The steering knuckle is one of the most critical yet often overlooked components in your vehicle’s steering and suspension systems. This heavy-duty casting serves as the central connection point where steering input, suspension movement, braking force, and wheel rotation all converge. When you turn your steering wheel, the steering knuckle is the component that actually pivots to change your wheel’s direction. When you hit a bump, it’s the knuckle that transfers suspension forces while maintaining precise wheel alignment. Despite handling thousands of pounds of force during normal driving, most drivers never think about steering knuckles until something goes wrong.

Understanding how steering knuckles work helps you recognize potential problems before they become safety hazards. A damaged or failing steering knuckle can lead to loss of vehicle control, which is why recognizing warning signs is crucial. This article explains what steering knuckles are, how they function within your vehicle’s steering and suspension systems, common failure modes, and what you need to know about replacement costs and professional service requirements.

What Is a Steering Knuckle and Why It’s Critical

Component Identity and Alternative Names

The steering knuckle goes by several names depending on the technical documentation you’re reading and the region where you’re located. In North American automotive terminology, “steering knuckle” is the standard term. European manufacturers and racing applications often call it an “upright,” while older technical manuals may refer to it as a “spindle” (though this can create confusion since “spindle” also refers to the hub shaft the wheel mounts to). Modern technical documentation sometimes uses “wheel carrier” as a more descriptive term that emphasizes its role in supporting the wheel assembly.

It’s important to clarify the terminology: the steering knuckle is the housing or structural component, while the hub or spindle is what the knuckle contains. The knuckle is the forged or cast metal structure with multiple connection points, not the rotating hub assembly itself. Think of it as the foundation that everything else bolts to.

Material Construction and Engineering

Steering knuckles are manufactured from three primary materials, each with distinct advantages for different applications. The material choice significantly affects weight, strength, cost, and durability.

Cast iron knuckles represent the traditional approach and remain common in many vehicles today. Specifically, ductile cast iron provides excellent strength with some flexibility to absorb impacts without shattering. These knuckles typically weigh 8-15 pounds for passenger vehicles and offer cost-effective manufacturing through casting processes. Cast iron provides excellent impact resistance and can withstand decades of service. However, cast iron is susceptible to corrosion in harsh environments, particularly in northern climates where road salt accelerates rust formation.

Forged steel knuckles offer superior strength-to-weight ratios and are preferred for heavy-duty trucks, off-road vehicles, and high-performance applications. The forging process aligns the metal’s grain structure, creating a component that can withstand extreme loads and impacts far beyond what cast iron can handle. Forged steel knuckles cost more to manufacture but provide significantly longer service life in demanding applications. Professional mechanics working on heavy-duty vehicles almost exclusively see forged steel knuckles due to the extreme loads these vehicles experience.

Aluminum alloy knuckles represent the modern lightweight alternative, offering 40-55% weight reduction compared to cast iron. Modern economy cars and performance vehicles increasingly use aluminum knuckles manufactured from heat-treated 7075 aluminum alloy or similar high-strength alloys. The reduced unsprung weight (weight not supported by the suspension) improves fuel efficiency, ride quality, and handling responsiveness. Aluminum also provides better heat dissipation for brake components, which improves brake performance during aggressive driving. However, aluminum may be more vulnerable to permanent deformation from severe impacts compared to cast iron, which is why proper replacement after collision damage is critical.

Physical Design Features and Mounting Points

The steering knuckle earned its name from its resemblance to a hand with multiple “fingers” protruding in different directions, each serving a specific connection purpose. Understanding these connection points helps you visualize how the knuckle integrates with other systems.

