Modern automatic transmissions have evolved far beyond simple hydraulic systems. At the heart of today’s most advanced gearboxes sits a sophisticated component called the mechatronic unit—an integrated electronic-hydraulic control center that manages every aspect of gear shifting. Whether you’re experiencing shifting problems in your VW, diagnosing a dashboard warning in your Audi, or simply want to understand how modern transmissions work, this comprehensive guide covers everything you need to know about transmission mechatronics.

TL;DR – Quick Facts

The mechatronic unit is the computerized brain of modern automatic transmissions, combining electronic sensors, hydraulic valves, and control software into a single integrated module. These units are most common in dual-clutch transmissions (DSG/DCT) from manufacturers like Volkswagen and Audi, but also appear in CVT and advanced planetary automatic transmissions.

Key Points:

- Most common failures involve solenoid malfunctions (40%), sensor issues (25%), and fluid contamination (20%)

- Service intervals typically range from 40,000 to 80,000 miles depending on transmission type

- Repair costs range from $500-$1,500 for specialist rebuilds versus $1,500-$10,000+ for replacement

- Professional diagnosis with manufacturer-specific scan tools is essential before attempting any repair

- Ignoring early warning signs leads to secondary damage costing thousands more

If you see flashing PRNDS lights on your dashboard, experience sudden loss of drive, or notice harsh shifting patterns, seek professional diagnosis immediately. The complexity of mechatronic systems makes them unsuitable for most DIY repairs without specialized equipment and expertise.

What is a Transmission Mechatronic Unit?

The Electronic-Hydraulic Brain

A mechatronic unit represents the fusion of mechanical, electronic, and hydraulic systems into a single compact control module. The term itself combines “mechanical” and “electronic” to describe this integrated approach. Think of it as the transmission’s command center—a sophisticated computer that makes hundreds of decisions per second about when to shift gears, how much hydraulic pressure to apply, and how to adapt to your driving style.

Unlike older transmissions that relied purely on hydraulic valve bodies controlled by mechanical governors and vacuum modulators, modern mechatronic systems use electronic sensors and computerized logic to achieve precise control. This integration enables the lightning-fast shifts you experience in dual-clutch transmissions and the seamless operation of automatic transmissions.

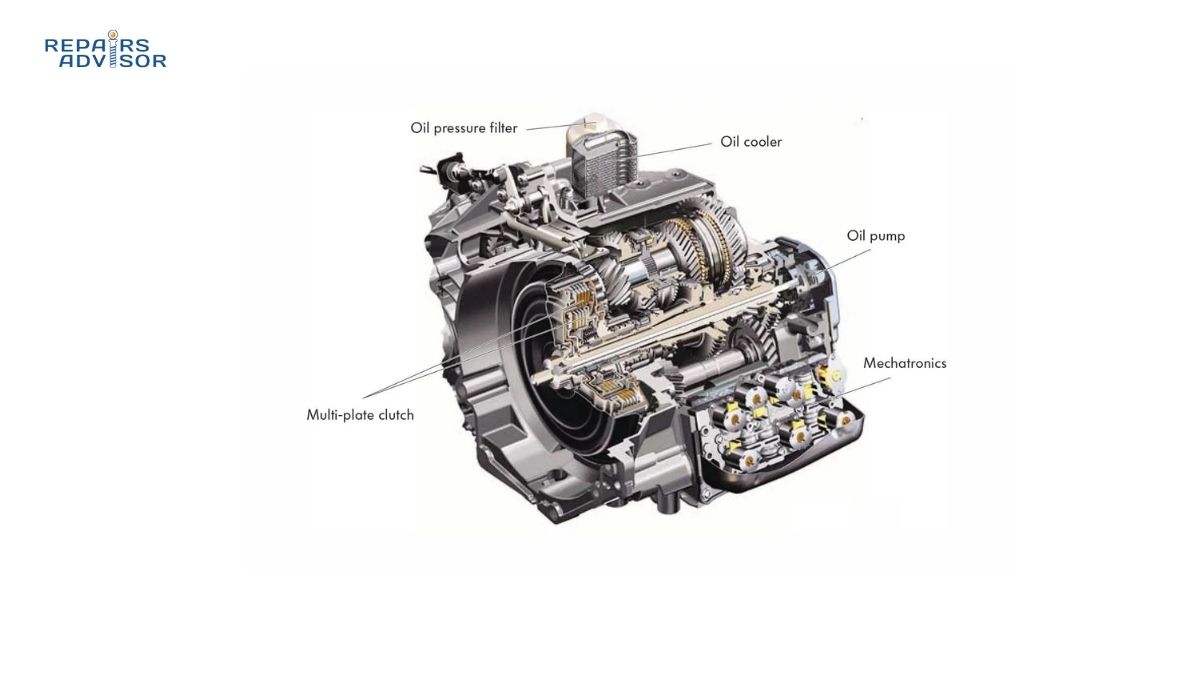

The mechatronic unit typically combines three critical systems:

Electronic Control Unit (TCU/TCM): A microprocessor-based computer running proprietary software algorithms that analyze sensor data and make gear selection decisions.

Hydraulic Valve Body: A precision-machined aluminum casting containing intricate fluid passages that direct high-pressure transmission fluid to clutches and actuators.

Electrohydraulic Solenoids: Electromagnetic valves that convert electrical signals from the TCU into hydraulic action, serving as the executive actuators that physically control fluid flow.

Historical Evolution from Hydraulic to Electronic Control

The journey to modern mechatronic systems began decades ago. Traditional automatic transmissions from the pre-2000s era used purely hydraulic valve bodies. These systems relied on mechanical governors that responded to vehicle speed and vacuum modulators that sensed engine load. While functional, they lacked the precision and adaptability of electronic control.

The transition phase in the mid-2000s saw the introduction of separate Transmission Control Modules (TCMs) that communicated with hydraulic valve bodies but remained physically distinct components. This hybrid approach improved shift quality and enabled features like sport modes and manual shift control.

The breakthrough came with fully integrated mechatronic modules around 2008. Volkswagen pioneered this technology with their Direct Shift Gearbox (DSG) system, first appearing in the 2003 Golf R32. By housing the electronic control unit, valve body, and solenoids in a single sealed module, manufacturers achieved better packaging, improved reliability through reduced connections, and enhanced performance through tighter integration.

Where You’ll Find Mechatronic Units

Mechatronic units have become standard equipment across multiple transmission technologies:

Dual-Clutch Transmissions (DSG/DCT): These systems depend entirely on mechatronic control. Volkswagen and Audi lead the market with their DSG variants including the DQ200 (7-speed dry clutch), DQ250 (6-speed wet clutch), and DQ381/DQ500 (7-speed wet clutch) transmissions. Ford’s PowerShift DCT, Porsche’s PDK, and BMW’s DCT also use sophisticated mechatronic modules.

CVT Transmissions: Continuously variable transmissions from Nissan, Subaru, Honda, and Toyota employ mechatronic control to manage pulley ratios and pressure. The CVT’s unique operation requires precise electronic modulation of hydraulic pressure to the variable pulleys.

Advanced Planetary Automatics: Modern multi-speed automatics like the ZF 8-speed, GM 10-speed, and Aisin AWF transmissions use mechatronic modules to control their complex planetary gear sets and multiple clutch packs.

Hybrid Powertrains: Toyota and Lexus hybrid vehicles use specialized mechatronic control for their e-CVT systems, managing the power split between gasoline engines and electric motors through planetary gear arrangements.

