Imagine shifting gears faster than the blink of an eye—literally. Modern dual-clutch transmissions can change gears in as little as 8 milliseconds, delivering seamless power without the fuel-wasting torque converter of traditional automatics or the skill demands of a manual gearbox. This “best of both worlds” technology has revolutionized both performance cars and everyday vehicles, yet it remains one of the most misunderstood drivetrain innovations in automotive history.

The dual-clutch transmission (DCT) concept dates back to 1939, when French engineer Adolphe Kégresse envisioned a self-shifting transmission that eliminated the difficult manual gear changes of his era. While Kégresse ran out of funding before building a working prototype, his idea would eventually transform motorsports and road cars alike. Porsche pioneered DCT development for racing in the 1980s, using their PDK (Porsche Doppelkupplungsgetriebe) transmission to win the 1986 World Sportscar Championship. The technology finally reached everyday drivers in 2003 when Volkswagen introduced the DSG transmission in the Golf R32.

Understanding how dual-clutch transmissions work helps you appreciate their performance advantages while making informed decisions about maintenance and potential issues. This guide explains the technology behind DCTs, their real-world benefits, common problems, and why professional service is essential for these complex systems.

⚠️ Safety Note: This article provides educational information only. All dual-clutch transmission diagnosis, repair, and service must be performed by qualified professionals with manufacturer-specific training and equipment. Improper procedures can cause transmission damage or sudden loss of vehicle control.

What Is a Dual-Clutch Transmission?