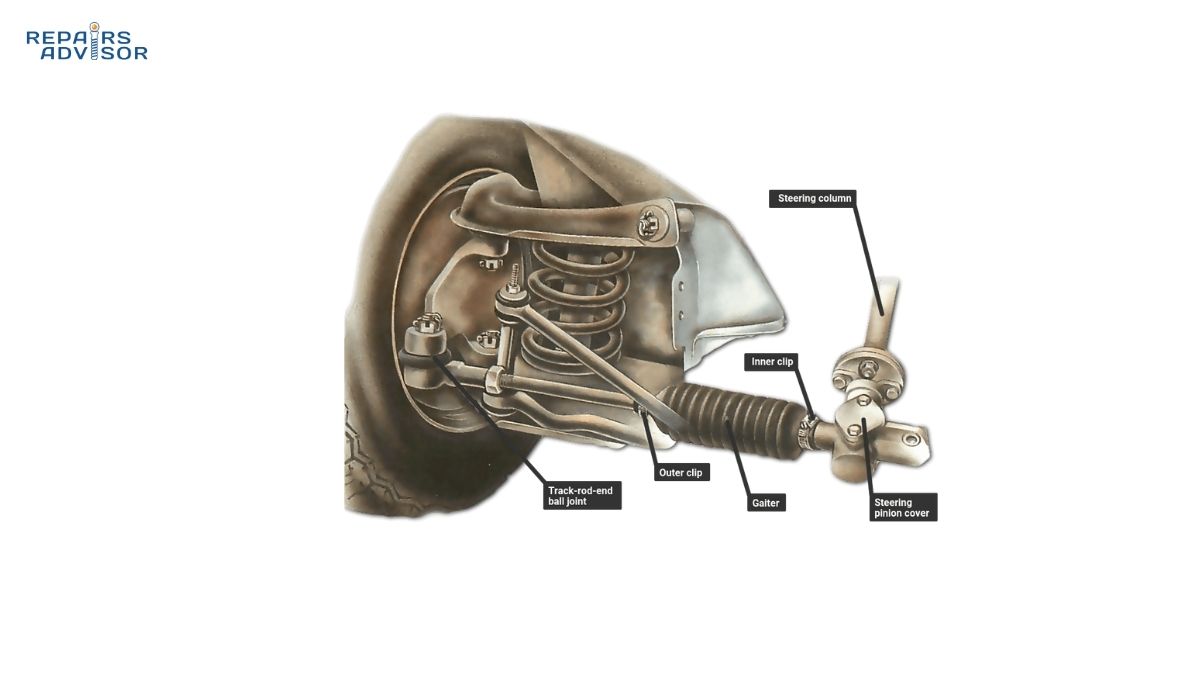

The upper connection point varies depending on suspension design. In MacPherson strut suspensions (the most common front suspension type), the knuckle bolts directly to the strut body through two or three large bolts with precisely machined mounting surfaces. In double wishbone or multi-link suspensions, the upper connection is a tapered hole that accepts an upper ball joint stud. This design difference significantly affects how the suspension moves and how forces transfer through the system.

The lower connection point universally uses a ball joint taper hole on modern vehicles. This conical hole accepts the ball joint stud from the lower control arm, allowing the knuckle to pivot for steering while accommodating suspension travel. The taper angle is precisely machined to create a metal-to-metal interference fit that, when properly torqued, can withstand tremendous forces without movement.

The steering arm protrudes laterally or forward from the knuckle body and contains another tapered hole for the tie rod end connection. When the steering rack pushes or pulls the tie rod, this arm translates that linear motion into rotational knuckle movement. The steering arm’s position and length affect the vehicle’s Ackermann steering geometry, which determines how the wheels turn at different angles during cornering.

Brake mounting points include threaded holes or mounting bosses precisely positioned to accept the brake caliper. These surfaces must maintain exact perpendicular alignment to the rotor mounting surface to prevent brake judder and uneven pad wear. The center of the knuckle features a precisely machined hub bore where the wheel hub and bearing assembly press-fits or bolts in place. Many modern knuckles include snap ring grooves to retain press-fit bearings.

