Every time you press your brake pedal, your vehicle relies on tribology—the science of friction, wear, and lubrication—to safely convert kinetic energy into heat. This seemingly simple act of stopping involves complex interactions between materials operating under extreme conditions: high speeds up to 15 meters per second, contact pressures reaching 4 MPa, and temperatures soaring beyond 1,200°F. Understanding brake pad rotor tribology reveals why your brakes work consistently and what happens when they don’t.

Brake pad rotor tribology encompasses three interconnected phenomena: friction generation between pad and rotor surfaces, heat management during energy conversion, and wear mechanisms that gradually consume both components. At the microscopic level, braking depends on a transfer layer—a nanometer-thick friction film that forms at the contact interface between pad and rotor. This transfer layer, composed of nanocrystalline metal oxides and compacted wear debris, stabilizes friction and protects both surfaces from excessive wear.

Modern disc brake systems represent the culmination of decades of tribological research. Engineers have developed sophisticated friction materials containing 10-25 different ingredients, each contributing specific properties to optimize the balance between stopping power, fade resistance, wear life, and noise control. Understanding how these materials interact at the atomic level helps explain why proper bedding-in procedures matter, why brake fade occurs during heavy use, and why material selection significantly impacts performance.

The science of brake tribology directly affects your safety. When brake pads and rotors function correctly, they provide predictable, consistent stopping power in virtually all conditions. When tribological processes go wrong—through contamination, overheating, or improper material selection—braking performance degrades rapidly, potentially leading to dangerous situations.

Safety Note: This article provides educational information about brake tribology. All brake system work requires proper tools, technical knowledge, and safety precautions. If you experience any brake problems—unusual noises, pedal changes, or warning lights—have your vehicle inspected by a qualified technician immediately. Never drive a vehicle with compromised braking performance.

Fundamentals of Brake Tribology

Tribology, derived from the Greek word “tribos” meaning rubbing, is the science studying interacting surfaces in relative motion. While tribology typically examines friction, wear, and lubrication together, brake systems represent a special case: dry friction applications where lubrication would be catastrophic. The absence of lubricants means brake tribology focuses intensely on managing friction and wear through material selection and surface engineering.

Understanding the Friction Couple

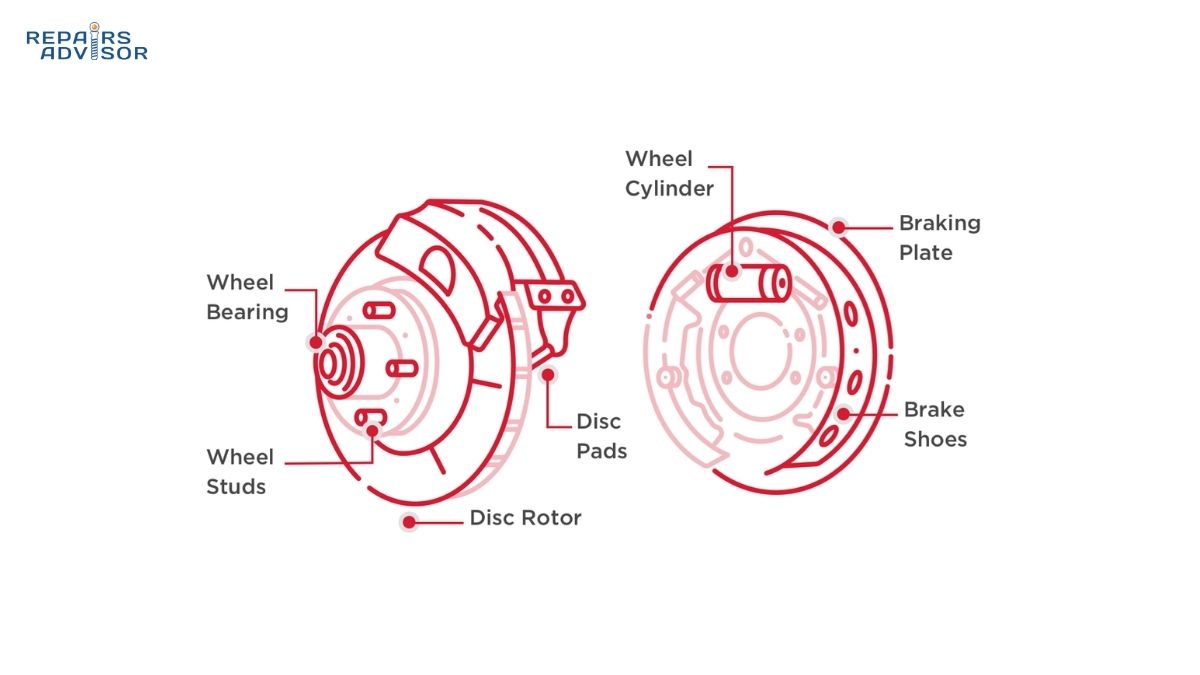

The brake friction couple consists of two dissimilar materials: the friction material bonded to the brake pad and the gray cast iron rotor. This material pairing isn’t arbitrary—it results from decades of optimization balancing performance, cost, manufacturability, and longevity.

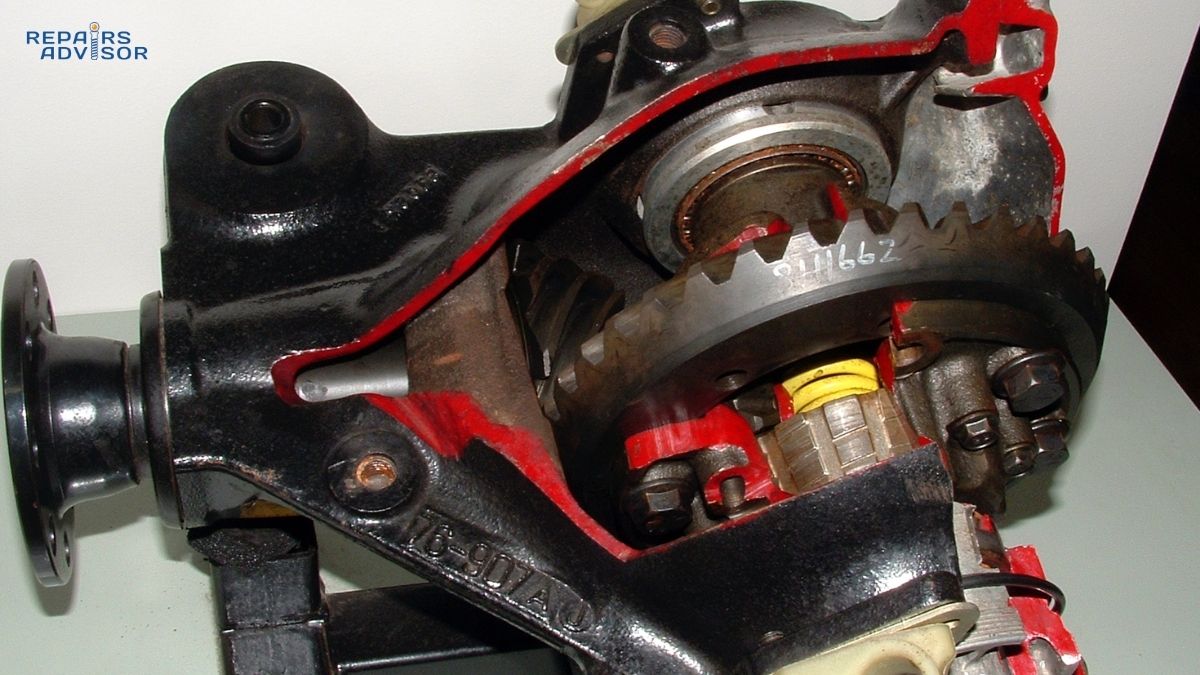

Gray cast iron dominates rotor applications because of its unique tribological properties. The material features Type A graphite flakes embedded in a predominantly pearlitic matrix. These graphite flakes serve multiple critical functions. First, they provide excellent thermal conductivity, allowing rapid heat dissipation—gray iron can conduct heat 3-4 times better than steel. Second, the graphite creates self-lubricating properties through film formation. During braking, surface graphite spreads across contact points, protecting metallic interfaces from direct metal-to-metal contact. Third, the graphite flakes act as “chip breakers,” causing the iron to fracture in controlled ways during machining, producing the smooth surfaces necessary for proper pad contact.

Modern rotors may contain small amounts of alloying elements—molybdenum, niobium, titanium, or vanadium—in concentrations of 0.1-0.3% by weight. These additions refine the microstructure, improving mechanical properties and tribological performance. Research shows that 0.20% niobium content optimizes the balance between fade resistance and wear characteristics across varying operating conditions.

