The steering column represents one of the most critical yet often overlooked components in your vehicle’s control system. Every time you turn the wheel, this carefully engineered assembly transmits your steering inputs while simultaneously providing crash protection that could save your life. Understanding how steering columns work, recognizing warning signs of failure, and knowing when professional service is necessary can help you maintain safe vehicle operation and avoid costly emergency repairs.

Modern steering columns do far more than simply connect your steering wheel to the road. They incorporate sophisticated collapsible safety designs that absorb impact energy during frontal collisions, adjustable mechanisms for driver comfort, and electronic sensors that integrate with advanced safety systems. Whether you’re an intermediate DIY enthusiast looking to understand your vehicle better, a professional technician seeking reference information, or a beginner wanting to grasp basic steering system operation, this comprehensive guide covers everything you need to know about steering column function, maintenance, and repair.

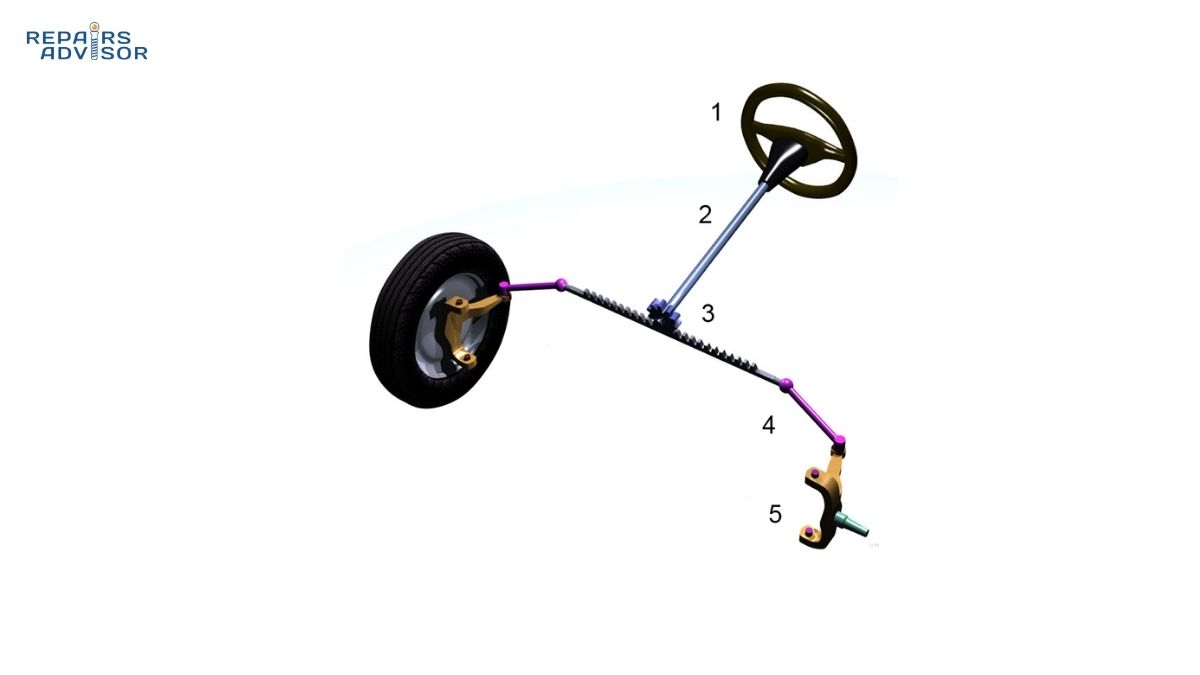

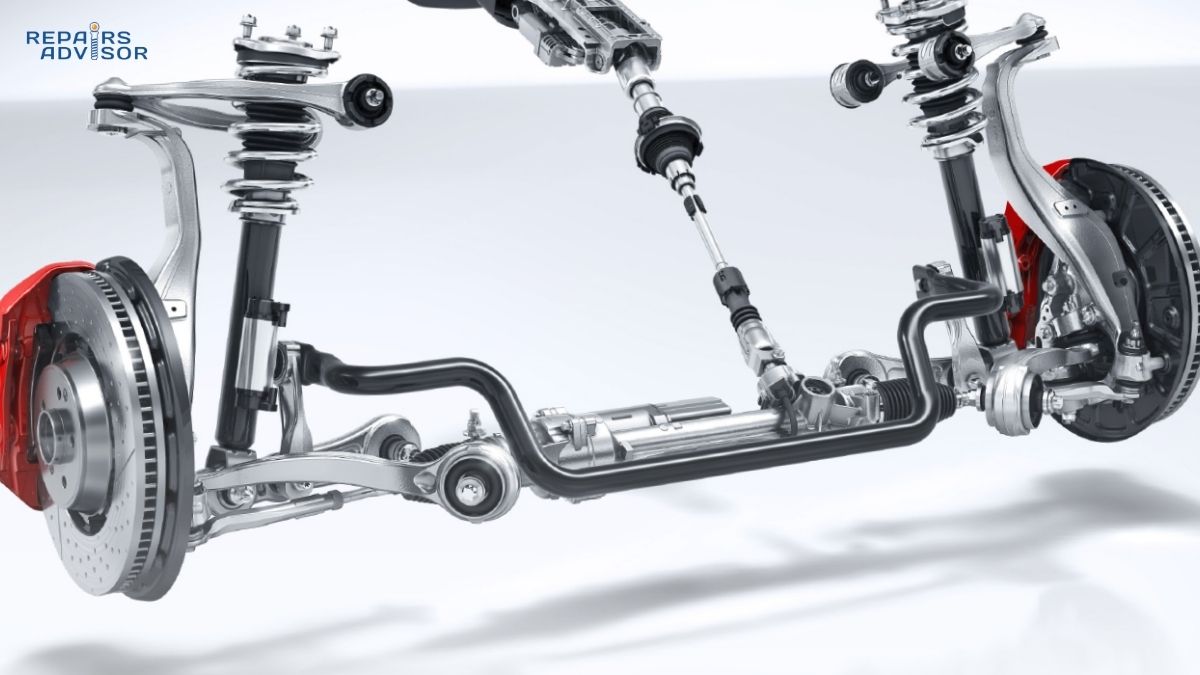

The steering column assembly consists of several key components working together: the steering shaft that transmits rotational motion, universal joints that accommodate angle changes, precision bearings that ensure smooth operation, and a protective housing that contains everything while providing structural support. These components must function flawlessly because steering column failure directly affects your ability to control the vehicle. Let’s explore how these systems work and what you need to know to keep them operating safely.

