Every time you drive, four small components silently support thousands of pounds while rotating at highway speeds, handling forces that would destroy lesser parts in minutes. Wheel bearings make modern driving possible by enabling smooth wheel rotation with minimal friction while simultaneously managing the extreme vertical loads from your vehicle’s weight, lateral forces during cornering, and impact forces from road irregularities. When these precision-engineered components fail, the consequences range from annoying humming noises to catastrophic wheel detachment at highway speeds.

Understanding how wheel bearings work helps you recognize early warning signs of failure, make informed decisions about repairs, and appreciate why proper maintenance and timely replacement are critical safety priorities. This guide explains the mechanical operation of different bearing types, identifies symptoms that indicate bearing problems, provides realistic lifespan expectations, and clarifies when professional service becomes necessary.

You’ll learn how ball bearings differ from tapered roller designs, why modern hub assemblies integrate multiple functions, what causes the characteristic humming noise of a failing bearing, and whether replacement is something you can tackle yourself or should leave to professionals. We’ll also cover realistic cost expectations, typical service life under various conditions, and the relationship between wheel bearings and critical safety systems like ABS and electronic stability control. Whether you’re diagnosing an unusual noise, planning for future maintenance, or simply curious about how your vehicle’s wheels stay attached while spinning thousands of times per mile, this comprehensive guide provides the knowledge you need.

What Are Wheel Bearings?