The mechatronic unit typically mounts inside the transmission housing, submerged in transmission fluid for cooling. This internal location protects the sensitive electronics but also means accessing the unit requires transmission oil pan removal and sometimes partial transmission disassembly.

How Mechatronic Units Work: System Architecture

Understanding mechatronic operation requires examining how its three core components work together to deliver smooth, efficient gear changes.

The Electronic Control Unit: The Decision Maker

At the heart of every mechatronic system sits a sophisticated microprocessor running proprietary control software. This electronic control unit continuously monitors 10 to 15 different sensors to build a complete picture of vehicle operation:

Vehicle Speed Sensor: Monitors road speed through wheel speed or transmission output shaft speed, helping the TCU determine optimal shift points.

Engine Data via CAN Bus: The TCU communicates with the Engine Control Unit over the vehicle’s communication network, receiving real-time information about engine RPM, throttle position, engine load, and torque output.

Transmission Sensors: Input and output shaft speed sensors track the rotational speed of transmission shafts, allowing the TCU to calculate gear ratios and detect slippage. Temperature sensors monitor fluid temperature, adjusting shift strategies when the transmission runs hot or cold.

Hydraulic Pressure Sensors: Multiple pressure sensors throughout the hydraulic system provide feedback on actual pressure versus commanded pressure, enabling closed-loop control.

Clutch Position Sensors (DCT-Specific): In dual-clutch systems, position sensors on each clutch actuator tell the TCU exactly where the clutch contact point lies, enabling precise engagement control.

The TCU processes this sensor data hundreds of times per second, making decisions about gear selection, shift timing, and hydraulic pressure modulation. Modern systems employ adaptive learning algorithms that adjust shift patterns based on driving style—whether you drive aggressively or conservatively, the transmission adapts over time.

Communication with other vehicle systems extends beyond the engine. The TCU coordinates with the Anti-lock Braking System during emergency braking, with traction control during wheel slip events, and with stability control during aggressive cornering. This integration ensures smooth power delivery even during challenging driving conditions.

The Hydraulic Valve Body: The Mechanical Executor

While the TCU makes decisions, the hydraulic valve body executes those commands through precise fluid control. This component consists of a precision-machined aluminum casting containing dozens of intricate passages, chambers, and valves.

The valve body’s job centers on directing high-pressure transmission fluid—typically operating at 150 to 300 PSI—to the right place at the right time. This pressurized fluid flows to clutch packs to engage specific gears, to gear actuators in automated manual transmissions to select gears, to torque converter lockup clutches to improve efficiency, and through cooling circuits to dissipate heat from clutch packs.

Understanding planetary gearsets and valve bodies reveals the mechanical sophistication required. The valve body contains several types of valves working in concert:

Manual Control Valves determine whether the transmission operates in Park, Reverse, Neutral, Drive, or Sport mode based on selector position.

Pressure Regulation Valves maintain system pressure within the correct operating range, adjusting for temperature and wear.

Selector Valves direct fluid flow to specific clutch packs or actuators based on signals from the solenoids.

The tolerances in a valve body approach micron-level precision. Any wear on valve seats or contamination in fluid passages can disrupt proper operation. This explains why fluid contamination represents such a serious problem for mechatronic systems—particles that would be harmless in older, simpler transmissions can cause valves to stick or seal improperly.

Electrohydraulic Solenoids: The Interface

Solenoids bridge the gap between electronic commands from the TCU and hydraulic action in the valve body. These electromagnetic valves convert electrical signals into mechanical movement, which in turn controls fluid flow.

A typical mechatronic unit contains 6 to 12 solenoids depending on transmission complexity:

Pressure Modulation Solenoids: These use pulse-width modulation (PWM) to vary hydraulic pressure precisely. By rapidly switching on and off at high frequency (up to 1000 Hz), they achieve smooth pressure transitions rather than abrupt on-off operation.

Shift Solenoids: Binary on-off solenoids that direct fluid flow to engage or disengage specific clutches or gear actuators.

Lockup Solenoids: Control the torque converter’s lockup clutch, improving fuel efficiency by eliminating fluid slippage when conditions permit.

Clutch Control Solenoids (DCT-Specific): Dual-clutch transmissions require individual solenoids for each clutch actuator, enabling the independent control necessary for smooth clutch-to-clutch shifts.

Each solenoid consists of an electromagnetic coil surrounding a movable plunger or valve. When the TCU applies voltage to the coil, it creates a magnetic field that moves the plunger, opening or closing a hydraulic passage. The resistance of these coils typically measures between 5 and 20 ohms—a specification technicians can verify during diagnosis.

Solenoids represent the most common failure point in mechatronic systems. The combination of heat, electrical stress, and contamination gradually degrades the coil insulation and mechanical components. When a solenoid fails, it disrupts the entire gear selection process.

The Complete Operating Cycle

Watching these components work together reveals the sophistication of modern transmission control:

- Sensor Input Collection: The TCU continuously monitors all sensors, updating its understanding of current operating conditions.

- Algorithm Processing: Based on sensor inputs, driver demands (throttle position), and programmed shift strategies, the TCU’s software determines the optimal gear for current conditions.

- Command Generation: When a shift is needed, the TCU calculates the exact solenoid commands required—which solenoids to energize, how much pressure to command, and the precise timing sequence.

- Hydraulic Actuation: Solenoids respond to TCU commands, modulating pressure and directing fluid flow through the valve body to the appropriate clutches or actuators.

- Mechanical Response: Clutches engage or disengage, gears shift, and power flows through the new gear ratio to the wheels.

- Feedback Loop: Sensors confirm the shift completed successfully, measuring actual gear ratio achieved and pressures attained. The TCU validates the result and adjusts future shifts if needed.

- Adaptive Learning: Over time, the system learns clutch wear patterns, driver preferences, and optimal shift strategies, storing this information in adaptive memory.

Dual-Clutch Operation: A Special Case

Mechatronic control reaches its peak sophistication in dual-clutch transmissions. These systems use two independent clutch packs—one for odd-numbered gears (1st, 3rd, 5th, 7th, and Reverse) and another for even-numbered gears (2nd, 4th, 6th). This arrangement enables pre-selection of the next likely gear.

Here’s how it works during acceleration: You’re in 2nd gear with the even clutch engaged and the even gearset transmitting power. Meanwhile, the mechatronic unit has already engaged 3rd gear on the odd gearset, but the odd clutch remains open, so no power flows through that path yet. When the TCU determines it’s time to shift to 3rd, it simultaneously releases the even clutch while engaging the odd clutch. This clutch-to-clutch swap happens in 50 to 200 milliseconds—faster than you can blink.

The mechatronic unit must manage this complex choreography with precision. Overlap between clutches must be minimized to prevent binding (both clutches engaged simultaneously), yet there can’t be a gap that creates power interruption. The system also performs rev-matching on downshifts, automatically blipping the throttle to synchronize engine speed with the lower gear before engagement.

This demanding control strategy explains why dual-clutch mechatronic units tend to be more complex and more failure-prone than those in conventional automatics. The rewards—lightning-fast shifts and excellent efficiency—come with increased sophistication and maintenance demands.

Common Mechatronic Unit Problems and Symptoms

Despite their sophistication, mechatronic units experience predictable failure patterns. Understanding these problems helps you recognize issues early and avoid expensive secondary damage.

