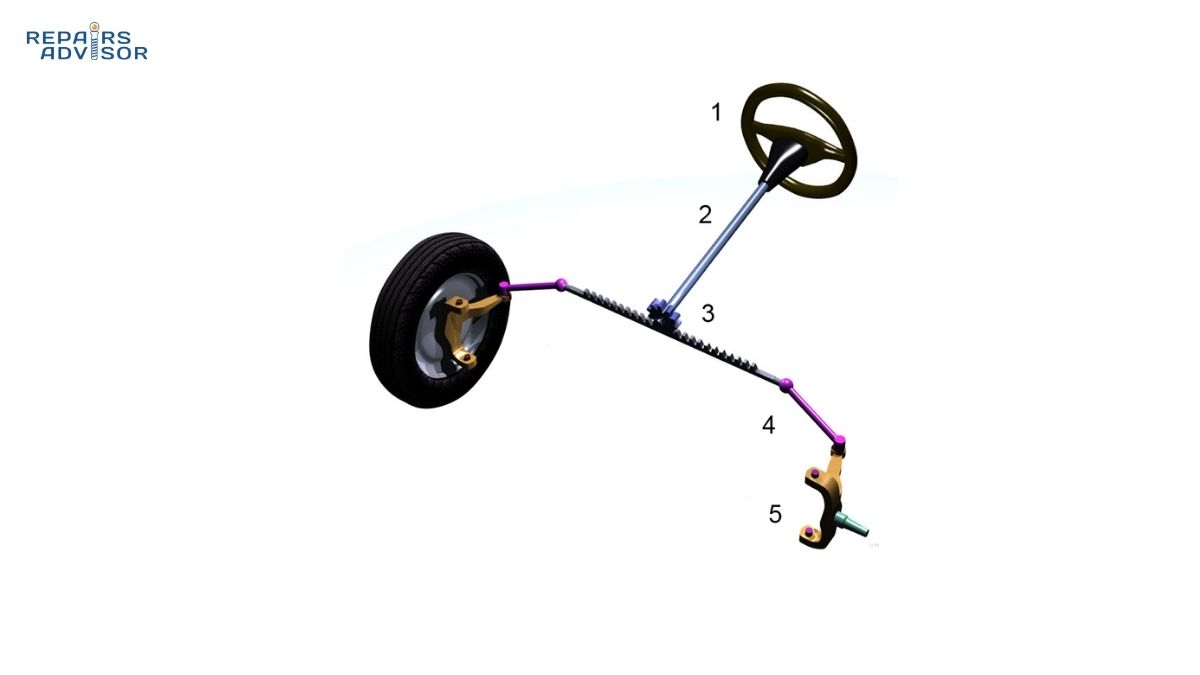

Column-assist systems mount the electric motor, torque sensor, and control module directly on the steering column assembly. The motor’s torque works together with the driver’s input to rotate the steering column shaft, which then transmits force through the intermediate shaft and pinion to the steering rack.

This compact design excels in applications requiring moderate steering assistance—primarily smaller vehicles and compact cars. The integrated mounting requires minimal installation space, making packaging straightforward for vehicle designers. Installation and maintenance are relatively simple since all the electronic components remain accessible without disturbing the rack assembly.

C-EPS delivers lightweight steering feel at parking speeds, becoming progressively firmer as velocity increases for stable highway handling. The system includes self-diagnosis capabilities and fail-safe operation, automatically reverting to manual steering if electrical faults occur. Many C-EPS systems allow customization through software, enabling manufacturers to tune steering characteristics for different vehicle variants using the same hardware.

For vehicles requiring moderate assist forces—generally those under 3,500 pounds—column-assist provides an economical, reliable solution with excellent efficiency characteristics.

Pinion-Assist EPS (P-EPS)

Pinion-assist systems relocate the electric motor from the column to the steering rack itself, where the motor provides assistance directly to the pinion of the rack-and-pinion steering gear. This configuration combines the precise adjustability of electric power steering with stronger road feedback characteristics.

P-EPS systems use a waterproof, compact, lightweight integrated motor-ECU unit mounted on the rack housing. The motor drives a gear mechanism (often via a toothed rubber belt) that engages the pinion shaft. This direct connection to the pinion delivers high rigidity and excellent dynamic steering performance, particularly during rapid maneuvers.