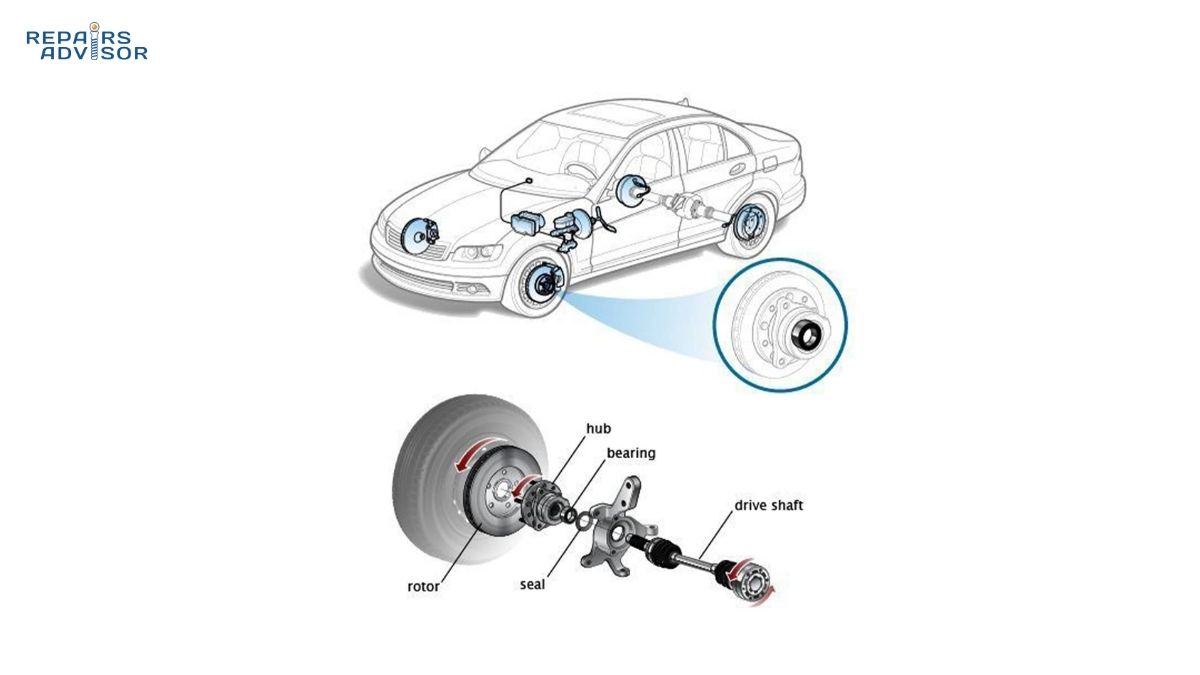

Wheel bearings are precision-engineered assemblies consisting of steel balls or rollers housed within metal rings called races, located inside the wheel hub assembly where they connect each wheel to its axle or spindle. These components serve three primary functions: they reduce friction to enable smooth wheel rotation, support the entire weight of the vehicle distributed across four contact patches, and handle the complex combination of radial loads from vehicle weight and axial loads from cornering and braking forces.

The fundamental engineering principle behind wheel bearings is elegantly simple yet remarkably effective. Rolling creates significantly less friction than sliding, which is why ancient civilizations independently discovered the wheel. A wheel bearing takes this principle and perfects it through precision manufacturing, creating a system where hardened steel balls or rollers rotate between two smooth, precisely machined surfaces. These rolling elements distribute the vehicle’s weight across their contact points rather than concentrating force at a single location, which would quickly cause wear and failure.

Modern sealed wheel bearings prevent contamination while retaining lubrication throughout their service life. The seal design represents a critical engineering challenge because it must prevent water, dirt, and road salt from entering the bearing while allowing thermal expansion and preventing grease from leaking out. High-temperature grease inside the bearing provides a protective film between metal surfaces, further reducing friction and preventing corrosion. The precision machining required for wheel bearings is extraordinary, with tolerances measured in thousandths of an inch to ensure smooth operation at all speeds and under all load conditions.

Each wheel bearing assembly contains several key components working together. The inner race, also called the cone, is fixed to the rotating spindle or axle and rotates with the wheel. The outer race, called the cup, remains stationary within the hub or steering knuckle and provides the outer rolling surface. Between these two races, the rolling elements—either balls or rollers—carry the actual load while minimizing friction through their rolling motion.

The cage, also called a retainer, separates and positions the rolling elements at even intervals around the bearing circumference. Without this cage, the balls or rollers would bunch together, creating uneven load distribution and rapid wear. Seals on both sides of the bearing prevent contaminants from entering while keeping the high-temperature grease inside where it belongs. This grease must withstand extreme conditions, from sub-zero temperatures in winter to over 200°F during normal operation and even higher temperatures near brake components.

On drive wheels, the bearing must also accommodate the CV joint or axle shaft passing through its center, adding complexity to the design. Modern bearings often integrate the ABS wheel speed sensor directly into the hub assembly, creating a multi-functional component that serves both mechanical and electronic purposes. This integration simplifies installation and reduces wiring complexity but also means bearing replacement affects your vehicle’s anti-lock braking and stability control systems.

Professional mechanics understand that modern sealed bearings are non-serviceable units requiring complete replacement when worn. Unlike older serviceable bearings that allowed periodic greasing and adjustment, today’s sealed designs sacrifice serviceability for superior reliability, longer life, and elimination of maintenance requirements. This design philosophy shift occurred because proper bearing adjustment required skill and experience, and incorrect adjustment caused premature failure. Sealed bearings eliminate these variables, though at the cost of higher replacement prices when they eventually wear out.

Types of Wheel Bearings

Ball Bearings

Ball bearings use spherical steel balls rolling between precisely machined inner and outer races, creating point contact that allows rotation with minimal friction. This design represents the most common bearing type in modern passenger vehicles because it offers an excellent balance of load capacity, friction characteristics, and packaging efficiency. The balls are typically hardened chrome steel, heat-treated to achieve extraordinary hardness while maintaining some flexibility to prevent brittle fracture under impact loads.

The geometry of ball bearings provides several important advantages for automotive applications. Because the contact between ball and race is theoretically a single point, rolling friction is minimized compared to the line contact of roller bearings. This lower friction translates directly into better fuel efficiency, a critical consideration in modern vehicle design. The compact nature of ball bearing design allows engineers to fit them into tight spaces, particularly important in front-wheel-drive vehicles where packaging constraints are severe.

