The continuously variable transmission represents one of the most significant innovations in automotive power delivery, yet it remains misunderstood by many drivers. While traditional automatic transmissions shift through a fixed number of gears, CVT technology takes a fundamentally different approach—offering infinite gear ratios for seamless acceleration and superior fuel efficiency. Understanding how CVTs work, their advantages and limitations, and proper maintenance requirements can help you make informed decisions about your next vehicle and keep your CVT-equipped car running reliably for years.

This comprehensive guide explains the mechanical principles behind CVT operation, compares them to conventional automatic transmissions, examines real-world performance characteristics, and provides essential maintenance guidance. Whether you’re considering purchasing a CVT-equipped vehicle or already own one, you’ll gain the technical knowledge needed to understand this technology and maintain it properly.

Why CVT Transmissions Are Critical for Fuel Efficiency and Performance

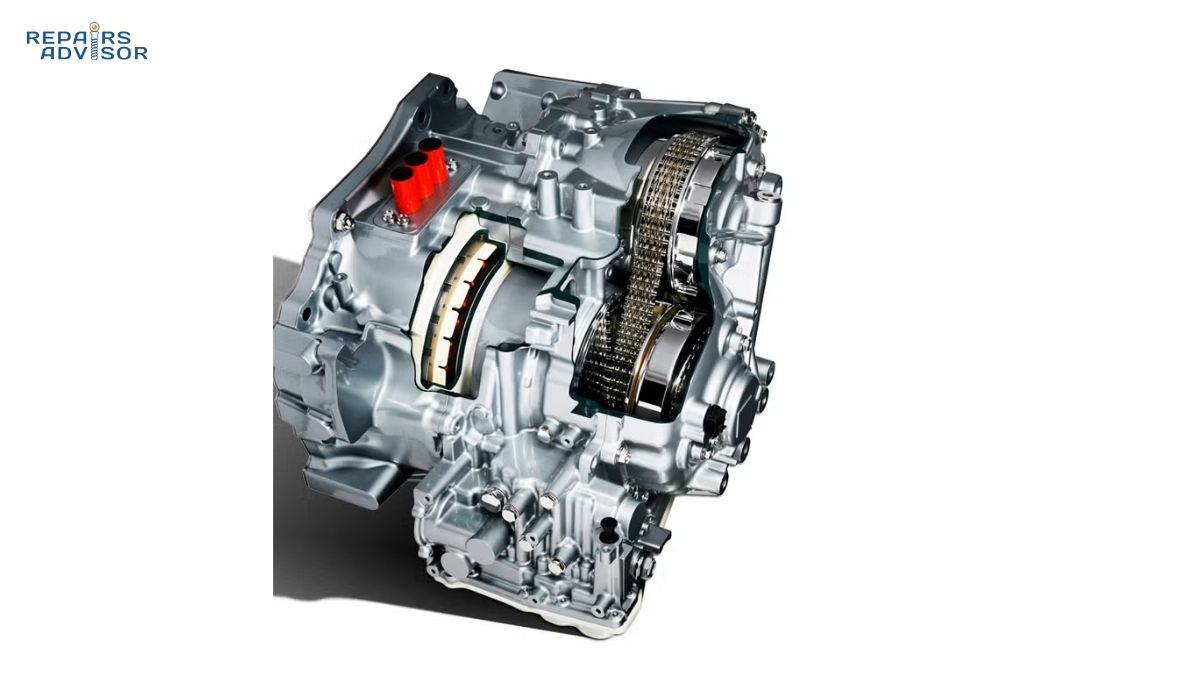

What is a CVT transmission and how does it work? A CVT (Continuously Variable Transmission) is an automatic transmission that uses a belt-and-pulley system to provide infinite gear ratios instead of fixed gears. Two variable-diameter pulleys connected by a steel belt or chain adjust continuously, allowing the engine to operate at its optimal RPM for maximum efficiency or power. This results in smooth, uninterrupted acceleration without the traditional gear shifts found in conventional automatics.

Unlike planetary gear-based automatics that shift between predetermined ratios, CVTs can select any ratio within their operating range. This fundamental difference allows the engine to maintain its most efficient or powerful RPM continuously, regardless of vehicle speed. The result is typically 10-15% better fuel economy compared to conventional automatics in the same vehicle, along with a notably smoother driving experience free from shift shock.

The technology addresses a core inefficiency in traditional transmissions: the compromise between available gear ratios and optimal engine operation. While an 8-speed automatic offers eight specific ratios, a CVT provides infinite ratios between its lowest and highest points. This means the engine can always operate at precisely the right RPM for the driving situation—whether that’s maximum power during acceleration or minimum fuel consumption during cruising.

Quick Facts:

- Function: Provides infinite gear ratios via variable pulley diameters

- Primary Category: Vehicle Control / Transmission Systems

- Maintenance Level: Moderate to High (requires specialized fluid changes every 30,000-60,000 miles)

- Failure Impact: Complete loss of forward/reverse motion, expensive replacement ($3,000-$5,000+)

- Best Applications: Fuel-efficient commuters, city driving, hybrid vehicles

- Limitations: Limited towing capacity, different driving feel, higher maintenance needs

Safety Note: CVT transmissions require specific maintenance procedures and fluids. Using incorrect automatic transmission fluid (ATF) instead of CVT-specific fluid can cause catastrophic transmission failure. Professional service is strongly recommended for fluid changes due to precise temperature-based fill procedures. Any transmission warning lights, slipping, or unusual noises require immediate professional diagnosis to prevent expensive damage.

The Evolution of CVT Technology

The concept of continuously variable transmissions dates back surprisingly far in engineering history. Leonardo da Vinci sketched a rudimentary CVT design for machinery in 1490, demonstrating the enduring appeal of infinitely variable ratios. However, practical automotive applications didn’t emerge until the 20th century.

The first vehicular use of a CVT occurred in the 1910s on a racing motorcycle, where the technology proved its ability to maintain optimal engine power. In 1958, the Dutch automaker DAF introduced CVT-equipped automobiles, making it the first production car manufacturer to adopt the technology. These early implementations used rubber belts and were limited to small displacement engines, but they demonstrated the fundamental advantages of seamless ratio changes.

Japanese manufacturers began serious CVT development in the late 1980s, with Subaru introducing the ECVT (Electronically Controlled Continuously Variable Transmission) in 1989. However, mainstream acceptance didn’t occur until the early 2000s when hybrid vehicles like the Toyota Prius popularized the technology. The Prius used a different type of CVT (planetary-based eCVT rather than belt-driven), but it introduced millions of drivers to the concept of transmission operation without fixed gear shifts.

Today, CVTs have become standard equipment in many fuel-efficient vehicles, appearing across manufacturers from budget-friendly compacts to premium sedans and crossovers. Modern CVTs can handle significantly more power than early versions, with some applications supporting up to 250 horsepower. The technology has evolved from an experimental curiosity to a mainstream solution for maximizing fuel economy and providing smooth power delivery.

CVT vs. Traditional Automatic Transmissions

Understanding the fundamental differences between CVT and conventional automatic transmissions helps explain both the advantages and limitations of each design.