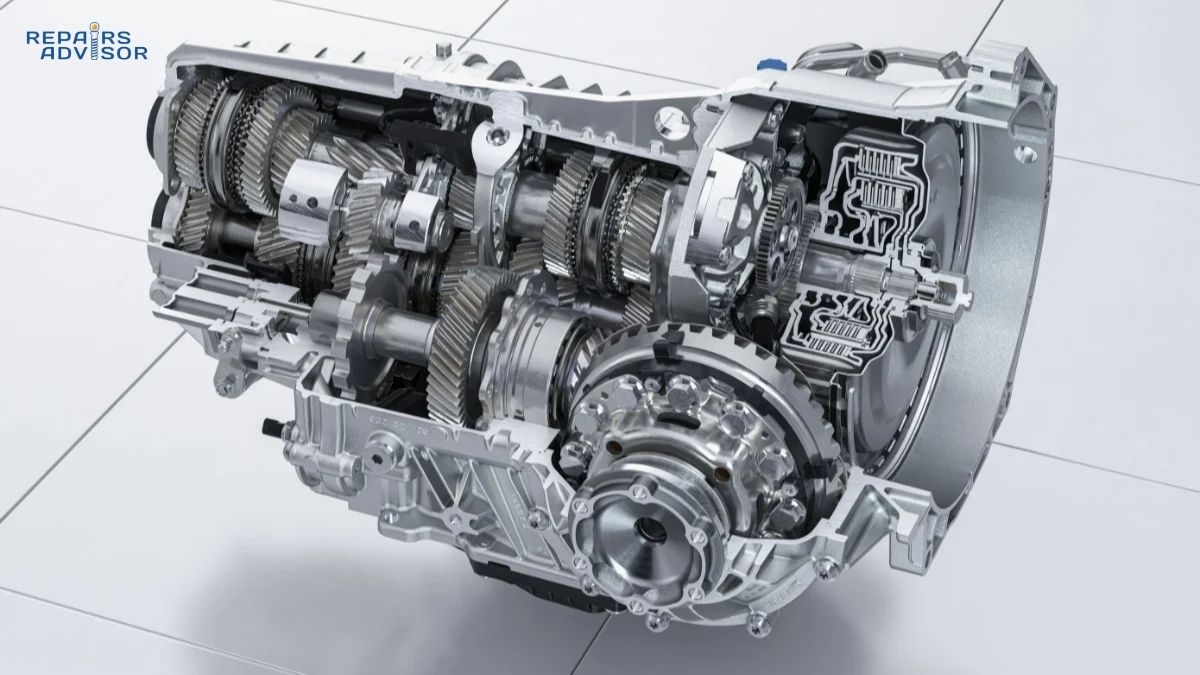

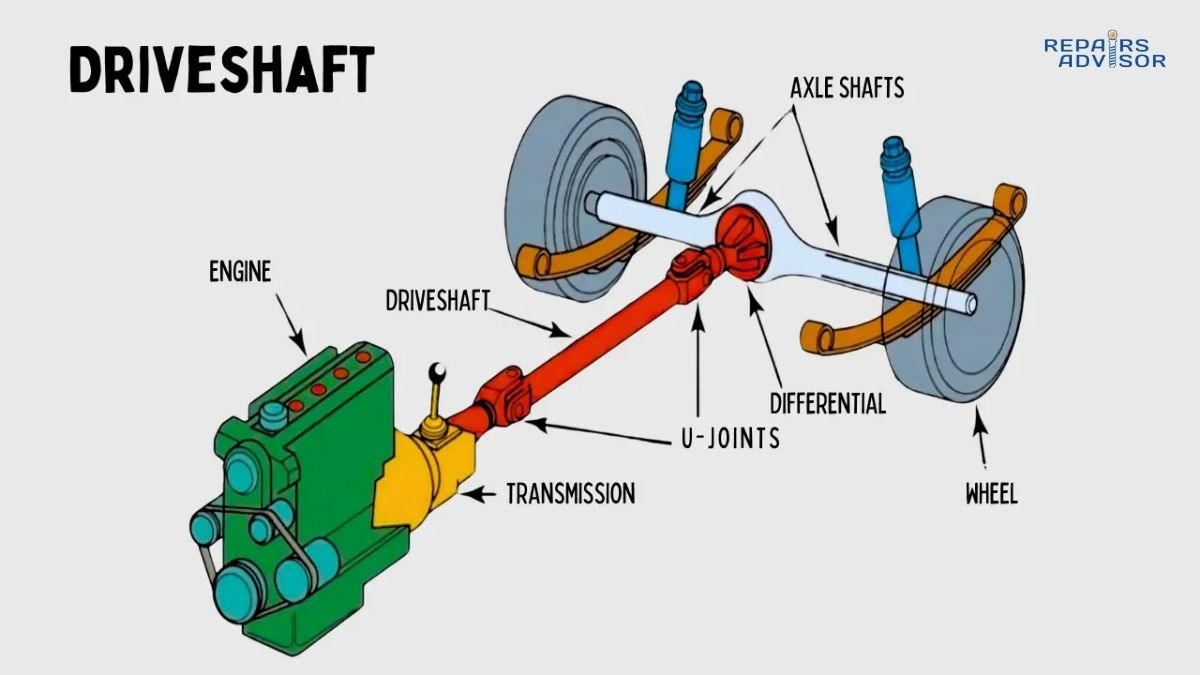

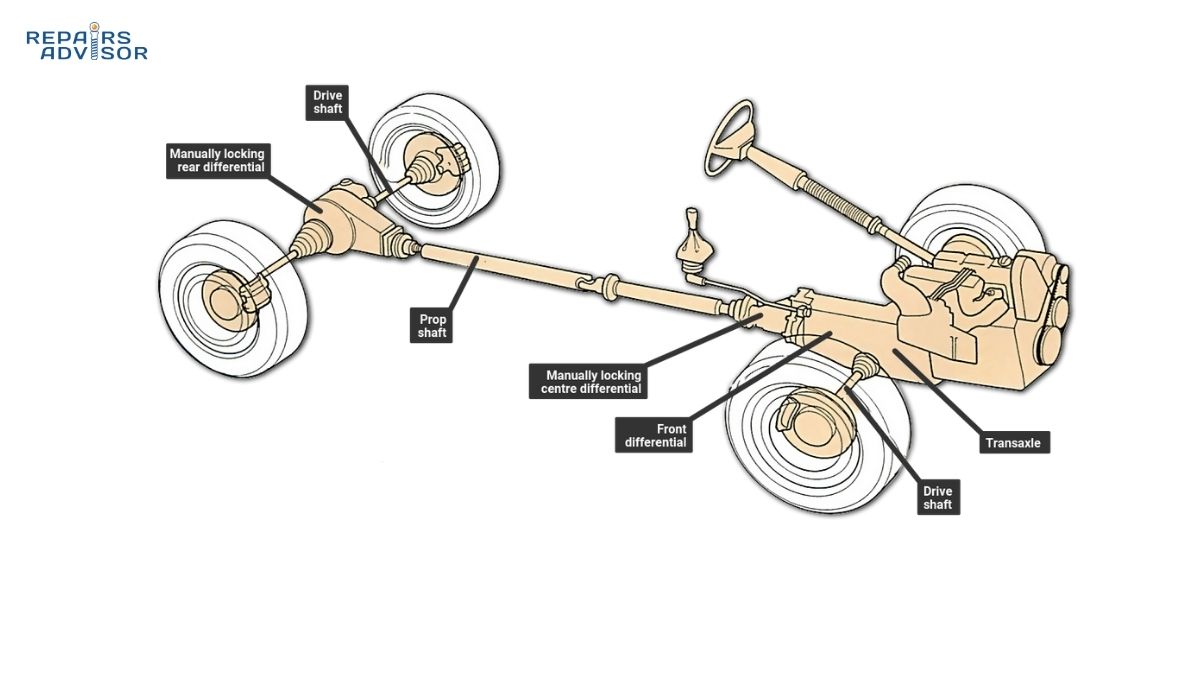

A dual-clutch transmission is essentially two automated manual transmissions housed in a single unit, each with its own clutch. Unlike traditional automatic transmissions that use a torque converter and planetary gearsets, DCTs employ the gear architecture of manual transmissions but eliminate the clutch pedal through electronic and hydraulic automation.

The fundamental innovation is simple yet brilliant: while you’re driving in one gear controlled by the first clutch, the second clutch pre-selects the next likely gear. When it’s time to shift, one clutch disengages while the other engages simultaneously, creating an uninterrupted flow of power to the wheels. This pre-selection process happens in milliseconds, faster than any human driver could manage with a conventional manual transmission.