Ball bearings handle both radial loads (perpendicular to the axis) and axial loads (parallel to the axis) effectively within their design limits. Modern angular contact ball bearings used in wheel applications are specifically designed with contact angles that optimize their ability to handle the combined loads experienced during driving. When you corner, the outside wheels experience both increased vertical load and lateral force trying to push the wheel sideways—ball bearings manage both simultaneously.

The sealed-for-life design common in modern ball bearing hub assemblies means the bearing, hub, and often the wheel speed sensor are integrated into a single unit. This integration eliminates external adjustment, prevents contamination through superior sealing, and simplifies replacement by converting a complex press-fit operation into a straightforward bolt-on procedure. However, this convenience comes at a price, as you must replace the entire assembly rather than just the bearing itself.

Typical applications for ball bearings include front-wheel-drive passenger cars where their compact design and lower friction benefit fuel economy, light-duty trucks and SUVs where loads remain within ball bearing capacity, and any modern vehicle using hub bearing assemblies with integrated ABS sensors. The quieter operation of ball bearings compared to roller designs also makes them preferable for passenger comfort, particularly in luxury vehicles where noise, vibration, and harshness receive intense engineering attention.

Tapered Roller Bearings

Tapered roller bearings employ cone-shaped rollers arranged between inner and outer rings that are themselves tapered segments, creating a design where all the geometric centerlines converge at a single point on the bearing’s axis. This geometry ensures pure rolling motion without any sliding, which would generate heat and cause rapid wear. The larger contact area created by the roller’s line contact compared to a ball’s point contact allows tapered roller bearings to handle significantly higher loads.

The construction of tapered roller bearings separates the inner ring (cone) and outer ring (cup) as distinct components, unlike ball bearings where the assembly is typically pressed together. The rollers themselves ride on angled surfaces with the small end of the cone toward the bearing center and the large end toward the outer diameter. A flange on the inner ring prevents the rollers from being expelled by the “pumpkin seed effect” where the tapered shape would otherwise push them out during rotation.

This design excels at handling combined radial and axial loads simultaneously, making it ideal for wheel bearing applications where cornering creates substantial lateral forces. A tapered roller bearing can support much higher loads than a similarly sized ball bearing because the line contact between roller and race distributes force over a larger area, reducing contact stress and extending fatigue life. This advantage becomes critical in trucks, SUVs, and any vehicle expected to carry heavy loads or tow trailers.

Traditional tapered roller bearings required periodic adjustment to set proper preload—the controlled amount of interference fit that eliminates play while not creating excessive friction. Mechanics adjusted these bearings by tightening the bearing nut while rotating the wheel to seat the components, then backing off the nut a precise amount. This procedure required skill and judgment because too tight caused heat and premature wear while too loose allowed play that pounded out the races. Modern sealed tapered roller bearing assemblies eliminate this adjustment requirement by setting preload during manufacturing.

Applications for tapered roller bearings include rear-wheel-drive vehicles (particularly on non-driven rear axles), heavy-duty trucks and full-size SUVs, trailer axles where extreme loads and lower speeds favor the design, and classic vehicles where serviceable bearings allow periodic maintenance. Some high-performance vehicles use tapered roller bearings specifically for their superior load capacity during aggressive cornering, even though ball bearings might otherwise suffice.

Hub Bearing Assembly (Modern Integrated Design)

The hub bearing assembly represents the third generation of wheel bearing technology, integrating the bearing, hub, mounting flange, and often the ABS sensor into a single sealed unit. This design philosophy prioritizes reliability, ease of installation, and elimination of adjustment over serviceability and cost. The bearing itself may use ball or tapered roller elements, but what distinguishes the hub assembly is the integration of previously separate components into one cohesive unit.