Primary Failure Modes

Solenoid Failures: The Most Common Problem

Solenoid malfunctions account for approximately 40% of mechatronic failures. These failures typically occur through two mechanisms:

Electrical coil burnout results from prolonged heat exposure and fluid contamination gradually degrading the wire insulation. When insulation fails, the coil develops internal shorts or opens circuits entirely, preventing the solenoid from functioning.

Mechanical sticking happens when carbon deposits, metal particles, or varnish buildup prevent the solenoid plunger from moving freely. Even with proper electrical function, a mechanically stuck solenoid can’t modulate pressure or direct flow correctly.

When solenoids fail, you’ll notice harsh, delayed, or completely missed gear shifts. Specific gears may become unavailable—for example, losing reverse gear or missing all odd-numbered gears in a dual-clutch system. The transmission often enters limp mode, defaulting to a single “safe” gear (usually 2nd or 3rd) to prevent further damage. Your scan tool will reveal fault codes in the P073x range for shift solenoids or P074x codes for pressure control solenoids.

Sensor Malfunctions: Feeding Bad Data

Sensor failures account for roughly 25% of mechatronic problems. Speed sensors fail when their magnetic elements become contaminated with metallic debris or when wiring harnesses suffer damage. Pressure sensors drift out of calibration from thermal stress, or their sensing diaphragms rupture from excessive pressure spikes. Position sensors wear internally as potentiometer contacts degrade, or their connectors corrode from moisture intrusion.

Symptoms of sensor failure can be particularly confusing. Your speedometer may drop to zero intermittently while driving. The transmission might refuse to engage any gear despite the selector being in Drive. You may experience an intermittent neutral sensation when stopped at traffic lights—the transmission randomly disengages, then re-engages when you press the accelerator.

Diagnostic trouble codes help identify sensor problems, with P0715 through P0727 indicating input and output speed sensor faults, and various pressure sensor codes in the P0840-P0847 range.

Fluid Contamination: The Silent Killer

Fluid contamination causes about 20% of mechatronic failures but often serves as a contributing factor in other failure modes. The problem develops gradually as clutch friction material wears and circulates through the transmission. This debris flows through the mechatronic unit, accumulating in valve body passages and solenoid screens.

Metal particles from gear wear create abrasive contamination that accelerates valve seat wear. Water ingress through failed breather valves or transmission cooler leaks introduces moisture that promotes corrosion and degrades transmission fluid properties.

The impact manifests as valve sticking, reduced pressure control accuracy, and solenoid clogging. Prevention requires strict adherence to service intervals with proper filter replacement. The mechatronic unit typically has its own fine mesh filter that must be changed during fluid service—many DIY fluid changes skip this crucial step.

Electronic Circuit Board Failures: Less Common but Catastrophic

Circuit board failures account for approximately 10% of mechatronic problems. The TCU circuit board experiences constant thermal cycling as the transmission heats up during use and cools when parked. This cycling gradually cracks solder joints, particularly around high-current components and connector pins.

Electronic components themselves degrade over time. Capacitors lose capacitance as their electrolyte dries out. Power transistors that drive solenoid coils can fail from electrical stress. Moisture intrusion through degraded seals allows condensation to form on the circuit board, causing corrosion and short circuits.

When circuit board problems occur, they often cause complete transmission failure. The TCU stops responding entirely, scan tools can’t communicate with the transmission module, and the vehicle won’t move. Unlike solenoid or sensor failures that may be intermittent or affect only certain gears, circuit board failures tend to be absolute.

Software Corruption: The Digital Gremlin

Software issues cause roughly 5% of mechatronic problems. Flash memory storing the TCU’s operating program can become corrupted by voltage spikes from alternator failures or jump-starting procedures. Adaptive learning parameters may drift so far out of range that the transmission can no longer function properly.

The solution usually involves ECU reflashing—uploading updated software to the TCU using manufacturer diagnostic equipment. Sometimes this resolves the issue completely; other times, it reveals underlying hardware problems that prevented proper operation.

Recognizing the Warning Signs

Mechatronic problems typically announce themselves progressively rather than catastrophically. Learning to recognize the early warning signs allows intervention before minor issues escalate into transmission-destroying failures.

Early Warnings (Days to Weeks)

The first hints of trouble appear as subtle changes in shift quality. You might notice occasional rough shifts, particularly when the transmission is cold or very hot. A slight delay when engaging Drive or Reverse—maybe just one or two seconds longer than usual—often signals developing issues. The transmission may “hunt” between gears on the highway, unable to decide whether to stay in 5th or shift to 6th. Listen for a subtle clunking noise during the 1st-to-2nd gear transition.

These symptoms seem minor, and many drivers dismiss them. However, they indicate that mechatronic control has become imprecise, whether from early solenoid wear, marginal sensors, or contaminated fluid affecting valve operation.

Progressive Symptoms (Weeks to Months)

As problems worsen, symptoms become more obvious and frequent. The transmission enters limp mode intermittently—suddenly limiting itself to a single gear but returning to normal operation after you restart the engine. Dashboard warnings appear: the EPC (Electronic Power Control) light illuminates in VW/Audi vehicles, or a generic transmission warning icon lights up.

Specific gears become unavailable intermittently. You might lose reverse gear for a few minutes, then it returns. Odd gears may disappear, leaving only even gears functional. The vehicle surges or lurches during steady-state cruising as clutch pressure fluctuates.

At this stage, stored diagnostic trouble codes accumulate. A professional scan reveals multiple related faults, suggesting systemic mechatronic deterioration rather than a single component failure.

Critical Failure Symptoms: Stop Driving Immediately

Some symptoms demand immediate action to prevent catastrophic transmission damage:

Flashing PRNDS lights (Park, Reverse, Neutral, Drive, Sport indicators) on your dashboard represent the transmission’s emergency signal. The mechatronic unit has detected a serious fault and disabled most transmission functions to prevent destruction.

Complete loss of drive despite the engine running normally means the mechatronic unit can’t engage any clutches or gears. Attempting to drive will cause towing charges at minimum.

Getting stuck in a single gear with no shifting capability—whether 2nd gear, 3rd gear, or reverse—indicates severe mechatronic malfunction.

Severe grinding or clunking noises that weren’t present before suggest the mechatronic unit is commanding conflicting clutch operations or allowing clutches to slip excessively.

Dashboard messages stating “Transmission Fault – Workshop” or similar warnings from Ford, VW, Audi, or other manufacturers should be heeded immediately.

When scan tools retrieve three or more related transmission fault codes simultaneously, the mechatronic unit has likely suffered multiple system failures.

Vehicle-Specific Problem Patterns

Certain mechatronic units have developed reputations for specific failure modes:

Volkswagen/Audi DSG Issues

The DQ200 7-speed dry clutch transmission, found in many VW and Audi vehicles from 2008-2015, suffers premature mechatronic failures particularly affecting pressure regulation. Owners report sudden loss of drive and harsh shifts, often under 60,000 miles.

The DQ381 7-speed wet clutch transmission, common in Tiguan models, exhibits a characteristic pattern of losing odd gears (1st, 3rd, 5th, 7th) while even gears continue functioning. The vehicle enters limp mode, restricting operation to 2nd gear only.

The DQ500 7-speed wet clutch transmission, used in higher-performance applications, proves generally more reliable but requires strict adherence to 40,000-mile service intervals. Neglected maintenance causes accelerated mechatronic wear.

Ford PowerShift DCT Problems

Ford’s DPS6 transmission in 2011-2016 Focus and Fiesta models became notorious for mechatronic-related problems. Shuddering during low-speed operation, overheating, and premature clutch wear affected hundreds of thousands of vehicles. Ford extended warranties and issued multiple recalls, but the fundamental design limitations of a dry dual-clutch system in stop-and-go traffic contributed to persistent problems.