The integrated housing structure enhances manufacturing precision and improves overall product reliability. Because assistance applies directly at the pinion, these systems provide stronger assist capability than column-mounted designs while maintaining responsive steering feel. This makes P-EPS suitable for mid-size vehicles and performance applications where steering precision matters.

The trade-off comes in cost and complexity. P-EPS systems are more expensive than C-EPS due to the waterproof motor-controller integration and rack-mounted design. However, the performance advantages justify the additional expense in many applications.

Dual-Pinion EPS (DP-EPS)

Taking pinion-assist design further, dual-pinion systems employ two separate pinion gears acting on the steering rack. The primary pinion connects to the steering column and handles driver input, while a secondary pinion, driven by an electric motor, provides assistance. This separation allows optimization of each pinion for its specific function.

The dual-pinion architecture offers significant design flexibility. Engineers can optimize the primary pinion for vehicle dynamics and steering feel while optimizing the secondary pinion purely for maximum assist force generation. The motor and controller can be positioned more flexibly, easing packaging constraints in crowded engine compartments.

DP-EPS provides even greater assist forces than single-pinion designs, making it suitable for larger vehicles including full-size SUVs and light trucks. Some systems incorporate variable gear ratios, where the rack teeth have different spacing along their length, providing quick response near center (for highway lane changes) and greater mechanical advantage near full lock (for parking maneuvers).

Rack-Assist EPS (R-EPS)

Rack-assist systems represent the most integrated design, with the electric motor and reduction gear forming a single unit with the steering rack itself. The motor typically drives a ball-screw mechanism via a toothed belt, applying force directly to the rack rather than through the pinion.

This configuration delivers the highest assist forces with the fastest response time and greatest precision, making R-EPS the preferred choice for luxury vehicles, performance cars, and larger SUVs. The high reduction gear ratios result in relatively low inertia, allowing smooth, responsive steering even in heavier vehicles.

Belt-driven rack-assist systems mount the motor on the side of the rack housing, where it drives the ball-screw through a toothed rubber belt. Direct-drive variants eliminate the belt, integrating the motor armature directly around the rack itself, though these are less common due to packaging and cost considerations.

R-EPS systems demonstrate the highest efficiency in converting electrical energy to steering assistance, often achieving better than 85% conversion efficiency. The sophisticated control algorithms and precise mechanical design deliver steering feedback quality that rivals or exceeds traditional hydraulic systems—addressing one of the early criticisms of electric power steering.

The steering geometry of your vehicle affects how all these EPS types deliver their assistance, with factors like caster, camber, and steering ratio influencing the feel and response you experience.

How EPS Works Step-by-Step

Understanding the complete operational cycle of an EPS system reveals how all these components work together to deliver seamless steering assistance. Let’s walk through what happens from the moment you begin to turn the steering wheel.

Step 1: Driver Input Detection

When you rotate the steering wheel, you’re applying torque to the input shaft of the steering column. This input shaft connects to the output shaft through a precisely calibrated torsion bar—essentially a twist-resistant spring. The forces you apply cause this torsion bar to twist slightly, creating a measurable deflection between the input and output shafts.

A magnetic ring attached to the torsion bar rotates relative to stationary Hall-effect sensors. As the bar twists under your applied force, the magnetic field changes, and the sensors generate corresponding voltage signals. These are typically dual analog signals that operate inversely to each other for redundancy and fault detection.

If you’re turning right, Signal 1 voltage increases while Signal 2 decreases. Left turns reverse this pattern—Signal 1 decreases as Signal 2 increases. The magnitude of voltage change corresponds directly to how hard you’re turning the wheel. A gentle lane change produces minimal torsion bar deflection and small voltage changes, while cranking the wheel for a tight parking maneuver generates significant deflection and large voltage swings.

The torque sensor continuously monitors these signals, transmitting the data to the electronic control unit dozens of times per second. This high-speed sampling ensures the system responds instantly to your inputs, with imperceptible lag between steering input and assistance delivery.

Step 2: ECU Processing and Calculation

The ECU receives torque sensor data and immediately begins processing multiple inputs to calculate the optimal assist level. Vehicle speed data arrives through the CAN bus—typically originating from wheel speed sensors monitored by the ABS module. The ECU also considers calculated motor temperature (based on current draw and operating duration) and accesses preprogrammed boost curves that define the relationship between speed, torque, and desired assist.