These assemblies bolt directly to the steering knuckle or axle housing without requiring specialized tools for installation. The preload is set during manufacturing and cannot be adjusted in service. The ABS reluctor ring (the toothed wheel that the wheel speed sensor reads) is often integrated into the bearing seal, ensuring precise sensor gap and eliminating a separate component. This integration improves reliability because the sensor gap cannot change due to wear or improper installation.

The sealed-for-life lubrication in hub assemblies uses specialized greases capable of maintaining their properties through extreme temperature cycling and remaining stable for 100,000+ miles. The seal design prevents water penetration even during deep water crossings, though driving through hub-deep water repeatedly can eventually compromise even the best seals. The complete sealing also prevents road salt and contaminants from reaching the bearing elements, addressing one of the primary failure modes of older serviceable bearings.

Advantages of hub bearing assemblies include complete elimination of adjustment procedures and the resulting installation errors, superior contamination protection through advanced seal designs, reduced installation time for service facilities, integration with ABS systems and traction control, and consistent, predictable performance throughout the service life. These benefits explain why virtually all modern vehicles use this design despite the higher replacement cost.

The trade-offs are significant but considered acceptable by manufacturers and most consumers. Hub assemblies cost substantially more than individual bearings, typically $150-$350 compared to $50-$150 for a standalone bearing. You cannot service them—when the bearing fails, you replace the entire assembly even if the hub and other components are perfect. Minor seal damage that would allow greasing and continued service in an old-style bearing necessitates complete replacement in a hub assembly. However, these disadvantages are offset by dramatically reduced maintenance requirements and superior reliability in typical use.

How Wheel Bearings Work: Operational Mechanics

Understanding the operational mechanics of wheel bearings reveals how these components manage the extreme conditions they face during normal driving. A single wheel bearing might support 500-1,200 pounds of static vehicle weight, then handle dynamic loads exceeding 3,000 pounds when you hit a pothole at highway speed, all while rotating smoothly enough that you never notice its presence until something goes wrong.

The load distribution process begins with vehicle weight pressing down on the suspension, which transfers force through the steering knuckle or axle housing to the outer race of the wheel bearing. This outer race remains stationary, held firmly in the hub or knuckle. The load then transfers through the rolling elements—balls or rollers—which distribute it across their contact points rather than concentrating it at a single location. Finally, the inner race receives this distributed load and transfers it to the axle or spindle.

When the wheel rotates, the inner race spins with the wheel assembly while the outer race remains stationary. The rolling elements rotate between these two races at approximately half the wheel’s rotational speed—they’re rolling against both the inner race moving in one direction and the outer race which is stationary, so their actual rotational speed splits the difference. The cage maintaining spacing between rolling elements also rotates, typically at the same speed as the rolling elements themselves, ensuring even load distribution and preventing elements from bunching together.

The friction reduction mechanism that makes this system so effective relies on several interacting factors. Rolling contact inherently creates about 90% less friction than sliding contact between the same materials under the same load. The high-temperature grease inside the bearing forms a microscopic protective film on all metal surfaces, further reducing friction and preventing direct metal-to-metal contact. Precision manufacturing tolerances of 0.001 inches or less ensure that surfaces remain smooth and properly aligned, minimizing any sources of resistance or vibration.

Heat management becomes critical because friction always generates some heat, and wheel bearings operate adjacent to brake components that can exceed 700°F during hard braking. Normal bearing operation generates 100-200°F internally, which the grease must withstand without breaking down or liquefying. Heat conducts through the hub assembly and dissipates to the surrounding air and wheel, but sustained high-speed driving or repeated heavy braking can temporarily push bearing temperatures significantly higher. The seal materials must survive this thermal cycling while maintaining their sealing effectiveness.