Friction materials have evolved dramatically from asbestos-based formulations to modern composite materials. Today’s brake pads classify into several categories based on metallic content and composition. Semi-metallic pads contain approximately 50% metal content, typically including steel fibers, iron particles, copper, and brass. Low-metallic pads, used in most European passenger cars, contain lower metal percentages balanced with organic materials and friction modifiers. Non-asbestos organic (NAO) pads use aramid fibers, glass, rubber particles, and Kevlar bonded with phenolic resins. Ceramic materials, representing the premium category, incorporate ceramic compounds with minimal metal content, offering excellent fade resistance and reduced dust generation.

Each friction material contains four essential ingredient classes. Binders, typically phenolic resins, hold the composite together and provide structural integrity at elevated temperatures. Reinforcement fibers—aramid, glass, ceramic, or metallic—contribute mechanical strength and thermal stability. Fillers such as barite, vermiculite, or cashew particles adjust density, thermal properties, and cost. Friction modifiers including graphite, molybdenum disulfide, or antimony trisulfide fine-tune friction characteristics and fade behavior.

Real Contact Area and Surface Topography

One of tribology’s most counterintuitive principles fundamentally affects brake performance: real contact between pad and rotor occurs only on microscopic high points, not across the entire visible surface. Measurements show that actual contact area represents just 15-20% of the pad’s total apparent area. This dramatic difference exists because neither surface is perfectly smooth—both feature microscopic peaks and valleys measured in micrometers.

When brake pads first contact rotors, pressure concentrates on the highest peaks. These contact points experience extreme stress, causing plastic deformation, elastic compression, and material displacement. Over time, through the process called “bedding-in” or “polishing,” the surfaces gradually conform to each other. High points wear down, valleys partially fill with compacted debris, and contact area increases until reaching a quasi-steady state representing optimal contact geometry.

The bedding process is critical for establishing proper tribological conditions. New brake systems lacking proper break-in exhibit unstable friction and poor performance. If heavy braking occurs before bedding completes, thermal deformations can permanently distort the rotor surface, creating uneven contact patterns that persist throughout the component’s life. This explains why brake fluid works in conjunction with proper mechanical setup—the entire hydraulic system from master cylinder through calipers must function correctly to allow gradual, controlled bedding.

Contact plateaus—raised areas several micrometers above the surrounding pad surface—form during operation. These plateaus vary in size and location depending on braking conditions, pad composition, and thermal history. Advanced microscopy reveals these plateaus aren’t simply polished metal surfaces but complex structures containing transferred material, compacted wear debris, and tribochemically modified compounds. The heterogeneous nature of these plateaus contributes to the complex friction behavior observed during braking.

The Transfer Layer Formation

The transfer layer represents perhaps the most critical and least visible aspect of brake tribology. This nanometer-scale friction film forms at contact interfaces between pad and rotor, fundamentally determining braking performance, wear rates, and friction stability.

Three-Layer Structure at Microscopic Contact Points

Advanced microscopy using focused ion beam (FIB) techniques reveals the transfer layer’s intricate structure. At contact plateaus, three distinct layers exist, each with unique composition and function:

Layer 1: The Primary Friction Film measures approximately 100 nanometers thick—roughly 1/1000th the thickness of a human hair. This ultrathin layer contains nanocrystalline metal oxides suspended in an amorphous matrix enriched with sulfur. The nanocrystalline structure, with grain sizes below 100 nanometers, provides exceptional mechanical properties. Sulfur enrichment comes from sulfide-based friction modifiers in the pad material, which decompose at elevated temperatures to form metal sulfides that reduce friction and improve fade resistance. X-ray analysis shows this layer contains primarily copper and sulfur from pad constituents, while zinc transfers preferentially to the rotor surface.

Layer 2: The Nanocrystalline Friction Layer consists of compacted wear debris that has undergone severe plastic deformation and tribochemical modification. Individual wear particles, originally 10-100 micrometers when generated, become crushed and compacted into this consolidated layer. The severe mechanical action during formation creates nanocrystalline structures with superior hardness and wear resistance compared to the parent materials. This layer thickness varies from 200-500 nanometers depending on braking severity and material composition.

Layer 3: The Mechanically Mixed Material Zone represents a transition region where friction layer material intermixes with the underlying pad substrate. This zone shows compositional gradients—gradually changing from friction layer composition to bulk pad composition over 1-2 micrometers depth. The mechanical mixing results from subsurface plastic flow and material displacement during high-stress contact.

Formation Process During Braking

Transfer layer formation involves simultaneous mechanical, chemical, and thermal processes. Understanding this formation mechanism explains why proper bedding-in procedures are essential and why improper break-in permanently compromises performance.

Mechanically, the sliding contact generates enormous local pressures at asperity contacts—potentially exceeding 1 GPa at individual contact points. These pressures cause plastic deformation, material displacement, and surface fracture. Soft constituents in the pad material (organic binders, soft metals) deform plastically, flowing into surface irregularities. Hard constituents (ceramic particles, hard metals) create cutting and plowing actions, generating wear debris. The severe mechanical action fragments particles, creating the nanocrystalline structures observed in the friction film.

Chemically, the sliding interface represents a highly reactive environment. Fresh metal surfaces, continuously exposed by wear processes, react readily with atmospheric oxygen. Iron from the rotor oxidizes to form iron oxides—primarily magnetite (Fe₃O₄) at lower temperatures and hematite (Fe₂O₃) at higher temperatures. Copper and other metals from pad materials also oxidize. Organic binders decompose at elevated temperatures, releasing carbon-rich residues that contribute to the friction film. Sulfide-based friction modifiers decompose around 400-600°F, forming metal sulfides that deposit in the friction layer. These tribochemical reactions occur orders of magnitude faster than normal corrosion because the mechanical action continuously exposes fresh reactive surfaces.

Thermally, the friction interface experiences extreme conditions. While bulk pad temperatures might reach 500-700°F during moderate braking, flash temperatures at individual asperity contacts spike dramatically higher—potentially exceeding 1,500°F for microseconds. These thermal pulses accelerate chemical reactions, soften materials temporarily, and drive decomposition reactions. The rapid heating and cooling cycles also contribute to surface fatigue, gradually fragmenting surface layers into the nanoparticles that comprise the friction film.

The establishment of stable tribological conditions—the “bedded” state—typically requires 20-30 brake applications from moderate speeds. During initial bedding, the friction coefficient may fluctuate as the transfer layer forms and stabilizes. Once established, this layer provides consistent friction and protects both surfaces from excessive wear. Racing applications often specify aggressive bedding procedures: 10-15 near-maximum-effort stops to rapidly develop the transfer layer under conditions similar to actual use.

Transfer Layer Functions and Stability

The transfer layer serves multiple critical functions beyond simply existing at the interface. First and most importantly, it stabilizes friction coefficients across varying conditions. Without the transfer layer, direct metal-to-metal contact between pad particles and cast iron would exhibit unstable friction, varying dramatically with speed, temperature, and applied pressure. The friction film’s nanocrystalline structure and mixed composition provides more consistent friction behavior.

Second, the transfer layer protects both pad and rotor from catastrophic wear. The layer acts as a solid lubricant, reducing direct contact between hard abrasive particles and the relatively soft gray iron. While “lubrication” might seem contradictory for a brake application, the transfer layer provides just enough interface modification to control wear while maintaining sufficient friction for effective braking.

Third, the layer functions as a thermal barrier and heat sink. The nanocrystalline structure and compositional complexity create thermal resistance, partially insulating the bulk pad material from peak interface temperatures. Simultaneously, metal oxides in the layer conduct heat away from the immediate contact zone into the rotor’s thermal mass.

Transfer layer stability depends critically on operating conditions. During dry braking, tribofilms form readily and persist between brake applications. The layer thickness builds gradually over repeated cycles, stabilizing after initial bedding. However, wet braking dramatically changes transfer layer dynamics. Water at the interface prevents oxidation reactions, washes away loose wear debris before compaction, and cools surfaces too rapidly for proper film formation. Research shows tribofilms barely form during wet braking, explaining the significantly different friction characteristics drivers experience in rain.

All brake pad surfaces show contact plateaus—the raised patches where transfer layers develop—but their distribution varies with conditions. Dry braking produces numerous well-distributed plateaus. Wet braking creates fewer, less stable plateaus that disintegrate more readily. The mechanical crushing action performed by entrapped wear debris or the disintegration of plateaus (accelerated by water) represents the primary wear mechanisms.

Understanding transfer layer formation reveals why brake system maintenance matters. Contamination by oils, fluids, or road chemicals interferes with proper layer formation. Glazed pads—those with shiny, hardened surfaces from overheating—have damaged or improperly formed transfer layers. Uneven wear patterns often indicate regions where proper transfer layers never developed. Proper disc brake system maintenance includes ensuring conditions that support healthy transfer layer formation and identifying failure modes that compromise this critical friction film.