Traditional Automatic Transmission Operation:

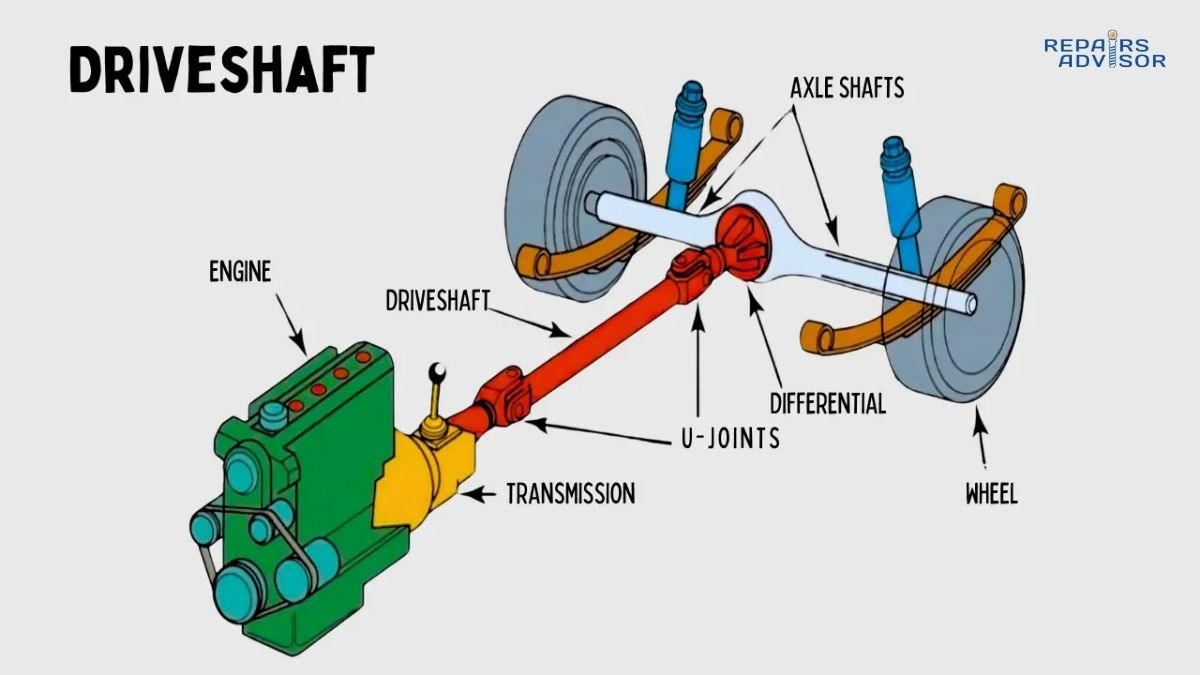

Conventional automatics use planetary gearsets and valve bodies to provide multiple fixed gear ratios—typically 6 to 10 in modern transmissions. Power flows from the engine through a torque converter, which uses hydraulic fluid coupling to smoothly multiply torque and allow the vehicle to idle in gear. When the transmission “shifts,” it physically engages different combinations of planetary gear components using hydraulic clutch packs.

The hydraulic valve body, controlled by electronic solenoids via the transmission control unit, directs pressurized fluid to specific clutches based on vehicle speed, throttle position, and other inputs. Each upshift or downshift involves releasing one clutch pack while engaging another—a process drivers feel as a distinct “shift event.” This mechanical complexity requires dozens of precision-machined components, extensive hydraulic circuitry, and sophisticated electronic control.

CVT Transmission Operation:

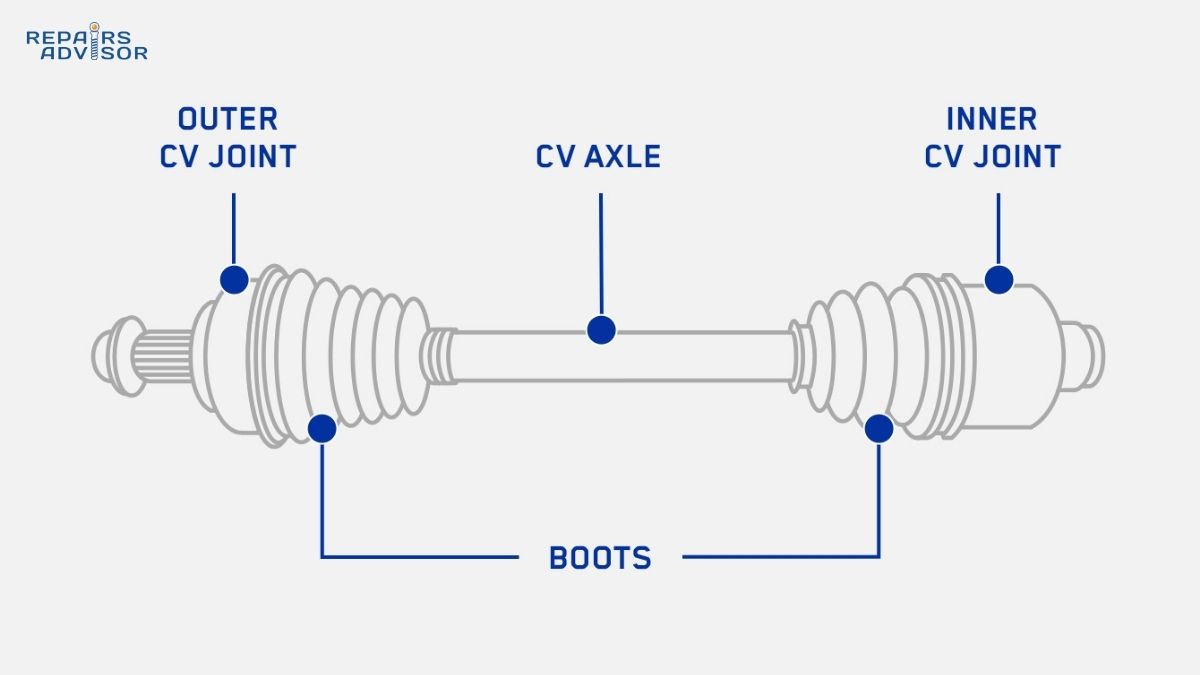

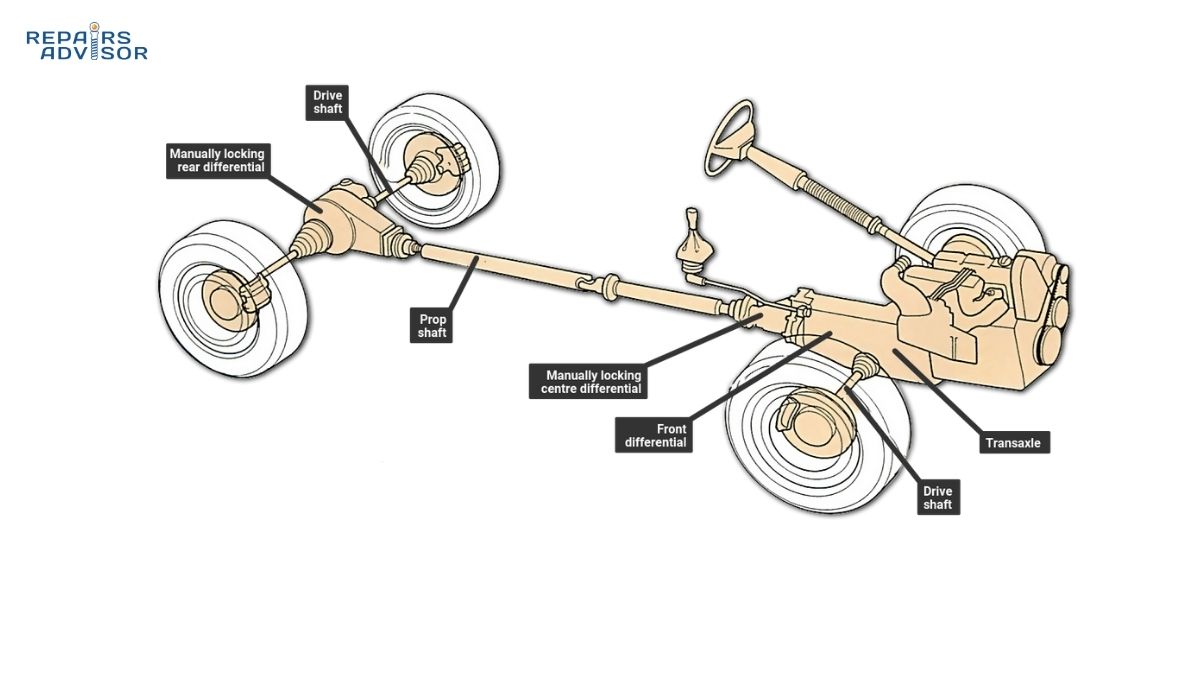

CVTs eliminate the fixed gear concept entirely. Instead of multiple planetary gear sets and clutch packs, they use two variable-diameter pulleys connected by a specialized steel belt or chain. As one pulley’s effective diameter increases, the other decreases proportionally, creating a continuously changing ratio. There are no discrete “gears” to shift between—the transmission can select any ratio within its operating range.