During operation, wheel bearings handle three distinct types of forces simultaneously. Radial forces act perpendicular to the axle, primarily from vehicle weight but also from road impacts when you hit bumps or potholes. A significant pothole impact can generate forces up to three times the static weight on that wheel—momentarily loading a bearing designed for 800 pounds with 2,400 pounds of impact force. Bearings incorporate safety factors of 4-6 times their rated load to handle these occasional extreme events without damage.

Axial forces act parallel to the axle, primarily from cornering but also from road crown (the slight tilt that allows water drainage). When you corner at highway speed, lateral acceleration can reach 0.5G or more, generating substantial sideways force trying to push the wheel away from the vehicle. This force must transmit through the bearing without causing excessive deflection or wear. Tapered roller bearings handle axial loads more effectively than ball bearings due to their larger contact area and optimized geometry.

Combined loading occurs continuously during real-world driving as you navigate curves while traveling over uneven pavement. The bearing must simultaneously handle vertical weight, lateral cornering force, and longitudinal forces from acceleration and braking. This complex loading explains why bearing design and material selection are so critical—the bearing must perform reliably under conditions that would quickly destroy a component not specifically engineered for the application.

The relationship between wheel bearings and vehicle safety systems demonstrates the integrated nature of modern automotive design. The wheel speed sensors that enable ABS, traction control, and stability control mount directly to or integrate with the wheel bearing. These sensors read a reluctor ring (toothed wheel) that rotates with the bearing, providing the vehicle’s computers with precise wheel speed information dozens of times per second. When a bearing develops excessive play, it can affect sensor operation, potentially triggering ABS or traction control warning lights even before you hear audible symptoms.

Symptoms of Wheel Bearing Failure

Recognizing wheel bearing failure symptoms early can prevent more serious damage, reduce repair costs, and most importantly, avoid the catastrophic consequences of complete bearing failure at highway speeds. The symptoms progress through identifiable stages, typically starting with subtle audible warnings and escalating to severe mechanical problems if ignored.

The most common and easily identifiable symptom is noise—specifically a humming, droning, growling, or grinding sound that increases with vehicle speed. This noise results from wear in the bearing races creating irregular surfaces that the rolling elements encounter with each rotation. In early stages, you might hear a faint humming at highway speeds that sounds similar to tire noise. As wear progresses, the noise becomes a louder droning that distinctly changes pitch with vehicle speed, following the wheel rotation rather than engine speed.

Advanced bearing wear produces growling or rumbling sounds that indicate significant damage to the races or rolling elements. These deeper, more aggressive noises mean the bearing has progressed beyond minor wear into serious degradation. In final stages before complete failure, you’ll hear grinding—the unmistakable sound of metal-on-metal contact indicating that protective grease has been lost and bearing components are destroying themselves. Some bearings also produce clicking or popping sounds, particularly during turns, which usually indicates the cage has broken or rolling elements have begun to separate.

Performing a diagnostic sound test helps identify which wheel has the failing bearing. Find a safe, empty stretch of road with good visibility and minimal traffic. Drive at a steady 40-50 mph to establish baseline noise, then make gentle left and right turns while maintaining constant speed. Load shifts to the outside wheels during cornering, so noise that increases during left turns typically indicates a failing right-side bearing, while noise increasing during right turns suggests left-side bearing failure. This test works because loading the failing bearing increases the pressure on damaged surfaces, amplifying the noise.

Physical symptoms often accompany or follow audible warnings. Steering feel may become loose or imprecise due to excessive play in the bearing allowing small amounts of wheel movement. This play might manifest as vibration in the steering wheel, particularly at highway speeds where small imbalances create noticeable oscillations. Some vehicles pull slightly to one side with a failing bearing, though this symptom is easily confused with alignment issues or tire problems. Uneven tire wear—particularly excessive wear on the inner or outer edge of a single tire—can result from the wheel tilting slightly due to bearing play.