Diagnosis and Testing Procedures

Accurate mechatronic diagnosis requires specialized equipment and manufacturer-specific knowledge. While you can perform basic fault code reading, comprehensive diagnosis demands professional-grade tools and expertise.

Professional Equipment Requirements

Manufacturer-Specific Diagnostic Systems

Generic OBD-II code readers provide basic fault codes but lack the depth needed for thorough mechatronic diagnosis. Professional-grade systems enable complete analysis:

For VW/Audi vehicles, systems like VCDS (VAG-COM), VAS 5051, or ODIS provide factory-level access to all transmission parameters. These tools read detailed fault codes, display live sensor data, perform output tests to command individual solenoids, execute adaptation procedures after repairs, and store freeze frame data capturing conditions when faults occurred.

Ford vehicles require IDS (Integrated Diagnostic System) or equivalent professional tools to access PowerShift DCT functions fully.

Other manufacturers have similar requirements—generic scanners simply can’t communicate at the depth necessary for mechatronic troubleshooting.

Oscilloscope for Electrical Analysis

When solenoid problems are suspected, an oscilloscope provides invaluable insight. Technicians use oscilloscopes to verify PWM (pulse-width modulation) signals to pressure control solenoids, check command-versus-response timing to detect electrical versus mechanical failures, and identify whether the TCU sends proper commands or if solenoids fail to respond correctly.

Hydraulic Pressure Testing Equipment

Measuring actual hydraulic pressure at various points in the system confirms whether the mechatronic unit achieves commanded pressures. This requires pressure gauges with transmission-specific adapters and test port access, which varies by transmission model.

Professional shops maintain extensive collections of these adapters for different transmission families. Pressure testing reveals whether low pressure results from worn pump, stuck pressure regulation valves, or faulty pressure control solenoids.

The Professional Diagnostic Workflow

Comprehensive mechatronic diagnosis follows a systematic process:

Step 1: Scan for Stored and Pending Fault Codes

The process begins with a complete system scan. Technicians don’t just check current codes—they also review pending codes that haven’t triggered the warning light yet, and freeze frame data showing vehicle conditions when each code set.

Multiple simultaneous codes often indicate mechatronic problems rather than isolated sensor failures. For example, seeing codes for multiple shift solenoids plus clutch position sensors suggests the mechatronic unit itself failed rather than individual component problems.

Step 2: Review Adaptation Values and Learned Parameters

Modern transmissions store adaptive values for clutch wear, shift timing, and pressure compensation. Examining these values reveals how far the system has drifted from factory specifications. Adaptive values at their limit suggest mechanical wear that adaptation can no longer compensate for.

Step 3: Perform Output Tests

Professional diagnostic systems can command individual mechatronic components. Technicians activate specific solenoids while listening and feeling for solenoid clicks. A solenoid that clicks confirms it receives electrical power and the coil functions, but doesn’t guarantee hydraulic operation—the valve might still stick mechanically.

Output tests can also command the transmission into specific gears or modulate clutch pressure while monitoring system response.

Step 4: Live Data Monitoring During Test Drive

Watching live data streams during a test drive reveals problems that don’t show up in parked testing. Technicians monitor input and output shaft speeds to verify gear ratios, pressure sensor readings to confirm commanded versus actual pressure, TCU gear commands versus actual gear engaged to identify selection failures, and transmission temperature and its effect on shift quality.

Intermittent problems often appear only during specific conditions—highway speeds, hard acceleration, hot transmission temperature—making test drive monitoring essential.

Step 5: Physical Inspection and Electrical Testing

If preliminary diagnosis points to mechatronic failure, the unit must be removed for inspection. With the mechatronic unit on the bench, technicians measure solenoid coil resistance using a multimeter. Each solenoid should measure within 1-2 ohms of its specification. Open circuits (infinite resistance) or shorts (near-zero resistance) indicate failed solenoids.

Visual inspection of the valve body reveals contamination, wear patterns, or damage. The circuit board examination may show burned components, corroded connections, or cracked solder joints.

DIY Diagnostic Limitations

Home mechanics face significant challenges diagnosing mechatronic problems:

Scan Tool Limitations: Even mid-grade consumer scan tools lack the manufacturer-specific protocols needed for complete mechatronic access. You might see generic transmission codes but miss the detailed data streams and adaptation values that reveal the full picture.

Symptom Overlap: Mechatronic symptoms can mimic other transmission problems. Harsh shifts might come from worn clutch packs rather than mechatronic issues. Loss of specific gears could result from mechanical selector problems rather than solenoid failures. Without comprehensive testing capability, you risk replacing an expensive mechatronic unit when simpler repairs would suffice.

No Bench Testing Capability: Home mechanics can’t test removed mechatronic units like professional shops do. Specialized test benches simulate transmission operation, confirming which specific solenoids or circuits failed.

When Professional Diagnosis Pays Off

Consider professional diagnosis an investment rather than an expense. Spending $100-$250 for comprehensive diagnosis can save thousands in misguided repairs. A skilled technician with proper equipment determines whether you need mechatronic repair ($500-$1,500), mechatronic replacement ($1,500-$5,000), or entirely different repairs like clutch packs ($1,000-$2,500).

Some shops apply diagnostic fees toward repairs if you proceed with service there. This arrangement makes professional diagnosis essentially free when you commit to the necessary repairs.

Maintenance and Prevention

Proper maintenance dramatically extends mechatronic life and prevents expensive failures. Unfortunately, many manufacturers promoted “lifetime fluid” myths that led to premature transmission failures. Understanding real-world service needs protects your investment.

Service Intervals by Transmission Type

Wet-Clutch Dual-Clutch Transmissions (DQ250, DQ381, DQ500)

These systems require service every 40,000 miles or 4 years, whichever comes first. The DQ381 variant received extended service intervals of 80,000 miles from some manufacturers, but transmission specialists strongly dispute this recommendation. Real-world evidence shows significantly higher failure rates when service is delayed beyond 40,000 miles.

Track or performance driving demands even more frequent service—consider 30,000-mile intervals when regularly driving aggressively or participating in track events. The additional heat and clutch wear accelerate fluid degradation and contamination.

Dry-Clutch DSG Transmissions (DQ200)

Despite the dry clutch design, the mechatronic unit still operates in fluid. Service every 40,000 miles remains essential regardless of manufacturer claims about “lifetime” fluid. The DQ200’s problematic reputation partly stems from owners following extended service intervals that allow contamination to build up.

CVT Transmissions

Continuously variable transmissions generally require service every 60,000 to 90,000 miles depending on manufacturer specifications. However, Nissan CVT owners benefit from aggressive 30,000 to 60,000-mile service intervals. Nissan CVTs have shown vulnerability to mechatronic problems when fluid service is neglected.

Planetary Automatics with Mechatronic Control

Modern multi-speed automatics like the ZF 8-speed and GM 10-speed benefit from 40,000 to 60,000-mile service intervals. Manufacturers have quietly revised earlier “lifetime fluid” claims after experiencing higher failure rates. Independent shops typically recommend 40,000-mile intervals as a conservative best practice.

What Proper Service Involves

Full Fluid Exchange Versus Drain-and-Fill

A simple drain-and-fill only removes about 60% of old fluid. The remaining contaminated fluid mixes with new fluid, diminishing the service effectiveness. Full fluid exchange using a flush machine removes 95% or more of old fluid while introducing fresh fluid throughout the system.