How Manufacturers Market DCT Technology

Different automakers use various names for their dual-clutch transmissions, though the underlying technology remains similar:

- DSG (Direct-Shift Gearbox) – Volkswagen, Audi, SEAT, Škoda

- PDK (Porsche Doppelkupplungsgetriebe) – Porsche

- DCT (Dual Clutch Transmission) – BMW, Hyundai, Kia

- PowerShift – Ford (now discontinued in most markets)

- TCT (Twin Clutch Transmission) – Alfa Romeo

- DCA (Dual Clutch Automatic) – Tata Motors

Why Choose DCT Over Traditional Automatics?

The performance and efficiency advantages of dual-clutch transmissions over conventional automatics are significant:

Efficiency gains are substantial—DCTs deliver 5-10% better fuel economy compared to traditional automatics, with Volkswagen claiming up to 20% improvement over their older 6-speed hydraulic automatic transmissions. This efficiency comes from eliminating the torque converter, which inherently wastes energy through fluid slippage.

Shift speed represents the most dramatic advantage. Where a skilled manual transmission driver might complete a shift in 150-250 milliseconds, DCTs accomplish the same task in 8-100 milliseconds depending on the system. This near-instantaneous shifting eliminates the “shift shock” and power interruption that characterizes both manual and automatic transmissions.

Mechanical efficiency improves because DCTs have fewer moving parts than planetary gear automatics. The direct gear-to-gear connection mimics a manual transmission’s mechanical efficiency while the automated clutch control removes human error from the equation.

Weight advantages also factor into the equation, as DCTs are generally lighter than equivalent traditional automatics, particularly in applications requiring high torque capacity.

How Dual-Clutch Transmissions Work

The magic of DCT technology lies in its ingenious two-clutch, two-shaft architecture that enables simultaneous gear pre-selection.

The Two-Clutch System Architecture

Understanding the physical layout is key to grasping how DCTs achieve their performance advantages. The system uses concentric input shafts—an inner solid shaft running through a hollow outer shaft, both rotating on the same axis but independently controlled.

The odd-gear clutch controls first, third, fifth, and seventh gears (plus reverse). This clutch connects to the inner input shaft and handles approximately half of the available gear ratios. When you’re accelerating in first gear, this clutch is engaged while the transmission’s computer simultaneously pre-selects second gear on the other shaft.

The even-gear clutch manages second, fourth, sixth, and eighth gears. Connected to the hollow outer shaft that surrounds the inner shaft, this clutch stands ready to engage the pre-selected even gear the moment the odd-gear clutch disengages.

This nested shaft design is the mechanical breakthrough that makes DCTs possible. Both shafts connect to a common layshaft (or countershaft) containing all the gear ratios, similar to how a manual gearbox operates. The key difference is that transmission synchronizers can pre-select gears on the disengaged shaft without affecting the currently active gear.

Sequential Shift Process: Step-by-Step

Let’s walk through exactly what happens during a typical acceleration scenario to understand the seamless power delivery that defines DCT operation.

Starting from a stop in first gear:

- The odd-gear clutch engages first gear on the inner input shaft

- The Transmission Control Unit (TCU) analyzes throttle position, vehicle speed, and acceleration rate

- Based on driving conditions, the TCU predicts you’ll upshift to second gear next

- While you’re accelerating in first gear, the even-gear clutch pre-selects second gear on the outer shaft (without engaging it yet)

- The vehicle accelerates smoothly with first gear fully engaged and second gear mechanically selected but not connected to engine power

Executing the upshift to second gear:

- The TCU determines the optimal shift point has arrived (based on engine RPM, throttle position, and vehicle speed)

- The odd-gear clutch begins disengaging, releasing first gear

- Simultaneously—within the same milliseconds—the even-gear clutch engages, connecting second gear to engine power

- The shift completes in 8-100 milliseconds with zero interruption in power delivery to the wheels

- While now driving in second gear, the TCU immediately pre-selects third gear on the odd-gear shaft

This process repeats throughout the gear range. The system’s intelligence lies in its predictive capability—the TCU constantly analyzes driving conditions to anticipate whether you’ll upshift, downshift, or maintain current gear.

Gear Pre-Selection Intelligence

The sophistication of modern DCT control systems rivals the electronic management in engine control units. The TCU processes multiple inputs to predict gear selection:

Throttle position and rate of change indicate driver intent—gradual acceleration suggests sequential upshifts, while sudden throttle application might trigger a skip-shift downshift for maximum acceleration.

Vehicle speed and acceleration data helps determine if the driver is maintaining highway speed, aggressively accelerating, or preparing to stop.

Engine RPM and torque output ensure shifts occur at optimal points for power delivery or fuel economy depending on drive mode selection.

Brake application status signals deceleration, triggering downshift pre-selection to provide engine braking and proper gear selection for acceleration out of corners.

GPS and navigation data (in advanced systems) can pre-select lower gears before steep grades or tight corners on known routes.

When the TCU’s prediction is correct—which happens the vast majority of the time—shifts are instantaneous. If the prediction is wrong (such as sudden throttle lift mid-corner or unexpected hard acceleration from cruising), a brief shift lag occurs while the correct gear is selected and engaged. Modern DCTs employ adaptive learning algorithms that continuously refine prediction accuracy based on individual driving patterns.

Wet vs Dry Clutch DCT Systems

Not all dual-clutch transmissions are created equal. The choice between wet-clutch and dry-clutch designs represents a fundamental engineering trade-off between durability and efficiency.