The brake system may exhibit symptoms related to bearing failure because of the proximity between these components. Modern integrated hub assemblies include the ABS wheel speed sensor, so bearing play can affect sensor operation and illuminate the ABS warning light on your dashboard. You might notice reduced brake performance or increased pedal travel if bearing play allows the rotor to move slightly, changing the relationship between rotor and brake caliper. Some drivers report a pulsing sensation in the brake pedal similar to ABS activation but occurring during normal braking.

Visible inspection with the wheel removed can reveal bearing problems. Excessive heat around the wheel hub after driving suggests a bearing generating unusual friction. You might see grease leaking from the hub assembly if the seal has failed, though this is less common with modern sealed bearings. With the wheel jacked up and secured, grasp the tire at 12 o’clock and 6 o’clock positions and rock it—any noticeable movement indicates excessive bearing play. Similarly, grasping at 3 o’clock and 9 o’clock and rocking should show no movement. Any clunking or grinding you feel or hear during this test confirms bearing wear.

Understanding symptom severity helps prioritize repair urgency. Early stage symptoms include faint humming noticeable only at highway speeds, with no handling changes or visible issues. At this stage, you can safely schedule repair within one to two weeks. Intermediate stage symptoms feature loud growling noise, noticeable vibration, possible ABS light illumination, and should prompt repair scheduling within a few days. Critical stage symptoms demand immediate professional service—grinding noises, severe wheel wobble, significant handling degradation, and risk of catastrophic failure that could cause wheel detachment.

Never ignore wheel bearing failure symptoms. A completely failed bearing can allow the wheel to separate from the vehicle at highway speeds, resulting in immediate loss of control and potentially causing serious multi-vehicle accidents. While bearings rarely fail suddenly without warning, once symptoms reach critical stages, catastrophic failure can occur with little additional notice. The cost of ignoring bearing problems far exceeds the repair expense when you factor in the safety risks and potential for secondary damage to suspension, brake, and steering components.

Wheel Bearing Lifespan and Maintenance

Modern wheel bearings typically last 85,000 to 100,000 miles under normal driving conditions, though this range varies considerably based on how you drive, where you drive, and how well you maintain related vehicle systems. Well-maintained vehicles in moderate climates with gentle driving habits regularly achieve 120,000 to 150,000+ miles on original bearings. Conversely, harsh conditions can cause bearing failure as early as 60,000 miles even in vehicles with otherwise excellent maintenance records.

Environmental factors significantly affect bearing lifespan, with water exposure ranking among the most destructive. Driving through deep water that reaches the wheel hubs risks forcing water past the seals through hydraulic pressure, diluting the grease and introducing contaminants. A single deep water crossing might not cause immediate failure, but repeated exposure gradually compromises seal integrity and bearing lubrication. Road salt accelerates this process by promoting corrosion of bearing surfaces and degrading seal materials, explaining why vehicles in northern climates often require more frequent bearing replacement than identical models in the south.

Mud and dust create abrasive contamination when they penetrate bearing seals, essentially creating a grinding paste that accelerates wear. Off-road driving exposes bearings to extreme contamination risk, particularly when crossing water or deep mud. Extreme temperature cycling—from sub-zero winter temperatures to summer heat exceeding 100°F combined with brake heat—stresses seal materials and affects grease properties. Bearings must maintain effectiveness across this entire temperature range while dealing with thermal expansion and contraction of all components.

Mechanical factors often cause premature bearing failure even in otherwise favorable conditions. Improper installation torque ranks as a leading cause of early failure because wheel bearing preload must fall within precise specifications. Overtightening crushes the bearing elements and creates excessive friction that generates heat and accelerates wear. Undertightening allows play that lets the bearing pound itself to destruction through impact loading. Many hub nuts are torque-to-yield designs requiring one-time use—reusing these fasteners compromises the precise clamping force needed for proper bearing life.