Quality shops also use flushing fluid treatments during exchange. These chemical additives break down varnish deposits and carbon buildup inside the valve body and mechatronic passages, restoring proper operation of sticky valves.

Critical Filter Replacement

Two filters require attention during DSG service: the internal transmission filter that protects the hydraulic pump, and the mechatronic filter—a fine mesh screen protecting the valve body and solenoids from contamination.

Many quick-lube shops and DIYers skip the mechatronic filter, not realizing it exists or how to access it. This oversight leaves contamination in place that will continue damaging the mechatronic unit.

Fluid Specification Matters

Using incorrect transmission fluid causes immediate problems. Dual-clutch transmissions require specific friction characteristics that generic “universal” ATF doesn’t provide. For example, VW specifies different fluids for different DSG variants: G 052 182 for DQ250, G 052 529 for DQ381, and G 055 025 for DQ500.

Using the wrong fluid affects shift quality, clutch engagement characteristics, and long-term wear rates. Always verify you’re using manufacturer-specified fluid, even if aftermarket alternatives cost less.

Post-Service Adaptation Procedures

After fluid service, the mechatronic unit requires adaptation using a manufacturer scan tool. This process teaches the TCU new clutch contact points (bite points) accounting for fresh fluid’s different properties. Without proper adaptation, you’ll experience rough shifts and potentially rapid clutch wear as the system operates with incorrect learned parameters.

Professional shops include adaptation in their service price. DIY mechanics must either have access to proper scan tools or pay a shop to perform adaptation after fluid service.

Driving Habits That Extend Mechatronic Life

How you operate your vehicle significantly impacts mechatronic longevity:

Warm-Up Considerations

Avoid aggressive acceleration and high-RPM shifts until the transmission reaches operating temperature (140-180°F). Cold fluid has higher viscosity, creating sluggish hydraulic response and higher mechanical loads on the mechatronic unit. Most vehicles with mechatronic transmissions benefit from gentle driving for the first 5-10 minutes, especially in cold weather.

Stop-and-Go Traffic Management

Dual-clutch systems experience significant thermal stress in heavy traffic. The clutches partially engage constantly, generating heat that the mechatronic unit must manage. On steep hills at traffic lights, shift to Neutral and use the parking brake rather than holding the vehicle on the clutch. This simple habit reduces clutch heat by several hundred degrees.

Performance Driving Considerations

Launch control and aggressive launches dramatically accelerate clutch and mechatronic wear. If you regularly use these features, increase service frequency to every 20,000-30,000 miles and consider a transmission cooler upgrade.

Towing Impacts

Towing significantly increases transmission thermal stress. The additional load generates more heat in clutches and fluid, accelerating wear on all components including the mechatronic unit. If you tow regularly, more frequent fluid service becomes essential—consider 30,000-mile intervals. An auxiliary transmission cooler helps manage temperature but doesn’t eliminate the need for increased maintenance.

Monitoring for Early Problems

Catching mechatronic problems early prevents secondary damage that multiplies repair costs. Develop these habits:

Pay Attention to Shift Quality Changes

Your transmission develops a characteristic shift feel over time. Any deviation from normal—slightly harder shifts, longer delays, different shift points—deserves investigation. Don’t adopt a “wait and see” attitude with transmission changes.

Temperature Awareness

If your vehicle displays transmission temperature warnings, stop immediately and allow cooling. Continued driving with an overheating transmission destroys clutches and mechatronic components within minutes.

Annual Diagnostic Scans

For vehicles with DSG transmissions over 8 years old or with more than 80,000 miles, consider annual diagnostic scans even without symptoms. These preventive scans reveal developing problems before they cause failures, allowing planned repairs rather than emergency towing and rushed decisions.

Professional shops often provide diagnostic scanning as a low-cost service during regular maintenance visits. The small investment in early detection pays dividends by catching problems before they cause secondary damage.

Repair Versus Replacement: Making the Right Decision

When faced with mechatronic failure, you have several options at vastly different price points. Understanding the trade-offs helps you make an informed decision.

Repair Costs and Processes

Component-Level Mechatronic Rebuild

Independent transmission specialists offer mechatronic rebuilding services ranging from $500 to $1,500 depending on transmission type and extent of damage. The process involves:

The shop removes your mechatronic unit, which requires dropping the transmission oil pan and sometimes partial transmission disassembly. Your unit is then cleaned, disassembled, and inspected. The valve body undergoes ultrasonic cleaning or solvent bath cleaning to remove all contamination. Failed solenoids are replaced with new or upgraded units. Worn valves and springs are replaced as needed. Electronic circuit boards receive inspection and repair of cracked solder joints or damaged components.

After reassembly, the unit undergoes testing on a specialized HIL (Hardware-In-Loop) test bench. This equipment simulates actual transmission operation, cycling the unit through all gears and pressure ranges to verify proper function before reinstallation.

The entire process typically takes 2-3 business days. Your vehicle sits immobile during this period unless you have a spare mechatronic unit to install temporarily.

Advantages of Rebuilding

The primary advantage is cost—rebuilding typically costs 60-70% less than OEM replacement. Many specialists use upgraded components that address known design weaknesses in the original units. Improved solenoid coil wire insulation, better circuit board conformal coating for moisture protection, and upgraded valve materials increase long-term reliability.

Reputable rebuilders offer impressive warranties—lifetime unlimited mileage warranties are common, reflecting confidence in their work quality. This warranty often exceeds what you’d receive from a dealer for OEM replacement.

Disadvantages of Rebuilding

The vehicle downtime for removal, shipping, rebuilding, and reinstallation spans several days to a week. You’ll need alternative transportation during this period. There’s also an inherent risk in working with used housings and valve bodies—while components get replaced, the core structure remains from your original unit.

OEM Mechatronic Replacement Costs

Dealership Replacement Pricing

Volkswagen and Audi dealerships charge $1,500 to $5,000 or more for complete mechatronic replacement depending on transmission model:

DQ200 units typically cost around $1,800 for parts plus $600 labor, totaling approximately $2,400. DQ381 units run about $2,500 parts plus $700 labor, totaling $3,200. DQ500 units cost roughly $3,000 parts plus $800 labor, totaling $3,800.

These prices include programming the new unit to your vehicle’s VIN and performing required adaptations.

The OEM Replacement Dilemma

Here’s a critical consideration: OEM replacement units often contain the same design flaws that caused your original unit to fail. Manufacturers typically don’t revise designs unless regulatory pressure or major recalls force changes. This means your $3,000 replacement unit may fail again in 40,000-60,000 miles for the same reasons the original failed.

The standard 1-year warranty provides limited peace of mind. If failure recurs at 15 months, you’re facing another $3,000+ repair.

When OEM Replacement Makes Sense

Despite these concerns, OEM replacement is appropriate in certain situations. If your vehicle remains under powertrain warranty or extended warranty coverage, use OEM replacement—you’re not paying for it. When dealer goodwill assistance is available (manufacturers sometimes contribute to out-of-warranty repairs for known defects), take advantage of this partial coverage.

For vehicles you plan to sell within 1-2 years, OEM replacement provides documentation that some buyers value. And when you need the absolute fastest turnaround, dealers often stock common mechatronic units for immediate installation.

Complete Transmission Replacement

When Full Replacement Becomes Necessary

Sometimes mechatronic failure causes or accompanies problems beyond the unit itself:

If you continued driving with failing mechatronic unit for weeks or months, erratic clutch control may have destroyed clutch packs. Slipping clutches generate metal contamination that circulates throughout the transmission. This contamination damages bearings, gears, and shaft surfaces.