At low speeds—below 15 mph in most systems—maximum assistance activates. Imagine parallel parking: the vehicle is barely moving, but you need to make sharp steering inputs. The ECU commands high motor current, delivering maximum assist force to make the heavy steering loads manageable. You can turn the wheel with minimal effort, even while stationary.

As vehicle speed increases, the ECU progressively reduces assistance according to the programmed boost curve. At highway speeds (60+ mph), assistance drops to 20-40% of maximum. This reduction serves two purposes: it provides better road feel and feedback through the steering wheel, and it increases steering stability. At high speeds, you need more deliberate steering inputs, and the increased resistance helps prevent overreaction to small wheel movements.

The ECU also monitors system temperature continuously. Electric motors generate heat during operation, and prolonged high-current operation can exceed thermal limits. If you repeatedly turn the steering wheel from lock to lock while stationary (a situation mechanics encounter frequently during diagnostic procedures), the system calculates rising motor temperature. When thermal limits approach, the ECU progressively limits current to prevent motor damage. On some vehicles, this thermal protection can set a diagnostic trouble code if thresholds are exceeded significantly.

For professionals, understanding the EPS motor and controller architecture provides deeper insight into these calculations, including how three-phase brushless motor control works and how fail-safe algorithms maintain partial functionality during certain fault conditions.

Step 3: Motor Activation and Assist Delivery

Once the ECU calculates the required assistance, it commands the electric motor to action. For brushless DC motors (the most common type), this involves precisely timed switching of transistor pairs that energize the motor’s three electromagnetic coils in specific sequences. The rotor contains permanent magnets, and the sequenced coil energization creates rotating magnetic fields that propel the rotor.

The direction of rotation depends on the energization sequence. Clockwise rotation uses the sequence A-B-C across the three coils. Counterclockwise rotation reverses this to C-B-A. By controlling which transistor pairs conduct and in what sequence, the ECU can instantly change motor direction and vary torque output with precision.

The motor shaft connects to reduction gearing—typically a worm gear that engages a larger gear on either the steering column shaft (in C-EPS), the pinion shaft (in P-EPS), or the rack itself via ball-screw (in R-EPS). This reduction multiplies the motor’s torque, allowing relatively small, high-speed motors to generate the substantial forces needed to move the steering rack.

As the motor operates, an integrated position sensor (motor resolver) monitors rotor position and rotation, feeding this information back to the ECU. This closed-loop feedback allows the ECU to verify that commanded assistance is actually being delivered and enables precise control of assist force throughout the steering motion.

From your perspective behind the wheel, this entire process is instantaneous and transparent. You turn the wheel, and it simply feels lighter than it would without power assistance. The variable assistance based on speed feels natural because it matches how you intuitively expect steering to behave.

Step 4: Continuous Monitoring and Adjustment

Unlike the set-it-and-forget-it operation of hydraulic power steering, EPS continuously adjusts assistance in real-time as conditions change. If you’re driving at 45 mph and suddenly slow down for a turn, the ECU immediately increases assistance to match the lower speed. Accelerating back onto the highway triggers progressive assistance reduction.

The system also integrates with vehicle stability control. If electronic stability control detects a loss of traction or skid condition, it can command the EPS system to apply corrective steering torque independently of driver input—or even counter to driver input if necessary to regain control. This integration enables advanced features impossible with purely hydraulic systems.

When equipped with lane-keeping assist or active lane centering, the ADAS controller sends steering angle commands directly to the EPS ECU. The system applies gentle corrective torque to keep the vehicle centered in its lane, while still allowing you to override these inputs with normal steering motions. The steering angle sensor provides the position feedback needed for these automated steering functions.

Temperature monitoring continues throughout operation. The ECU tracks cumulative motor heating and allows the system to cool during periods of straight-ahead driving. Under normal driving conditions, thermal limits rarely come into play. However, during low-speed maneuvering with frequent lock-to-lock steering (think: attempting to extract your vehicle from a tight parking spot), thermal protection may activate, temporarily limiting assist force until motor temperature decreases.