Wet-clutch DCT systems bathe their clutch plates in transmission fluid or specialized automatic transmission fluid (ATF). This oil bath provides several advantages: superior heat dissipation enables handling of higher torque outputs (500+ Nm or 370+ lb-ft), smoother clutch engagement reduces shudder at low speeds, and extended clutch life results from better thermal management. The trade-off comes in slightly higher parasitic drag from the oil, reducing efficiency by 1-3% compared to dry-clutch systems.

Examples of wet-clutch DCTs include Volkswagen’s DQ250 (6-speed), Porsche’s PDK (7 and 8-speed variants), Mercedes-AMG’s 8-speed Speedshift DCT, and most performance-oriented dual-clutch applications where torque capacity and durability justify the efficiency penalty.

Dry-clutch DCT systems operate with their clutch plates in air, similar to conventional manual transmission clutch systems. The absence of oil bath reduces parasitic losses, yielding approximately 3% better fuel economy compared to equivalent wet-clutch systems. This efficiency advantage makes dry-clutch DCTs attractive for economy-focused applications.

However, dry-clutch systems face significant limitations. Torque capacity maxes out around 250-350 Nm (184-258 lb-ft), restricting their use to smaller engines. Heat dissipation proves challenging without oil cooling, making these transmissions prone to overheating during sustained low-speed operation, heavy traffic, or aggressive driving. The result is accelerated clutch wear and the jerky low-speed behavior that has plagued systems like Ford’s PowerShift and Volkswagen’s DQ200.

The reliability issues with certain dry-clutch DCTs—particularly Ford’s dual-clutch transmission in the Focus and Fiesta—have significantly impacted public perception of DCT technology as a whole, despite wet-clutch systems demonstrating much better durability records.

DCT Components and Control Systems

Understanding the major components helps demystify DCT operation and explains why these transmissions require specialized service.

Key Mechanical Components

The dual clutch assembly forms the heart of the system. Two multi-plate clutches are arranged either concentrically (one surrounding the other) or side-by-side, depending on manufacturer design. Each clutch pack contains multiple friction discs that engage under hydraulic or electromechanical pressure. Clutch actuators—either hydraulic cylinders or electric motors with ball-screw mechanisms—control the precise engagement and disengagement of each clutch pack.

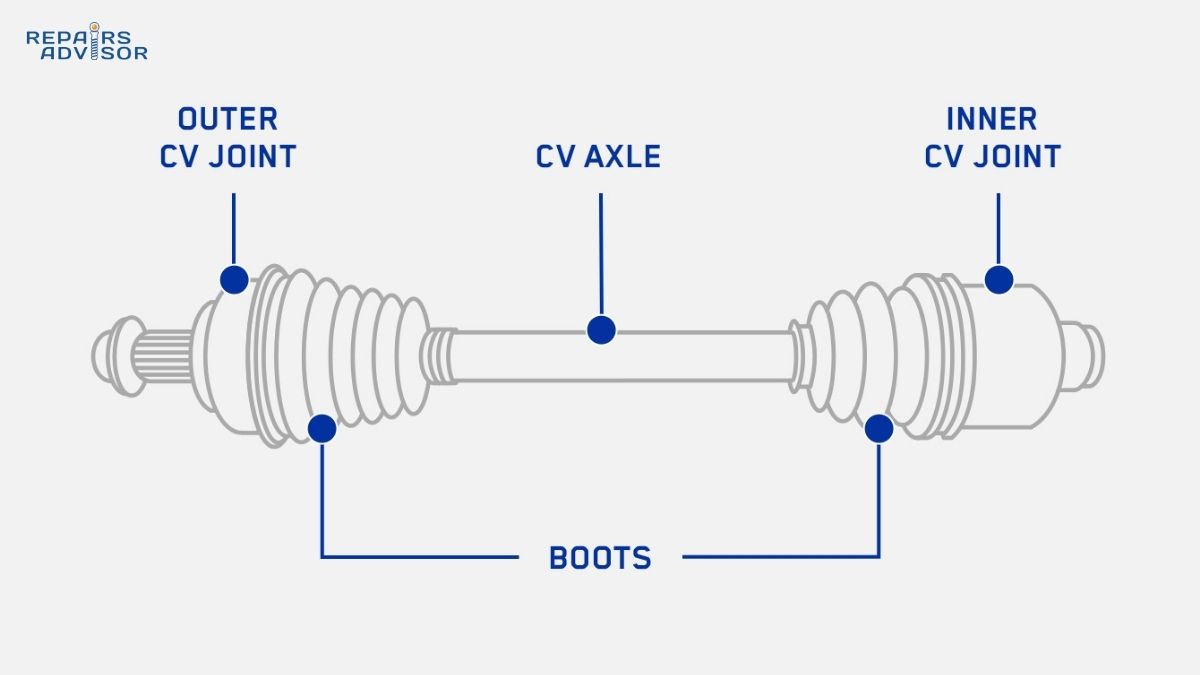

Gear sets and shafts mirror manual transmission architecture. The concentric input shafts (inner solid and outer hollow) connect to their respective clutches. A countershaft or layshaft carries all the gear ratios in constant mesh, just like a manual gearbox. Output shafts transmit power to the differential and ultimately to the wheels. Each gear ratio has its own synchronizer assembly that allows smooth engagement when pre-selected.