Impact damage from potholes, curb strikes, and excessive speed over speed bumps can instantly damage bearing races, creating the pitted or brinelled surfaces that generate noise and accelerate failure. A single severe impact might not cause immediate symptoms, but the damage accumulates over subsequent miles until failure becomes evident. Overloading your vehicle beyond its rated capacity increases bearing stress beyond design limits, particularly affecting the bearings on the more heavily loaded axle. Vehicle manufacturers specify load limits for good reason—exceeding them shortens the life of bearings, suspension components, brakes, and tires.

Unbalanced wheels create vibration that translates into dynamic loading on wheel bearings, accelerating wear through rapid load cycling. What might seem like a minor vibration from a lost wheel weight actually subjects bearings to thousands of additional load cycles per mile. Similarly, worn suspension components transfer excessive loads to bearings because the suspension can’t properly control wheel motion. A worn control arm bushing or shock absorber allows movement that increases dynamic loading on bearings.

Modern sealed bearings require no periodic maintenance under normal circumstances. The “sealed for life” lubrication means you never add grease or adjust preload. The best preventive maintenance involves inspecting bearings during routine brake service or tire rotations. Listen for unusual noises during test drives, check for play when the wheel is jacked up, and inspect seal integrity for any signs of leaking. If you notice any symptoms, have the bearing professionally evaluated rather than waiting for complete failure.

Older serviceable bearings required repacking with grease every 30,000-40,000 miles, a procedure involving complete disassembly, cleaning, inspection, fresh grease application, reassembly, and careful preload adjustment. This maintenance-intensive approach gave way to sealed designs because proper bearing service required skill and time that many owners and even some service facilities lacked. Incorrect adjustment caused more premature failures than it prevented, driving the industry toward maintenance-free sealed units.

For specific maintenance intervals and procedures, consult factory service information for your vehicle make and model. Ford service manuals, Toyota service manuals, and Chevrolet service manuals provide manufacturer-specific torque specifications, installation procedures, and diagnostic procedures. Following these specifications ensures proper bearing life and prevents premature failure from installation errors.

Wheel Bearing Replacement: Process and Costs

Professional wheel bearing replacement follows a systematic procedure requiring specific tools, precise torque specifications, and thorough understanding of brake and suspension systems. The general process begins by lifting the vehicle and securing it on jack stands, then removing the wheel and tire assembly. The brake caliper must be removed and suspended with wire to prevent stress on the brake hose—never let the caliper hang by its hydraulic line. The brake rotor or drum comes off next, followed by disconnecting the ABS sensor wiring if the bearing assembly includes an integrated sensor.

For hub bearing assemblies, several mounting bolts secure the unit to the steering knuckle or axle housing. These bolts typically require significant torque to remove, particularly on older vehicles where corrosion has occurred. Once these bolts are removed, the hub assembly slides out, making this style of bearing relatively straightforward to replace. However, press-in bearing designs require special tools to extract the old bearing from the hub or knuckle without damage, then press the new bearing in with perfect alignment. This process demands a hydraulic press, proper support fixtures, and experience to avoid damaging the new bearing during installation.

Installation reverses the removal process but demands meticulous attention to critical specifications. The new bearing must align perfectly in its bore—even slight misalignment during pressing causes immediate damage. Cleanliness is essential because any contamination introduced during installation accelerates wear. The hub nut or axle nut requires torquing to the exact manufacturer specification, typically 150-250 ft-lbs depending on vehicle design. Many of these nuts are prevailing-torque fasteners designed for single use, so reusing an old nut compromises the precise clamping force needed for proper bearing preload.

After reassembly, technicians verify proper installation through several checks. The wheel should rotate smoothly without binding or roughness. There should be zero detectable play when rocking the wheel on the hub. The ABS sensor gap must fall within specifications if applicable. A test drive confirms normal operation, quiet running, and proper integration with the vehicle’s ABS and stability control systems.