At this point, replacing only the mechatronic unit leaves you with a transmission full of contaminated fluid and damaged components. Shift quality may improve temporarily but further failures follow quickly.

Transmission Replacement Costs

New transmissions cost $4,000 to $10,000+ including parts and labor. Remanufactured transmissions range from $3,000 to $7,000 installed. These prices reflect the complexity of modern transmissions—a complete ZF 8-speed or VW DSG transmission contains hundreds of precision components.

Making the Full Replacement Decision

Consider complete transmission replacement only when diagnosis reveals extensive internal damage beyond mechatronic failure. Multiple mechanical problems—gear noise, bearing rumble, shaft wear—combined with mechatronic issues justify this approach.

Vehicles with very high mileage (150,000+) and deferred maintenance history may benefit from fresh-start transmission replacement rather than piecemeal repairs. However, for most situations involving isolated mechatronic failure in otherwise healthy transmissions, repair or mechatronic replacement alone provides better value.

The Decision Matrix

Choose Mechatronic Rebuild When:

Your vehicle has under 100,000 miles with good maintenance history. Diagnostic fault codes point to specific solenoid or sensor failures. Testing shows no evidence of clutch pack damage—no slipping during acceleration, smooth engagement when functioning properly. You’re working with a reputable independent transmission specialist with DSG or DCT expertise. Long-term reliability matters more than immediate turnaround time.

Choose OEM Mechatronic Replacement When:

Warranty or extended warranty covers the repair cost. The manufacturer offers goodwill assistance for known defects in your transmission model. You need the fastest possible repair with minimal downtime. You plan to sell the vehicle within 1-2 years and want documentation of dealer service.

Consider Complete Transmission Replacement When:

Diagnosis reveals extensive clutch pack damage from prolonged mechatronic problems. Transmission fluid shows heavy metal contamination indicating internal component failure. Your vehicle exhibits multiple mechanical problems—gear noise, bearing rumble, shaft wear—beyond just mechatronic issues. The vehicle has very high mileage (150,000+) with significant deferred maintenance.

Insurance and Warranty Considerations

Extended Warranty Coverage

Most extended warranty policies cover mechatronic unit replacement, though specific terms vary. Review your policy carefully—some require dealer service, others allow independent repair shops. Deductibles typically range from $50 to $200, making expensive mechatronic repairs quite affordable under warranty coverage.

File claims promptly and maintain complete documentation of all transmission service. Warranty companies may deny claims if you can’t prove proper maintenance.

Manufacturer Goodwill Programs

Volkswagen, Audi, and other manufacturers occasionally offer goodwill assistance for vehicles experiencing mechatronic failures outside warranty periods. Success depends on service history, mileage, and the specific defect pattern.

Build your case by documenting all maintenance with receipts showing you followed service intervals. Research your specific transmission model online—if widespread problems exist, reference Technical Service Bulletins (TSBs) or recall information when requesting assistance.

Consumer Rights Considerations

In some regions, consumer protection laws provide recourse for premature component failures. UK and European consumers have stronger protections than US buyers. Mechatronic failures under 60,000 miles on vehicles with complete service history may qualify for manufacturer contribution under “reasonable durability” standards.

Consult consumer protection agencies in your region before accepting full repair costs on low-mileage failures.

DIY Considerations and Professional Service

The allure of saving $600-$1,000 in labor costs tempts many mechanically inclined owners to attempt DIY mechatronic replacement. Understanding the requirements and risks helps you decide whether this project suits your skill level.

Required Skills and Equipment for DIY

Mechanical Skill Level Required

Mechatronic replacement demands intermediate to advanced mechanical aptitude. You must feel comfortable working underneath a raised vehicle, handling delicate electrical connectors, following precise torque specifications, and troubleshooting problems if the repair doesn’t go perfectly. Previous transmission work experience helps significantly.

Essential Tools and Equipment

You’ll need a professional-quality hydraulic floor jack rated for your vehicle’s weight, plus jack stands with appropriate load ratings. A transmission jack or specialized support fixture helps when removing the oil pan—trying to catch several quarts of fluid while supporting the pan with one hand while removing the last bolts with the other hand leads to messy failures.

Quality metric socket sets including Torx bits are essential—mechatronic mounting bolts typically use E-Torx or standard Torx designs. A torque wrench capable of measuring both ft-lbs and degrees of rotation is required for proper bolt tightening. Many mechatronic mounting bolts require torque-plus-angle tightening (torque to X ft-lbs, then rotate an additional Y degrees).

Transmission fluid fill equipment specific to your transmission type is necessary. DSG transmissions require precise fill procedures with fluid temperature monitoring—you can’t simply pour fluid in until it’s full.

Clean workspace with adequate lighting is critical. Any contamination introduced during service—dirt, lint, metal particles—will damage the freshly installed mechatronic unit immediately.

Software Requirements: The Dealbreaker for Most DIYers

Here’s where most DIY attempts fail: you must have access to manufacturer-specific diagnostic software. Generic scan tools cannot perform the required adaptation procedures. Without adaptation, your new mechatronic unit won’t know where clutch contact points are, resulting in harsh shifts and rapid clutch wear.

For VW/Audi vehicles, VCDS (VAG-COM) software with a compatible interface cable costs around $200-$400. This represents a significant investment for a single repair, though it provides capabilities for other maintenance and repairs. Ford, GM, and other manufacturers require even more expensive professional scan tools or factory software access.

New mechatronic units also require VIN coding to your specific vehicle. This security feature prevents theft but complicates DIY installation. Some aftermarket scan tools can perform coding; others cannot. Verify capabilities before purchasing.

The Physical Removal Process

Step-by-Step Overview

Proper mechatronic replacement follows this sequence:

Raise and securely support the vehicle on professional-quality jack stands. Vehicle ramps work poorly for this job—you need underneath access with adequate working clearance.

Drain transmission fluid by removing the drain plug or oil pan, capturing 6-8 quarts of fluid. Dispose of old fluid properly at recycling centers.

Remove the transmission oil pan carefully once fluid drains. The last bolts require one-handed work supporting the pan’s weight while threading out bolts. Expect fluid spillage regardless of preparation.

Disconnect electrical connectors from the mechatronic unit. These typically contain 14-20 pins in delicate plastic housings. Note connector orientation carefully—forcing connectors backward damages pins.

Remove mechatronic mounting bolts following manufacturer-specified sequence. Six to ten Torx bolts typically secure the unit. Some transmissions use captive bolts that shouldn’t be fully removed.

Carefully withdraw the mechatronic unit avoiding damage to valve body gaskets or sealing surfaces. Units weigh 5-10 pounds and can slide out suddenly once fully unbolted.

Installation reverses removal with critical attention to gasket replacement. Old gaskets must be completely removed without leaving fragments on sealing surfaces. New gaskets require proper positioning—they can shift during mechatronic installation, causing leaks.

Proper bolt torque sequence and specification is absolutely critical. Follow manufacturer procedures exactly. Under-torquing allows fluid leaks and mechatronic movement. Over-torquing cracks aluminum housings or damages valve bodies.

Refill transmission fluid following specific procedures for your transmission type. DSG transmissions require temperature-specific fill procedures—you must monitor fluid temperature with a scan tool and add fluid until overflow occurs at exactly the specified temperature (typically 35-45°C).

Perform adaptation procedures using manufacturer scan tools. This step cannot be skipped regardless of what internet forums suggest.