Hydraulic and mechanical systems provide the muscle to operate clutches and shift forks. A hydraulic pump maintains system pressure, typically 40-60 bar (580-870 psi). An accumulator stores pressurized fluid for rapid clutch actuation. The valve body, packed with solenoids, directs hydraulic pressure to specific actuators. Shift forks physically move synchronizer collars to engage gears. A dedicated transmission fluid cooling system manages the substantial heat generated during operation—particularly important in wet-clutch designs.

Electronic Control and Mechatronics

The Transmission Control Unit (TCU) serves as the DCT’s brain, processing massive amounts of data in real-time. Input signals flood in from numerous sensors: throttle position sensor, multiple speed sensors (vehicle speed, individual wheel speeds), engine RPM, brake pedal position, drive mode selector position, and transmission fluid temperature. The TCU processes this information through complex algorithms that determine optimal shift points, clutch slip control parameters, and which gear to pre-select.

Output commands flow to clutch actuators (controlling engagement pressure and timing), hydraulic valve body solenoids (directing fluid flow), and shift fork actuators (engaging selected gears). The TCU also communicates continuously with the Engine Control Unit, requesting torque reduction during upshifts to minimize driveline shock and coordinating throttle blipping for downshifts in manual mode.

Modern DCTs employ adaptive learning that continuously refines shift quality. The system monitors clutch engagement characteristics, adjusting pressure and timing to compensate for clutch wear over time. Shift point optimization adapts to individual driving styles—aggressive drivers receive sportier shift programming, while gentle driving triggers earlier upshifts for fuel economy.

The mechatronic unit integrates the valve body, control module, and solenoids into a single assembly mounted directly on the transmission. This compact integration reduces hydraulic line lengths and improves response time, but it also represents a common and expensive failure point. When mechatronic units fail—often due to solenoid wear, valve body wear, or electronic component failure—replacement typically costs $2,000-$5,000 including parts and labor. The good news is that manufacturers regularly release software updates that can resolve many shift quality issues without hardware replacement.

Advantages of Dual-Clutch Transmissions

The engineering sophistication of DCT technology delivers measurable real-world benefits across multiple performance dimensions.

Performance Benefits

Shift speed represents the most dramatic advantage over other transmission types. Professional drivers executing perfect manual upshifts might achieve 150-250 millisecond shift times under ideal conditions. DCTs complete the same operation in 8-100 milliseconds depending on system design and shift mode. This translates to tangible acceleration improvements—tests show DCT-equipped vehicles consistently accelerate 0.2-0.5 seconds faster to 60 mph compared to identical models with manual transmissions, entirely due to optimized shift timing and eliminated power interruption.

The absence of “shift shock” creates a seamless acceleration experience. Unlike manual transmissions where the clutch must disengage (interrupting power) or traditional automatics where the torque converter must unlock and planetary gears reconfigure, DCTs maintain constant power flow through gear changes. One clutch remains engaged until the exact millisecond the other clutch completes engagement, ensuring uninterrupted torque delivery to the wheels.

Efficiency gains prove equally impressive. Real-world testing consistently demonstrates 5-10% better fuel economy compared to traditional automatic transmissions. Volkswagen’s engineering data claims 20% improvement over their previous 6-speed hydraulic automatic and 6% better efficiency than a comparable manual transmission—primarily because the DCT always selects the optimal gear for current conditions without human error.

The efficiency advantage stems from multiple factors. Eliminating the torque converter removes 3-5% parasitic losses inherent in fluid coupling. Direct mechanical connection through gears maintains efficiency comparable to manual transmissions. Optimized shift points ensure the engine operates in its most efficient RPM range more consistently than human-controlled manuals. The result is measurably lower CO2 emissions—a critical factor in meeting increasingly stringent corporate average fuel economy standards.

Driver Experience Advantages

Versatility defines the DCT user experience. Full automatic mode handles daily commuting and traffic with the convenience of a traditional automatic—no clutch pedal to fatigue your left leg, no need to think about gear selection. Yet when the road turns interesting, manual mode with paddle shifters provides the engagement and control that driving enthusiasts crave, executing shifts faster than any manual driver while maintaining both hands on the steering wheel.

Modern DCTs offer multiple drive modes that fundamentally alter transmission behavior. Comfort mode prioritizes early upshifts and gentle clutch engagement for maximum fuel economy and refinement. Sport mode holds lower gears longer, executes more aggressive shifts, and pre-selects gears optimized for acceleration rather than efficiency. Some systems offer custom modes where drivers can independently select engine response, suspension damping (if equipped with adaptive damping), and transmission aggressiveness.

Advanced integration with other vehicle systems enables sophisticated features impossible with traditional transmissions. Launch control systems in performance applications precisely modulate clutch slip and engine torque to achieve optimal acceleration from standstill without wheel spin or excessive driveline shock. Downshift blipping automatically matches engine speed to the lower gear, eliminating the jolt of an unmatched downshift while producing that satisfying exhaust bark that enthusiasts love.

Integration with electronic stability control and traction control systems allows the DCT to instantly select optimal gears for maximum traction when the system detects wheel slip. The transmission can simultaneously downshift for engine braking while stability control applies individual wheel braking to regain vehicle control.

