What Is Variable Valve Lift?

Variable valve lift is an engine technology that automatically adjusts how far engine valves open based on driving conditions, improving both fuel efficiency and performance by up to 15%. This advanced cam switching technology allows engines to optimize valve operation for different scenarios – using low valve lift (4-6mm) during light driving for maximum fuel economy, and high valve lift (8-12mm) during acceleration for maximum power output.

Unlike traditional fixed valve systems that use the same valve opening amount at all times, variable valve lift mechanisms employ sophisticated hydraulic valve actuation systems controlled by the engine’s computer. Popular systems include Honda’s VTEC operation, BMW’s Valvetronic system, and Nissan’s VVEL technology, each using different approaches to achieve variable lift mechanisms.

Variable valve lift technology represents one of the most sophisticated approaches to optimizing engine performance across varying operating conditions. This advanced system addresses the fundamental compromise between fuel efficiency and power delivery that has limited conventional engines for decades.

Why Variable Valve Lift Is Critical for Engine Performance

Variable valve lift systems provide unprecedented control over engine breathing characteristics, adapting valve operation to match engine speed, load, and efficiency requirements in real-time. This advanced technology addresses a fundamental limitation of conventional valve systems: the compromise between low-end efficiency and high-performance capability.

For Intermediate DIY Enthusiasts: Understanding variable valve lift operation helps you appreciate why modern engines can deliver both excellent fuel economy and strong performance. While these systems require specialized diagnostic tools for troubleshooting, recognizing their operation principles enables better maintenance planning and helps you communicate effectively with professional technicians when complex issues arise.

For Professional Mechanics: Variable valve lift diagnosis requires understanding multiple control strategies across different manufacturers. Honda’s VTEC operation uses discrete cam switching between two profiles, BMW’s Valvetronic system provides continuously variable lift control from 0.2mm to 12mm, and Nissan’s VVEL employs electric motor-driven cam switching technology. Each system demands manufacturer-specific diagnostic procedures and specialized scan tool capabilities.

For Beginners: Think of variable valve lift like adjustable windows in your house – sometimes you want them fully open for maximum airflow, other times partially open for controlled ventilation. The engine’s computer automatically adjusts these “windows” (valves) hundreds of times per minute to optimize performance and efficiency.

Modern variable valve lift systems typically achieve 10-15% improvements in fuel efficiency during light-load conditions while maintaining full power capability when needed. This dual-benefit approach makes these systems essential components in meeting increasingly stringent emissions and efficiency standards.