For a detailed technical explanation of steering column operation, see our complete guide on How Steering Columns Work: Connection and Safety.

Understanding Steering Column Components and Construction

The steering shaft forms the backbone of the entire column assembly. Manufactured from durable cold-rolled steel to precise specifications, this shaft must transmit steering torque reliably while withstanding the stresses of daily driving. The upper end connects to the steering wheel through a splined interface that ensures positive engagement, while the lower end attaches to either an intermediate shaft or directly to the steering gear depending on vehicle design. Modern steering shafts incorporate multiple sections joined by universal joints, allowing the column to navigate the angle changes required between the steering wheel position and the steering gear location.

Column bearings play a crucial role in steering column operation, supporting the rotating shaft while handling both rotational and thrust forces. These sealed bearings are strategically positioned at key points along the column to eliminate play while maintaining smooth, low-friction operation. Quality bearings use high-grade lubricants designed for consistent performance across varying temperatures and driving conditions. When bearings wear, drivers typically notice increased steering effort, unusual noises during turns, or a loose feeling in the steering wheel. Bearing replacement requires column disassembly and should be performed by experienced technicians familiar with proper torque specifications and reassembly procedures.

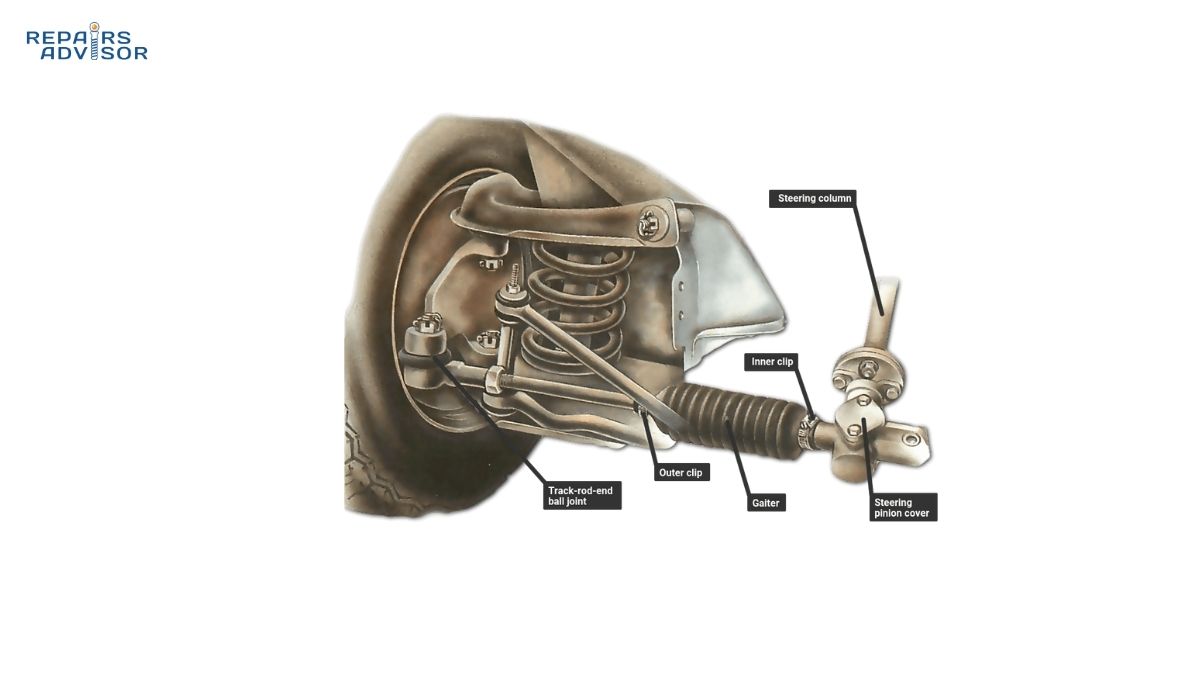

Universal joints, commonly called U-joints, enable the steering column to operate through angle changes while transmitting rotational motion smoothly. These joints consist of hardened steel components that pivot on needle bearings, allowing the column to flex as the suspension moves or the vehicle travels over uneven surfaces. The positioning of U-joints is engineered to maintain proper steering geometry while working within the space constraints of the engine compartment and dashboard area. Quality U-joints are essential for responsive steering feel—worn joints create play in the steering system and may produce clicking or clunking noises during turns.

The column housing provides structural support and protection for all internal components. Constructed from durable materials with strategic reinforcements at bearing locations and shaft connection points, the housing maintains alignment throughout the column’s service life. Modern housings also incorporate mounting points for various integrated systems including the ignition switch, multi-function switches for turn signals and wipers, and the driver’s airbag assembly. The housing design must balance strength requirements with collapsibility for crash safety, a challenging engineering compromise that modern manufacturers have refined through extensive testing and development.

Intermediate shafts connect the lower steering column to the steering gear in most modern vehicles. These shafts typically include additional universal joints and use splined connections that allow for slight length variations as the suspension moves through its travel. The intermediate shaft design isolates road vibrations from transmitting into the steering wheel while maintaining precise steering response. Some vehicles use a flexible coupling or “rag joint” rather than universal joints, providing similar functionality through a different mechanical approach. Understanding your vehicle’s specific configuration helps when diagnosing steering problems, as symptoms can vary based on intermediate shaft design.

For detailed information on how the steering column connects to the steering gear, visit How Rack and Pinion Steering Works: Precision Control.

The tilt mechanism in adjustable steering columns allows drivers to customize steering wheel position for optimal comfort and visibility. This mechanism typically pivots on a ball joint or pin located in the upper column section, with a locking lever or electric motor securing the chosen position. The locking mechanism must hold firmly during driving while allowing smooth adjustment when released—a worn tilt mechanism that won’t lock properly creates a serious safety hazard as the steering wheel may shift position unexpectedly during vehicle operation. Premium vehicles often incorporate memory settings that automatically adjust steering position when different drivers select their preset preferences.