EPS vs. Hydraulic Power Steering

Understanding the differences between electronic and hydraulic power steering helps explain why the industry transitioned so completely to electric systems. The comparison reveals both objective performance differences and subjective preferences that vary among drivers.

Fuel Efficiency: The most significant objective advantage of EPS is fuel economy. Hydraulic systems use engine-driven pumps that operate constantly whenever the engine runs, consuming approximately 3-5 horsepower even when driving straight. This parasitic loss occurs 24/7 during vehicle operation. EPS motors only draw current during actual steering maneuvers, reducing average power consumption by 75-85%. In real-world driving, this translates to approximately 1 mpg improvement—a substantial benefit when multiplied across millions of vehicles. For hybrid and electric vehicles, the efficiency advantage is even more pronounced, as every watt saved extends electric range.

Maintenance Requirements: Hydraulic systems require periodic fluid checks, occasional fluid replacement, and monitoring for leaks from hoses, pump seals, and rack seals. Power steering fluid breaks down over time, accumulating contamination and losing its lubricating properties. While not frequent, hydraulic system maintenance represents an ongoing cost and inconvenience. EPS eliminates this entirely—there’s no fluid to check, no hoses to leak, and no pump to wear out. The electric motor is essentially maintenance-free for the vehicle’s lifespan under normal operation.

Weight Considerations: Removing the hydraulic pump, fluid reservoir, pressure hoses, and rack-mounted hydraulic actuator saves 15-25 pounds depending on vehicle size. Every pound of weight reduction improves fuel economy, acceleration, and handling dynamics. For manufacturers pursuing ever-stricter fuel economy standards, these weight savings contribute meaningfully to meeting regulatory targets.

Road Feel and Feedback: This is where subjective preferences emerge. Hydraulic systems provide direct mechanical connection between the steering rack and the steering wheel through incompressible hydraulic fluid. Many driving enthusiasts praise the “connected” feeling this provides, particularly in performance applications. Early EPS systems received criticism for numb, disconnected steering feel that provided little feedback about road surface conditions or tire grip levels.

However, modern EPS systems have largely closed this gap through sophisticated software calibration. Premium vehicles now offer selectable steering modes (comfort, normal, sport) that alter assist curves and even inject artificial feedback signals to simulate the mechanical feel of hydraulic systems. Some argue this is synthetic and inferior to genuine hydraulic feedback. Others appreciate the programmability and consistency of electric systems.

Advanced Feature Integration: EPS enables features impossible with hydraulic systems. Lane-keeping assistance requires the ability to apply steering torque independent of driver input—something hydraulic systems can’t do without complex additional actuators. Automated parking, adaptive cruise control with steering, and the automated driving features under development all depend on electronic steering control. As vehicles progress toward higher levels of automation, EPS becomes essential infrastructure.

Failure Modes: Both systems allow manual steering if assistance fails, but with different characteristics. If a hydraulic system fails while the engine runs, you retain some residual assistance from whatever pressure remains in the system. EPS failure results in immediate reversion to unassisted steering. However, EPS systems often incorporate fail-operational modes that maintain partial assistance even with certain faults detected. Modern reliability means both systems rarely fail completely, but it’s worth understanding the behavior if it occurs.

Repair and Diagnostic Costs: Hydraulic systems use mechanical components that can often be repaired with conventional tools and general automotive knowledge. A leaking pump can be replaced without specialized electronics expertise. EPS diagnosis typically requires manufacturer-specific scan tools and software access to read control module data and perform calibration procedures. While EPS systems may be more reliable, when problems do occur, diagnostic and repair costs tend to be higher due to the specialized electronic equipment and training required.

For context on the mechanical steering components both systems share, our article on tie rods, ball joints, and steering columns covers the linkage elements that connect the power steering system to the wheels.

Common EPS Problems and Symptoms

Despite their general reliability, EPS systems can develop faults that affect steering performance. Recognizing these symptoms helps you identify problems early and seek appropriate professional service.

EPS Warning Light Activation

The most obvious indicator of an EPS problem is the illumination of the power steering warning light on your instrument cluster. This light may appear as “EPS,” “Power Steering,” or a steering wheel icon. When this light activates, the system has detected a fault and stored one or more diagnostic trouble codes.

