How Car Batteries Work: Energy Storage and Chemical Reactions

You turn the key in your ignition or press the start button, and your engine roars to life. This seemingly simple act depends entirely on a sophisticated electrochemical device under your hood: your car battery. Without a functioning battery, even the most powerful engine becomes nothing more than several hundred pounds of immobile metal. The […]

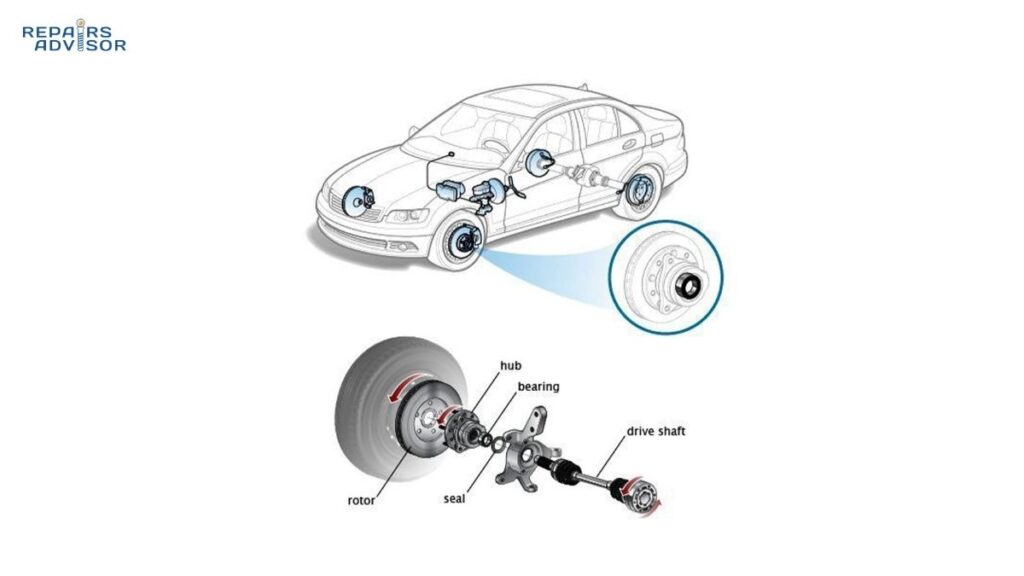

How Wheel Bearing Systems Work: Load Support & Rotation

Every time you drive, four small components silently support thousands of pounds while rotating at highway speeds, handling forces that would destroy lesser parts in minutes. Wheel bearings make modern driving possible by enabling smooth wheel rotation with minimal friction while simultaneously managing the extreme vertical loads from your vehicle’s weight, lateral forces during cornering, […]

How Bump Stops Work: Suspension Travel Limiting

Every time your vehicle hits a pothole, speed bump, or rough terrain, a small but critical component prevents thousands of dollars in suspension damage. Bump stops—those often-overlooked rubber or polyurethane cushions in your suspension system—serve as the final line of defense between controlled suspension travel and catastrophic component failure. While most drivers never think about […]

How Steering Knuckles Work: Wheel Support

The steering knuckle is one of the most critical yet often overlooked components in your vehicle’s steering and suspension systems. This heavy-duty casting serves as the central connection point where steering input, suspension movement, braking force, and wheel rotation all converge. When you turn your steering wheel, the steering knuckle is the component that actually […]

How Control Arm Bushings Work: Compliance and Isolation

Your steering wheel vibrates slightly when you accelerate. There’s a subtle clunking sound over bumps that wasn’t there before. Your car seems to wander on the highway, requiring constant correction. These seemingly minor annoyances often point to a single culprit: worn control arm bushings. These small rubber or polyurethane components rarely get the attention they […]

How Ball Joints Work: Pivot Points

Every time you turn your steering wheel while driving over uneven pavement, a remarkable mechanical component makes it possible: the ball joint. These precision-engineered pivot points are working constantly beneath your vehicle, enabling your wheels to move up and down with the suspension while simultaneously turning left and right for steering. Without properly functioning ball […]