Friction Coefficient Dynamics

The coefficient of friction (COF) quantifies the relationship between normal force pressing surfaces together and the tangential force resisting sliding motion. In brake systems, COF typically ranges from 0.3 to 0.5, though specific values vary with material combinations, operating conditions, and interface state. Understanding COF dynamics explains why brakes sometimes feel different, why fade occurs, and why material selection critically impacts performance.

Factors Affecting Friction Coefficient

Contact pressure profoundly influences friction behavior, though not always intuitively. Classical friction theory suggests friction should be independent of contact area and normal load—but brake systems routinely violate these assumptions. Real brake testing consistently shows friction coefficient gradually decreasing as applied pressure increases. At 0.5 MPa contact pressure, a pad-rotor pair might exhibit COF of 0.45. Increasing pressure to 2.0 MPa might reduce COF to 0.38. This behavior results from several mechanisms: increased pressure compacts the transfer layer more densely, changes the balance between adhesive and abrasive wear mechanisms, and alters the fraction of contact area experiencing plastic deformation versus elastic contact.

Sliding velocity creates complex friction relationships. At very low speeds (below 0.5 m/s), friction typically increases slightly—the “stick-slip” regime where adhesive forces dominate. As speed increases through the normal driving range (1-15 m/s), friction often decreases moderately due to thermal effects and changes in wear mechanisms. Some material combinations show friction initially decreasing with speed, then increasing again at higher velocities. This complex velocity dependence explains why brake feel varies between parking lot maneuvers and highway braking.

Temperature represents the most dramatic influence on friction coefficient. At ambient temperatures (70-100°F), most brake materials exhibit their baseline friction characteristics. As temperature increases through normal operating range (300-500°F), friction typically remains relatively stable—the design objective for brake materials. However, as temperatures approach 600-800°F, many friction materials exhibit fade: friction coefficient drops substantially, sometimes to 60-70% of baseline values. This fade results from multiple mechanisms occurring simultaneously: organic binders soften or decompose, generating gas films that separate surfaces; hard constituents become embedded deeper into the pad matrix as binders soften, reducing their cutting action; and thermal expansion creates dimensional changes affecting contact geometry.

Moisture dramatically alters friction behavior. Wet braking typically exhibits 15-30% lower friction coefficients compared to dry conditions. Water interferes with transfer layer formation, acts as a lubricant at the interface, and prevents the oxidation reactions that contribute to friction film development. Additionally, water can temporarily penetrate the porous friction material matrix, altering internal structure and reducing stiffness. The coefficient of friction recovery as brakes dry varies by material—some recover quickly after several applications, while others require longer drying periods.

Material Combinations and Friction Behavior

The difference between pure metal-to-metal friction and composite friction materials sliding against cast iron is substantial and critical for understanding brake design. Pure metal contacts typically exhibit high friction (COF 0.6-1.2) but catastrophic wear rates and extreme sensitivity to surface conditions. The composite friction materials in brake pads deliberately reduce maximum friction while dramatically improving wear resistance, fade behavior, and friction stability.

Semi-metallic pads with 40-60% metal content provide friction coefficients around 0.35-0.42 across wide temperature ranges. The metal fibers and particles provide structural integrity and thermal conductivity but must be balanced with softer constituents that enable transfer layer formation. Low-metallic pads, dominant in European applications, typically exhibit COF around 0.38-0.45 with excellent cold performance but more pronounced fade characteristics at extreme temperatures. NAO (non-asbestos organic) pads generally show friction coefficients of 0.36-0.40, with excellent noise characteristics but typically lower fade resistance and reduced wet performance. Ceramic pads, the premium category, maintain COF around 0.40-0.42 with exceptional fade resistance and minimal dust generation, though sometimes criticized for reduced cold-weather bite.

Rotor material also influences friction behavior. Standard gray cast iron provides the baseline reference. Compact graphite iron (CGI), used in some heavy-duty applications, exhibits 5-10% higher friction coefficients but also generates higher temperatures due to its superior hardness. Alternative materials like aluminum metal matrix composites (Al-MMC) show approximately 25% higher friction coefficients than cast iron but create different wear patterns on pad materials, requiring specifically formulated pads for optimal performance.

Friction Stability and Driver Experience

What drivers perceive as “brake feel” or “pedal modulation” directly results from friction coefficient behavior. Stable friction creates predictable, linear brake response—press the pedal harder, get proportionally more braking force. Unstable friction produces unpredictable behavior: sometimes grabby, sometimes requiring excessive pedal force, always creating driver uncertainty.

Solid lubricants in friction material formulations critically affect friction stability. Graphite, the most common solid lubricant, provides consistent friction across wide temperature ranges and reduces noise by damping vibrations at the interface. However, too much graphite reduces friction coefficient below acceptable levels. Molybdenum disulfide (MoS₂) provides excellent high-temperature stability and fade resistance but costs significantly more than graphite. Antimony trisulfide (Sb₂S₃) offers a balanced approach, improving fade resistance while maintaining acceptable friction levels. Research shows friction materials containing 7% graphite + 3% Sb₂S₃ demonstrate better friction stability and fade resistance compared to formulations with 10% graphite alone.

Modern electronic systems including ABS, traction control, and electronic stability control depend on predictable friction behavior. These systems measure wheel speeds and calculate brake force requirements based on friction coefficient assumptions. When actual friction deviates significantly from these assumptions—during fade, contamination, or improper bedding—electronic systems may not function optimally. This represents another reason why proper brake maintenance and appropriate material selection matter beyond basic stopping distance considerations.

For intermediate DIY mechanics, understanding friction dynamics reveals why various brake “upgrades” may not perform as expected. Installing high-performance pads designed for track use on a daily driver might increase pedal effort unacceptably because cold friction is optimized differently. Conversely, budget pads might save money initially but exhibit unstable friction, creating safety concerns and shortening rotor life through excessive wear. Matching friction materials to actual use requirements—considering temperature ranges, wet operation frequency, and noise sensitivity—ensures optimal tribological performance.

Thermal Management and Fade Characteristics

Braking converts kinetic energy into thermal energy at rates that would challenge even industrial heat exchangers. A single emergency stop from highway speeds generates enough heat to boil a kettle of water. Effective thermal management and understanding fade characteristics represent critical aspects of brake tribology that directly impact safety.

Heat Generation and Temperature Distributions

When a 3,500-pound vehicle decelerates from 60 mph to zero, it dissipates approximately 260 kilojoules of kinetic energy—equivalent to running a 1,500-watt space heater for three minutes. This energy concentrates in the small contact area between pads and rotors, creating tremendous thermal intensity. During normal driving with moderate braking, interface temperatures reach 300-500°F. Aggressive highway braking pushes temperatures to 700-900°F. Emergency maximum-effort stops can spike interface temperatures above 1,200°F temporarily. Descending mountain grades or repeated track stops can sustain temperatures of 1,000-1,400°F for minutes at a time.

The heat distribution between pad and rotor is decidedly unequal. Research shows rotors absorb approximately 90-95% of generated thermal energy, with pads absorbing only 5-10%. This distribution results from fundamental physics: the rotor’s much larger thermal mass, continuous rotation exposing fresh cool surfaces to airflow, and superior thermal conductivity of gray cast iron compared to friction materials. The rotor essentially functions as a heat sink, absorbing thermal energy during braking and dissipating it to airflow during non-braking periods.

Temperature measurement reveals dramatic gradients within brake components. The friction surface reaches peak temperatures, while material just 5-10mm below the surface remains hundreds of degrees cooler. This temperature gradient creates thermal stresses—expansion of hot surface layers constrained by cooler internal material. These thermal stresses contribute to several failure modes: surface cracking (heat checking), warping, and in extreme cases, catastrophic structural failure.

Modern brake booster systems and hydraulic components must function reliably despite heat conducted through calipers into brake fluid. Temperatures above 400°F degrade even high-quality DOT 4 brake fluid, potentially causing vapor lock—formation of gas bubbles that compress rather than transmitting hydraulic force. This explains why proper brake fluid specifications and regular fluid service are essential thermal management considerations.

Brake Fade Mechanisms and Recovery

Brake fade—the temporary reduction in braking efficiency at elevated temperatures—represents one of tribology’s most safety-critical phenomena. Three distinct fade mechanisms occur at different temperature ranges and through different physical processes.

Friction fade occurs when pad materials reach temperatures that cause binders to soften, decompose, or generate gas films. Phenolic resins, the most common binder system, remain stable to approximately 400-450°F but begin decomposing above 500°F. This decomposition releases volatile gases that create a microscopic film between pad and rotor surfaces, effectively acting as a lubricant that dramatically reduces friction coefficient. Some materials exhibit friction coefficients dropping to 0.20-0.25 during severe fade—less than half their normal values. The temperature at which fade begins varies dramatically by pad formulation. Budget pads might fade at 600°F, while premium performance pads maintain friction to 1,000°F or beyond.