These codes fall into two main categories. “C-series” codes (typically C1XXX) indicate problems within the EPS system itself—torque sensor malfunctions, motor failures, control module faults. “U-series” codes (U0XXX or U1XXX) suggest communication problems between the power steering control module and other vehicle systems, such as lost CAN bus communication with the engine control unit or ABS module.

Some EPS systems enter a “limp mode” when certain faults occur, providing reduced assistance or reverting to manual steering completely. The warning light provides your first indication that professional diagnosis with a proper scan tool is needed to identify the specific fault.

Increased Steering Effort

The most common symptom EPS owners experience is increased steering effort—the wheel becomes harder to turn, especially at low speeds. This can occur suddenly (complete loss of assistance) or develop gradually (progressive reduction in assist force).

Sudden, complete loss of assistance typically indicates motor failure, control module malfunction, or severe electrical faults. The steering wheel becomes noticeably heavy, particularly when parking or making tight turns. While the vehicle remains controllable, the effort required increases dramatically compared to power-assisted operation.

Gradual increases in steering effort may suggest torque sensor degradation, electrical connection problems, or control module issues that cause the system to provide less than optimal assistance. Battery voltage problems can also cause this symptom—if your battery is weak or failing, the EPS motor may not receive adequate power to deliver full assist force.

Professional diagnostic approach begins with the basics: checking battery voltage (should be at least 12.4V with engine off, 13.5-14.5V with engine running), inspecting wiring connections for corrosion or damage, and scanning for stored diagnostic codes. Many intermittent EPS problems trace back to simple electrical issues rather than failed components.

Inconsistent or Uneven Assist

If steering feels easier turning in one direction than the other, the problem often involves the steering angle sensor or its calibration. This sensor tells the control module the steering wheel’s position, and if its zero-point reference is incorrect, the system may provide asymmetric assistance.

This symptom commonly appears after wheel alignment work, steering knuckle replacement, or other repairs that disturb the steering system. Many vehicles require specific steering angle sensor calibration procedures after such work—a step sometimes overlooked by shops unfamiliar with EPS service requirements. The calibration procedure typically involves driving straight ahead while the scan tool establishes a new zero reference point.

Mechanical binding in the steering linkage or rack can also cause uneven assist. If the system encounters unusual resistance in one direction (perhaps from damaged rack boots, contaminated rack bushings, or worn tie rod ends), it may feel like inconsistent assist when the real problem is mechanical rather than electrical.

Strange Noises When Steering

Unusual sounds emanating from the steering system during turning warrant investigation. EPS systems can produce several types of noises when malfunctioning:

Whining or buzzing sounds typically indicate electric motor issues. The motor windings may be failing, or the motor controller may be commanding abnormal current levels due to sensor or control problems. These sounds often correlate with steering wheel position—loudest at certain angles, quieter at others.

Clicking or clunking noises suggest mechanical problems rather than electrical issues. These sounds may originate from worn reduction gears, failing universal joints in the steering column, or loose mounting hardware. While not strictly EPS system faults, they require attention to maintain proper steering function.

Squeaking sounds may point to the electric motor specifically, particularly the motor bearings or brushes (in systems using brushed motors). These high-pitched sounds occur during motor operation and may change frequency as motor speed varies.

Any steering noise warrants professional inspection to identify the source and determine whether it indicates a safety concern requiring immediate attention.

Steering Wander or Poor Centering

If your vehicle doesn’t track straight or you must constantly correct the steering to maintain lane position, the underlying cause could involve the EPS system, mechanical alignment issues, or a combination of both.

Steering angle sensor problems can cause wander symptoms. If the sensor reports incorrect steering position, the control module may apply inappropriate assistance levels or fail to provide proper centering force. The EPS system can generate a subtle “return to center” torque based on steering angle sensor input, and if this calibration is wrong, the vehicle won’t self-center properly.

However, steering wander also results from improper wheel alignment (incorrect toe, caster, or camber settings), worn suspension components, or mechanical steering system wear. Professional diagnosis should evaluate both the electronic system and the mechanical steering geometry to identify the actual cause.

Don’t assume an EPS-equipped vehicle has electrical problems just because steering behavior seems abnormal. Many “EPS problems” turn out to be conventional mechanical issues that would occur regardless of power steering type.

Sudden Power Steering Disengagement

The most concerning symptom—and fortunately the least common—is sudden, complete loss of power steering assistance while driving. This is a safety-critical situation requiring immediate attention.