Variable Valve Lift Parts and Construction Explained

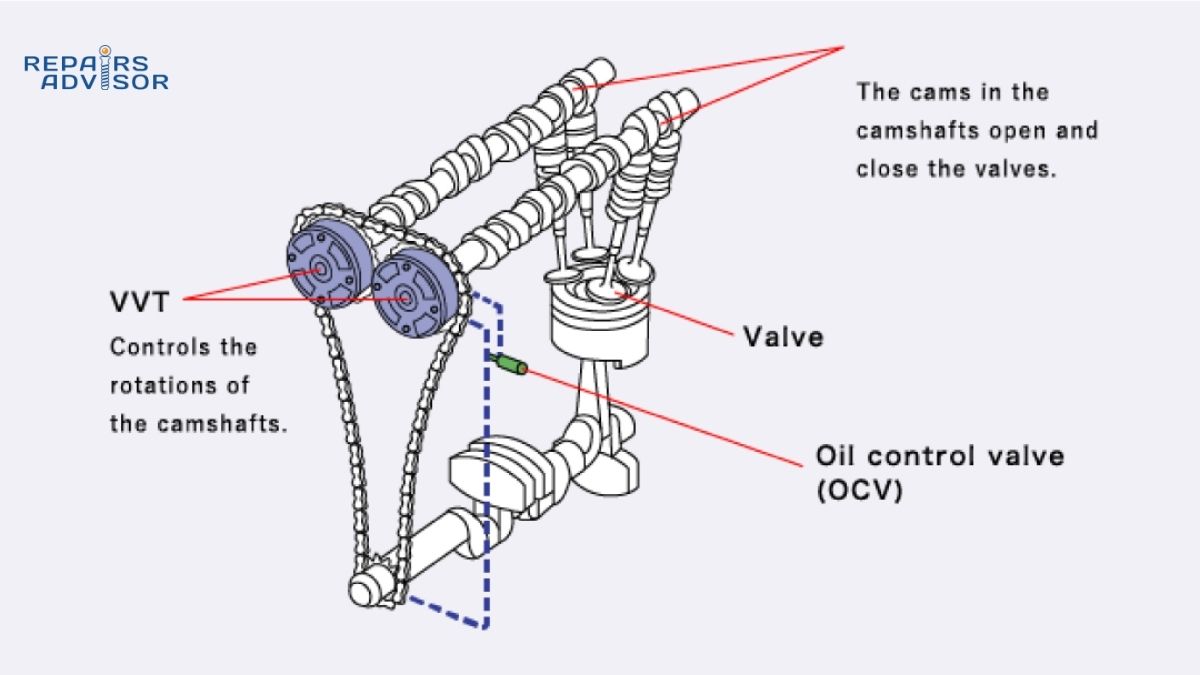

Variable valve lift systems integrate multiple precision components working in harmony to provide seamless lift adjustment. The core architecture varies between manufacturers, but all systems share common fundamental elements designed to modify valve lift characteristics dynamically.

Switching Tappets and Multi-Profile Cams form the mechanical foundation of many variable valve lift systems. Switching tappets contain hydraulically-operated mechanisms that can engage different cam lobes or rocker arm profiles through precision cam switching technology. These tappets house precision-machined switching pins that move laterally under hydraulic pressure ranging from 350-500 kPa (51-72 psi), connecting the valve operation to either low-lift or high-lift cam profiles within 40-100 milliseconds.

Multi-profile cams feature multiple lift contours on a single camshaft, with different profiles optimized for various engine operating conditions. Low-lift profiles typically provide 4-6mm of valve lift with 220-240° duration for efficiency-focused operation, while high-lift profiles offer 8-12mm lift with 260-280° duration for maximum airflow and performance. The cam switching technology ensures seamless transitions between profiles without valve float or mechanical interference.

Hydraulic Actuators and Control Systems manage the switching between lift profiles through precisely controlled oil pressure systems operating at 4-6 bar (58-87 psi) for reliable hydraulic valve actuation. These actuators receive pressurized engine oil through dedicated oil galleries and solenoid-controlled valves that respond within 10-20 milliseconds of ECU commands. The hydraulic actuators must operate reliably across temperature ranges from -40°C to +150°C and maintain precise timing to avoid valve damage during switching events.

Electronic Control Unit Integration coordinates variable valve lift operation with other engine systems including variable valve timing, fuel injection, and ignition timing through 32-bit processing capabilities. The ECU processes inputs from multiple sensors including throttle position (0.5V-4.5V signal range), engine speed (up to 8,000 RPM monitoring), coolant temperature, and intake manifold pressure at refresh rates up to 1000Hz to determine optimal lift requirements for current operating conditions.

Advanced systems like BMW’s Valvetronic system incorporate continuously variable lift control rather than discrete switching between profiles. These systems use electrically-controlled intermediate lever actuators and eccentric shaft mechanisms to provide infinitely variable lift adjustment between 0.2mm minimum and 12mm maximum values, with positioning accuracy within ±0.1mm through servo motor control and feedback sensors.

Oil Pressure Management requires dedicated hydraulic circuits to ensure reliable switching operation. These circuits include pressure accumulators, check valves, and filtering systems to maintain clean, consistent oil pressure to the switching mechanisms. Engine oil quality becomes critically important for variable valve lift reliability.

How Variable Valve Lift Works: Step-by-Step Operation

Variable valve lift operation involves continuous monitoring of engine conditions and real-time adjustment of valve lift characteristics to optimize performance and efficiency. The process requires precise coordination between mechanical, hydraulic, and electronic systems.

Initial System Activation begins when the engine starts and oil pressure reaches operating levels. The ECU performs system diagnostics and initializes all variable valve lift components to default operating positions. Most systems default to low-lift mode during startup to ensure smooth cold-engine operation and reduced emissions.

Sensor Input Processing provides the foundation for lift control decisions. The ECU continuously monitors throttle position, engine RPM, manifold absolute pressure, coolant temperature, and exhaust oxygen content. This data creates a comprehensive picture of engine operating conditions and driver demands.

Lift Profile Selection occurs through ECU analysis of current operating conditions against programmed performance maps. Light throttle applications with low engine speeds typically trigger low-lift operation for maximum fuel efficiency. Aggressive throttle inputs or high engine speeds activate high-lift profiles for maximum power output.

Hydraulic Switching Sequence begins with the ECU energizing appropriate solenoid valves to direct pressurized oil to switching tappets or actuator mechanisms. The switching must occur during valve closure periods to prevent mechanical interference. Advanced systems use cam position sensors to ensure proper timing of switching events.

Profile Engagement involves mechanical coupling between the selected cam profile and valve operation. In switching tappet systems, hydraulic pressure moves switching pins to engage the appropriate cam lobe. Continuously variable systems adjust intermediate rocker arms to achieve the desired lift value.

System Feedback and Monitoring provides confirmation of successful profile changes through position sensors and performance monitoring. The ECU verifies that actual valve lift matches commanded lift values and adjusts operation if discrepancies are detected.