Real-World Applications

DCT technology has proliferated across the automotive spectrum. High-performance sports cars leverage DCTs for their superior acceleration and track capability: Porsche’s PDK-equipped 911 models, Ferrari’s 458 and later models, the Bugatti Veyron’s 7-speed Ricardo-designed DCT handling 1,250 Nm of torque, and Mercedes-AMG’s entire performance lineup.

Mainstream vehicles have embraced DCT technology for its efficiency and refinement: Volkswagen’s entire DSG lineup spanning the Golf, Jetta, Passat, and Arteon, Audi’s S-Tronic system in A3, A4, and performance S/RS models, and Hyundai/Kia’s 7DCT and 8DCT systems across their product ranges—the Hyundai Veloster N and Kia Stinger being notable enthusiast-focused applications.

Even motorcycles have adopted DCT technology, with Honda pioneering the application in the VFR1200F sports tourer (2010), CRF1000L Africa Twin (2016), and the entire NC750 series. The motorcycle DCT operates identically to automotive systems but packages everything in a much more compact space, demonstrating the technology’s versatility.

Common DCT Problems and Maintenance

Understanding common failure modes and maintenance requirements helps you maximize DCT longevity while recognizing when professional service becomes necessary.

Known Issues and Failure Modes

Jerky low-speed operation represents the most common complaint from DCT owners, particularly in dry-clutch systems. The problem stems from clutch slip characteristics during low-speed maneuvering. When crawling in traffic or parking, the transmission must constantly slip the clutch to maintain smooth motion—exactly like feathering a manual transmission clutch in stop-and-go traffic. However, unlike a manual where the driver precisely controls clutch engagement, the DCT’s programmed clutch control algorithms must balance smoothness against clutch wear.

This results in the characteristic “jerky” feeling when pulling away from a stop or during low-speed maneuvering. Some vehicles exhibit hesitation for 1-2 seconds when the driver applies throttle from a complete stop, particularly when the transmission is cold. The issue typically improves as the transmission learns your driving style through adaptive programming, but it never completely disappears in some dry-clutch systems.

Clutch wear and overheating plague certain DCT applications—most notoriously Ford’s PowerShift and Volkswagen’s dry-clutch DQ200. Premature clutch failure can occur at mileages as low as 30,000-50,000 miles in severe cases, far short of the 100,000+ miles typical for well-maintained manual transmission clutches.

The problem stems from extended periods of clutch slip during traffic, hill starts, and parking maneuvers. Unlike wet-clutch systems where transmission oil dissipates heat, dry-clutch systems rely on airflow for cooling—inadequate during sustained low-speed operation. Symptoms of clutch wear include increasing shudder or vibration during acceleration, slipping sensation (engine revs rise without corresponding acceleration), burning smell (overheated clutch material), and eventual inability to engage gears.

Mechatronic unit failures represent the most expensive DCT problem. The integrated valve body, control module, and solenoid pack contains dozens of electronic and hydraulic components operating in a harsh environment—exposed to heat, vibration, and hydraulic pressure cycles. Common failure modes include solenoid coil burnout, valve body wear causing hydraulic leaks, electronic control board failures (often due to heat or moisture ingress), and software corruption.

Symptoms of mechatronic failure include harsh or delayed shifts, inability to engage certain gears, transmission stuck in failsafe mode (typically third gear only), and transmission fault codes stored in the TCU. The unfortunate reality is that mechatronic units typically cannot be economically repaired—replacement with new or remanufactured units costing $2,000-$5,000 represents the standard fix.

Shift quality issues manifest in various ways. The transmission may exhibit delayed shifts when TCU gear prediction proves incorrect—you’ll notice 0.5-1 second lag while the system disengages the pre-selected gear and engages the gear you actually need. “Hunting” between gears on moderate grades represents another common complaint, where the transmission constantly shifts between third and fourth gear trying to find optimal engine load. Harsh engagement at low speeds, particularly when cold, affects some systems.

Many shift quality issues can be addressed through TCU software updates. Manufacturers continuously refine transmission control algorithms based on customer feedback and field experience. Before condemning mechanical components, always check with your dealer about available software updates for your specific transmission—these updates are often performed at no charge under warranty or goodwill policies.

Essential Maintenance Requirements

Fluid service represents the most critical preventive maintenance for DCT longevity. Unlike the misleading “lifetime fill” claims some manufacturers made in early DCT applications, regular transmission fluid changes significantly extend transmission life.

For wet-clutch DCT systems, fluid change intervals typically range from 40,000 to 60,000 miles depending on manufacturer specifications. Volkswagen specifies 40,000 miles for DSG service under normal conditions, reduced to 30,000 miles for towing or severe service (frequent trailer towing, extensive mountain driving, police/taxi service, or commercial delivery use). The service includes replacing transmission fluid, cleaning or replacing the transmission filter, and checking for software updates.

Dry-clutch DCT systems require less frequent fluid changes since the clutches themselves don’t contaminate the transmission oil. However, the gear sets and hydraulic actuators still require clean, properly-specified lubricant. Check your owner’s manual for specific intervals—many manufacturers specify 60,000-80,000 mile intervals for dry-clutch systems.