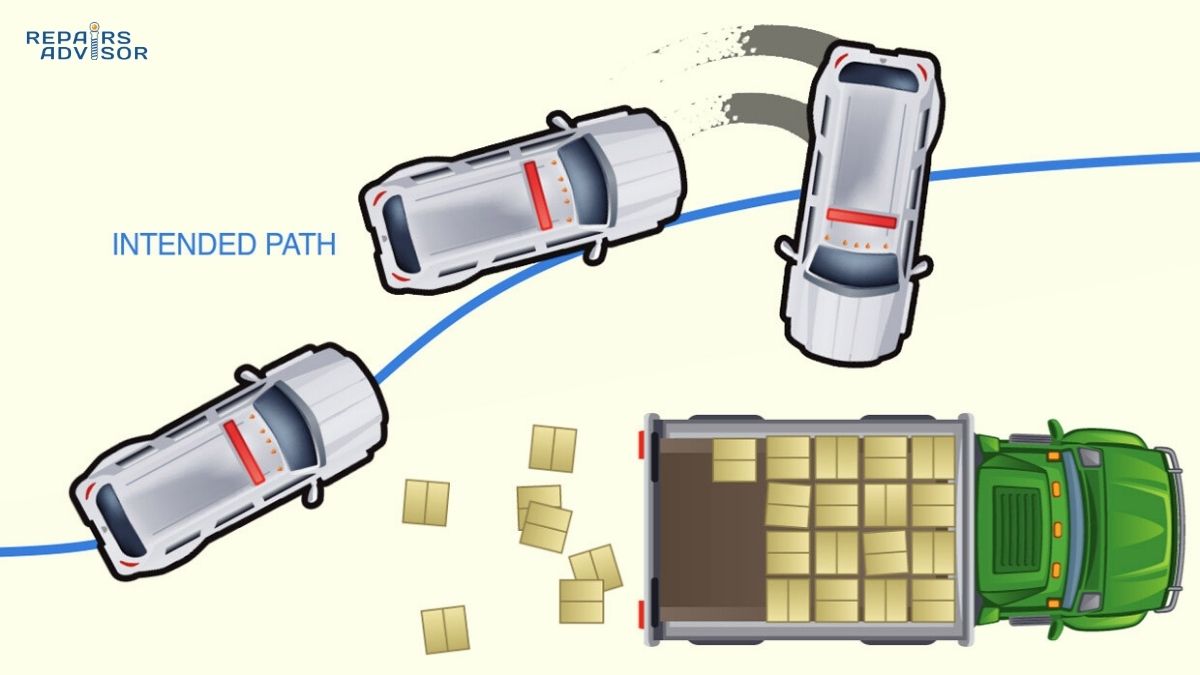

Green fade describes poor performance on new or recently machined brakes that haven’t completed proper bedding. Without an established transfer layer, friction behaves erratically and generally measures lower than properly bedded brakes. Green fade typically resolves after 20-50 moderate brake applications that allow proper transfer layer formation. Racing applications address this through aggressive track-side bedding procedures before competition begins.

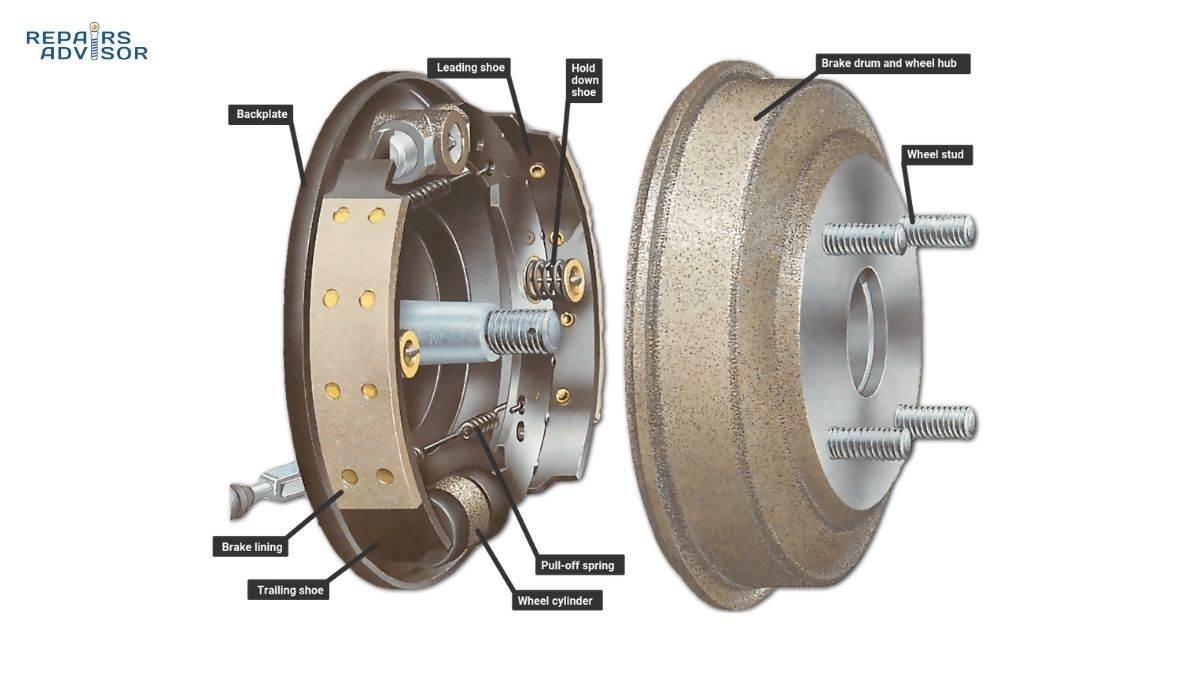

Water fade results from moisture contamination reducing friction through multiple mechanisms. Water at the interface prevents proper transfer layer formation and adhesion. Water absorbed into porous friction materials reduces their effective stiffness, allowing greater deformation under braking loads and reducing contact pressure at the interface. Older vehicles with drum brakes were particularly susceptible to water fade because enclosed drum designs trapped water. Modern ventilated disc brakes dissipate water more effectively but still exhibit 15-30% reduced friction when wet. Repeated wet braking gradually dries the system and restores normal friction—usually within 5-10 applications.

Fade recovery characteristics vary substantially by friction material chemistry. Some materials recover quickly as temperature decreases—exhibiting full friction within minutes of reduced thermal load. Others show hysteresis: friction remains depressed even after cooling, requiring additional brake applications to re-establish proper transfer layers and restore normal friction. This recovery behavior represents a critical consideration for applications involving repeated hard braking, such as mountain driving or track use.

Chemical changes during severe overheating can permanently degrade friction materials. Above approximately 900-1,000°F, many organic constituents carbonize—forming hard, glassy carbon structures rather than decomposing into gases. This carbonization, called “glazing,” creates a hard, smooth surface layer with very poor friction characteristics. Glazed pads require surface removal (resurfacing or replacement) to restore proper friction—simply cooling doesn’t restore function.

Heat Management Strategies

Effective brake system design employs multiple strategies to manage thermal loads and prevent fade. Rotor design represents the first line of defense. Solid rotors, used on smaller, lighter vehicles, rely on their thermal mass and surface area for heat dissipation. Ventilated rotors incorporate internal vanes that pump air through the rotor during rotation, dramatically improving cooling. Research shows ventilated rotors can reduce maximum temperatures by 30-50% compared to solid rotors of equivalent thickness. Slotted rotors feature circumferential or radial grooves that improve initial bite, help clear debris and gases from the interface, and provide additional surface area for heat dissipation. Drilled rotors include through-holes that reduce weight, improve cooling, and provide aesthetic appeal but potentially sacrifice some structural integrity.

Material selection balances competing requirements. Standard gray cast iron provides excellent thermal properties for most applications. High-carbon formulations maximize thermal conductivity at the expense of ultimate strength—acceptable for applications where thermal management is paramount. Alloying additions like molybdenum or niobium improve fade resistance by optimizing microstructure. Alternative materials like carbon ceramic offer extraordinary fade resistance and weight savings but cost 10-20 times more than cast iron.

Pad material selection equally impacts thermal performance. Performance-oriented pads use high-temperature binders, heat-resistant fibers, and fade-resistant formulations that maintain friction coefficient to higher temperatures. However, these materials often sacrifice cold-weather performance—they may require heating before reaching optimal friction levels. Daily-driver pads optimize for broad temperature range operation, accepting somewhat lower maximum temperature capability in exchange for consistent performance from ambient to moderate temperatures.