Finally, modern knuckles include an ABS sensor port – a mounting hole positioned to place the wheel speed sensor close to the tone ring on the hub assembly. This positioning is critical for proper anti-lock brake system operation.

Critical Role in Vehicle Safety and Control

The steering knuckle performs multiple critical safety functions simultaneously. It supports the entire corner weight of the vehicle – typically 1,000-1,500 pounds per front corner for a mid-size sedan, and significantly more for trucks and SUVs. This load exists even when the vehicle is stationary, creating constant stress on the knuckle structure.

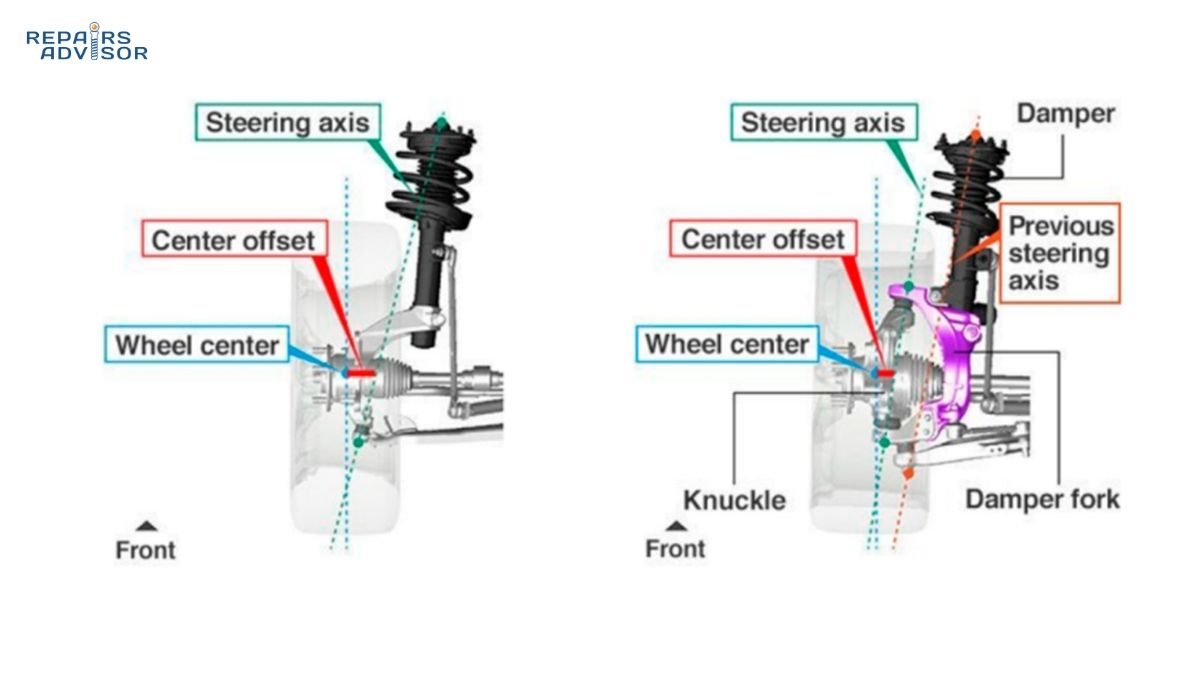

During steering maneuvers, any deflection or play in the knuckle directly translates to imprecise steering response. The knuckle must maintain rigid dimensional stability to preserve steering geometry angles including camber, caster, and steering axis inclination (SAI). These alignment angles determine how your vehicle handles, how tires wear, and how the steering feels.

As an integration hub, the steering knuckle represents a single point of failure for multiple systems. A cracked knuckle can simultaneously compromise steering control, suspension geometry, brake mounting, and wheel bearing support. This is why professional mechanics treat steering knuckle damage with extreme seriousness – it’s not just one system that fails, but potentially all four at once.