When this occurs, the steering wheel becomes very heavy, similar to a vehicle with no power steering. The vehicle remains controllable, but significantly more effort is required to turn, particularly at low speeds. Your first priority is to safely slow down, increase following distance, and carefully maneuver to a safe stopping location.

Sudden disengagement typically results from control module failure, severe wiring damage (such as from impact or rodent damage), or critical electrical faults. The EPS warning light will almost certainly illuminate, and multiple diagnostic codes will be stored. This situation requires immediate professional service—do not continue normal driving with complete loss of power steering.

⚠️ CRITICAL SAFETY WARNING: If power steering fails completely while driving, the vehicle becomes difficult but not impossible to steer. Do not panic—maintain firm grip on the steering wheel, reduce speed immediately, and avoid sudden steering inputs. Increase following distance significantly. Signal and carefully move to the roadside or other safe location at the earliest opportunity. Have the vehicle towed to a service facility for diagnosis. Do not attempt to continue driving normally without power steering—the significantly increased effort required makes emergency maneuvers nearly impossible and creates serious safety hazards.

EPS Diagnosis and Professional Service

Properly diagnosing EPS problems requires specialized equipment and training. Understanding the diagnostic process helps you appreciate why professional service is recommended for electronic steering systems.

The Diagnostic Process

Scan Tool Diagnosis (Essential): The foundation of EPS diagnosis is connecting a professional-grade scan tool to read diagnostic trouble codes from the power steering control module. Generic OBD-II code readers provide limited functionality—they may not access manufacturer-specific control modules at all. Professional-level scan tools (costing $2,000-$10,000 depending on capabilities) communicate with the EPS control module to retrieve:

- Stored diagnostic trouble codes (DTCs) with detailed fault descriptions

- Freeze frame data showing operating conditions when codes set

- Live data streams displaying real-time sensor values, motor current, commanded assistance levels, and calculated temperatures

- Actuator tests allowing technicians to command motor operation directly to verify functionality

Electrical System Verification: Before diving into complex diagnostics, technicians verify basic electrical system health. Battery voltage must meet minimum specifications—typically at least 12.4V with the engine off and 13.5-14.5V with the engine running. Weak batteries cause numerous EPS problems because the motor cannot draw adequate current to deliver full assistance. Similarly, corroded battery terminals, damaged wiring, or loose connectors can interrupt power delivery or signal transmission.

Sensor Testing: When diagnostic codes point to sensor problems, technicians use multimeters or oscilloscopes to verify sensor operation. Torque sensors produce dual analog voltage signals that should mirror each other inversely. An oscilloscope reveals signal quality, detecting noise, dropouts, or incorrect voltage ranges. Steering angle sensors output digital signals or analog voltages that should correlate precisely with actual steering wheel position.

Component Testing: For suspected motor or control module failures, testing may involve resistance measurements on motor windings, verification of proper controller output signals, and checking communication between the EPS control module and other vehicle systems via CAN bus. Some diagnostic procedures require removing the motor for bench testing to isolate electrical problems from mechanical binding issues.

Why Professional Service Is Recommended

The complexity and cost of proper EPS diagnosis makes professional service the practical choice for most owners:

Specialized Equipment Requirements: Manufacturer-specific scan tools capable of accessing EPS control modules, performing calibrations, and updating control software cost thousands of dollars. Few DIY enthusiasts can justify this investment for occasional personal vehicle service. Generic code readers miss critical data and cannot perform necessary calibration procedures.

Software Programming and Calibration: Many EPS repairs require control module reprogramming, steering angle sensor calibration, or learned value resets—procedures accessible only through professional scan tools. After replacing major components (motor, control module, torque sensor), calibration procedures ensure proper system operation. These aren’t optional—skipping calibration can result in poor steering feel, warning lights, or degraded performance.

Safety-Critical System Considerations: Steering system failures directly affect vehicle control and safety. Unlike diagnosing a malfunctioning radio or non-critical sensor, EPS diagnosis errors could result in loss of steering assistance in traffic. The stakes justify professional expertise and proper diagnostic procedures.

Warranty Protection: Attempting DIY repairs on EPS components may void manufacturer warranties or extended warranty coverage. Professional diagnosis and repair preserves your warranty rights and provides recourse if problems persist after service.