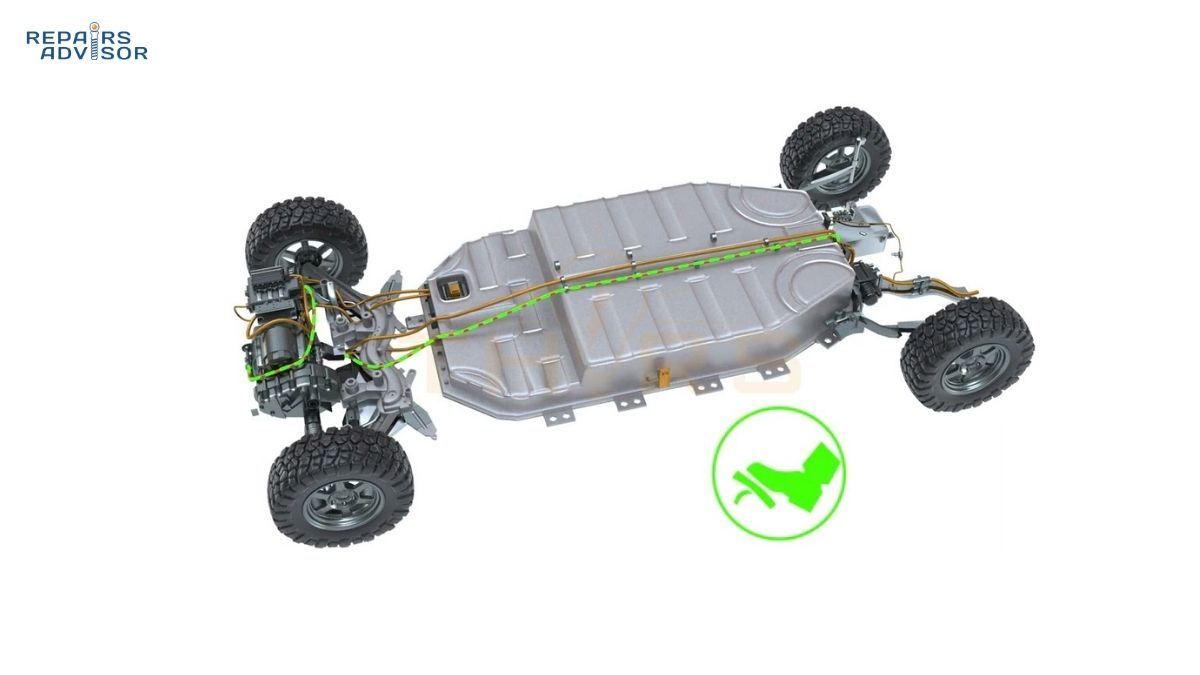

System-level cooling solutions address extreme thermal loads. Brake cooling ducts, common on performance vehicles, route airflow directly to brake rotors, substantially improving heat dissipation during sustained hard braking. Heat shields protect adjacent components from radiant and conductive heat transfer. In hybrid and electric vehicles, regenerative braking reduces reliance on friction braking, decreasing thermal loads during normal driving while friction brakes remain available for emergency situations.

Professional Insight: Thermal management represents one area where aftermarket “upgrades” can create problems. Installing oversize rotors without corresponding brake system modifications may trigger ABS or stability control issues. Aggressive track pads on street vehicles might never reach optimal operating temperature during normal driving, providing poor performance and accelerating wear. Proper thermal management requires system-level thinking, not just swapping individual components.

Safety Warning: Driving on severely faded brakes significantly increases stopping distances and reduces vehicle controllability. If you experience brake fade—soft pedal, reduced stopping power, burning smell—pull over safely when possible, allow extended cool-down time (15-30 minutes minimum), and have the system inspected before continued driving. Repeated severe fade can cause permanent damage requiring component replacement.

Wear Mechanisms and Material Loss

Wear—the gradual removal of material from solid surfaces through mechanical action—represents an inherent aspect of brake tribology. Understanding wear mechanisms reveals why brake components have finite service lives, why some materials last longer than others, and why certain operating conditions accelerate component replacement needs.

Types of Wear in Brake Systems

Abrasive wear occurs when hard particles cut, plow, or fracture softer material. In brake systems, abrasive wear manifests in multiple ways. Hard constituents in friction materials—ceramic particles, hard metal fragments, oxidized compounds—act as cutting tools against the relatively soft gray cast iron rotor. Conversely, iron particles embedded in the pad surface abrade the pad material itself. Environmental contaminants—road dust, sand, metal particles from corroded components—entrained at the interface contribute additional abrasive action. The severity of abrasive wear depends on particle hardness relative to the surfaces being worn, particle size (larger particles cause deeper cuts), and applied load (higher loads push particles deeper into surfaces).

Adhesive wear results from localized bonding between surfaces followed by material transfer. At the microscopic level, extremely high pressures at asperity contacts can cause local cold welding—atoms from one surface bonding to the other surface. Continued relative motion fractures these bonds, but material transfers from one surface to the other in the process. In brake systems, adhesive wear contributes significantly to transfer layer formation. Material from the pad friction material adheres to the rotor surface, gradually building the friction film. Some of this transferred material remains permanently, while other portions detach as wear particles. The balance between material transfer and removal determines transfer layer stability.

Fatigue wear develops through repeated stress cycles causing progressive surface damage. Each brake application subjects surface layers to compressive stresses, tensile stresses during unloading, and shear stresses from sliding. After thousands of cycles, this repeated loading initiates subsurface cracks that propagate toward the surface. Eventually, these cracks intersect, releasing wear particles. Rotor surface “heat checking”—the pattern of fine cracks visible on heavily used rotors—represents fatigue wear in progress. These cracks, if allowed to progress unchecked, can propagate through the rotor thickness, causing catastrophic failure. Thermal cycling—repeated heating and cooling—accelerates fatigue wear by adding thermal stresses to mechanical stresses.

Tribochemical wear involves chemical reactions at the sliding interface that produce compounds with different mechanical properties than parent materials. The fresh surfaces continuously exposed by mechanical wear react rapidly with atmospheric oxygen. Iron oxidizes, forming iron oxides that are typically softer than metallic iron and remove more easily. Pad constituents also oxidize and chemically transform. High interface temperatures accelerate these reactions. The tribochemically modified surface layer, while protecting deeper material from direct contact, itself wears away continuously. Tribochemical wear rates depend strongly on temperature—typically doubling for each 100-150°F temperature increase in the range of 400-800°F.

Real brake systems exhibit transitions between wear mechanisms as operating conditions change. At low speeds and moderate temperatures, abrasive and adhesive wear dominate. As speeds and temperatures increase, fatigue and tribochemical wear become more significant. Understanding which mechanism dominates under specific conditions helps explain observed wear patterns and predict service life.

Factors Affecting Wear Rates

Contact pressure dramatically influences wear rates, though the relationship isn’t simply linear. Doubling brake line pressure doesn’t double wear rate—it typically increases wear by 60-80% due to changes in the dominant wear mechanism. At low pressures, adhesive wear dominates and wear rate increases roughly linearly with load. At moderate pressures, abrasive wear becomes significant and wear rate accelerates. At very high pressures, the transition to plastic deformation creates different wear behavior—sometimes even reducing wear rate as surfaces conform better and distribute loads more evenly.

Sliding velocity affects wear through multiple pathways. Increased velocity generates higher interface temperatures, accelerating tribochemical wear. Higher speeds also increase the kinetic energy of wear debris particles, making them more effective abrasives when trapped at the interface. However, very high speeds can create aerodynamic effects that help clear wear debris from the contact zone, potentially reducing abrasive wear. Research measuring wear rates at velocities from 1-15 m/s shows complex relationships: wear sometimes increasing monotonically with speed, sometimes showing minima at intermediate velocities, depending on the specific material combination.

Temperature represents perhaps the most influential factor in wear rate. In the range of ambient to 400°F, wear rates remain relatively stable—within a factor of 2-3 across this range. Above 500°F, wear rates begin accelerating rapidly. At 700-800°F, wear rates may be 5-10 times higher than at ambient temperature. This acceleration results from multiple simultaneous mechanisms: binder softening allowing hard particles to embed deeper and cause more damage, accelerated oxidation producing easily-removed oxide layers, and thermal softening reducing material hardness. Extreme temperatures above 900°F can cause catastrophic wear rates—sometimes consuming 1mm of pad thickness in a single severe braking event.

Environmental factors including moisture, chemical contamination, and debris significantly impact wear. Water at the interface generally increases wear rates by 50-100% compared to dry braking. The water prevents proper transfer layer formation, washes away protective oxide films, and accelerates corrosion processes. Chemical contamination from oils, hydraulic fluids, or road treatments interferes with transfer layer formation and can dramatically accelerate wear. Foreign particles—sand, road grit, rust scale from corroded components—act as three-body abrasives, accelerating wear on both pad and rotor surfaces.