Risk Assessment: What Can Go Wrong

High-Risk Scenarios

Improper gasket installation causes immediate fluid leaks. Transmission fluid seepage through valve body gaskets leads to low fluid levels within hundreds of miles, causing overheating and shift problems.

Incorrect bolt torque creates multiple problems. Under-tightened bolts allow fluid leaks and mechatronic movement inside the transmission. Over-tightened bolts crack valve bodies or housing—a catastrophic failure requiring complete transmission replacement.

Fluid contamination during service represents an insidious problem. Dirt introduced while the transmission is open circulates through the system, damaging the fresh mechatronic unit. You might not notice problems immediately, but contamination causes failure within thousands of miles.

Failed adaptation procedures result from inadequate scan tool capability. The transmission “works” but shifts harshly and wears clutches rapidly. By the time you recognize the problem, significant clutch damage has occurred.

Incorrect fluid level from improper fill procedures causes overheating (too little fluid) or aeration and shift problems (too much fluid). Both scenarios damage the transmission.

Realistic Timeline and Cost Savings Analysis

First-time DIY mechatronic replacement typically requires 6-10 hours including cleanup. Experienced DIYers complete the job in 4-6 hours. This time investment spans multiple days when accounting for parts delivery, inevitable trips to buy forgotten supplies, and waiting for help with heavy components.

Labor cost savings range from $600 to $1,000 depending on your local shop rates and vehicle complexity. However, this savings comes with significant risk. If mistakes cause $2,000+ in secondary damage, you’ve lost money compared to professional service.

When Professional Service Is Essential

Situations Requiring Expert Help

Lack of access to proper diagnostic equipment makes DIY attempts foolish. Without manufacturer scan tools, you can’t verify the mechatronic unit is truly the problem, and you can’t adapt the new unit after installation.

Limited mechanical experience amplifies risk dramatically. If you’ve never worked on transmissions, mechatronic replacement isn’t an appropriate learning project.

Vehicles under warranty or extended warranty void coverage with DIY repairs. The potential savings don’t justify losing thousands in warranty protection.

Intermittent symptoms require professional diagnosis before parts replacement. The mechatronic unit might not be the problem—replacing it wastes money while leaving the real issue unresolved.

Selecting a Qualified Repair Shop

What to Look For

Seek DSG or DCT specialists rather than general transmission shops. General shops often lack specific experience with sophisticated mechatronic systems, leading to misdiagnosis and improper repairs.

Verify the shop owns manufacturer-specific diagnostic equipment. Ask directly: “Do you have VCDS/VAS for VW/Audi?” or “Do you have IDS for Ford?” Shops without proper equipment can’t perform necessary programming and adaptation.

Request quotes for both repair and replacement options. Shops offering component-level repairs demonstrate advanced capabilities—they’re not just parts swappers.

Check reviews focusing on transmission work specifically. A shop might excel at brakes and engine work but struggle with complex transmission diagnosis. Look for consistent positive feedback about transmission repairs.

Ask about warranty coverage. Reputable shops warrant their work for 12-24 months minimum. Lifetime warranties indicate exceptional confidence in repair quality.

Red Flags to Avoid

Run from shops that immediately recommend complete transmission replacement without thorough diagnosis. This approach maximizes their profit while potentially costing you thousands unnecessarily.

Avoid shops that can’t explain their diagnostic findings or show you relevant fault codes and data. Transparency builds trust—secrecy suggests either incompetence or dishonesty.

Be wary of unusually low quotes that seem too good to be true. Quality mechatronic work requires time, expertise, and proper equipment. Rock-bottom pricing suggests corners will be cut somewhere.

The Future of Mechatronic Technology

As automotive technology evolves toward electrification and increased autonomy, mechatronic systems continue developing in fascinating directions.

Current Technology Trends

Greater Integration and Miniaturization

Modern mechatronic designs pack more functionality into smaller packages. Park lock actuators, gear position sensors, and temperature monitoring increasingly integrate directly into mechatronic modules rather than existing as separate components. This consolidation reduces wiring complexity, improves reliability by eliminating connection points, and enables more compact transmission packaging.

Advanced materials science contributes to reliability improvements. Improved solenoid coil insulation withstands higher temperatures without degradation. Ceramic valve materials resist wear better than traditional steel alloys. Circuit board conformal coating protects against moisture and contamination more effectively than older designs.

Software Sophistication

The latest mechatronic control algorithms employ artificial intelligence and machine learning to adapt to driver behavior. These systems don’t just react to throttle input—they predict your intentions based on historical patterns. If you typically accelerate hard from specific intersections, the transmission prepares accordingly, holding lower gears longer for better response.

Predictive maintenance monitoring analyzes operating parameters to identify developing problems before failure occurs. Advanced systems alert drivers when adaptation values approach limits or when temperature patterns suggest developing issues. This early warning enables planned maintenance rather than emergency repairs.

Some manufacturers now offer over-the-air software updates for transmission control modules. Tesla pioneered this approach, but traditional manufacturers increasingly adopt it. Software improvements can enhance shift quality, adjust shift points for better efficiency, or even modify transmission behavior based on driver feedback—all without visiting a service department.

Adaptations for Hybrid and Electric Vehicles

Hybrid Powertrain Integration

Toyota and Lexus pioneered e-CVT systems that use mechatronic control to manage power split between gasoline engines and electric motors through planetary gear arrangements. These systems require no traditional clutches but depend entirely on precise electronic control of motor-generators and mechanical brakes within the planetary gear set.

The electric motor controllers in hybrid systems communicate constantly with the e-CVT mechatronic unit, coordinating power flows and optimizing efficiency across hundreds of operating parameters.

Multi-Speed EV Transmissions

While most electric vehicles use single-speed transmissions requiring minimal control electronics, performance EVs increasingly adopt multi-speed designs. The Porsche Taycan’s 2-speed transmission and Audi e-tron GT’s similar system use simplified mechatronic modules compared to internal combustion applications.

These EV mechatronics manage fewer components—no torque converter, no complex planetary gear sets, just clutch packs for gear engagement. However, they operate in higher voltage environments (800V architecture) requiring different electronic components and safety systems.

Single-Speed EV Simplification

The majority of electric vehicles use single-speed reduction gearboxes with minimal mechatronic control. Park pawl actuation represents the only electronically controlled function in most EV transmissions. This dramatic simplification eliminates many failure modes associated with complex automatic transmissions, though it removes the performance and efficiency benefits of multi-speed operation.

Reliability Improvements Based on Lessons Learned

Manufacturer Responses to Early Failures

The wave of mechatronic failures in mid-2010s dual-clutch transmissions forced manufacturers to improve designs. Updated solenoid coil wire uses higher-temperature insulation that maintains integrity at elevated operating temperatures. Improved fluid sealing prevents contamination from entering valve bodies through redesigned gasket materials and sealing surfaces. Circuit board conformal coating now provides better moisture protection, reducing corrosion-related failures.

Service Interval Reality Check

The “lifetime fluid” marketing that contributed to widespread failures in the 2010s is gradually disappearing. Manufacturers quietly revise maintenance schedules acknowledging that 40,000 to 60,000-mile service intervals prevent expensive failures. Some companies explicitly state in updated technical documentation that “lifetime” means “life of the powertrain warranty” rather than vehicle life.

This honest reassessment benefits consumers who follow current service recommendations rather than outdated “lifetime” claims from original owner’s manuals.