The knuckle also serves as the first line of defense during pothole strikes and curb impacts. The forces from these impacts travel through the tire, into the wheel hub, and directly into the knuckle structure before transferring to the suspension components. A properly designed knuckle absorbs and distributes these impact forces, protecting more expensive components like the strut or control arms.

How Steering Knuckles Work – Step-by-Step Operation

Steering Input Translation

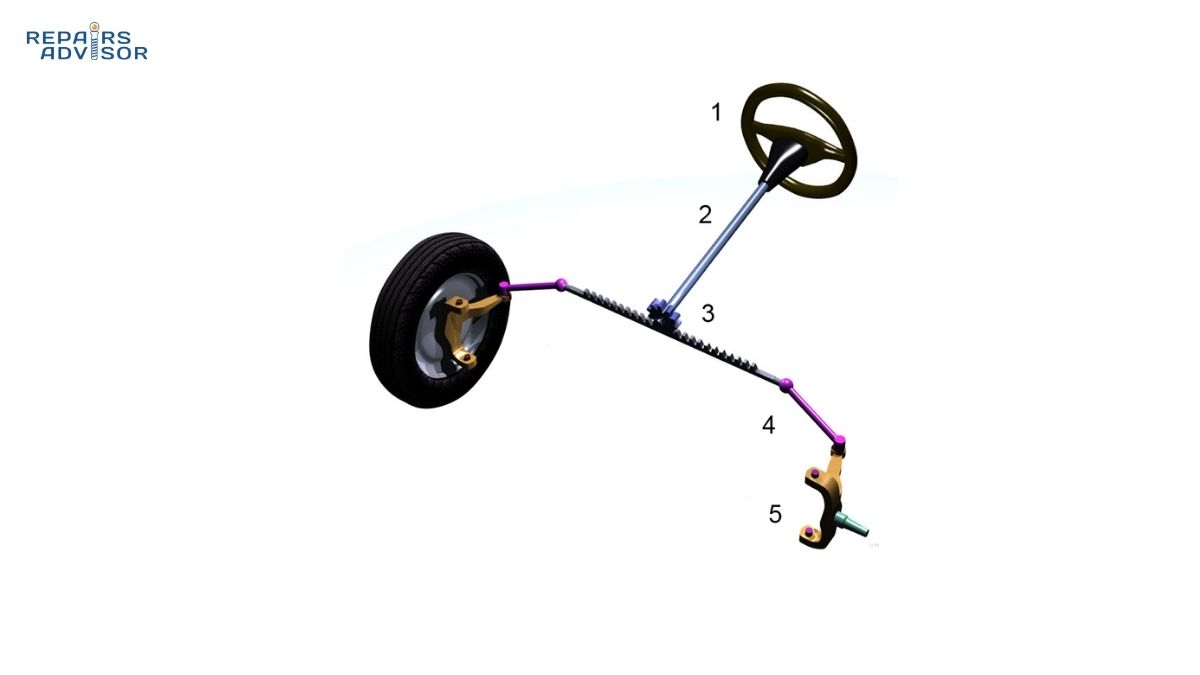

When you rotate the steering wheel, the rack and pinion steering system converts that rotational motion into linear movement of the steering rack. The rack pushes or pulls the tie rod laterally (side-to-side), and the tie rod end forces the steering knuckle to pivot on its ball joint mounting points.

This pivoting action occurs because the knuckle is mechanically constrained by the ball joints but free to rotate around the steering axis defined by the line between the upper and lower pivot points. In a MacPherson strut system, this axis runs through the upper strut mount and the lower ball joint. In a double wishbone system, it runs through both upper and lower ball joints.

The steering knuckle typically pivots approximately ±45 degrees from center, though this varies by vehicle design and intended use. During aggressive maneuvers like emergency lane changes, the tie rod can push or pull with forces exceeding 200-400 pounds. The knuckle must transmit this force smoothly while maintaining precise angular control of the wheel.