Collapsible Steering Column Safety Design

The collapsible steering column stands as one of the most important safety innovations in automotive history. Before this technology appeared in 1967, introduced by General Motors, rigid steering columns caused countless severe injuries and fatalities during frontal collisions. The solid steel shaft that connected steering wheel to steering gear would often impale the driver’s chest during impact, turning a survivable crash into a fatal accident. The collapsible design fundamentally changed this dynamic by creating controlled energy absorption that protects the driver while maintaining steering control until the moment of maximum impact.

Modern collapsible steering columns use telescoping construction with inner and outer sleeves that slide together during impact. The critical component is the tolerance ring, which features wavelike protrusions around its circumference that act as a controlled spring. Under normal driving conditions, this ring holds the inner and outer sections firmly together with no movement or play. When impact forces exceed a specific threshold—typically around 11,000 Newtons or approximately 2,500 pounds of force—the tolerance ring allows the inner shaft to slip inside the outer housing. This controlled collapse absorbs impact energy that would otherwise transfer directly to the driver’s body.

Federal Motor Vehicle Safety Standards mandate specific performance requirements for collapsible steering columns. FMVSS 204 addresses steering control rearward displacement, while FMVSS 208 covers occupant crash protection including steering column behavior during frontal impacts. These standards require that columns collapse in a controlled manner, absorbing energy without creating sharp edges or projections that could cause additional injuries. Testing protocols include dropping weights onto steering columns and measuring peak deceleration forces—modern columns must keep deceleration below 80g to meet certification requirements. Manufacturers invest heavily in computer modeling and crash testing to ensure their designs not only meet minimum standards but provide optimal protection across a wide range of collision scenarios.

The engineering of collapsible steering columns involves carefully balanced compromises. The lower mounting point must allow the column to slip toward the driver during impact, shearing or breaking away under less than 550 pounds of force. Meanwhile, the upper mounting point must be rigid enough to absorb forces from engine-side impacts that could push the column toward the driver from below, requiring resistance to forces exceeding 750 pounds. This dual-direction protection ensures the column behaves correctly regardless of which direction impact forces approach from. The mounting system design is so critical that aftermarket column replacements must meet the same stringent requirements as original equipment, and installation torque specifications must be followed precisely to ensure proper function.

Universal joint separation provides additional protection during severe frontal impacts. The lower universal joint is designed to separate under extreme force, preventing the steering gear and intermediate shaft from being pushed through the column into the passenger compartment. This separation typically occurs after the telescoping section has fully collapsed, providing a secondary level of protection. The separated joint also prevents steering gear mounting points from transferring excessive force into the vehicle structure, helping maintain crash energy absorption throughout the front structure as designed. For detailed information on steering linkage components and their safety functions, see How Tie Rods, Ball Joints & Columns Work: Steering Linkage.

Column angle significantly affects collapse effectiveness. Engineering studies have demonstrated that more horizontal column angles allow the telescoping mechanism to function optimally, keeping the steering wheel in the correct position to work with airbag deployment. Vertical column angles, more common in older vehicles, were less effective because they couldn’t prevent the driver from sliding upward over the steering wheel toward the windshield. Modern vehicles use carefully calculated column angles in conjunction with properly positioned seat belts and airbags to create an integrated safety system. This is why proper seat belt use remains critical—the collapsible column works as designed only when the driver is properly restrained and positioned.

Airbag integration represents another crucial aspect of collapsible column design. The column must maintain proper airbag position throughout the collapse sequence, ensuring the airbag deploys in the correct location relative to the driver. Timing is essential—the airbag must inflate before the column completes its collapse stroke, providing a cushion between driver and steering wheel. Modern columns include features that help maintain airbag alignment during collapse, such as guided channels and reinforced sections around the airbag module. This integration requires extensive testing because even minor variations in collapse timing or geometry can affect airbag effectiveness.

After any frontal collision severe enough to trigger collapsible column operation, complete column replacement is mandatory. Even if external damage isn’t visible, internal collapse mechanisms have activated and cannot be reset or reused. The tolerance rings, crush zones, and other energy-absorbing features are designed for single-use, and attempting to continue using a collapsed column creates extreme danger. Insurance companies and collision repair facilities understand this requirement, and proper repair procedures always include full column replacement along with careful inspection of steering gear, intermediate shaft, and mounting points.

Steering Column Types and Variations

Manual steering columns represent the oldest and simplest design, consisting of a continuous shaft that runs from steering wheel to steering gearbox with direct mechanical linkage throughout. These columns, most commonly found in vehicles manufactured before the 1970s and in some economy vehicles through the 1990s, require significant physical effort to turn, especially at low speeds or when stationary. The advantage of manual columns lies in their mechanical simplicity and direct feedback—drivers feel precise road feedback through the wheel. However, the high steering effort makes parking maneuvers and low-speed turning physically demanding, which is why power steering assistance became standard equipment in most vehicles.

Power steering integration fundamentally changed steering column design. Hydraulic power steering systems typically mount the control valve in the steering gear rather than in the column, but the column housing must accommodate hydraulic lines and provide proper support for increased forces. Some vehicles positioned the hydraulic control valve assembly within or directly adjacent to the column, requiring modifications to the housing structure. These hydraulic-assisted columns maintain the basic mechanical connection while adding hydraulic boost that reduces steering effort dramatically. The column itself must be engineered to handle the additional forces generated by power steering, requiring stronger materials and reinforced mounting points. Learn more about hydraulic power steering operation at How Hydraulic Power Steering Works: Pressure Control & Assistance.

Electric power steering columns incorporate the assist motor directly into the column assembly in many modern vehicles. This column-mounted EPS design, often called C-EPS, places an electric motor and reduction gearing around or adjacent to the steering shaft within the column housing. The motor provides steering assist based on torque sensor input, which measures how hard the driver is turning the wheel. This sensor, also mounted within or immediately adjacent to the column, must provide highly accurate measurements because the electric motor responds instantly to torque sensor signals. C-EPS columns require significantly more robust housings to contain the motor assembly while maintaining the collapsible safety design—a challenging engineering problem that modern manufacturers have solved through creative use of breakaway brackets and controlled deformation zones.