How Control Arms Work: Suspension Geometry

Your vehicle’s suspension system contains dozens of components working together to deliver a smooth ride and precise handling. Among these, control arms serve as critical structural links that most drivers never think about—until something goes wrong. These unassuming metal components play a fundamental role in keeping your wheels properly positioned through every turn, bump, and […]

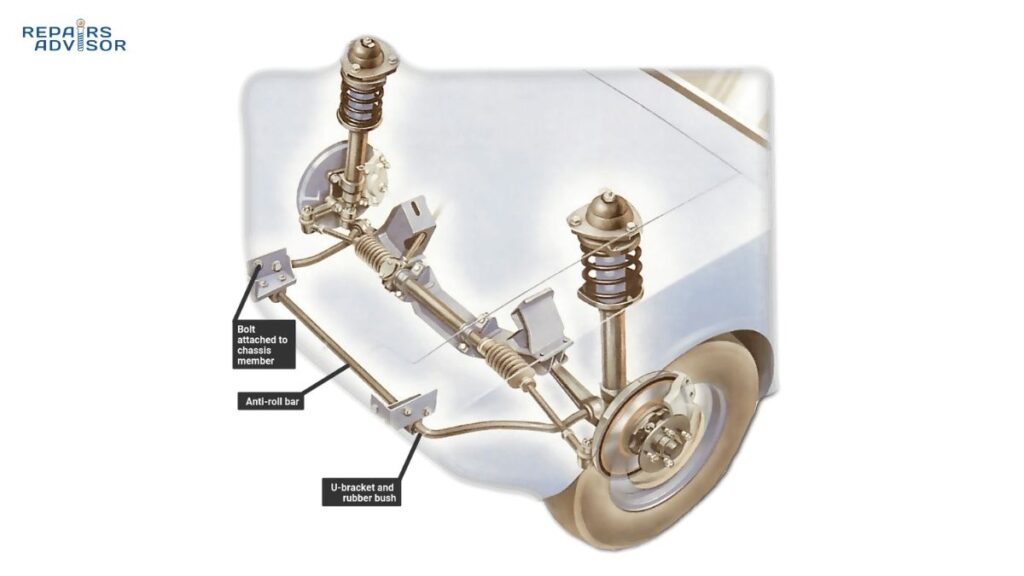

How Anti-Roll Bars Work: Body Roll Control

Picture this: you’re taking a highway exit ramp a bit faster than usual, and you feel your vehicle leaning heavily to one side. That unsettling sensation of body roll isn’t just uncomfortable—it’s reducing your tire contact with the road and compromising your vehicle’s stability. Enter the anti-roll bar, a deceptively simple component that plays a […]

How Active Suspension Works: Dynamic Control

Modern luxury and performance vehicles possess a remarkable ability—they can transform their character instantly, morphing from comfortable cruisers to precision handling machines in milliseconds. This technological marvel is active suspension, a sophisticated system that revolutionizes how vehicles interact with the road. Unlike traditional passive suspension that relies on fixed springs and dampers to provide a […]

How Suspension Springs Work: Load Support

Every time you drive over a pothole, speed bump, or uneven road surface, your suspension springs are working behind the scenes to keep your ride comfortable and your vehicle stable. These unsung heroes absorb thousands of impacts daily, yet most drivers never think about them until something goes wrong. Understanding how suspension springs work isn’t […]