The entire wheel assembly – tire, wheel, brake rotor, and hub – rotates with the knuckle during steering. This is why the knuckle must be so robust: it’s turning not just the tire, but several hundred pounds of rotating mass while simultaneously supporting the vehicle’s weight.

Suspension Movement Accommodation

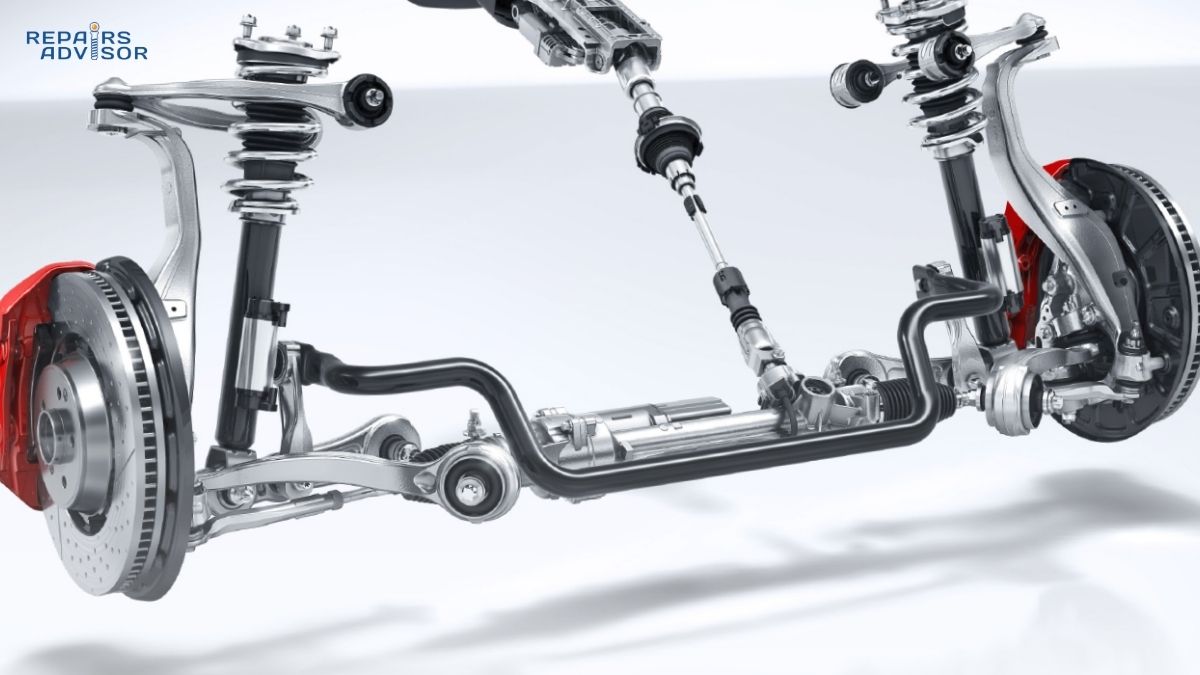

While handling steering inputs, the steering knuckle must simultaneously accommodate vertical suspension movement as the vehicle travels over road irregularities. The ball joint connections allow the knuckle to move up and down with suspension compression and extension while maintaining its ability to pivot for steering.

In MacPherson strut systems, the knuckle bolts rigidly to the strut body, creating a single unit that moves together. The strut provides both the spring support and damping function. The knuckle pivots only on the single lower ball joint, which must accommodate both the suspension’s vertical motion and the steering’s rotational motion. This is why lower ball joints in strut systems experience such demanding service conditions. Typical vertical suspension travel ranges from 6-8 inches total (measuring from full compression to full extension), and the knuckle follows this entire range of motion.

In double wishbone systems, the knuckle connects to both upper and lower ball joints, which allows multi-directional articulation. As the suspension compresses or extends, both ball joints rotate slightly to allow the control arms to follow their arcs while the knuckle maintains its vertical orientation (or controlled camber change, depending on design). This dual ball joint arrangement provides superior control over wheel alignment angles during suspension travel, which is why performance vehicles and luxury cars often use this more complex and expensive design.