Critical fluid specification: Use ONLY the exact transmission fluid specified by the manufacturer. DCT fluids have unique properties—precise viscosity for hydraulic actuator response, specific friction modifiers for wet-clutch systems, and thermal stability for high-temperature operation. Using incorrect fluid, including generic “multi-vehicle ATF” or manual transmission fluid, will cause clutch shudder, shift quality problems, and accelerated wear. The modest savings on fluid cost isn’t worth risking a $5,000+ transmission replacement.

Software updates can dramatically improve DCT behavior without mechanical intervention. Manufacturers release periodic TCU software updates that refine shift timing, adjust clutch engagement algorithms, improve gear pre-selection logic, and enhance adaptive learning capabilities. These updates can resolve many drivability complaints—particularly jerky low-speed operation and shift hesitation.

Check with your manufacturer’s authorized dealer about available software updates for your specific vehicle. Many updates are performed at no charge, especially for vehicles still under warranty. Some manufacturers proactively notify owners when important updates become available, while others require you to inquire during service visits.

Driving technique optimization significantly impacts DCT longevity, particularly for dry-clutch systems. Think of DCT operation like an automated manual transmission rather than a traditional automatic:

- Avoid prolonged low-speed creeping. In heavy traffic, allow gaps to open then accelerate smoothly rather than constantly inching forward at 2-3 mph. Each instance of low-speed crawling requires clutch slip that generates heat and wear.

- Use the parking brake on hills. When stopped on an incline, don’t hold the vehicle with throttle alone—this forces extended clutch slip. Apply the parking brake or (on vehicles so equipped) use the automatic hill-hold function.

- Allow the transmission to warm up. Like engines, transmissions operate most efficiently at normal operating temperature. Avoid aggressive driving or heavy loads until the transmission fluid reaches operating temperature—typically 5-10 minutes of normal driving.

- In manual mode, avoid excessive launch control use. While launch control systems are engineered to handle abuse, frequent maximum-attack launches accelerate clutch wear. Reserve launch control for special occasions rather than every stoplight.

- Minimize stop-and-go driving when possible. Route selection that favors flowing traffic over stop-and-go reduces clutch cycling. Obviously not always practical, but worth considering for regular commutes.

Warning Signs Requiring Professional Attention

Certain symptoms indicate developing DCT problems that warrant immediate professional evaluation:

- Check engine light with transmission codes – Modern diagnostic systems monitor dozens of DCT parameters. Fault codes in the P07XX range specifically indicate transmission control system issues. Don’t ignore these warnings.

- Transmission temperature warning light – Indicates overheating that can cause permanent clutch damage if operation continues. Stop safely and allow cooling before proceeding, then have the system evaluated.

- Unusual noises during shifts – Grinding, clunking, or whining noises indicate mechanical problems requiring immediate diagnosis. These sounds never resolve themselves and typically worsen rapidly.

- Vibration or shudder during acceleration – Especially when cold or at low speeds, indicates clutch wear or hydraulic control problems. Early intervention can prevent more extensive damage.

- Delayed engagement from stop – If the lag from releasing brake to actual vehicle movement exceeds 2-3 seconds, or if the engagement is harsh, immediate service is required.

If you experience any of these symptoms, schedule professional diagnosis immediately. DCT problems rarely resolve themselves and typically worsen rapidly once symptoms appear.

DCT vs Other Transmission Types

Understanding how DCT compares to alternative transmission technologies helps you make informed decisions when purchasing a vehicle.

DCT vs Manual Transmission

The comparison between DCTs and traditional manual transmissions reveals trade-offs between involvement, simplicity, and performance.

DCT advantages over manual:

- Eliminates clutch pedal operation, reducing driver fatigue in traffic

- Achieves faster shifts than humanly possible (8-100ms vs 150-250ms)

- Prevents missed shifts, money shifts (accidentally selecting wrong gear), and clutch damage from improper technique

- Typically delivers better fuel economy through optimal shift point selection

- Frees driver attention for vehicle control rather than shift execution

Manual advantages over DCT:

- Lower initial purchase cost ($1,000-$2,000 typically)

- Simpler mechanical design with fewer failure modes

- Less expensive to repair—clutch replacement $800-$1,500 vs DCT clutch pack $3,000-$6,000

- More durable when properly operated—manual clutches routinely exceed 100,000 miles

- Provides direct mechanical connection feel that some enthusiasts prefer

- Allows techniques like left-foot braking and specific gear holding impossible with automated systems

The choice often comes down to intended use. Daily driver in heavy traffic? DCT’s convenience proves invaluable. Weekend fun car on twisty roads? Some enthusiasts still prefer the involvement of a proper manual despite the DCT’s superior performance.

DCT vs Traditional Automatic

Comparing DCTs to conventional planetary-gear automatic transmissions highlights efficiency versus refinement trade-offs.