Most CVTs still incorporate a torque converter for launch and idle capability, though some newer designs (like Toyota’s Direct-Shift CVT) add a fixed first gear to improve low-speed responsiveness. The system operates at extremely high hydraulic pressures—often exceeding 1,000 PSI—to maintain belt grip on the pulley surfaces. Electronic control systems monitor vehicle speed, throttle input, and engine load to continuously adjust pulley positions for optimal performance or efficiency.

Key Differences:

| Aspect | Traditional Automatic | CVT |

| Gear Ratios | Fixed (6-10 speeds) | Infinite within range |

| Shift Feel | Distinct shift events | Seamless, no shifts |

| Weight | 180-250 lbs typical | 130-170 lbs typical |

| Complexity | High (planetary sets, multiple clutches) | Moderate (pulleys, belt, hydraulics) |

| Fuel Economy | Good | Excellent (10-15% better) |

| Durability | Generally 200,000+ miles | 80,000-200,000 miles (varies by manufacturer) |

| Repair Cost | $2,000-$4,000 (often rebuildable) | $3,000-$5,000+ (usually full replacement) |

| Towing Capacity | Good to excellent | Limited (light loads only) |

| Driving Feel | Traditional, familiar | Smooth but different |

The choice between technologies involves tradeoffs. CVTs excel at fuel efficiency and smooth operation, while conventional automatics offer more familiar driving dynamics, better towing capability, and typically longer service life. Some manufacturers like Honda also offer dual-clutch transmissions as an alternative, which provide both efficiency and sporty shift characteristics.

How CVT Transmissions Work: Technical Deep Dive

The belt-and-pulley CVT represents the most common design in automotive applications. Understanding its mechanical operation reveals why CVTs deliver such different characteristics compared to conventional transmissions.

Variable-Diameter Pulley System

The heart of a CVT consists of two cone-shaped pulleys (also called sheaves or variators) connected by a specialized belt or chain. Each pulley comprises two conical faces that can move closer together or farther apart, changing the effective diameter where the belt rides.

Driving Pulley (Input Pulley):

The driving pulley connects to the engine crankshaft, typically through a torque converter (though some designs use a wet clutch). This pulley receives engine power and transmits it to the belt. Hydraulic actuators or electronic servos control the gap between the pulley’s two conical faces. As the cones move closer together, they force the belt to ride higher on the pulley, increasing the effective diameter. When the cones separate, the belt settles lower between them, decreasing the effective diameter.

This diameter change directly affects the gear ratio. A larger driving pulley diameter relative to the driven pulley creates a higher gear ratio (overdrive), while a smaller driving pulley diameter creates a lower ratio (more torque multiplication).

Driven Pulley (Output Pulley):

The driven pulley connects to the vehicle’s final drive and wheels. It operates in mirror image to the driving pulley—as one pulley’s diameter increases, the other decreases to maintain constant belt tension. The driven pulley’s position determines how many rotations of the input shaft produce one rotation of the output shaft.

This coordinated movement happens continuously and automatically. Hydraulic pressure, controlled by the transmission computer, adjusts both pulleys simultaneously in response to throttle input, vehicle speed, and programmed shift logic. The system can select any ratio between its mechanical limits in milliseconds.

Belt or Chain Component:

Early CVTs used rubber belts, but modern automotive applications exclusively use metal components. Most employ a steel belt constructed from multiple layers of thin steel bands held together by numerous metal blocks or segments. Some manufacturers (notably Subaru) use a chain design instead.

The metal belt or chain operates under tremendous stress. During normal operation, it experiences over 1,000 PSI of clamping force from the pulley faces. This high pressure creates the necessary friction to transmit power without slipping. The belt must be strong enough to handle engine torque while flexible enough to conform to the changing pulley diameters.

Unlike traditional manual transmission or automatic designs that use meshing gear teeth, CVTs rely on friction between the belt and pulley surfaces. This fundamental difference explains why CVTs require specialized fluid and why they’re sensitive to contamination or improper maintenance.

How Ratio Changes Occur

The CVT’s ability to seamlessly change ratios while under power represents its defining characteristic. Here’s how the system transitions between “gears”:

Low Ratio (First Gear Equivalent – Maximum Acceleration):

When you accelerate from a stop, the CVT selects its lowest ratio for maximum torque multiplication. The driving pulley assumes a small effective diameter (cones far apart, belt riding low), while the driven pulley takes on a large effective diameter (cones close together, belt riding high). This configuration allows the engine to rotate many times for each rotation of the output shaft, multiplying torque for strong acceleration.

In this configuration, engine RPM can rise quickly while the vehicle accelerates more slowly—similar to a manual transmission in first gear. The CVT can hold this ratio as long as needed, or it can begin changing ratios immediately based on throttle input and vehicle speed.

High Ratio (Overdrive – Cruising Efficiency):

During highway cruising, the CVT selects its tallest ratio for fuel economy. The driving pulley opens to its maximum effective diameter (cones close together, belt riding high) while the driven pulley assumes its minimum diameter (cones far apart, belt riding low). Now the output shaft rotates faster than the input shaft—an overdrive condition that allows the engine to maintain low RPM at high vehicle speeds.

This overdrive ratio often exceeds what conventional automatics can provide. Where an 8-speed automatic might offer a 0.67:1 final ratio, some CVTs achieve 0.50:1 or lower, allowing engine speeds under 2,000 RPM at 70 mph.

Seamless Transition:

The magic of CVT operation lies in the transition between these extremes. As you accelerate, hydraulic pressure simultaneously adjusts both pulleys—increasing the driving pulley’s diameter while decreasing the driven pulley’s diameter. This happens continuously and progressively, with infinite ratios available between the lowest and highest points.

The rate of ratio change depends on throttle input and programmed shift logic. During gentle acceleration, the CVT may change ratios quickly to keep engine RPM low and maximize efficiency. Under hard acceleration, it may hold the engine at its power peak (typically 5,000-6,500 RPM) while the vehicle speed increases—a characteristic often called the “rubber band effect.”

Modern engine management systems work in close coordination with the CVT controller. The engine computer monitors throttle position sensors and other inputs, communicating with the transmission to optimize the combined powertrain response. This integration allows for sophisticated control strategies like simulated shift points (for driver familiarity) or aggressive ratio changes for passing maneuvers.

Alternative CVT Designs

While belt-and-pulley systems dominate automotive applications, several alternative CVT designs exist:

Toroidal CVT:

This design replaces belts and pulleys with rotating discs and power rollers. Two discs face each other—one connected to the engine input, the other to the output shaft. Power rollers positioned between the discs transmit torque by friction. Tilting the rollers changes the effective diameter where they contact each disc, altering the gear ratio.

Toroidal CVTs offer some advantages over belt-driven designs: reduced friction losses, more compact packaging, and potentially higher torque capacity. However, they require extremely precise manufacturing and expensive materials to handle the contact stresses. Nissan has used toroidal CVTs in some Infiniti models, though belt-driven designs remain more common.

Hydrostatic CVT:

Popular in agricultural and industrial equipment, hydrostatic CVTs use hydraulic pumps and motors rather than mechanical components. An engine-driven variable-displacement pump delivers pressurized fluid to hydraulic motors that drive the wheels. Changing the pump’s displacement varies the output speed and torque.

These systems excel in high-torque, low-speed applications and can handle extreme loads that would destroy belt-driven CVTs. However, they’re heavier, more expensive, and less efficient than mechanical CVTs. You’ll find hydrostatic drives in combine harvesters, some tractors, and heavy construction equipment, but rarely in passenger vehicles.

Launch Gear CVT (Hybrid Design):

Several manufacturers now incorporate a fixed first gear into otherwise conventional CVT designs. Nissan and Toyota have implemented this approach to address the “rubber band” feeling during initial acceleration. The transmission uses a traditional clutch-engaged first gear from standstill up to approximately 15-25 mph, then seamlessly transitions to CVT mode for higher speeds.