Material compatibility between pad and rotor crucially affects wear life. Mismatched materials—for example, ceramic pads paired with low-quality rotors, or aggressive racing pads on standard rotors—often exhibit unacceptable wear rates. The optimal pairing balances hardness (too similar creates high wear on both components, too dissimilar creates excessive wear on the softer component), thermal expansion (mismatched expansion can create contact pressure variations), and chemical compatibility (some pad constituents aggressively attack certain rotor materials).

Wear Debris and Environmental Concerns

Every brake application generates wear particles—typically 10-50 milligrams per stop for a passenger vehicle. These particles follow three pathways. Some particles become trapped between pad and rotor surfaces, acting as abrasive third bodies that accelerate additional wear until they escape the contact zone or are crushed into the transfer layer. Some debris compacts into the transfer layer, becoming permanently part of the friction film structure. The remaining particles, representing 20-50% of total wear debris, become airborne as particulate matter emissions.

Brake wear particulate emissions have emerged as an environmental concern. A typical vehicle generates 5-10 grams of brake wear particles per 1,000 kilometers driven. With over one billion vehicles worldwide, this represents approximately 5-10 million tons annually of brake wear particulates entering the environment. These particles, predominantly in the size range of 0.1-10 micrometers, can be inhaled and contribute to air quality issues in urban areas.

Particle composition reflects both pad and rotor materials. Analysis shows brake wear particles typically contain 50-70% iron from rotor wear, 10-30% friction material constituents, and 10-20% oxidized compounds formed during braking. Of particular concern, many friction materials historically contained copper as a thermal conductor and friction modifier. Copper concentration in brake particles can reach 5-15%, and this copper eventually enters waterways through stormwater runoff, where it is toxic to aquatic organisms. This environmental concern has driven regulatory action—California and Washington State have implemented regulations requiring reduction of copper content in friction materials, with complete phase-out of certain copper compounds by 2025.

The trend toward Cu-free (copper-free) friction materials represents a significant tribological challenge. Copper provided multiple beneficial functions: excellent thermal conductivity, contribution to transfer layer formation, and friction stabilization. Replacing copper while maintaining performance requires careful reformulation using alternative thermal conductors (brass, tin, other alloys) and friction modifiers (non-copper sulfides, ceramic materials). Early Cu-free formulations sometimes exhibited inferior fade resistance or reduced friction stability, but current generation materials have largely resolved these issues.

Service Life Considerations and Maintenance

Typical brake pad service life ranges from 25,000-70,000 miles depending on driving conditions, vehicle weight, pad material, and driver behavior. Front pads typically wear 2-3 times faster than rear pads because weight transfer during braking loads the front axle more heavily. Pad thickness measurement provides the primary wear assessment—most pads begin at 10-12mm thickness and require replacement when worn to 2-3mm remaining.

Rotor wear occurs more slowly than pad wear—typically one rotor replacement for every 2-3 pad replacements. However, rotors have minimum thickness specifications stamped on the casting. Operating rotors below minimum thickness risks catastrophic failure through cracking or structural collapse. Modern rotors are relatively thin to reduce weight and improve thermal response, making it essential to measure thickness at each brake service and compare to specifications.

Uneven wear patterns indicate underlying problems requiring attention. Tapered pad wear—one end thinner than the other—typically indicates stuck caliper slides or seized guide pins preventing proper caliper movement. Inner pad wearing faster than outer pad (or vice versa) suggests piston problems or caliper mounting issues. Rotor thickness variation—the rotor being thinner in some locations around its circumference—creates pedal pulsation and indicates machining problems, excessive heat distortion, or localized material issues.

Professional brake inspection should occur every 12,000-15,000 miles or annually. This inspection should include pad thickness measurement, rotor thickness measurement and runout check, caliper slide/guide pin lubrication and function verification, and brake fluid condition assessment. Addressing wear-related issues early—before complete pad consumption exposes backing plates or before rotors wear through minimum thickness—prevents expensive additional damage and maintains safety margins.

For DIY enthusiasts, understanding wear mechanisms reveals why component quality matters. Budget brake pads using inferior friction materials might save $50 but could wear out in 20,000 miles while consuming rotor material excessively, requiring rotor replacement that negates any initial savings. Premium pads might last 60,000 miles and preserve rotor life, providing better total cost of ownership despite higher initial cost. Similarly, quality rotors with proper metallurgy resist heat checking and distortion, often lasting through 2-3 pad replacements, while cheap rotors might require replacement at every pad change.

The integration of brake wear monitoring into modern vehicles reflects tribology’s importance. Many vehicles now feature electronic pad wear sensors—simple circuits that break when pads wear to minimum thickness, triggering dashboard warnings. Advanced systems use brake-by-wire technology to estimate wear rates mathematically based on brake applications, temperatures, and operating conditions. Future systems may incorporate actual thickness measurement using ultrasonic or inductive sensors, providing real-time wear status without requiring visual inspection.

Advanced Materials and Friction Optimization

The evolution of brake friction materials represents one of automotive engineering’s ongoing success stories. From early brake systems using asbestos-based materials to modern nanoengineered composites, continuous material science advances have improved performance, durability, and environmental compatibility while addressing changing regulatory requirements.

Friction Material Evolution and Modern Formulations

Historical asbestos-based friction materials dominated brake applications from the 1920s through the 1980s. Asbestos offered excellent thermal stability, good friction characteristics, and low cost. However, health concerns about asbestos fiber inhalation—causing asbestosis and mesothelioma—led to complete elimination from brake materials. The transition away from asbestos created significant technical challenges because asbestos had provided unique combinations of properties difficult to replicate.

Modern friction material formulation represents sophisticated materials science. A typical brake pad contains 10-25 distinct ingredients, each serving specific functions. The formulation process balances competing requirements: high friction vs. low wear, fade resistance vs. cold-weather performance, noise control vs. aggressive initial bite, environmental compliance vs. cost.

Binder systems form the matrix holding other constituents together. Phenolic resins remain the industry standard, offering good thermal stability to approximately 500°F, adequate mechanical strength, and reasonable cost. Modified phenolic resins incorporating additives like rubber particles improve noise characteristics but may sacrifice some fade resistance. Advanced binder systems using polyimides or other high-temperature polymers can survive 700-800°F but cost significantly more.

Reinforcement fibers provide mechanical strength and thermal stability. Aramid fibers (Kevlar family) offer excellent strength-to-weight ratios and good thermal properties. Glass fibers cost less but provide lower strength and thermal stability. Ceramic fibers excel in thermal applications but can create aggressive wear on rotors if not properly balanced. Metallic fibers (steel, copper, brass) conduct heat effectively and contribute to the transfer layer but increase density and can affect friction behavior. Many formulations use hybrid fiber systems combining multiple types for optimal property balance.

Filler materials adjust density, thermal properties, and manufacturing characteristics while managing cost. Barite (barium sulfate) provides high density and good thermal stability. Vermiculite offers low thermal conductivity, helping insulate backing plates from friction surface heat. Cashew particles from natural cashew nut shells provide renewable, low-cost filler with good friction properties. Many formulations incorporate recycled or waste materials as fillers, improving sustainability.

Friction modifiers fine-tune tribological behavior. Graphite remains the most common solid lubricant, providing stable friction and reducing noise through vibration damping. However, graphite can reduce friction coefficient excessively if over-used. Molybdenum disulfide (MoS₂) provides excellent high-temperature stability and superior fade resistance but costs substantially more than graphite. Metal sulfides including antimony trisulfide (Sb₂S₃) and tin sulfide offer balanced performance, improving fade resistance while maintaining acceptable friction levels. Research demonstrates that combinations of solid lubricants often outperform single-component systems—for example, 7% graphite + 3% Sb₂S₃ provides better performance than 10% graphite alone.

Abrasives intentionally incorporated into friction materials control rotor conditioning and transfer layer formation. Aluminum oxide, silicon carbide, and zirconium oxide particles act as controlled abrasives, maintaining rotor surface roughness in optimal ranges and preventing excessive transfer layer buildup that could cause noise or uneven friction. However, excessive abrasive content accelerates rotor wear unacceptably—formulations typically limit abrasives to 5-10% by weight.

Rotor Material Innovations

While gray cast iron continues dominating rotor applications, material science advances have improved properties and enabled alternatives for specialized applications. Standard gray cast iron contains approximately 3.0-3.5% carbon, primarily in graphite flake form, with 2.0-2.5% silicon and small amounts of manganese, sulfur, and phosphorus. This composition provides the optimal balance of thermal conductivity, mechanical strength, machinability, and cost for passenger vehicle applications.

Optimized gray cast iron formulations incorporate small amounts of alloying elements to refine microstructure. Molybdenum additions of 0.2-0.5% improve strength and thermal stability without significantly affecting thermal conductivity or cost. Niobium in concentrations of 0.1-0.3% refines eutectic cell size and graphite flake distribution, improving mechanical properties and fade resistance. Research shows 0.20% niobium provides the best balance—reducing sensitivity to operating conditions, improving brake efficiency, and enhancing wear resistance. Titanium and vanadium serve similar functions but can make the material difficult to machine if concentrations exceed optimal levels.