Column-mounted EPS systems offer several advantages over traditional hydraulic power steering. They eliminate the parasitic drag of a constantly-running hydraulic pump, improving fuel efficiency by 2-4% in typical driving. The electric motor provides assist only when needed, drawing power only during steering maneuvers. Electronic control also enables advanced features like variable assist curves that provide more effort at highway speeds for stability and less effort during parking. However, C-EPS columns are more complex to service, often requiring complete column replacement rather than component-level repairs, and the electronic systems require specialized diagnostic equipment for troubleshooting. For comprehensive information on electric power steering technology, see How Electronic Power Steering Works: Electric Assistance.

Tilt steering columns provide vertical angle adjustment, allowing drivers to position the steering wheel at a comfortable height for their seating position. The mechanism typically uses a ball joint or pivot pin in the upper column section, with a locking lever that clamps the column in place once adjusted. When the lever is released, the column pivots freely to the desired position, then locks securely when the lever is engaged. Quality tilt mechanisms must provide firm locking with no play or movement during driving, while also allowing smooth, easy adjustment when released. Worn tilt mechanisms that won’t lock properly create a dangerous situation—imagine the steering wheel tilting away unexpectedly during a sharp turn.

Telescoping steering columns offer fore-aft adjustment, moving the steering wheel closer to or farther from the driver. This adjustment is particularly valuable for drivers who need more clearance between the steering wheel and their body, or for those who prefer reaching farther forward to the wheel. Telescoping mechanisms typically use a two-piece upper column shaft with internal splines that allow one section to slide within the other while maintaining positive rotational connection. The locking mechanism must clamp both sections together firmly to eliminate any play. Many modern vehicles combine tilt and telescoping adjustment, providing comprehensive steering wheel positioning that accommodates drivers of widely varying sizes and preferences.

Electronic adjustment systems have replaced manual levers in many premium vehicles. These systems use electric motors to adjust both tilt angle and telescoping position, often with memory settings that recall preferred positions for different drivers. When a driver selects their preset, the motors automatically move the steering wheel to the saved position. These electronic systems integrate with vehicle entry systems, automatically moving the wheel up and forward when the driver exits for easier entry and exit, then returning to the preset position when the vehicle is started. While convenient, electronic adjustment systems add complexity and cost, and failures typically require expensive column replacement rather than simple mechanical repairs.

Advanced steering column features continue to evolve with vehicle technology. Steering angle sensors, essential for electronic stability control and lane-keeping systems, mount within the column housing to measure steering wheel position with high precision. These sensors use optical encoding wheels that track steering wheel rotation through multiple revolutions, providing absolute position information to the vehicle’s safety systems. The sensors require calibration after any steering system service, including wheel alignment, and this calibration typically requires factory scan tools. For detailed information on steering angle sensor operation and calibration requirements, visit How Steering Angle Sensors Work: Position Detection.

Recognizing Common Steering Column Problems and Symptoms

Steering wheel binding represents one of the most common steering column problems, typically caused by worn universal joints that create resistance at certain steering angles. Drivers notice that steering feels smooth through most of the turning range but becomes stiff or catches at specific positions. This symptom often appears gradually, starting as barely noticeable resistance that progressively worsens over time. The binding occurs when needle bearings within the universal joint wear unevenly, creating flat spots or areas of increased friction. Left unaddressed, binding can progress to complete seizure of the universal joint, making steering extremely difficult or impossible at certain wheel positions.

Grinding or clicking noises during steering maneuvers indicate mechanical problems within the column assembly. These sounds typically come from worn needle bearings in the steering shaft, damaged universal joints, or failing column bearings. Clicking noises often occur once per steering wheel revolution, suggesting problems with the main column bearings or upper shaft bearing. Grinding sounds that vary with steering wheel position usually indicate universal joint wear. Both symptoms warrant prompt professional inspection because bearing or joint failure can lead to sudden loss of steering control. The sounds may be subtle initially but typically grow louder as wear progresses.

Excessive play in the steering wheel—sometimes called “sloppy steering”—creates a disconnected feeling when driving. The steering wheel can move through several degrees of rotation before the front wheels begin to turn, forcing drivers to constantly make steering corrections to maintain straight-line tracking. Play can originate from worn splines where the steering shaft connects to intermediate shaft or steering gear, loose mounting brackets, or worn universal joints. Intermediate DIYers can perform preliminary diagnosis by having someone rock the steering wheel back and forth while watching the intermediate shaft and steering gear connections to identify where the play originates. However, any play in steering components requires professional assessment and repair due to safety criticality.

Vibration transmission through the steering wheel can indicate several different column-related issues. Continuous vibration at certain speeds often points to wheel balance problems rather than column issues, but vibration that varies with steering wheel position suggests column bearing wear or damaged intermediate shaft components. Universal joint problems can create cyclic vibration that drivers feel as a shudder or pulsation during turns. Distinguishing between different vibration sources requires systematic diagnosis, often including test drives under various conditions and careful inspection of all steering system components from wheel bearings through the entire steering linkage. For comprehensive information on related steering components, see How Steering Knuckles Work: Wheel Support.

Tilt mechanism failures present obvious symptoms—the steering wheel either won’t lock in the adjusted position or the adjustment mechanism jams and won’t move. When the lock mechanism fails, the steering wheel may tilt down or up unexpectedly during driving, creating a dangerous loss of control. This problem often results from worn locking teeth or a broken locking pin, and it requires immediate attention. Never drive a vehicle with a tilt mechanism that won’t lock properly. Conversely, a jammed tilt mechanism that won’t release may indicate broken pivot components or seized locking mechanism, requiring column disassembly for repair. Electronic tilt mechanisms can fail due to motor problems, controller faults, or mechanical binding, requiring specialized diagnostic procedures.