What DIY Enthusiasts Can Handle

While complex EPS diagnosis requires professional capability, some basic troubleshooting falls within DIY skillsets:

Visual Inspection: Carefully inspect visible wiring harnesses for damage, rodent chewing, or corrosion. Check connectors at the motor and control module (if accessible) for proper seating, bent pins, or corrosion. Examine the steering column and rack boots for obvious damage.

Battery Testing: Use a multimeter or battery tester to verify adequate battery voltage and condition. Many “EPS problems” resolve after replacing a marginal battery that can’t deliver adequate current under load.

Generic Code Reading: While limited in capability, generic OBD-II code readers can identify if EPS-related codes are present, providing information to share with service professionals. However, these readers cannot typically access manufacturer-specific EPS codes or live data.

DIY diagnosis serves mainly to identify obvious problems (failed battery, damaged wiring) and provide informed questions when consulting professional technicians. The actual repair of most EPS faults remains firmly in professional territory.

For perspective on related steering components that may cause symptoms mistaken for EPS problems, understanding rack-and-pinion geometry helps distinguish mechanical from electrical issues.

Maintenance and Prevention

One of EPS’s greatest advantages is minimal maintenance requirements compared to hydraulic systems. However, a few best practices help maximize system lifespan and avoid problems.

Minimal Routine Maintenance

No Fluid Services: The most obvious difference from hydraulic steering is the complete absence of fluid-related maintenance. There’s no power steering fluid to check, no reservoir to monitor, no fluid to replace, and no hoses to inspect for leaks. This eliminates an entire category of scheduled maintenance.

No Belt Replacements: Unlike hydraulic systems with engine-driven pumps requiring serpentine belt service, EPS has no belt connecting to the engine. The electric motor operates independently, eliminating another maintenance point.

Battery Health Matters: While not strictly EPS maintenance, keeping your vehicle’s battery in good condition prevents EPS problems. Weak batteries cause the motor to receive insufficient voltage, resulting in reduced assist force or system faults. Replace batteries preventively at 3-5 year intervals, keep terminals clean, and address charging system problems promptly.

Wheel Alignment Maintenance: Proper alignment reduces steering loads and prevents excessive wear on EPS components. Misaligned wheels create higher steering resistance, forcing the motor to work harder. Schedule alignment checks after suspension work, if steering pull develops, or at tire replacement intervals.

Best Practices for EPS Longevity

Avoid Extended Lock-to-Lock Steering: While occasionally turning the steering wheel to full lock won’t harm the system, repeatedly cranking the wheel from lock to lock while stationary can trigger thermal protection. This commonly occurs during vehicle recovery from tight parking spots or when testing the system. If the EPS warning light illuminates during such maneuvers, it may indicate thermal limiting. Stop the steering motion and allow 15-20 seconds for the motor to cool before continuing.

Regular Electrical System Checks: During routine oil changes or inspections, ask technicians to verify that wiring harnesses near the motor and control module remain secure and undamaged. Inspect for chafing where harnesses contact body panels or suspension components. Clean battery terminals annually to prevent voltage drop issues.

Address Warning Lights Immediately: If the EPS warning light illuminates, schedule diagnostic service promptly. Electronic systems often fail progressively—a minor sensor issue today can cascade into complete system failure if ignored. Early diagnosis typically results in less expensive repairs than waiting until complete failure occurs.

Post-Service Calibration Requirements

Several service procedures require steering angle sensor recalibration to maintain proper EPS operation:

After Wheel Alignment: Many vehicles require steering angle sensor calibration after alignment adjustments. The calibration procedure establishes the sensor’s zero reference point with the wheels pointing straight ahead. Without recalibration, the vehicle may pull slightly or provide asymmetric steering assistance.

After Steering Component Replacement: Replacing steering racks, steering columns, tie rods, or suspension components that alter steering geometry necessitates recalibration. The procedure varies by manufacturer but typically involves driving straight ahead while the scan tool captures a new zero reference.

After Battery Disconnection: Some vehicles lose steering angle sensor calibration when battery power is interrupted. If you notice pulling, off-center steering wheel, or stability control warning lights after battery replacement or disconnection, recalibration may be needed.