Modular Repair Approaches

Newer mechatronic designs increasingly allow component replacement without complete unit replacement. Removable solenoid packs, replaceable sensor modules, and accessible circuit boards enable targeted repairs at lower cost than replacing entire assemblies.

This modularity helps both professional repair shops and vehicle owners by reducing parts costs and diagnostic complexity. When a specific solenoid fails, replacing just that component costs hundreds rather than thousands for complete mechatronic replacement.

Conclusion: Navigating Mechatronic Complexity

Transmission mechatronics represent one of modern automotive engineering’s most sophisticated achievements—and one of its most expensive potential failure points. These integrated electronic-hydraulic control modules deliver the seamless shifting, excellent efficiency, and performance capabilities we’ve come to expect from automatic transmissions. However, their complexity demands respect, proper maintenance, and professional service when problems arise.

Key Takeaways

Understanding the System

Mechatronic units integrate electronic control units, hydraulic valve bodies, and electrohydraulic solenoids into single modules that manage all transmission operations. They appear primarily in dual-clutch transmissions (DSG/DCT), CVT systems, and modern multi-speed planetary automatics. The most common applications are in Volkswagen and Audi vehicles, though Ford, Porsche, BMW, and other manufacturers use similar technology.

Recognizing Problems Early

Solenoid failures cause 40% of mechatronic problems, manifesting as harsh shifts, missing gears, or limp mode operation. Sensor malfunctions account for 25% of failures, creating erratic behavior and intermittent symptoms. Fluid contamination contributes to 20% of problems by causing valve sticking and solenoid clogging. Circuit board failures and software glitches round out the remaining 15% of issues.

Early warning signs include occasional rough shifts, slight delays engaging gears, and intermittent problems that resolve after restarting. Progressive symptoms escalate to more frequent limp mode, specific missing gears, and dashboard warnings. Critical symptoms like flashing PRNDS lights, complete loss of drive, or severe grinding demand immediate professional attention.

Maintenance Prevents Expensive Failures

Service intervals of 40,000 to 80,000 miles depending on transmission type keep mechatronic systems healthy. Proper service includes complete fluid exchange with flushing treatment, both transmission and mechatronic filter replacement, manufacturer-specified fluid selection, and post-service adaptation procedures using diagnostic equipment.

Driving habits significantly impact longevity: allow proper warm-up before aggressive driving, use neutral and parking brake during extended stops rather than holding on clutches, avoid excessive launch control or aggressive starts, and increase service frequency when towing or operating in severe conditions.

Repair Options and Costs

Component-level mechatronic rebuilds by independent specialists typically cost $500-$1,500 with lifetime warranties, offering the best value for most situations. OEM mechatronic replacement through dealerships runs $1,500-$5,000+ but may contain the same design flaws as the original unit. Complete transmission replacement costs $3,000-$10,000+ and is necessary only when mechatronic problems caused secondary damage to clutches or internal components.

Professional Service Recommendations

Given the complexity, specialized diagnostic equipment requirements, and software adaptation needs, mechatronic diagnosis and repair should be performed by transmission specialists with manufacturer-specific expertise. DIY attempts carry significant risk of expensive mistakes without proper scan tools and experience.

Select repair shops based on DSG/DCT specialization, ownership of manufacturer diagnostic equipment, willingness to offer both repair and replacement options, positive transmission-specific reviews, and comprehensive warranty coverage.

When to Seek Immediate Help

Don’t delay professional consultation when you experience:

- Flashing PRNDS dashboard indicator lights

- Complete loss of drive despite engine running

- Transmission stuck in single gear

- Dashboard transmission warning messages

- Sudden harsh shifts or grinding noises that weren’t present previously

- Multiple transmission fault codes stored simultaneously

Early diagnosis prevents secondary damage. The cost of professional evaluation ($100-$250) represents tiny insurance against misdiagnosis or unnecessary repairs costing thousands.

Final Thoughts on Mechatronic Reliability

Modern mechatronics achieve remarkable performance and efficiency when properly maintained. While failures generate frustration and expense, most problems result from deferred maintenance or ignorance of early warning signs rather than fundamental design flaws. Following service intervals, addressing symptoms promptly, and selecting qualified repair shops when problems arise maximizes mechatronic longevity and minimizes lifetime ownership costs.

For more information on transmission systems, diagnostic procedures, and vehicle maintenance, explore our comprehensive automotive repair resources. Whether you drive a Volkswagen, Audi, or any vehicle with mechatronic transmission control, understanding these systems empowers better maintenance decisions and more confident troubleshooting when problems occur.

Safety Disclaimers and Professional Consultation

⚠️ CRITICAL SAFETY WARNINGS

Professional Diagnosis Required: Mechatronic unit symptoms overlap significantly with other transmission problems including worn clutch packs, mechanical valve body issues, and hydraulic pump failures. Attempting repairs based solely on symptoms without comprehensive diagnosis wastes money and may cause additional damage. Always obtain professional diagnosis using manufacturer-specific diagnostic equipment before replacing any components.

Specialized Equipment Essential: Manufacturer scan tools are absolutely required for proper mechatronic diagnosis, programming, and adaptation. Generic OBD-II code readers provide only surface-level information and cannot perform necessary procedures. Attempting mechatronic work without proper diagnostic capability results in incomplete repairs, harsh shifting, rapid wear, and potential transmission damage.

Fluid Contamination Risk: Any work involving mechatronic removal must be performed in a meticulously clean environment. Introducing even tiny amounts of contamination—dirt, lint, metal particles—during service causes immediate mechatronic failure. Home garages rarely provide adequate cleanliness for this sensitive work.

High Voltage Safety (Hybrid/EV Systems): Hybrid and electric vehicle transmission systems involve high voltage circuits up to 800 volts. Contact with these systems can cause serious injury or death. Only technicians with proper high-voltage certification and safety equipment should service hybrid or electric vehicle transmissions.

Warranty Implications: DIY mechatronic replacement typically voids any remaining powertrain warranty coverage. The potential labor cost savings rarely justify losing thousands in warranty protection. Verify warranty status before attempting any DIY transmission repairs.

Correct Fluid Specification Critical: Using incorrect transmission fluid causes immediate damage to mechatronic units and clutch packs. Generic “universal” ATF does not meet the specific friction characteristics required by dual-clutch and other advanced transmissions. Always verify and use manufacturer-specified fluid even if alternatives cost less.

Adaptation Procedures Mandatory: New or repaired mechatronic units require adaptation using manufacturer scan tools to learn clutch contact points and system parameters. Operating without proper adaptation causes harsh shifts, rapid clutch wear, and premature failure. This procedure cannot be skipped regardless of internet advice suggesting otherwise.

When In Doubt, Consult Professionals: Transmission repairs rank among the most expensive automotive repairs, with costs reaching $10,000+ for complete failures. The investment in professional diagnosis ($100-$250) represents negligible cost compared to misdiagnosis or improper repair. For complex transmission issues, professional service from specialists with manufacturer-specific expertise delivers optimal outcomes and long-term reliability.

This Guide Provides General Information Only: Every vehicle and situation differs. This article offers educational content about mechatronic systems but cannot substitute for professional evaluation of your specific vehicle and circumstances. When facing transmission problems, consult qualified transmission specialists familiar with your vehicle make, model, and transmission type.

For questions about transmission mechatronics, diagnosis procedures, or repair options specific to your vehicle, consult qualified transmission specialists in your area. Proper maintenance and early problem detection remain the most effective strategies for managing mechatronic complexity and minimizing lifetime transmission costs.