The steering wheel not returning to center after completing a turn indicates serious problems requiring immediate professional attention. Normal steering systems naturally return the wheel to straight-ahead position due to caster angle in the front suspension geometry. When this self-centering action fails, possible causes include seized bearings in the steering column, binding universal joints, problems with the steering gear, or issues with front suspension components. This symptom can also indicate problems with alignment or tire pressure, but column-related causes must be ruled out through systematic inspection. A steering wheel that fights against returning to center creates constant driver workload and increases accident risk.

Off-center steering wheel position when driving straight reveals alignment problems in most cases, but can also indicate steering column misalignment after service or collision repairs. The steering wheel should point straight ahead with the vehicle tracking straight on level road. When the wheel is cocked to one side while driving straight, either the wheels are misaligned or the column has been reassembled incorrectly relative to the steering gear position. Proper diagnosis requires checking wheel alignment first, then inspecting steering component installation if alignment is correct. This seemingly simple symptom can indicate serious problems that affect tire wear, fuel economy, and vehicle handling.

Electrical symptoms often accompany mechanical column problems in modern vehicles. Warning lights for power steering, electronic stability control, or ABS may illuminate when column-mounted sensors fail or lose calibration. Turn signal, wiper, or cruise control switches mounted on the column may malfunction, requiring column disassembly for replacement. Ignition switch problems can prevent vehicle starting or cause electrical faults throughout the vehicle. These electrical issues sometimes require complete column removal for access, making labor costs significant even when replacement parts are inexpensive. Modern vehicles with integrated electronic systems may require reprogramming after column service to restore full functionality. Additional information on electronic power steering control systems is available at How EPS Motor + Controller Works: Electric Power Steering Control.

Physical damage from collisions, even relatively minor ones, can affect steering column alignment and operation. After any frontal impact, professional inspection of the steering column and mounting points is essential to verify structural integrity and proper function. Damage may not be immediately visible—internal collapse mechanisms may have partially activated without obvious external signs. Side impacts can also affect column geometry if they’re severe enough to shift the dashboard structure. Insurance companies typically authorize thorough steering system inspection after any collision, recognizing that hidden damage could create safety hazards.

Theft-related damage represents another common source of steering column problems. Forced ignition lock cylinder removal often damages the column housing, steering shaft, and internal components. Modern vehicles with electronic immobilizer systems are less vulnerable to simple theft attempts, but older vehicles or those targeted by unsophisticated thieves may suffer extensive column damage. Repairing theft damage typically requires complete column replacement because drilling, prying, or hammering to defeat the ignition lock compromises structural integrity and safety functions. Insurance coverage for theft damage usually includes full column replacement when necessary.

Steering Column Location and Access

The steering column extends from behind the steering wheel through the dashboard firewall into the engine compartment, with its path carefully engineered to provide proper steering geometry while accommodating space constraints. The upper section, visible from the driver’s seat, attaches to the underside of the dashboard with substantial mounting brackets designed to hold the column securely during normal operation while allowing controlled collapse during collisions. The column then passes through the firewall—the metal panel separating passenger compartment from engine bay—via a sealed opening that prevents exhaust fumes and water from entering the cabin. Understanding this path is essential for service work and for recognizing potential collision damage.

Visual identification of steering column components begins with the steering wheel and column shroud—the plastic cover that surrounds the upper column section and conceals the internal mechanisms. This shroud typically consists of upper and lower sections held together by screws or clips, providing access to the column shaft, tilt mechanism, and various mounted switches after removal. Behind the shroud, you’ll find the multi-function switch assembly that controls turn signals, headlights, and wipers on most vehicles. The ignition lock cylinder protrudes from the column housing, with the key entry point visible on the right side in most vehicles.

Accessing the steering column for service requires specific tools and careful attention to safety procedures. Basic tools include a socket set with metric and standard sizes, a torque wrench for proper reassembly, trim removal tools to avoid breaking plastic clips, and a steering wheel puller for vehicles requiring wheel removal. Safety equipment is absolutely critical—safety glasses protect eyes from falling debris or spring-loaded components, while gloves protect hands from sharp edges. Most importantly, the vehicle battery must be disconnected before beginning any work that could disturb the airbag system. Airbag capacitors can hold enough charge to deploy the airbag for several minutes after battery disconnection, so waiting at least 15 minutes before starting work provides an additional safety margin.

The difficulty level for steering column work ranges from moderate for simple switch replacement to very high for complete column removal and replacement. Experienced DIY mechanics with proper tools and airbag system knowledge can successfully complete some column repairs, but first-time attempts should be reserved for non-critical components and undertaken with abundant caution. Professional technicians typically complete column removal in 2-3 hours, while DIYers should allow 4-6 hours or more for unfamiliar procedures. The complexity involves not just mechanical disassembly but also electrical connector management, proper documentation of component positions for reassembly, and maintaining safety system integrity throughout the process.