High-carbon, high-conductivity gray iron formulations maximize thermal conductivity at the expense of mechanical strength. These materials contain higher carbon percentages (3.5-4.0%) and are used primarily in heavy truck applications where thermal management is paramount. The increased graphite content provides superior heat dissipation but reduces tensile strength, requiring thicker, heavier rotors to maintain structural integrity.

Compact graphite iron (CGI) represents an alternative material gaining traction in heavy-duty and railroad applications. CGI features graphite in compact, worm-like forms rather than flakes. This structure provides approximately 50% higher strength than gray iron while retaining 80-90% of its thermal conductivity. However, CGI typically exhibits higher wear rates and reaches higher operating temperatures than gray iron when used with standard friction materials. CGI applications require careful material matching—proper pad selection is essential to achieve acceptable wear life and thermal performance.

Aluminum metal matrix composites (Al-MMC) offer dramatic weight reductions—typically 50-60% lighter than cast iron rotors. These materials consist of aluminum alloy matrices reinforced with silicon carbide or aluminum oxide particles. Al-MMC rotors provide excellent thermal conductivity and corrosion resistance. However, they exhibit approximately 25% higher friction coefficients than cast iron, creating different system dynamics that may trigger ABS or stability control interventions if not properly calibrated. Additionally, Al-MMC rotors cause different wear patterns on pad materials, often requiring specially formulated pads. Cost remains prohibitive for mainstream applications—Al-MMC rotors typically cost 3-5 times more than cast iron equivalents.

Carbon ceramic rotors represent the ultimate performance solution. These materials consist of carbon fiber reinforcement in a silicon carbide matrix, produced through complex manufacturing processes involving carbonization and silicon infiltration at high temperatures. Carbon ceramic rotors resist fade to temperatures exceeding 1,800°F, weigh 50% less than cast iron, and can last 100,000+ miles with proper use. However, they cost 10-20 times more than cast iron rotors and require specifically formulated pads. Carbon ceramic technology remains limited to exotic sports cars and extreme performance applications where cost is secondary to performance.

Surface treatments extend rotor life and improve initial performance. High-velocity oxygen fuel (HVOF) coating processes apply thin layers of carbide or oxide materials to rotor surfaces, improving wear resistance and corrosion protection. Laser cladding with materials like Inconel 718 can improve tribological properties and enable rotor refurbishment—research shows cladded surfaces exhibit twice the hardness of base gray iron with excellent adhesion. Nitriding processes diffuse nitrogen into surface layers, creating extremely hard surface zones (700-900 HV) that resist wear and heat checking. However, surface treatments add cost and complexity, limiting their use to premium or specialized applications.

Balancing Performance Requirements

Brake material selection involves navigating competing requirements that cannot be simultaneously optimized. High friction coefficients improve stopping power but often increase wear rates and may compromise noise characteristics. Fade resistance requires high-temperature binders and heat-resistant constituents that sometimes provide poor cold-weather performance. Long wear life typically requires harder, more durable materials that may be noisier or more expensive. Environmental compliance restricts certain high-performance ingredients like copper or antimony compounds.

Daily driving applications prioritize balanced performance across wide operating ranges. Materials must provide adequate friction from cold starts at 0°F to moderate temperatures around 500°F. They should exhibit long wear life (50,000+ miles), low dust generation to prevent wheel discoloration, and quiet operation under all conditions. Cost constraints typically limit formulations to approximately $20-40 per axle set for aftermarket replacement pads.

Heavy-duty applications emphasize thermal stability and fade resistance. Materials must maintain friction coefficients through repeated hard braking from high speeds, sustaining temperatures of 800-1,000°F for extended periods. Wear life, while important, is secondary to preventing fade and maintaining stopping power. These applications often accept higher noise levels, increased dust, and premium pricing in exchange for superior thermal performance.

Performance and track applications push tribological limits. Materials must resist fade at extreme temperatures (1,200-1,600°F), provide aggressive initial bite even when cold, and maintain consistent friction through temperature cycling. Wear rates become less critical—performance pads might last only 10,000-20,000 miles on street use—because applications involving sustained hard braking consume pads rapidly regardless of formulation. These materials often exhibit poor noise characteristics and may not perform well in normal street driving because they require heat to reach optimal operating conditions.

The integration of regenerative braking in hybrid and electric vehicles creates new tribological requirements. Friction brakes in these vehicles often experience extended periods without use as regenerative systems handle routine braking. This infrequent use can allow rust formation on rotor surfaces and may prevent proper transfer layer maintenance. New friction material formulations address this challenge through more aggressive rotor-conditioning abrasives and materials that maintain function despite irregular use patterns.

Looking forward, emerging regulations restricting heavy metals, continuing pressure to reduce particulate emissions, and demands for improved noise characteristics will drive continued material innovation. Research focuses on bio-based friction materials using renewable ingredients, nanoengineered composites with precisely controlled structures, and adaptive materials that modify their friction properties based on operating conditions. The science of brake tribology continues advancing, ensuring safer, more durable, and more environmentally friendly braking systems.

Practical Implications for Vehicle Owners

Understanding brake tribology provides valuable insights for making informed decisions about brake service, component selection, and maintenance practices. While professional service remains essential for safety-critical brake work, knowledge of tribological principles helps vehicle owners optimize brake performance and longevity.

Choosing Appropriate Brake Components

Component selection significantly impacts brake performance, longevity, and satisfaction. The “best” brake materials depend entirely on specific use requirements, climate conditions, and personal priorities.

For daily commuting in moderate climates, mid-grade ceramic or low-metallic pads provide optimal balance. These materials offer consistent friction from cold starts, adequate fade resistance for typical driving (rarely exceeding 500°F), quiet operation, and 40,000-60,000 mile service life. Ceramic formulations excel in reducing brake dust—important for maintaining wheel appearance—and provide quieter operation but sometimes cost 20-30% more than low-metallic alternatives. Low-metallic pads may generate more dust but often provide slightly better cold-weather bite and cost less. Standard gray cast iron rotors serve these applications well—premium rotors offering minimal benefits that don’t justify cost premiums.

Cold climate driving requires materials maintaining friction at low temperatures. Some high-performance pads optimized for fade resistance perform poorly below 100°F, requiring several brake applications before reaching effective friction levels. Standard OEM-replacement pads typically optimize for broad temperature ranges including cold-weather operation. Corrosion resistance becomes more important in winter environments where road salt accelerates rotor deterioration—consider coated rotors or frequent driving to prevent rust buildup during extended non-use periods.

Towing and hauling applications demand thermal management. Heavier loads create significantly higher thermal stress during braking—descending mountain grades with trailers can sustain brake temperatures above 800°F for 10-15 minutes continuously. Heavy-duty friction materials using high-temperature binders and fade-resistant formulations are essential. These pads might sacrifice some cold-weather performance and generate more dust but maintain crucial fade resistance. Upgraded rotors featuring thicker cross-sections or improved ventilation help dissipate thermal loads. Some applications benefit from auxiliary braking systems—exhaust brakes or electromagnetic retarders—that reduce reliance on friction brakes during sustained descents.

Performance driving including track days or aggressive mountain driving pushes beyond daily-driver material capabilities. Track-oriented pads use racing-derived formulations that resist fade to 1,200-1,600°F, provide aggressive bite even when cold, and maintain consistent friction through temperature cycling. However, these materials exhibit significant compromises for street use: shortened wear life (often 10,000-20,000 miles even in daily driving), excessive dust generation, potential noise issues, and sometimes poor cold-weather operation because materials require heat to reach optimal friction. Additionally, aggressive pads often accelerate rotor wear, requiring more frequent rotor replacement. Many performance enthusiasts maintain two brake pad sets—street pads for daily driving and track pads installed before competition events.

Matching pad and rotor materials is essential. Aggressive pads paired with soft rotors create unacceptable rotor wear. Conversely, mild pads on very hard rotors may not establish proper transfer layers, resulting in poor performance and potential noise. When replacing either component, verify compatibility—pad manufacturers typically specify appropriate rotor hardness ranges, and rotor manufacturers identify compatible pad types.

Proper Bedding-In Procedures

New brake pads and rotors require careful break-in to establish optimal transfer layers and achieve maximum performance. The bedding process creates the initial friction film, ensures proper contact geometry, and sets the foundation for consistent operation throughout component life.

Typical bedding procedures involve 6-10 moderate stops from 40-60 mph, applying firm but not maximum pedal pressure to heat components without inducing fade. After each stop, immediately accelerate back to speed without allowing complete vehicle stops—this prevents localized transfer layer buildup that can create uneven friction. The entire sequence should heat pads and rotors to approximately 400-500°F—visible as a slight blue tinge on rotors after cooling. After completing the bedding sequence, drive at moderate speeds for 5-10 minutes without braking, allowing components to cool gradually. Avoid hard braking or sustained slow-speed driving for the first 200-300 miles while transfer layers fully stabilize.