This hybrid design combines the responsive launch characteristics of a conventional automatic with the efficiency and smoothness of a CVT at cruising speeds. The added complexity slightly increases weight and cost, but many drivers find the driving experience more satisfying than pure CVT operation.

CVT Operation in Real-World Driving Scenarios

Understanding how CVTs respond in different driving situations helps explain both their advantages and the unfamiliar sensations that sometimes surprise drivers.

Starting from a Stop

When you press the accelerator from a standstill, a CVT-equipped vehicle behaves somewhat differently than a conventional automatic. The transmission immediately selects its lowest ratio—equivalent to first gear in a traditional transmission. If the vehicle uses a torque converter (most do), you’ll feel the same smooth engagement as any automatic when you release the brake.

What differs is what happens next. In a conventional automatic, you’d feel the engine RPM rise, then drop as the transmission upshifts to second gear, then rise and fall again for third gear. With a CVT, engine RPM can remain relatively constant while the vehicle accelerates, or it may rise to a predetermined power peak and stay there. This steady engine speed during acceleration represents the “rubber band effect” that some drivers find disconcerting.

Vehicles equipped with a launch gear CVT provide more familiar behavior. The fixed first gear engages like a traditional automatic, with the engine revving up before the system transitions to CVT mode at around 15-20 mph. This design addresses the main complaint about CVT driving feel while retaining the efficiency benefits at higher speeds.

Moderate Acceleration and Normal Driving

During typical acceleration—merging onto a highway, passing slower traffic, or climbing moderate hills—the CVT continuously adjusts its ratio to balance power delivery and efficiency. The transmission computer considers multiple inputs: throttle position, vehicle speed, engine load, and even transmission temperature.

For efficiency-oriented driving, the CVT will change ratios quickly to keep engine RPM low. This maximizes fuel economy but can sometimes feel sluggish if you need sudden power. More aggressive throttle inputs trigger different programming: the transmission may hold a lower ratio longer, allowing engine RPM to rise into the power band before gradually increasing the ratio.

Many modern CVTs incorporate “shift points” programmed into their control logic. While the transmission is still continuously variable, it’s programmed to make more noticeable ratio changes at specific speeds to mimic the feel of a conventional automatic. Some systems even create slight interruptions in power delivery during these programmed “shifts” to provide familiar tactile feedback.

Maximum Performance Acceleration

When you press the accelerator to the floor, a CVT responds very differently than a conventional automatic. Instead of rapidly shifting through gears with engine RPM rising and falling, the CVT typically allows engine RPM to jump to the power peak (around 5,000-6,500 RPM for most engines) and stay there. The ratio then changes progressively to increase vehicle speed while maintaining this constant engine speed.

This operating strategy maximizes acceleration because the engine continuously delivers peak power. However, it also produces the characteristic CVT “drone”—a constant high engine pitch that many drivers find unpleasant. The engine sounds like it’s working much harder than in a conventional automatic, even though it’s simply maintaining optimal RPM.

Some performance-oriented CVTs address this issue with more aggressive programming. They may allow engine RPM to rise and fall slightly during hard acceleration, creating a more engaging sound and feel. Subaru’s Lineartronic CVT and Nissan’s Xtronic CVT both employ these strategies in sporty models.

Highway Cruising and Fuel Economy

This is where CVTs truly excel. During steady-speed highway driving, a CVT can select the precise ratio that keeps engine RPM at its most efficient point—typically between 1,500-2,000 RPM at 60-70 mph. The infinite variability means the transmission can optimize for the exact load conditions: slight uphills, headwinds, or vehicle weight.

Conventional automatics must choose from their fixed ratios. Even an 8-speed automatic can only approximate the ideal ratio, while a CVT can hit it exactly. This accounts for much of the 10-15% fuel economy advantage CVTs provide. The engine operates at its “sweet spot” on the brake-specific fuel consumption map, where it produces the required power with minimum fuel.

The CVT also responds intelligently to minor speed changes. Rather than hunting between gears as some automatics do, it makes subtle ratio adjustments you barely notice. This creates a serene, refined cruising experience with minimal driveline disturbance.

Downshifting and Engine Braking

When you need to slow down or engine brake on descents, a CVT can provide comparable behavior to a conventional automatic. Lifting off the throttle causes the transmission to maintain a lower ratio, allowing engine compression braking to assist vehicle deceleration. The amount of engine braking depends on how far you’ve released the throttle and whether you’re in a special mode like “Sport” or “Low.”

Many CVTs incorporate paddle shifters or a manual mode with simulated gears—typically 6-8 positions. These don’t represent real fixed gears (the CVT still varies ratios continuously), but they limit the range of ratios available. Selecting “3” might restrict the transmission to ratios equivalent to first through third gears, providing stronger engine braking on mountain descents.

Some drivers find CVT engine braking less effective than conventional automatics, particularly older designs. The lack of mechanical gear engagement means the system relies entirely on hydraulic control and programming. Modern CVTs have improved significantly in this area, with more sophisticated control logic that better anticipates driver needs.

Advantages of CVT Transmissions

CVT technology offers several compelling benefits that explain its growing adoption across the automotive industry.

Superior Fuel Efficiency

The CVT’s primary advantage is fuel economy. Independent testing consistently shows 10-15% better fuel consumption compared to conventional automatics in the same vehicle. This improvement stems from the CVT’s ability to keep the engine operating at its most efficient RPM continuously.

Internal combustion engines have a specific RPM range where they produce required power with minimum fuel consumption. This “island” on the brake-specific fuel consumption (BSFC) map represents the engine’s thermal efficiency peak. Conventional transmissions can only approximate this ideal operating point using their fixed gears. A CVT can maintain it precisely regardless of vehicle speed or load.

The efficiency advantage is most pronounced in city driving, where frequent acceleration and deceleration occur. The CVT eliminates the energy losses associated with shift events and can more aggressively target low RPM operation. Highway efficiency gains are smaller but still meaningful, with the CVT selecting ratios taller than most automatics can provide.

This improved efficiency translates directly to reduced emissions. Better fuel economy means less CO2 per mile driven. Combined with modern emission control systems and catalytic converters, CVT-equipped vehicles often achieve the lowest emissions in their class.

Smooth, Refined Driving Experience

The absence of shift shock represents another key CVT advantage. Every upshift or downshift in a conventional automatic involves momentarily interrupting torque delivery while clutch packs release and engage. Even the best automatics produce a slight jolt during shifts. Performance transmissions may shift quickly, but they’re never truly seamless.

CVTs eliminate this entirely. Acceleration is linear and uninterrupted from standstill to top speed. There’s no surge-and-drop pattern as the transmission shifts, no momentary power loss, no driveline shudder. For passengers, especially those prone to motion sickness, this smoothness provides a more comfortable experience.

The refinement extends to normal driving. CVTs don’t “hunt” between gears during light throttle driving on rolling terrain. They make subtle ratio adjustments you barely notice rather than full gear changes that produce noticeable engine speed changes. This creates a serene, luxurious character that suits premium and comfort-oriented vehicles.

Lighter Weight and Simpler Design

A typical CVT weighs 50-80 pounds less than a comparable multi-speed automatic. This weight reduction comes from eliminating multiple planetary gear sets, numerous clutch packs, and the extensive hydraulic circuitry required to control them. The CVT’s simpler architecture requires fewer precision-machined components, reducing manufacturing complexity.

Lower vehicle weight improves handling, acceleration, fuel economy, and brake life. It also allows engineers to optimize weight distribution for better dynamics. The compact packaging of CVTs creates additional benefits—more interior space or flexibility in component placement.

Manufacturing costs are typically lower for CVTs than complex 8-10 speed automatics, though this advantage has diminished as CVT production has scaled up and conventional automatics have benefited from mature manufacturing processes. The cost savings can be passed to consumers or invested in other vehicle features.

Optimal Power Delivery

While the “rubber band effect” bothers some drivers, it actually represents optimal use of available power. By holding engine RPM at the power peak during full-throttle acceleration, a CVT allows the engine to continuously deliver maximum output. A conventional automatic alternates between producing peak power (just before each upshift) and lower power (just after upshifting when RPM drops).