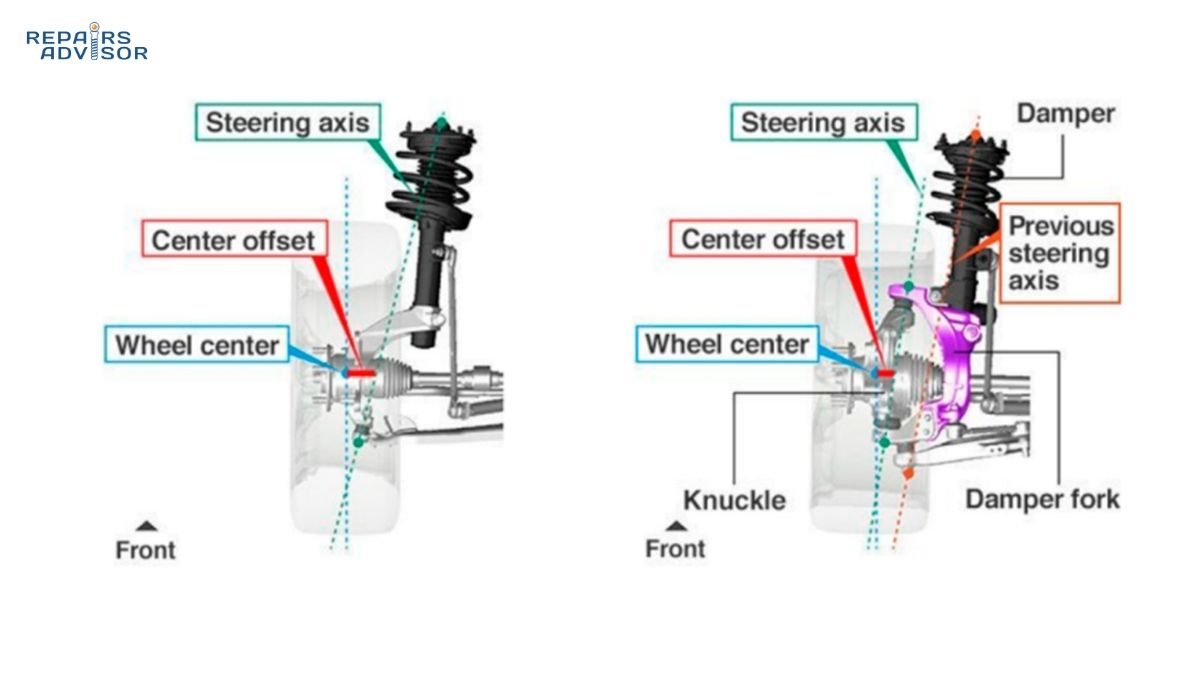

Vehicle design variations significantly affect steering column configuration and access requirements. Front-wheel-drive vehicles typically have relatively short steering columns that connect directly to the steering rack positioned transversely across the front of the vehicle. The compact packaging of FWD powertrains places the steering rack close to the firewall, minimizing intermediate shaft length. Rear-wheel-drive vehicles use longer intermediate shafts because the steering gearbox mounts farther back in the engine bay, necessitating additional universal joints to manage the extended shaft length and increased angle changes. All-wheel-drive and four-wheel-drive vehicles may have additional complexity due to transfer case positioning that affects intermediate shaft routing.

The engine compartment side of the column reveals the intermediate shaft and its connection to the steering gear. This area provides access to the lower universal joint, which can often be serviced without removing the entire column. The intermediate shaft typically includes a flexible coupling or additional universal joint to accommodate suspension movement and dimensional variations. Some vehicles use a “rag joint”—a flexible disc coupling that serves similar purpose through a different mechanical approach. Inspecting these lower connections requires working under the dashboard and sometimes removing lower dash panels or other components for adequate access.

Hybrid and electric vehicles introduce additional complexity through high-voltage electrical systems integration. While the basic steering column mechanical design remains similar, the surrounding area contains orange high-voltage cables that power various systems. These cables must never be disturbed without proper training and safety equipment, as they carry voltages capable of causing serious injury or death. Hybrid/EV steering columns may also integrate differently with the vehicle’s control systems, requiring specialized knowledge for proper diagnosis and repair. Service information specific to hybrid and electric vehicles should always be consulted before attempting any steering system work.

Working space around the steering column is typically confined, requiring patience and sometimes creativity to access fasteners and connections. Lower dash panels often must be removed to reach column mounting bolts, and the driver’s seat should be fully retracted to provide maximum working room. Some procedures require working simultaneously from above the column (through the steering wheel opening) and below (from the footwell), making a second person helpful for difficult tasks. Adequate lighting is essential—a headlamp or bright trouble light helps see fasteners and connections in the shadowed areas around the column.

For information on related suspension components that connect to the steering system, see How Your Car’s Suspension Works.

Steering Column Maintenance and Service

Routine maintenance for steering columns is relatively minimal compared to other vehicle systems, but regular inspection helps identify developing problems before they create safety hazards. Annual inspection during regular vehicle service should include visual examination of the column shroud for cracks or damage, verification that the tilt mechanism locks securely, listening for unusual noises during steering wheel rotation, and checking for excessive play or binding. Technicians typically perform these checks as part of comprehensive vehicle inspections, but attentive drivers often notice problems first through changes in steering feel or the appearance of new sounds.

Lubrication requirements for steering columns vary by design and age. Older columns may have grease fittings that require periodic lubrication with chassis grease, typically during oil change intervals. Modern sealed columns rarely need lubrication, as bearings and joints are pre-lubricated during assembly with lubricants designed to last the vehicle’s service life. Never attempt to lubricate sealed components with inappropriate materials—this can actually cause problems by contaminating existing lubricants or damaging seals. When service information specifies lubrication points, use only the recommended lubricant type and apply the specified amount. Over-lubrication can cause as many problems as under-lubrication.

Mounting bolt torque verification represents an important but often overlooked maintenance item. Steering column mounting bolts can loosen over time due to vibration and thermal cycling, potentially affecting steering feel and creating safety hazards if severe enough. These bolts must be torqued to precise specifications—too loose and the column may shift position or transmit vibration, too tight and the collapsible safety function may be impaired. Torque specifications are vehicle-specific and must be obtained from reliable service information sources. DIY mechanics with quality torque wrenches can verify mounting bolt torque, but remember that disturbing these fasteners on airbag-equipped vehicles requires following proper safety procedures.

Professional service becomes mandatory for several steering column procedures due to safety system integration and specialized requirements. Any work involving airbag removal or column removal must be performed by technicians trained in airbag system service procedures and equipped with proper tools and facilities. Airbags are pyrotechnic devices containing explosive propellant—improper handling can cause deployment resulting in serious injury. Professional shops follow specific procedures for safely disabling, removing, and reinstalling airbag modules, including proper storage of removed modules and verification of system functionality after service.

Steering angle sensor calibration requires specialized diagnostic equipment available only in professional shops and dealerships. After any service that affects steering component positions—including wheel alignment, tie rod replacement, or column service—the steering angle sensor must be calibrated to establish new zero-point reference. Without proper calibration, electronic stability control and other safety systems may not function correctly because they rely on accurate steering angle information. The calibration procedure typically involves centering the steering wheel precisely, then using a scan tool to command the vehicle’s computer to store this position as the new zero reference point.