These calibration procedures require professional scan tools and vehicle-specific knowledge. Always inform your service facility about EPS-related work to ensure proper calibration procedures are performed. Your car’s suspension system works in concert with the steering, and changes to one system often require corresponding adjustments to the other.

When to Seek Professional Consultation

Several situations warrant immediate professional evaluation:

- Any EPS warning light activation—don’t dismiss it as a glitch

- Changes in steering feel or effort—progressive problems indicate developing faults

- Unusual noises when steering—clicking, buzzing, or whining sounds require diagnosis

- Post-accident steering evaluation—even minor impacts can damage sensors or wiring

- After deep water driving—if connections got wet, preventive inspection avoids corrosion problems

The key to EPS longevity is promptly addressing problems when they first appear. Electronic systems don’t improve on their own—early intervention prevents minor issues from becoming major repairs.

Conclusion

Electronic power steering represents one of the most successful technology transitions in automotive history. What began as a fuel-efficiency strategy has evolved into enabling technology for the advanced safety and automation features reshaping personal transportation.

For beginners, the essential takeaway is simple: EPS delivers better fuel economy and requires less maintenance than hydraulic systems, but when problems occur, professional diagnosis with specialized equipment becomes necessary. Understanding the basics helps you communicate effectively with service advisors and make informed decisions about repairs.

Intermediate DIY enthusiasts gain practical advantage from understanding component interaction. When that EPS warning light appears, knowing the difference between a calibration issue (often inexpensive) and motor failure (costly) helps you ask the right diagnostic questions. Recognizing that battery voltage problems can mimic EPS failures may save unnecessary component replacement.

Professional technicians benefit from the systematic approach to EPS diagnosis—starting with battery and electrical basics before diving into complex sensor testing or control module replacement. Understanding the integration between EPS, stability control, and ADAS explains why seemingly unrelated codes sometimes appear together and why communication network problems manifest as steering issues.

The four EPS system types—column-assist, pinion-assist, dual-pinion, and rack-assist—demonstrate how the same basic technology scales across vehicle applications from subcompacts to full-size trucks. Each configuration optimizes the fundamental components (motor, sensors, ECU) for different performance requirements and packaging constraints.

Looking forward, EPS technology continues evolving. Variable-ratio systems adjust steering sensitivity dynamically. Steer-by-wire technology, already appearing in some new vehicles, eliminates the mechanical connection entirely. The next generation of automated driving features will make ever-greater demands on steering system capability and precision.

Key Takeaway for Each Audience

Beginners: EPS is more efficient than hydraulic steering, needs virtually no maintenance, but requires professional service when problems occur. The system can revert to manual steering if electrical faults occur, ensuring you maintain control even during system failures.

Intermediate DIY Enthusiasts: Understanding component interaction helps with troubleshooting decisions and meaningful dialogue with service professionals. Basic electrical system checks (battery voltage, connection inspection) fall within DIY capabilities, but EPS repair remains professional territory due to specialized equipment and safety considerations.

Professional Technicians: Systematic diagnosis starting with fundamentals (battery, connections, basic electrical) often identifies problems more efficiently than immediately jumping to scan tool diagnosis. Control module reprogramming and sensor calibration require manufacturer-specific capabilities, making these investments essential for shops regularly servicing modern vehicles.

Final Safety Reminder

Power steering systems are safety-critical—they directly affect your ability to control the vehicle, especially during emergency maneuvers. While EPS systems prove generally reliable, any indication of malfunction (warning lights, steering effort changes, unusual noises) justifies immediate professional evaluation. Don’t postpone diagnosis, hoping minor symptoms will resolve themselves. Electronic systems typically worsen without intervention, and steering system failure in traffic represents a serious safety hazard.

Understanding how EPS works empowers you to maintain your vehicle more effectively, recognize problems early, and communicate knowledgeably with service professionals. Whether you’re making a purchase decision between vehicles with different steering systems, evaluating a repair estimate, or simply curious about automotive technology, this knowledge serves you well throughout your vehicle ownership experience.

For professional diagnosis of EPS issues, comprehensive understanding of your vehicle’s steering configuration, or assistance evaluating steering system service recommendations, consult qualified technicians with proper diagnostic equipment and training. Proper maintenance and early problem detection ensure reliable, responsive steering performance for many years of safe driving.