This characteristic particularly benefits smaller displacement engines with narrow power bands. A 1.5-2.5 liter four-cylinder might have peak power at 6,000 RPM but significantly less at 4,000 RPM. A conventional automatic must shift at predetermined points, causing power to drop. A CVT can hold 6,000 RPM throughout acceleration, extracting maximum performance from the engine.

The instant ratio response also eliminates “downshift lag.” When you need sudden power for passing, a conventional automatic must decide whether to downshift, select the appropriate gear, and execute the shift—a process taking 0.5-1.0 seconds. A CVT simply adjusts its ratio immediately, providing instant response.

Environmental Benefits

Beyond reduced fuel consumption and CO2 emissions, CVTs contribute to environmental goals in other ways. Their lighter weight means less raw material consumption during manufacturing. Simpler construction reduces the environmental impact of production. Extended highway range on each tank of fuel provides practical benefits to drivers while reducing petroleum consumption.

As manufacturers work to meet increasingly stringent corporate average fuel economy (CAFE) standards, CVTs have become an essential tool. They allow conventional gasoline vehicles to approach the efficiency of hybrids, reducing the need for expensive electrification while still achieving regulatory compliance.

Disadvantages and Challenges of CVT Transmissions

Despite their advantages, CVTs come with significant limitations and challenges that buyers should understand before purchasing a CVT-equipped vehicle.

Durability and Reliability Concerns

CVT reliability varies dramatically between manufacturers and model years, making generalized statements difficult. However, CVTs as a category have shorter expected lifespans than conventional planetary automatic transmissions.

Early Generation Problems (2000s-2010s):

First-generation CVTs from many manufacturers suffered serious reliability issues. Nissan’s infamous Jatco JF011E transmission, used in millions of Nissan and Mitsubishi vehicles from 2007-2015, experienced widespread failures between 60,000-120,000 miles. Complaints included shuddering, slipping, overheating, and complete failure.

These problems stemmed from several design limitations: inadequate belt strength for the applied loads, insufficient cooling capacity causing overheating during hard use, valve body issues leading to improper pressure control, and bearing failures in the pulley mechanisms. The high replacement cost ($3,000-$5,000 or more) often totaled older vehicles.

Modern Improvements:

Current CVTs have addressed many early issues. Manufacturers now use reinforced steel belts that resist stretching and wear. Enhanced cooling systems with dedicated coolers prevent overheating. Improved hydraulic control provides better pressure regulation. More sophisticated programming reduces stress during hard acceleration and hill climbing.

Many modern CVTs from Honda, Toyota, and Subaru demonstrate good reliability with proper maintenance. However, they still generally don’t match the 200,000-300,000 mile lifespan that well-maintained conventional automatics can achieve. Most CVTs should be considered serviceable to 150,000-200,000 miles with excellent maintenance, less with neglect.

Repair vs. Replace:

A critical disadvantage is that CVTs typically require complete replacement when they fail. Conventional automatics can often be rebuilt, with failed clutch packs or valve bodies replaced while reusing the basic transmission case and gears. CVT failures usually contaminate the entire system with metal debris from the belt or pulley surfaces, making rebuild impossible.

This replacement-only reality means repair costs for CVTs are typically higher than rebuilding a conventional automatic. The lack of rebuild options also means fewer independent transmission shops can service CVTs, leaving owners dependent on dealership service at premium prices.

Limited Towing Capacity

CVTs are poorly suited for towing due to the stress it places on the belt-and-chain system. While conventional automatic transmissions use robust gear-to-gear power transfer, CVTs rely on friction between the belt and pulley surfaces. Towing generates sustained high loads that can cause excessive belt slip, heat buildup, and premature wear.

Most CVT-equipped vehicles have towing ratings of 1,000-1,500 pounds maximum—enough for a small utility trailer or lightweight camper, but inadequate for boat trailers, horse trailers, or travel trailers. Some vehicles explicitly prohibit towing entirely when equipped with CVT.

The temperature management challenges are particularly severe. Towing uphill at highway speeds forces the CVT to operate at high power levels continuously. Even with a dedicated transmission cooler, sustained towing can push CVT temperatures into the danger zone (above 240°F), accelerating fluid breakdown and belt wear.

If you regularly tow anything heavier than 1,500 pounds, a conventional automatic transmission or manual is strongly recommended. Even light towing requires diligent cooling system maintenance and shorter transmission fluid change intervals.

Driving Feel and “Rubber Band Effect”

The CVT’s operating characteristics feel fundamentally different from conventional automatics, and many drivers find the sensation unpleasant or disconcerting.

Engine RPM Disconnect:

During moderate to hard acceleration, a CVT typically allows engine RPM to rise to a predetermined point (4,000-6,500 RPM) and remain constant while the vehicle accelerates. This is optimal for performance and efficiency, but it feels wrong to drivers accustomed to traditional automatics. The engine sounds like it’s revving high with little corresponding acceleration, then the sound stays constant rather than rising and falling with speed.

This “rubber band effect” creates a psychological disconnect between throttle input and vehicle response. Your brain expects engine pitch to vary with speed and acceleration, and when it doesn’t, the experience feels sluggish or unresponsive even when actual acceleration is adequate.

Lack of Shift Points:

Conventional automatics provide tactile and audible feedback through shift events. You feel the slight surge as the transmission upshifts, hear the engine RPM drop, and subconsciously use these cues to judge vehicle behavior. CVTs eliminate this feedback entirely, which some drivers experience as boring or disconnected.

The monotonous engine drone during acceleration can be particularly annoying. Rather than the rising-and-falling melody of a conventional transmission working through gears, a CVT under hard acceleration produces a sustained high-pitch whine. Enthusiast drivers often find this unpleasant and unstimulating.

Manufacturer Responses:

Many manufacturers now program simulated shift points into CVT control logic. The transmission still varies ratios continuously, but it makes more pronounced changes at specific speeds to mimic gear changes. Some even reduce power momentarily during these programmed “shifts” to create familiar tactile feedback.

Paddle shifters and manual modes offer another solution. While these don’t provide true fixed gears, they limit the CVT’s ratio range to simulate 6-8 gear positions, giving drivers more control over engine behavior and creating a more engaging experience.

Higher Maintenance Requirements and Costs

CVTs require more frequent service than conventional automatics, and the service itself is more complex and expensive.

Fluid Change Intervals:

While conventional automatics often specify 60,000-100,000 mile fluid change intervals (or “lifetime” fill that actually means 150,000 miles), CVTs typically require service every 30,000-60,000 miles. The higher operating pressures and friction-based power transfer cause faster fluid degradation.

Skipping or delaying CVT fluid changes dramatically increases failure risk. The specialized fluid performs multiple critical functions: lubricating moving parts, providing hydraulic pressure, and creating proper friction between belt and pulleys. Degraded fluid leads to belt slip, overheating, and accelerated wear.

Specialized Fluid Requirements:

CVT fluid differs significantly from conventional automatic transmission fluid (ATF). It contains specific friction modifiers to balance grip and slip at the belt-pulley interface, higher extreme-pressure additives to protect against the crushing loads in the pulley contact patches, and different base stocks optimized for CVT operation.

Using conventional ATF in a CVT causes catastrophic failure—often within a few hundred miles. The incorrect friction characteristics cause belt slip, rapid overheating, and destruction of the belt and pulley surfaces. Even small amounts of ATF contamination can cause problems.

CVT fluid is also more expensive. A typical fluid change requires 8-12 quarts and may cost $150-300 at a dealership, compared to $80-150 for conventional ATF service. The specialized knowledge required means many independent shops won’t service CVTs or charge premium rates to do so.

Temperature Sensitivity:

CVTs require precise fluid level setting based on temperature. Overfilling causes aeration as the fluid contacts moving components, leading to pressure control problems and component damage. Underfilling prevents proper lubrication and causes air to enter the hydraulic system.

The filling procedure typically requires a scan tool to monitor transmission temperature, warming the CVT to a specific temperature range (typically 95-105°F), then adjusting fluid level via an overflow tube or dipstick reading. This precision requirement makes DIY service risky unless you have proper equipment and training.