Column replacement after collision represents another area where professional service is essential. The replacement procedure requires precise positioning and torque specifications to ensure proper collapsible function. Mounting brackets must be correctly installed, electrical connections properly mated, and the intermediate shaft coupling assembled to precise alignment specifications. After installation, the steering wheel must be centered, the steering angle sensor calibrated, and the entire system tested to verify proper operation. Most manufacturers require post-installation confirmation using factory diagnostic equipment to ensure all safety systems recognize the new column and function correctly.

Component-level repairs within the column assembly require specialized knowledge and proper tools. Universal joint replacement, bearing replacement, and ignition switch service all involve partial or complete column disassembly. These procedures can be technically challenging even for experienced mechanics due to the precision fits, spring-loaded components, and safety-critical nature of the work. Service manuals provide detailed disassembly and reassembly procedures, but misassembling even small components can affect column operation or compromise safety functions. Professional technicians familiar with steering column service have advantages in specialized tools, reference information, and experience that help ensure successful repairs.

For related information on ball joint maintenance and service, which shares some diagnostic procedures with steering column work, visit How Ball Joints Work: Suspension Pivot Points.

DIY maintenance capabilities for steering columns include visual inspections that can identify obvious problems like damaged shrouds, torn boots, or loose mounting hardware. Testing the tilt mechanism for proper locking and smooth operation requires no special tools or training. Listening for unusual noises during steering wheel rotation while stationary can help identify developing bearing problems. Monitoring steering wheel return-to-center after turns reveals potential binding issues. These basic checks provide valuable information without involving complex disassembly or safety system disturbance.

Understanding your own limitations is crucial when considering steering column work. If you lack experience with airbag systems, proper training and tools, or confidence in your mechanical abilities, professional service is always the safer choice. The safety-critical nature of steering components means that mistakes can have serious consequences. Insurance may not cover accidents resulting from improper DIY repairs, and liability concerns make professional service the prudent choice for most steering column work. That said, informed vehicle owners who understand how steering columns work can better communicate with service providers and make educated decisions about recommended repairs.

Preventive care practices extend steering column service life and reduce the likelihood of problems. Avoid aggressive steering maneuvers that stress the column components unnecessarily—rapid steering wheel spinning or jerking the wheel with excessive force creates wear. Don’t lean on the steering wheel when the vehicle is parked with the engine off, as this loads the column bearings in ways they’re not designed to handle. Keep the column area clean and dry to prevent corrosion—wipe up spilled beverages immediately and don’t allow water to collect around the column boot where it passes through the firewall. Most importantly, address unusual symptoms promptly rather than waiting for problems to worsen.

Understanding Steering Column Replacement Costs

Replacement cost for steering columns varies dramatically based on several key factors, with total expenses ranging from $530 to over $1,550 for complete professional service. The largest variable is the column type required for your specific vehicle. Manual steering columns represent the lowest cost option, typically $300-$500 for the part, because they contain only mechanical components without power assistance or electronic features. These simple columns have become increasingly rare as power steering has become universal in modern vehicles, but they remain the most affordable option for older vehicles and certain economy models.

Power steering columns occupy the middle price range, with parts costs between $500 and $1,200 depending on whether the vehicle uses hydraulic or electric power steering. Hydraulic power steering columns must accommodate control valves and fluid passages, while electric power steering columns contain assist motors and torque sensors. The electronic components in EPS columns increase manufacturing costs and replacement prices. Original equipment manufacturer parts typically cost 20-30% more than aftermarket alternatives but offer guaranteed fit and finish along with manufacturer warranties. Quality aftermarket columns from reputable suppliers provide good value, though careful attention to specifications ensures proper fitment and functionality.

Electronic adjustable steering columns command premium prices due to their complex mechanisms and integrated electronics. These columns, found in luxury and premium vehicles, contain motors for tilt and telescoping adjustment, position sensors, and control modules. Parts costs for these sophisticated assemblies can reach $1,500-$2,200 or more, with some high-end vehicles requiring even more expensive OEM-only components. The electronic adjustment mechanisms are typically not serviceable at the component level—column replacement is usually necessary when these systems fail. Memory function and integration with vehicle entry systems add further complexity and cost.

Labor costs for column replacement typically range from $350 to $500 based on shop rates and job complexity. Professional technicians usually complete straightforward column replacements in 2-3 hours, though some vehicles require longer times due to space constraints or additional components that must be removed for access. Dealership service departments typically charge $150-$200 per hour for labor, while independent shops average $80-$120 per hour. Mobile mechanics often provide the most competitive labor rates due to lower overhead costs, typically 10-20% below shop rates while offering the convenience of service at your location.

Additional services frequently accompany column replacement and affect total costs. Steering angle sensor calibration is essential after column replacement and may be included in the base labor price or billed separately for $50-$150 depending on equipment requirements and calibration complexity. Wheel alignment is strongly recommended after any steering system service, adding $50-$200 to the total bill but ensuring proper tracking and even tire wear. Some technicians discover related problems during column replacement—worn intermediate shaft universal joints, damaged ignition switches, or corroded electrical connections—that should be addressed while the column is removed to avoid repeat labor charges later.

Geographic location significantly influences pricing, with substantial regional variations in both parts and labor costs. Urban areas with higher costs of living typically see higher shop rates and parts prices, while rural areas generally offer more competitive pricing. Regional labor rate variations can exceed 50% between major metropolitan areas and small towns. Parts prices also vary regionally due to shipping costs, dealer networks, and local market competition. Online parts retailers sometimes offer better prices than local suppliers, though DIYers must weigh shipping costs and return policies against potential savings.

Salvage yards present budget-conscious alternatives for steering column replacement. Used columns from low-mileage donor vehicles typically cost $40-$75 for self-service salvage yards where you remove parts yourself, or $75-$150 for yards that pull parts for customers. Remanufactured columns from specialty rebuilders occupy a middle ground, offering refreshed components with new wear items and warranties at prices between used and new OEM. When considering used or remanufactured columns, verify compatibility carefully—columns must match not just vehicle make and model but also specific options like tilt steering, column shifter, and airbag type.

Insurance coverage often applies to collision-related column replacement, and understanding coverage helps manage out-of-pocket costs. Comprehensive and collision policies typically cover column damage from accidents, with coverage amounts depending on policy deductibles and vehicle value. Some policies cover theft-related damage that affects the column, though specific coverage varies. When filing claims, document all damage thoroughly with photographs and obtain detailed repair estimates from qualified shops. Insurance adjusters understand that modern column replacement requires proper calibration and testing, and reputable shops ensure claims include all necessary procedures for safe, complete repairs.