Cost for wheel bearing replacement varies substantially based on vehicle design, parts quality, and labor rates in your area. Parts cost ranges from $50-$150 for an individual bearing, $150-$350 for a standard hub assembly with integrated bearing, and $200-$500+ per assembly for luxury or high-performance vehicles. Some European luxury vehicles use particularly expensive hub assemblies incorporating additional sensors and features, pushing costs even higher.

Labor costs depend on job complexity and location. Front bearings on vehicles with bolt-on hub assemblies typically require 1.5-2.5 hours of labor at $100-$250 total. Rear bearings often take longer due to more complex suspension geometry and access issues, running $150-$350 in labor. Dealership service departments charge $125-$200 per hour in most markets, while independent shops typically charge $80-$120 per hour. Press-in bearings requiring special equipment add to labor time and cost.

Total replacement cost combining parts and labor typically runs $250-$500 per wheel for front bearings and $350-$700 per wheel for rear bearings. Replacing all four bearings simultaneously costs $1,000-$2,200 total, though this is rarely necessary unless the vehicle has been severely neglected or subjected to extreme conditions. Most vehicles need bearing replacement on individual wheels as they develop symptoms rather than requiring all four simultaneously.

DIY bearing replacement is appropriate under specific conditions. If your vehicle uses simple bolt-on hub assemblies, you have mechanical experience working on brakes and suspension, you own or can borrow the necessary tools (including a precise torque wrench), and you have time to complete the job correctly, you can successfully replace bearings yourself. The money saved—potentially $150-$300 per wheel in labor costs—makes DIY attractive for mechanically inclined owners.

However, professional service becomes necessary for press-in bearing designs requiring a hydraulic press, integrated hub and knuckle assemblies where the bearing cannot be separated, unfamiliar or inexperienced DIYers who lack confidence in brake system service, lack of specialized tools like bearing pullers and torque wrenches, and safety-critical applications where installation errors could cause catastrophic failure. The consequences of improper installation—from bearing failure to brake problems to potential wheel separation—far exceed any money saved through DIY replacement when the job exceeds your skill level.

Conclusion

Wheel bearings serve as critical safety components that support your vehicle’s weight while enabling smooth wheel rotation with minimal friction. These precision-engineered assemblies handle extraordinary loads under challenging conditions, from highway speeds to pothole impacts to extended cornering forces. Understanding the three main bearing types—ball bearings offering compact efficiency, tapered roller bearings providing heavy-duty capacity, and modern hub assemblies integrating multiple functions—helps you make informed decisions about maintenance and repairs.

Most wheel bearings deliver 85,000-100,000 miles of reliable service, though this lifespan varies considerably based on driving conditions, vehicle loading, and maintenance of related systems. Environmental factors like water exposure, road salt, and contamination significantly affect longevity, while mechanical issues from improper installation or impact damage can cause premature failure. Recognizing warning signs—humming or grinding noises, steering vibration, loose handling, ABS light illumination—allows early intervention before minor problems become major failures.

Professional replacement typically costs $250-$700 per wheel including both parts and labor, with costs varying based on vehicle design and local labor rates. While some hub assemblies are DIY-friendly for experienced mechanics, bearing replacement generally requires proper tools, precise torque specifications, and thorough understanding of brake system safety. The critical nature of wheel bearings demands correct installation—errors can result in premature failure, brake problems, or catastrophic wheel separation.

If you experience any wheel bearing symptoms, have your vehicle inspected by a qualified technician immediately. While bearings rarely fail suddenly without warning, ignoring symptoms risks progression to catastrophic failure that could cause loss of vehicle control at highway speeds. When in doubt about whether to attempt DIY replacement, professional service ensures correct installation and prevents safety-critical failures that could endanger you and others on the road.

For detailed service procedures, manufacturer-specific torque specifications, and comprehensive diagnostic information, explore repair manuals matched to your vehicle’s make and model. Understanding how these essential components work helps you recognize when problems develop and make informed decisions about maintenance and repair priorities.