Performance Limitations

CVTs can’t handle the power levels that conventional automatics can support. The belt or chain’s strength limit typically caps applications at 250 horsepower and 200-220 lb-ft of torque. Higher output engines overwhelm the belt’s grip capacity, causing slip and rapid wear.

This limitation explains why you won’t find CVTs in sports cars, muscle cars, or high-performance variants of mainstream vehicles. The torque converter and planetary gear-based automatic remains the standard for applications above 250 HP. Even dual-clutch transmissions, which share some efficiency advantages with CVTs, can handle significantly more power.

The cooling requirements also pose challenges for performance applications. Track driving or sustained high-speed operation generates heat levels that can quickly degrade CVT components. Dedicated cooling system modifications help, but they add cost and complexity.

CVT Maintenance: Essential Requirements for Longevity

Proper maintenance represents the single most important factor in CVT longevity. Following manufacturer recommendations—or exceeding them—can mean the difference between 80,000 miles and 180,000 miles of service life.

Understanding CVT Fluid

CVT fluid serves multiple critical functions that differ from conventional ATF, making it essential to understand its unique requirements.

Why CVT Fluid Is Fundamentally Different:

Unlike conventional automatic transmissions that use gear-to-gear power transfer, CVTs rely on friction between the belt and pulley surfaces to transmit hundreds of horsepower. The fluid must create precisely controlled friction—enough grip to prevent belt slip, but allowing controlled slip for smooth operation.

CVT fluid contains specialized friction modifiers that conventional ATF lacks. These additives maintain stable friction characteristics across wide temperature ranges and pressures exceeding 1,000 PSI. The fluid must also protect belt and pulley surfaces from scoring and wear under these extreme contact pressures, requiring high levels of extreme-pressure (EP) additives.

The base stock viscosity differs from ATF as well. CVT fluid typically has higher viscosity to maintain protective films under high pressure, while also flowing readily for hydraulic control. The shear stability—resistance to viscosity breakdown under stress—must be exceptional given the forces involved.

Color and Identification:

CVT fluid color varies by manufacturer. Many use green or yellow fluid to distinguish it from red ATF, making accidental misapplication less likely. However, some CVT fluids are red, so color alone isn’t definitive. Always verify the fluid type from the owner’s manual or transmission service information.

The characteristic sulfur smell of CVT fluid results from the high EP additive content. This pungent odor is normal—it doesn’t indicate degradation or contamination. Fresh CVT fluid may smell nearly as strong as used fluid.

The Critical Importance of Correct Fluid:

Using conventional ATF in a CVT produces catastrophic results. The incorrect friction characteristics cause immediate belt slip. Within a few miles, the belt begins overheating. Within a few hundred miles, the belt surface degrades and the pulleys score. Complete transmission failure typically occurs before 1,000 miles.

Even small amounts of ATF contamination can accelerate wear. If ATF is accidentally added to a CVT, the transmission should be completely flushed and refilled with correct fluid immediately. The cost of this service is trivial compared to replacing a damaged transmission.

Always use manufacturer-specified CVT fluid or approved alternatives. Generic “universal CVT fluid” may meet basic specifications, but compatibility testing with your specific transmission design may be limited. Manufacturer fluids or high-quality licensed alternatives (like Valvoline MaxLife CVT or Mobil 1 Synthetic CVT) provide the best assurance of correct performance.

Recommended Fluid Change Intervals

CVT fluid change recommendations vary by manufacturer, model year, and driving conditions. Understanding these variables helps you determine the right service schedule.

Normal Driving Conditions:

Most manufacturers specify 30,000-60,000 mile intervals for normal driving:

- Nissan/Jatco CVTs: 30,000-60,000 miles depending on model year (newer models have longer intervals)

- Honda CVT: 25,000-40,000 miles, or when Maintenance Minder indicates service

- Toyota CVT: 60,000 miles or 96 months, though more conservative 30,000-mile intervals recommended by many technicians

- Subaru Lineartronic: 30,000 miles for severe service, 50,000-60,000 for normal conditions

These “normal driving” definitions assume: regular highway driving with sustained speeds, moderate climate conditions, gentle acceleration and braking, minimal stop-and-go traffic, and no towing or heavy loads.

Severe Service Conditions:

Severe service driving requires more frequent fluid changes—typically every 25,000-30,000 miles regardless of manufacturer. Severe conditions include:

- Extensive stop-and-go city driving

- Extreme hot weather (above 90°F consistently) or extreme cold (below 0°F)

- Mountainous or hilly terrain with frequent elevation changes

- Frequent short trips (under 10 miles) without full warm-up

- Any towing, even within rated capacity

- Dusty or muddy environments

- Delivery or taxi service (frequent starts/stops)

If your driving pattern includes any of these conditions regularly, follow the shortest recommended interval. Given the high cost of CVT replacement vs. fluid change cost, the conservative approach pays dividends.

The Case for More Frequent Changes:

Many transmission specialists recommend fluid changes every 30,000 miles regardless of manufacturer specifications or driving conditions. Their reasoning: CVT failure rates decrease significantly with more frequent fluid changes, 30,000-mile changes cost $150-300 while CVT replacement costs $3,000-5,000+, and extending intervals to save $200-400 over vehicle life isn’t worth the failure risk.

This aggressive maintenance schedule makes particular sense for: vehicles with known CVT reliability issues (2007-2015 Nissan/Jatco transmissions), high-mileage vehicles (over 100,000 miles), vehicles you intend to keep long-term, and any severe-service driving patterns.

Professional Service vs. DIY Fluid Changes

CVT fluid changes require more precision than conventional automatic transmission service, making professional service advisable for most owners.

Why Professional Service Is Recommended:

The temperature-based fill procedure represents the primary complexity. Most CVTs require the fluid to be at a specific temperature (typically 95-105°F) when setting the final level. Too cold and you’ll overfill; too hot and you’ll underfill. Both conditions cause problems.

Professional technicians use scan tools to monitor transmission temperature via the fluid temperature sensor. They warm the vehicle to operating temperature, circulate the transmission through all gears, then monitor temperature while adding fluid to the correct level. Many transmissions use an overflow tube system—fluid is added until it overflows at the correct temperature, automatically setting the proper level.

The equipment requirements include: scan tool with live data capability, correct fluid (often 8-12 quarts), fluid pump or funnel system to add fluid, drain pan for old fluid, and possibly new drain plug washers or filter (if equipped).

Dealership service ensures use of correct OEM fluid and proper procedures. The technician will have performed dozens or hundreds of CVT services on your specific transmission design. They’ll notice any abnormalities during service like excessive metal in the drained fluid or unusual colors indicating contamination.

Cost runs $200-350 at most dealerships for basic fluid change, more if filter replacement is required or if the pan must be dropped. This includes correct fluid, proper fill procedure, and usually a multi-point inspection of transmission operation.

DIY Considerations and Cautions:

Experienced DIYers can perform CVT fluid changes successfully, but several important considerations apply:

You must obtain the exact correct fluid. Generic “universal CVT” products exist, but manufacturer-specific or licensed alternatives (like Valvoline MaxLife CVT that meets multiple OEM specifications) provide better assurance. Purchase from reputable suppliers to avoid counterfeit fluid.

Research your specific transmission’s fill procedure thoroughly. YouTube videos and enthusiast forums often provide detailed guides, but verify the information applies to your exact year, model, and transmission type. Service manuals provide authoritative procedures.

A quality scan tool or OBD2 adapter with live data capability is essential for monitoring fluid temperature during fill. Basic code readers won’t suffice—you need to see actual temperature readings from the transmission fluid temperature sensor.

Understand that drain-and-fill (removing drain plug and refilling) only exchanges 60-70% of total fluid. The torque converter, valve body, and transmission cooler retain significant old fluid. Multiple drain-and-fill cycles (typically 3-4) are needed to completely refresh the fluid. Each cycle requires running the vehicle, cycling through gears, then draining and refilling again.

Some transmissions require the pan to be dropped to access a filter or screen. This involves gasket or RTV sealant replacement, additional cleanup, and potentially more complex fill procedures. Not all CVTs have serviceable filters.