Variable Valve Lift Systems by Manufacturer

Different manufacturers have developed unique approaches to variable valve lift technology, each with distinct advantages and diagnostic requirements:

| System | Type | Lift Range | Switching Time | Control Method | Key Features |

| Honda VTEC | Discrete 2-stage | 6mm → 11mm | 50-80ms | Hydraulic pin switching | Mechanical cam switching, high reliability, distinctive crossover sound |

| BMW Valvetronic | Continuous variable | 0.2mm → 12mm | Real-time | Electric servo motor | Throttle-free operation, infinite adjustment, complex mechatronics |

| Nissan VVEL | Continuous variable | 1mm → 11mm | 100ms response | Electric motor + eccentric cam | Independent intake/exhaust control, advanced ECU integration |

| Toyota VVT-iW | Discrete 2-stage | 5mm → 9mm | 40-60ms | Oil pressure switching | Integrated with VVT-i timing system, simplified maintenance |

| Audi AVS | Continuous variable | 2mm → 11.5mm | Real-time | Electromagnetic actuators | Cylinder deactivation integration, premium performance focus |

VTEC Operation Characteristics:

Honda’s VTEC operation relies on mechanical cam switching technology with two distinct cam profiles per cylinder. The system uses a hydraulic valve actuation mechanism that locks rocker arms together above 4,500-5,800 RPM (varies by engine), creating the characteristic VTEC engagement sound and immediate performance increase.

Valvetronic System Technology:

BMW’s Valvetronic system eliminates the traditional throttle body through continuously variable lift control. The system uses an intermediate lever between the camshaft and valve, controlled by an electric servo motor and eccentric shaft assembly. This allows precise control of engine load through valve lift rather than throttle restriction, improving efficiency by 5-10% compared to throttled engines.

Variable Valve Lift Location and Access Guide

Variable valve lift components are integrated throughout the engine’s valve train system, with primary components located in the cylinder head assembly and control systems distributed throughout the engine bay. Understanding component locations is essential for proper diagnosis, maintenance, and repair procedures.

Cylinder Head Integration houses the core variable valve lift mechanisms including switching tappets, rocker arm assemblies, and cam follower systems. These components are typically located beneath the valve cover and require valve cover removal for inspection or service. Access generally requires disconnecting ignition coils, wiring harnesses, and various engine accessories.

Hydraulic Control Valve Location varies by manufacturer but commonly mounts on the cylinder head or engine block near the oil filter housing. These solenoid-controlled valves regulate oil pressure to switching mechanisms and require electrical connection to the engine harness. Honda VTEC systems typically locate these valves on the cylinder head end, while BMW Valvetronic systems integrate control valves into the valve cover assembly.

ECU and Sensor Integration involves multiple sensors throughout the engine bay including cam position sensors, oil pressure switches, and dedicated valve lift position sensors. Cam position sensors typically mount near the camshaft timing gear, while oil pressure sensors often integrate into the hydraulic control valve assemblies.

Oil Supply System Access requires understanding of engine oil flow paths to variable valve lift hydraulic components. Many systems incorporate dedicated oil galleries with specific oil flow requirements that differ from standard engine lubrication circuits. Oil pump modifications or dedicated hydraulic pumps may supply these systems.

Diagnostic Connection Points include manufacturer-specific diagnostic connectors and service ports. Professional-level diagnosis often requires direct connection to ECU communication networks and may need specialized adapters for proper system communication.

Safety Considerations for Access include proper engine support when removing valve covers, careful handling of precision hydraulic components, and awareness that many variable valve lift systems operate under high oil pressure even when the engine is off. Residual hydraulic pressure can remain in accumulator systems for extended periods after engine shutdown.

The integration of variable valve lift technology with other advanced engine systems including direct fuel injection and turbocharging creates complex diagnostic scenarios that benefit from systematic, manufacturer-specific approaches to troubleshooting and repair.

For intermediate DIY enthusiasts, understanding these operation principles helps explain why variable valve lift engines may exhibit different performance characteristics during warm-up periods or when using lower-quality engine oil. Professional mechanics need to recognize that variable valve lift diagnosis often requires manufacturer-specific scan tools capable of commanding system operation and monitoring real-time performance data.

Safety Notice: Variable valve lift systems operate under high hydraulic pressure and integrate with critical engine timing components. Always consult manufacturer service procedures and use appropriate safety equipment when working on these systems. Improper service procedures can result in engine damage or personal injury.

Professional Recommendation: Complex variable valve lift diagnosis and repair should be performed by technicians with manufacturer-specific training and diagnostic equipment. These systems require precise timing, calibration, and testing procedures that exceed typical DIY repair capabilities.