For vehicle brand-specific repair manual information and cost considerations, see resources for popular brands like Ford and Toyota.

The value proposition of professional service becomes clear when considering the safety criticality of steering columns. While the cost might seem high, professional installation ensures proper torque specifications, correct airbag reinstallation, necessary calibrations, and warranty protection. Mistakes in column replacement can compromise crash protection, affect steering control, or cause airbag malfunctions—risks far exceeding the cost of professional service. Quality shops stand behind their work with warranties covering both parts and labor, providing peace of mind that DIY installation cannot match. The specialized knowledge and proper equipment required for steering column service justify professional labor costs for this safety-critical component.

Timing column replacement strategically can affect costs. Non-urgent replacements scheduled during off-peak periods may qualify for discounted labor rates at some shops. Combining column service with other scheduled maintenance like wheel alignment or suspension work may reduce overall labor costs through efficient labor bundling. However, never delay necessary steering column repairs to save money—the safety risks far outweigh any potential cost savings. Symptoms like binding, excessive play, or tilt mechanism failure require immediate professional attention regardless of timing or cost considerations.

Conclusion: Maintaining Your Steering Column’s Safety and Function

The steering column performs far more than its basic function of connecting steering wheel to front wheels. This sophisticated assembly integrates crash safety features that have saved countless lives since collapsible designs appeared in the late 1960s. The telescoping collapse mechanism absorbs impact energy during frontal collisions, providing crucial protection when combined with airbags and seat belts. Understanding this safety function helps vehicle owners appreciate why proper maintenance and timely replacement are essential—a compromised steering column defeats one of your vehicle’s most important passive safety systems.

Modern steering columns incorporate advanced features including electronic power steering assistance, adjustable positioning for driver comfort, and sensors that enable stability control and other safety systems. These integrated technologies make steering columns more capable but also more complex, requiring specialized knowledge for proper service. Professional technicians with appropriate training, tools, and diagnostic equipment are best equipped to service these sophisticated assemblies while maintaining their safety functions and electronic system integration.

Regular maintenance provides the foundation for reliable steering column operation. Annual inspections during routine vehicle service should include checks for unusual noises, binding, excessive play, or other symptoms that indicate developing problems. The relatively minimal maintenance requirements—mostly consisting of visual inspection and operational testing—make it easy to monitor column condition without extensive time investment. However, seemingly minor symptoms like slight binding or small amounts of play warrant professional evaluation, as these often indicate problems that will worsen if left unaddressed.

Warning signs of steering column problems require prompt attention due to safety implications. Binding that affects steering smoothness, grinding or clicking noises during turns, excessive play that creates sloppy steering feel, vibration transmission through the wheel, and tilt mechanism failures all indicate problems requiring professional diagnosis. Don’t ignore these symptoms or delay inspection—steering column failure can create dangerous loss of vehicle control with potentially catastrophic consequences. Modern diagnostic equipment allows trained technicians to quickly identify problems and recommend appropriate repairs.

Professional service boundaries exist for good reasons with steering column work. Airbag systems contain pyrotechnic devices that require special handling procedures and tools for safe service. Steering angle sensors need precise calibration using manufacturer-specific equipment after any steering system service. Proper column replacement requires exact torque specifications and alignment procedures to ensure collapsible safety features function correctly. These requirements place most steering column service beyond DIY capabilities, making professional technicians the appropriate choice for nearly all column repairs.

Collision damage assessment requires particular attention regarding steering columns. Even relatively minor frontal impacts can activate collapse mechanisms, and the damage may not be externally visible. Professional inspection after any collision should include thorough evaluation of column condition, mounting integrity, and proper function. Never assume an apparently intact column remains safe after impact—internal collapse mechanisms may have partially activated, compromising future crash protection. Insurance companies and collision repair facilities understand these concerns and typically authorize comprehensive steering system inspection and necessary replacements after accidents.

Cost considerations should be balanced against safety requirements when making repair decisions. While steering column replacement can exceed $1,500 for complex electronic columns, this investment protects the far more valuable asset of your safety and the safety of your passengers. Professional installation ensures proper function, appropriate calibration, and warranty protection that DIY work cannot provide. The specialized knowledge and proper equipment required for steering column service justify professional labor costs for this safety-critical component.

Prevention remains the most cost-effective approach to steering column maintenance. Avoid aggressive steering maneuvers that stress components unnecessarily. Don’t use the steering wheel as a handle for entering or exiting the vehicle. Address spills and moisture promptly to prevent corrosion. Most importantly, respond quickly to unusual symptoms rather than waiting for problems to worsen. These simple practices extend column service life while maintaining optimal function and safety.

For comprehensive information on vehicle steering systems, explore our Steering System Category resources. Vehicle-specific repair manual information is available through our brand resources including Toyota and other major manufacturers. Understanding how your specific vehicle’s steering column operates empowers you to make informed maintenance decisions and communicate effectively with service providers.

The steering column represents one of your vehicle’s most important safety features, deserving attention and proper maintenance throughout your vehicle’s service life. Whether you’re an intermediate DIY enthusiast seeking to understand your vehicle better, a professional technician referencing best practices, or a beginner learning about automotive systems, recognizing the steering column’s critical role helps ensure safe vehicle operation. When problems arise, trust qualified professionals to diagnose and repair this safety-critical component, maintaining the crash protection and reliable steering control that modern steering columns provide.

Safety Disclaimer: Steering column service involves safety-critical components including airbag systems, collapsible safety mechanisms, and vehicle control systems. Improper service, modification, or installation can result in serious injury or death during collisions, or loss of vehicle control during normal operation. This article provides educational information only and does not constitute professional mechanical advice or authorization to perform repairs. Always consult qualified automotive service professionals for steering column diagnosis, service, and repair. Never attempt to service airbag systems or steering columns without proper training, tools, and safety equipment. The information provided is for general understanding purposes and should not replace manufacturer service procedures or professional expertise.