The risk of under or overfilling remains significant. Too little fluid causes poor lubrication, air entrainment, and slipping. Too much causes aeration as fluid contacts moving parts, leading to pressure control problems. Either condition can damage the transmission.

If you’re not confident in your ability to follow the procedure precisely, professional service is strongly recommended. The $200-300 service cost is modest insurance against $3,000+ transmission replacement resulting from improper service.

Warning Signs of CVT Problems

Early detection of CVT issues can prevent complete failure and allow for less expensive intervention. Learn to recognize these warning signs:

Immediate Professional Attention Required:

These symptoms indicate serious problems requiring immediate diagnosis:

- Slipping or jerking during acceleration: The transmission briefly loses connection or grabs inconsistently, indicating belt slip or valve body issues

- Delayed engagement: Several seconds pass between shifting to Drive/Reverse and feeling the transmission engage

- Burning smell: Overheated fluid produces a distinct acrid odor indicating excessive friction, inadequate cooling, or fluid breakdown

- Unusual noises: Whining, grinding, buzzing, or groaning sounds that vary with vehicle speed point to bearing failure, belt wear, or pulley damage

- Dashboard warning lights: Transmission warning light, check engine light with transmission codes, or low fluid warning lights

- Shuddering at low speeds: Vibration or pulsation particularly noticeable when accelerating gently from stops

Do not continue driving with these symptoms. Further operation can transform a potentially repairable issue (like a failed pressure sensor or contaminated fluid) into complete transmission failure requiring replacement.

Early Intervention Signs:

These symptoms suggest developing problems that warrant attention soon:

- Fluid color change: CVT fluid turning from green/yellow to brown indicates thermal degradation; black fluid indicates severe overheating

- Hesitation during acceleration: Brief pause before power delivery, particularly when downshifting for passing

- Minor vibration: Slight shudder at specific speeds that wasn’t present before

- Reduced fuel economy: Unexplained 2+ MPG decrease suggests transmission efficiency loss from belt slip or incorrect ratio selection

Schedule professional diagnosis if you notice these symptoms. A fluid analysis can determine whether the fluid has degraded beyond safe levels. Pressure tests can identify valve body or pump problems. Early intervention may allow for fluid flush, solenoid replacement, or other repairs short of complete transmission replacement.

Additional Maintenance Best Practices

Beyond fluid changes, several other practices promote CVT longevity:

Regular Inspections:

During each oil change, have a technician: inspect for transmission fluid leaks around seals, cooler lines, and drain plug; check fluid level if a dipstick is accessible; verify fluid color and smell for degradation signs; and listen for unusual transmission noises during test drive.

Cooling System Maintenance:

The transmission cooling system shares components with engine cooling in many vehicles. Maintain cooling system health by: replacing engine coolant on schedule (degraded coolant reduces heat transfer); ensuring radiator fans operate properly; keeping radiator and transmission cooler fins clean; replacing thermostats if CVT overheating occurs; and considering auxiliary transmission cooler installation for severe service.

Driving Habits for Longevity:

Your driving style directly impacts CVT life:

- Allow the transmission to warm up before aggressive acceleration (1-2 miles of gentle driving)

- Avoid prolonged wide-open throttle acceleration (use passing acceleration sparingly)

- Minimize towing whenever possible; never exceed rated capacity

- Use proper transmission mode for conditions (Eco mode reduces stress)

- Avoid “rocking” vehicle when stuck in snow/mud (breaks belt)

- Allow cool-down period after hard driving before shutting off engine

Software Updates:

Manufacturers periodically release transmission control module updates to address issues or improve operation. Check with your dealership annually about available updates. Many updates require no charge and can resolve shift quality issues, improve fuel economy, or reduce wear patterns that cause premature failure.

CVT Reliability by Manufacturer

CVT reliability varies dramatically between manufacturers. Understanding these differences helps inform purchase decisions and service strategies.

Honda CVTs – Generally Reliable

Honda’s CVT designs demonstrate above-average reliability across most applications. The company has manufactured CVTs since the late 1990s and has refined designs through multiple generations.

Strengths:

- Conservative engineering approach prioritizes durability over maximum efficiency

- Strong track record in Civic, Accord, CR-V, and HR-V models

- Generally achieve 150,000-200,000+ miles with proper maintenance

- Fewer widespread failure patterns compared to some competitors

Considerations:

- Earlier CVTs (pre-2015) had more issues than current designs

- Still requires diligent fluid maintenance every 25,000-40,000 miles

- Some models show minor vibration issues around 60,000-80,000 miles

- Maintenance Minder system provides automatic service reminders

Honda CVTs earn recommendation for buyers prioritizing reliability, particularly in current-generation models (2015+).

Toyota CVTs – Above Average Reliability

Toyota approaches CVT design conservatively, with careful engineering and extensive testing before production release.

Strengths:

- Strong reliability record across most models

- Direct-Shift CVT (with launch gear) addresses driving feel concerns while maintaining reliability

- Extensive hybrid eCVT experience (though eCVT is fundamentally different technology)

- Generally good to 150,000-200,000+ miles with normal maintenance

Considerations:

- Some models use Aisin CVT designs (used across multiple brands)

- Official service intervals at 60,000 miles, though 30,000 recommended by many technicians

- Corolla and Camry CVTs show good long-term reliability

- RAV4 hybrid uses eCVT (planetary-based, extremely reliable)

Toyota CVTs represent safe choices, particularly for buyers who maintain vehicles properly and keep them long-term.

Nissan/Jatco CVTs – Mixed Record

Nissan pioneered mass-market CVT adoption but suffered significant reliability problems with early designs that damaged the brand’s reputation.

The Jatco JF011E Problem:

This notorious transmission appeared in millions of Nissan and Mitsubishi vehicles from 2007-2015 (Altima, Rogue, Sentra, Versa, Murano, Pathfinder, Outlander). Common failure modes include: shuddering and vibration during acceleration, overheating particularly in stop-and-go traffic or uphill driving, complete failure between 60,000-120,000 miles, valve body issues causing pressure control problems, and bearing failures in pulley mechanisms.

Nissan extended warranties on many affected models, but the damage to CVT reputation was severe. Many automotive professionals and consumers now avoid all Nissan CVTs based on these experiences.

Modern Improvements (2016+):

Current Nissan CVTs show meaningful improvements: reinforced steel belts replace earlier designs, enhanced cooling systems prevent overheating, better hydraulic control provides more consistent pressure, improved valve body designs reduce failure rates, and some models now feature launch gear CVTs for better launch feel.

Current Recommendations:

For 2016+ Nissan models: follow aggressive 30,000-mile fluid change schedule, research specific model/year for known issues, consider extended warranty for used purchases, and budget for potential transmission work. Models still using JF011E (through 2015 in some applications): recommend avoidance unless very low price compensates for risk, if purchased, change fluid immediately and every 30,000 miles, budget for transmission replacement as maintenance item, and consider it a shorter-term vehicle.

Subaru CVTs – Generally Reliable

Subaru’s Lineartronic CVT uses a chain drive rather than belt, providing different characteristics.

Strengths:

- Chain-driven design handles torque better than belts

- Well-suited to AWD applications with proper engineering

- Generally reliable in Outback, Forester, Crosstrek, and Impreza

- Conservative service recommendations (30,000-50,000 miles)

Considerations:

- Some early models (2010-2014) had more issues than current designs

- Chain-driven design produces different sound characteristics

- Still requires diligent fluid maintenance

- Not suitable for aggressive performance driving despite WRX application

Subaru CVTs earn recommendation for buyers needing AWD with CVT efficiency, provided proper maintenance schedule is followed.

Warranty Considerations

Given CVT reliability concerns, warranty coverage becomes particularly important:

New Vehicle Warranties:

- Most manufacturers: 5 years/60,000 miles powertrain coverage

- Nissan (select models): Extended to 10 years/120,000 miles for CVT specifically

- Hybrid eCVTs often covered under hybrid component warranty (8-10 years/100,000-150,000 miles)

Used Vehicle Purchases:

- Certified pre-owned programs typically extend powertrain coverage 7 years/100,000 miles total

- Third-party extended warranties available, though CVT coverage may be limited or excluded

- For 2007-2015 Nissan/Jatco transmissions, extended warranty highly recommended

- Verify whether warranty covers full transmission replacement vs. repairs only

Is a CVT Right for You? Decision Guide

CVT technology suits specific use cases excellently while falling short for others. This decision framework helps determine whether a CVT-equipped vehicle matches your needs.