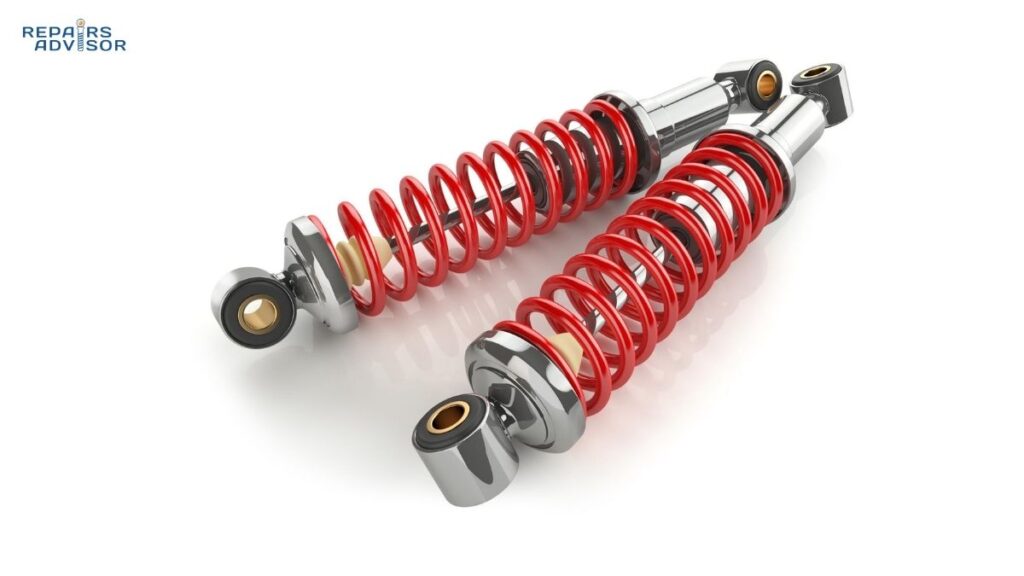

How Shock Absorbers and Struts Work: Damping Control

Have you ever hit a pothole and felt your car smoothly recover, or watched another vehicle continue bouncing like a pogo stick? That difference comes down to one critical component: shock absorbers. These unassuming cylindrical devices play a dual role that most drivers underestimate—they’re not just about comfort, they’re essential safety equipment that directly affects […]

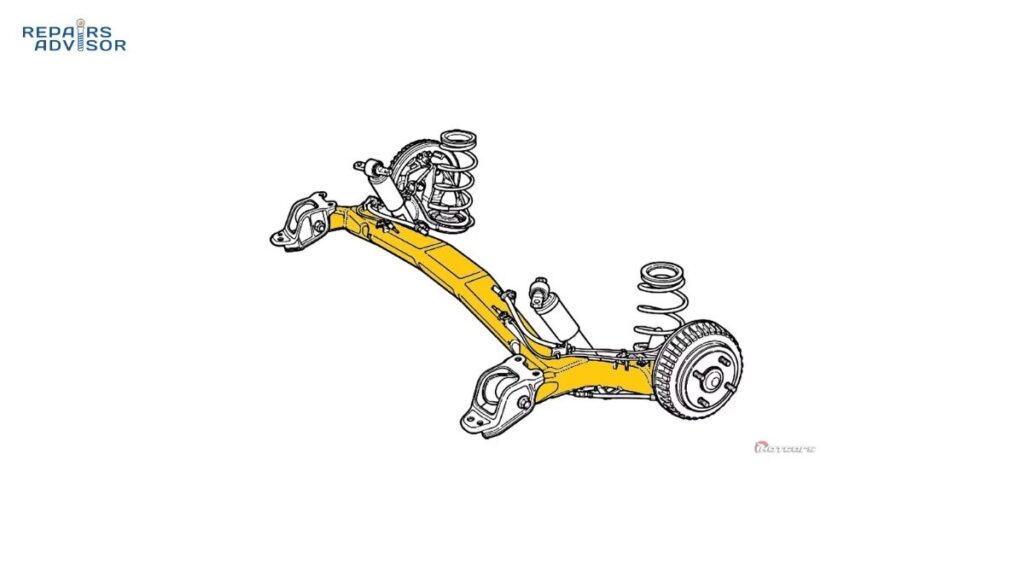

How Rear Torsion-Beam Suspension Works: FWD Architecture

When you’re shopping for a compact car or researching your vehicle’s suspension system, you’ll likely encounter the term “torsion beam suspension.” This rear suspension design has powered millions of vehicles worldwide, from budget-friendly economy cars to track-ready hot hatches like the Honda Civic Type R and Renault Mégane RS. Understanding how torsion beam suspension works […]