DCT advantages over traditional automatics:

- 5-10% better fuel efficiency from eliminating torque converter losses

- Faster acceleration due to uninterrupted power delivery during shifts

- 50-100 lbs lighter (depending on application and gear count)

- More direct, engaging driving feel appreciated by enthusiast drivers

- Reduced mechanical complexity (fewer planetary gears, no torque converter)

Traditional automatic advantages over DCT:

- Smoother operation at low speeds without clutch slip shudder

- More refined for luxury applications where smoothness trumps performance

- More forgiving in heavy traffic with less risk of premature clutch wear

- Lower repair costs for common wear items (torque converters $800-$1,500 vs DCT mechatronics $2,000-$5,000)

- Proven long-term durability—many traditional automatics routinely exceed 200,000 miles with basic maintenance

Modern high-quality automatic transmissions (ZF 8-speed, Aisin 8-speed) have largely closed the efficiency gap with DCTs while maintaining superior refinement. This explains why many manufacturers have moved away from DCT technology in non-performance applications.

DCT vs CVT

The comparison between DCTs and continuously variable transmissions (CVT) represents fundamentally different engineering philosophies.

DCT advantages over CVT:

- Better acceleration feel with distinct, tactile gear changes

- More engaging for enthusiast drivers who prefer traditional transmission behavior

- Higher torque capacity—DCTs handle 750+ Nm while most CVTs max out around 350 Nm

- Less “rubber band” effect—engine RPM matches vehicle speed progression more naturally

- Typically more responsive to driver inputs with paddle shifter control

CVT advantages over DCT:

- Theoretically more efficient through infinite ratio variability (though real-world advantage is minor)

- Smoother operation with zero perceptible shift points

- Lower manufacturing cost in economy car applications

- Simpler electronic control without gear pre-selection complexity

Performance-oriented vehicles almost universally favor DCTs over CVTs, while economy-focused applications often choose CVTs for cost and refinement. Few enthusiast drivers would voluntarily choose a CVT over a DCT given the option.

Conclusion

Dual-clutch transmission technology represents one of automotive engineering’s most impressive achievements—seamlessly combining the efficiency and performance of manual transmissions with the convenience of automatics. The two-clutch, pre-selection architecture enables shift times measured in milliseconds, delivering uninterrupted power flow that translates to both faster acceleration and improved fuel economy.

The benefits are substantial and measurable: 5-10% better fuel efficiency than traditional automatics, shift speeds faster than any human driver can achieve, elimination of shift shock for smooth acceleration, and the versatility to operate as either a refined automatic or engaging manual depending on driver preference. These advantages explain DCT proliferation from exotic supercars down to mainstream compact vehicles.

However, DCT technology isn’t without trade-offs. The complexity that enables superior performance also introduces potential reliability concerns and expensive repair costs. Certain dry-clutch systems have earned poor reputations due to premature clutch wear and jerky low-speed operation—issues largely resolved in modern wet-clutch designs but which have tainted public perception of the technology. Mechatronic unit failures can result in repair bills exceeding $5,000, while proper maintenance requires manufacturer-specific service at higher cost than conventional automatics.

When DCT Makes Sense

Dual-clutch transmissions excel in specific applications:

Performance-oriented driving leverages DCT’s lightning-fast shifts and uninterrupted power delivery. Track enthusiasts, canyon carvers, and anyone who values maximum acceleration will appreciate what DCTs offer—superior performance compared to manuals without requiring clutch pedal operation.

Efficiency-focused applications benefit from the 5-10% fuel economy improvement over traditional automatics. While modern high-quality conventional automatics have closed this gap, DCTs still hold a slight advantage particularly in smaller, lighter vehicles where every percentage point of efficiency matters.

Enthusiast daily drivers represent DCT’s sweet spot—vehicles that must handle commuting duties but still deliver engagement when desired. The ability to operate as a refined automatic in traffic yet provide immediate manual control via paddle shifters offers genuine versatility.

DCTs make less sense for applications prioritizing ultimate refinement over performance (luxury cruisers), vehicles primarily operated in heavy urban traffic (where low-speed shudder becomes frustrating), or situations where absolute minimum repair cost is paramount (high-mileage budget vehicles where a $5,000 transmission repair exceeds vehicle value).

Understanding Enables Better Ownership

Knowledge of DCT operation, common issues, and maintenance requirements transforms you from a passive owner into an informed custodian of sophisticated technology. You can now recognize warning signs before they become catastrophic failures, understand why proper fluid service intervals matter, make informed decisions when purchasing vehicles equipped with DCT systems, and communicate effectively with service professionals using proper terminology.

Most importantly, you understand that while DCTs deliver impressive performance and efficiency advantages, they require professional service from qualified technicians with manufacturer-specific training and diagnostic equipment. This isn’t a limitation—it’s simply the reality of working with complex mechatronic systems that integrate mechanical, hydraulic, and electronic control in ways that exceed typical DIY capabilities.

The Professional Service Imperative

This guide has emphasized professional service requirements throughout, and it bears repeating: dual-clutch transmission diagnosis and repair must be performed by qualified professionals with proper training, manufacturer-specific diagnostic equipment, and access to technical service information. The complexity, specialized tools required, and potential safety consequences of incorrect procedures put DCT service firmly in the professional realm.

Attempting DIY diagnosis or repair without proper capabilities risks transmission damage, expensive improper repairs, and potentially unsafe vehicle operation. When DCT concerns arise, consult a qualified transmission specialist or manufacturer-authorized dealer service department. The cost of proper professional diagnosis and service represents sound investment in your vehicle’s long-term reliability and your safety.