Best Applications for CVT Transmissions

Ideal Scenarios:

CVTs excel when: daily commuting dominates usage (especially city driving), fuel economy represents top priority, comfort and smoothness highly valued, vehicle use is light-duty without towing needs, and primary use is small to midsize sedans, crossovers, or compact SUVs.

Consider CVT If You:

- Drive 60% or more city miles with frequent stops

- Prioritize fuel savings (2-4 MPG advantage) over driving engagement

- Prefer automatic convenience over manual control

- Plan to keep vehicle long-term with proper maintenance habits

- Value serene, smooth operation over performance feel

- Can budget for 30,000-60,000 mile fluid changes

Particularly Strong Applications:

- Commuter cars with primarily highway and suburban use

- Second vehicles for local errands and daily driving

- Hybrid vehicles (where CVT efficiency complements electric propulsion)

- Vehicles for drivers who dislike shift shock in conventional automatics

- City driving where constant acceleration/deceleration occurs

When to Choose Conventional Automatic Instead

Better Alternatives:

Conventional planetary gear automatics remain superior for: any regular towing needs (even 2,000-3,000 lbs), high-performance or spirited driving, preference for traditional transmission feel, larger vehicles/trucks/SUVs with heavy-duty use, budget concerns about CVT repair costs, and higher horsepower applications.

Consider Conventional Automatic If You:

- Tow regularly, even light trailers or small boats

- Enjoy engaging driving experience and responsive acceleration

- Find CVT engine drone unpleasant or monotonous

- Concerned about long-term repair costs and transmission longevity

- Have access to budget-friendly independent transmission repair shops

- Prefer proven technology with decades of refinement

- Need maximum durability (200,000-300,000 mile expectations)

Specific Use Cases Favoring Conventional:

- Pickup trucks and body-on-frame SUVs

- Any vehicle used for work or commercial purposes

- Performance variants and sport-oriented models

- Vehicles operated in extreme climates (desert, mountain)

- Fleet or delivery vehicles with hard use patterns

Hybrid and Electric Vehicle Considerations

Hybrid “CVTs” – Different Technology:

Many hybrids described as having “CVT” actually use planetary-based power split devices (like Toyota/Lexus Hybrid Synergy Drive). These systems share the seamless operation of CVTs but mechanically resemble planetary automatic transmissions. They’re extremely reliable—often lasting the life of the vehicle without service.

If considering a hybrid, the “eCVT” or “HSD” system shouldn’t raise the reliability concerns associated with belt-driven CVTs. Regenerative braking systems and dual-motor architecture in hybrids actually reduce stress on transmission components.

Pure Electric Vehicles:

Single-speed EV transmissions eliminate concerns about gear changes entirely. The single reduction gear handles all speeds from 0-top speed, providing instant torque without any shifting complexity. If powertrain simplicity appeals, EVs offer the ultimate solution.

The CVT Purchase Checklist

Before purchasing a CVT-equipped vehicle, consider these factors:

Research Specific Model:

- Check reliability databases (Consumer Reports, J.D. Power) for specific year/model CVT reliability

- Search owner forums for common issues with that exact transmission

- Verify whether that model/year had extended CVT warranty coverage (often indicates known problems)

- Confirm the exact CVT model number (some manufacturers use multiple designs)

Test Drive Thoroughly:

- Drive in various conditions (city, highway, hills)

- Test hard acceleration to experience “rubber band effect”

- Verify you find the CVT driving characteristics acceptable

- Listen for any unusual noises during operation

Maintenance History (Used Vehicles):

- Verify CVT fluid changes occurred per schedule (30,000-60,000 mile intervals)

- Confirm correct CVT fluid was used (not conventional ATF)

- Check for any transmission repairs or warranty claims

- Test for smooth operation without slipping, shuddering, or delays

Budget Planning:

- Factor regular CVT fluid changes into ownership cost ($150-300 every 30,000-60,000 miles)

- Consider extended warranty for used CVT vehicles (especially Nissan 2007-2015)

- Budget emergency fund for potential transmission replacement ($3,000-5,000+)

- Verify dealer/specialist availability in your area for CVT service

Conclusion: Making the Informed CVT Decision

CVT technology has matured significantly since its troubled early implementations. Modern CVTs from reputable manufacturers can deliver 150,000-200,000+ miles of reliable service when properly maintained, offering genuine fuel economy and smoothness advantages. The key to CVT success lies in matching the technology to appropriate use cases and committing to diligent maintenance.

CVTs Excel When:

- Fuel efficiency represents top priority

- Daily driving patterns emphasize city and suburban commuting

- Smooth, refined operation matters more than sporty performance

- Vehicle use remains light-duty without towing requirements

- Owner commits to manufacturer-recommended maintenance schedules

CVTs Fall Short When:

- Regular towing needs exceed 1,500 pounds

- Driving enthusiasm and engagement are priorities

- High-mileage durability (250,000+ miles) is expected

- Budget constraints make $150-300 fluid changes every 30,000-60,000 miles challenging

- Performance applications require power handling above 250 HP

Critical Maintenance Requirements:

Success with CVT ownership depends absolutely on proper maintenance:

- Follow Aggressive Fluid Change Schedule: Change CVT fluid every 30,000-60,000 miles maximum, with 30,000 miles recommended for longevity. Use only manufacturer-specified CVT fluid—never conventional ATF.

- Address Warning Signs Immediately: Any slipping, jerking, delayed engagement, unusual noises, or warning lights require immediate professional diagnosis. Early intervention can prevent complete transmission failure.

- Professional Service Recommended: The temperature-based fill procedure and critical importance of correct fluid make professional CVT service advisable for most owners. The $200-300 service cost provides insurance against expensive mistakes.

- Research Specific Models: Not all CVTs are equal. Honda, Toyota, and Subaru generally demonstrate good reliability. 2007-2015 Nissan/Jatco transmissions warrant particular caution. Always research your specific year, model, and transmission design before purchase.

When Professional Consultation Is Required:

Immediate Attention Needed For:

- Any transmission warning lights or dashboard messages

- Slipping sensation during acceleration or gear engagement

- Delayed engagement when shifting to Drive or Reverse

- Burning smell or dark/black fluid color

- Grinding, whining, buzzing, or unusual noises

- Shuddering or vibration during operation

- Sudden decrease in fuel economy (3+ MPG)

Regular Maintenance Services:

- CVT fluid changes at 30,000-60,000 mile intervals

- Transmission inspection during routine oil changes

- Cooling system maintenance affecting transmission temperature

- Software updates addressing transmission control issues

Pre-Purchase Inspection (Used Vehicles):

- Complete transmission function test including hard acceleration

- Fluid condition inspection and color verification

- Computer scan for stored transmission fault codes

- Service history verification for proper CVT maintenance

Final Recommendation:

CVT technology represents a legitimate solution for fuel-efficient, smooth-operating vehicles when applied correctly. The keys to success are: selecting a vehicle with proven CVT reliability record (post-2015 Honda, Toyota, or Subaru preferred), committing to manufacturer-recommended maintenance, understanding and accepting CVT driving characteristics, and recognizing that CVTs suit specific applications better than others.

For fuel-conscious commuters driving primarily city and highway miles without towing needs, modern CVTs deliver measurable benefits. For performance enthusiasts, frequent towers, or those seeking maximum long-term durability, conventional planetary automatic transmissions remain the better choice.

The worst outcome is purchasing a CVT without understanding its characteristics and requirements, then neglecting maintenance and expecting conventional automatic transmission behavior. Educate yourself, maintain diligently, and CVT technology can serve you well for 150,000-200,000+ miles.

For specific repair procedures, technical service bulletins, or vehicle recommendations, consult factory service manuals or qualified transmission specialists with CVT expertise. The investment in proper professional service pays dividends in transmission longevity and reliability.