Performance pads often require more aggressive bedding. Track-oriented materials may specify 10-15 hard stops from 70-80 mph to rapidly develop transfer layers under conditions similar to actual competition use. Some racing pads never achieve optimal performance in street driving because they require sustained high temperatures to complete bedding properly.

Consequences of improper bedding include uneven transfer layer formation creating friction variation (pedal pulsation), reduced friction coefficients potentially increasing stopping distances 10-20%, accelerated wear from improper contact geometry, and brake noise from unstable friction behavior. The time invested in proper bedding—typically 30-45 minutes—pays dividends in performance, longevity, and satisfaction throughout component life.

Maintenance Best Practices

Regular inspection prevents minor issues from becoming safety hazards or expensive repairs. Recommended inspection intervals include every 12,000-15,000 miles or annually, whichever occurs first. This inspection should assess pad thickness (replace when 2-3mm remaining), rotor thickness (measure and compare to stamped minimum), surface condition checking for heat checking, cracks, or severe rust, caliper operation verifying slide pins move freely, and brake fluid condition (clear amber color indicates good condition, dark brown suggests contamination or age-related degradation).

Caliper maintenance often receives insufficient attention despite critically affecting brake tribology. Sticking caliper slides or seized guide pins prevent proper pad-to-rotor contact, creating uneven wear patterns and reduced performance. At each inspection, guide pins should be removed, cleaned of old grease and contaminants, inspected for corrosion or damage, and relubricated with high-temperature synthetic brake grease. Similarly, caliper pistons should fully retract without binding—sluggish piston movement indicates seal degradation requiring caliper service or replacement.

Cleaning brake components during maintenance improves performance and enables better inspection. Brake dust accumulation on calipers, pad backing plates, and rotor vents reduces heat dissipation and can embed into surfaces affecting friction. Use brake parts cleaner—never use petroleum-based cleaners or compressed air that can embed particles into friction surfaces. Wheel wells should be cleaned regularly to remove road salt and corrosive chemicals that accelerate component deterioration.

Recognizing Tribological Failure Modes

Understanding tribological principles helps identify problems requiring professional attention. Glazed pads—those with shiny, hardened surfaces—result from overheating causing binder material to carbonize into glassy layers. Glazed pads exhibit substantially reduced friction and cannot be restored through cooling—the affected surface layer requires removal through resurfacing or pad replacement. Glazing typically results from sustained hard braking (mountain descents without downshifting), excessive loads (towing beyond rated capacity), or riding brakes during driving.

Uneven pad wear patterns indicate underlying mechanical problems. Tapered wear—one end of the pad significantly thinner—suggests seized caliper slides preventing proper floating movement. Inner pad wearing faster than outer (or vice versa) indicates piston problems, caliper mounting issues, or hydraulic pressure imbalance. These wear patterns not only shorten component life but compromise braking effectiveness and safety. Addressing root causes—typically caliper service—is essential rather than just replacing worn pads.

Excessive dust generation beyond normal levels indicates accelerated wear from improper material matching, contaminated friction surfaces, or mechanical problems causing uneven contact. While all brakes generate dust, excessive accumulation (requiring weekly cleaning to maintain appearance) suggests problems requiring investigation.

Noise and vibration represent tribological instability. High-pitched squealing results from friction-induced vibrations at audio frequencies—often caused by improper bedding, contamination, or worn pads exposing backing plate. Low-frequency groaning indicates stick-slip friction behavior from improper lubrication or contaminated surfaces. Grinding noises signal metal-to-metal contact—complete pad wear allowing backing plates to contact rotors, creating severe damage requiring rotor replacement in addition to pads. Any new or worsening brake noise warrants inspection—early intervention prevents expensive damage and maintains safety margins.

When to Seek Professional Service

While understanding tribology enhances knowledge, brake system work requires specialized tools, technical knowledge, and safety awareness that most DIY enthusiasts lack. Professional service is essential for caliper rebuilds or replacement requiring brake fluid system opening and bleeding, rotor replacement ensuring proper installation torque and runout specifications, hydraulic system diagnosis addressing master cylinder, brake booster, or line issues, ABS or electronic system problems requiring scan tools and specialized knowledge, and any situation where brake performance or safety is questionable.

Even intermediate DIY mechanics comfortable with pad replacement should recognize limitations. Improper brake service—incorrect pad installation, contaminated friction surfaces, inadequate caliper servicing, or missed mechanical problems—creates safety hazards. The few hundred dollars saved through DIY brake work provides poor value if work quality is insufficient or problems are missed that compromise stopping ability.

Professional brake specialists possess training, experience, and equipment unavailable to most DIY enthusiasts: precision measurement tools for accurate thickness and runout assessment, proper brake bleeding equipment ensuring complete air removal, diagnostic scan tools for electronic system analysis, and specialized knowledge of manufacturer-specific procedures and specifications. Perhaps most valuable, experienced technicians recognize subtle symptoms indicating developing problems, enabling proactive intervention before component failure.

Understanding brake tribology shouldn’t encourage inappropriate DIY work but rather facilitates informed communication with professional technicians, enables better component selection decisions, helps recognize symptoms indicating problems, and provides knowledge for proper vehicle operation and maintenance planning. Your vehicle’s braking system represents the most critical safety system—treat it accordingly through regular professional maintenance and immediate attention to any performance changes.

Conclusion: The Future of Brake Tribology

The science of brake tribology—studying friction, wear, and thermal management at pad-rotor interfaces—represents a mature yet continuously evolving field. Understanding how transfer layers form between brake pads and rotors, why friction coefficients vary with operating conditions, and how thermal dynamics affect fade characteristics provides insights into one of automotive engineering’s most critical yet often overlooked technologies.

Several trends will shape brake tribology’s future. Environmental regulations continue restricting heavy metals and requiring reduced particulate emissions. The industry has successfully eliminated asbestos and is actively reducing copper content to protect aquatic ecosystems from brake dust contamination. Future regulations may target additional constituents, requiring continuous material innovation to maintain performance while improving environmental compatibility. Research into bio-based friction materials using renewable ingredients shows promise—cashew particles, natural fibers, and organic binders may partially replace petroleum-derived and mined materials.

The proliferation of hybrid and electric vehicles fundamentally changes brake system usage patterns. When regenerative braking handles routine deceleration, friction brakes may remain unused for extended periods. This infrequent use creates challenges: rotor rust accumulation between uses, transfer layer degradation from lack of maintenance, and potential complications from long component life (pads lasting 100,000+ miles might exceed their shelf life before wearing out mechanically). New friction materials must function reliably despite irregular use while providing full emergency stopping capability when needed.

Advanced driver assistance systems and eventual autonomous vehicles will change brake tribology requirements. Automated emergency braking subjects brake systems to computer-controlled maximum-effort stops rather than modulated driver inputs. Adaptive cruise control and traffic jam assist create different brake usage patterns than traditional driving. Future brake materials must accommodate these changing use cases while maintaining reliability and performance.

Material science advances enable capabilities impossible with conventional materials. Nanoengineered friction materials with precisely controlled structures optimize friction and wear behavior at molecular levels. Adaptive materials that modify properties based on operating conditions—increasing friction when cold, enhancing fade resistance when hot—represent research frontiers. Advanced rotor coatings applied through laser cladding or thermal spray processes extend service life and enable component refurbishment rather than replacement.

Despite these innovations, fundamental tribological principles remain unchanged. Brake systems will continue converting kinetic energy into thermal energy through friction. Transfer layers will remain essential for stable friction and controlled wear. Thermal management will always challenge engineers as vehicle weights increase and performance expectations grow. Understanding these principles—the science of how brake pad rotor tribology works—provides foundation for appreciating both current technology and future innovations.

For vehicle owners, respecting brake tribology’s complexity means recognizing that simple components involve sophisticated science. Proper material selection matching use requirements, correct bedding procedures establishing optimal transfer layers, regular maintenance preserving mechanical function, and immediate attention to performance changes all contribute to safe, reliable brake operation. While modern brake systems provide outstanding performance and durability when properly maintained, they remain safety-critical components requiring professional service and careful attention.

The science is complex, but the message is simple: Your brakes depend on tribology working correctly. Understanding the science helps you make better decisions about maintenance and component selection. Professional service ensures the science translates into safety. Any unusual brake behavior—noise, vibration, reduced effectiveness, warning lights, or changes in pedal feel—requires immediate professional inspection. Never compromise on brake service—your life and others’ lives depend on proper brake function.

For comprehensive information about brake system components and maintenance, explore our complete brake system guides and vehicle safety resources.