Multi-link suspension systems represent the most sophisticated approach, with multiple control arms connecting to the knuckle at different points. Each link controls a specific aspect of wheel movement and alignment. These systems offer the best ride quality and handling performance but require professional-level expertise for service and alignment.

Brake Force Management

The steering knuckle plays a crucial role in the braking system by providing the structural mounting point for the brake caliper. When you apply the brakes, the caliper clamps the brake pads against the rotor with tremendous force – often 1,500-2,000 pounds per wheel during aggressive braking.

This clamping force creates a powerful braking torque that tries to rotate the caliper around the rotor. The knuckle must resist this torque through its caliper mounting points. The threaded holes that secure the caliper are torqued to specifications typically ranging from 40-80 ft-lbs, creating a rigid connection that prevents any movement between the caliper and knuckle.

During braking, the knuckle assembly can reach operating temperatures of 300-500°F, with the rotor itself exceeding 700°F during aggressive use. The knuckle body helps dissipate this heat, which is why aluminum knuckles often provide better brake performance – aluminum conducts heat approximately three times more effectively than cast iron.

The mounting surface where the hub and rotor attach must maintain precise perpendicular alignment to prevent brake pulsation and uneven pad wear. Any distortion of this surface from impact damage will cause brake problems even if the knuckle hasn’t cracked. This is why professional collision repair facilities always check knuckle alignment after front-end impacts.

Load Distribution and Stress Points

The steering knuckle must distribute multiple simultaneous loads throughout its structure. At rest, static loads from the vehicle’s weight create constant compression stress. During driving, dynamic loads from acceleration, braking, and cornering multiply these forces significantly.

Understanding stress concentration points helps explain why knuckles crack in predictable patterns. The ball joint taper holes experience the highest stress during impact events like pothole strikes. The sudden shock load concentrates force at the junction between the tapered hole and the knuckle body. This is typically where you’ll find the first hairline cracks on a damaged knuckle.

The strut mounting area experiences significant bending stress during suspension compression, particularly when combined with braking forces. The brake caliper mounting area handles torsional stress every time you apply the brakes. The tie rod mounting point sees lateral stress during aggressive steering inputs, particularly during emergency maneuvers or spirited driving.

When knuckles fail, cracks typically initiate at one of these stress concentration points and propagate through the body over time. Professional technicians inspect these areas carefully during routine service, looking for telltale signs of stress cracking, especially on vehicles that have experienced collision damage or are used in demanding applications.

High-performance vehicles often use reinforced knuckles with additional material thickness at these critical stress points. Some aftermarket manufacturers offer upgraded knuckles with improved metallurgy or structural reinforcement for track use or heavy-duty applications.

Common Steering Knuckle Problems and Symptoms

Impact Damage – The Primary Failure Cause

The vast majority of steering knuckle failures result from impact damage rather than normal wear. Unlike components that gradually degrade through use, steering knuckles are designed to last the vehicle’s lifetime under normal conditions. However, they’re vulnerable to sudden shock loads that exceed their design limits.

Curb strikes at moderate to high speeds represent the most common cause of knuckle damage. When you hit a curb with the wheel turned, the lateral impact force transfers directly through the tire into the knuckle’s steering arm and ball joint mounting points. Even impacts that seem minor can create hairline cracks that weaken the structure. The damage may not be immediately apparent, manifesting only as gradual alignment drift or steering feel changes over subsequent weeks or months.

Pothole impacts cause different damage patterns, particularly when they occur with the wheels turned. The sudden vertical force combined with the angular loading can bend the knuckle body or distort the ball joint tapers. Deep potholes hit at highway speeds can exceed the knuckle’s impact design limits, especially on vehicles with low-profile tires that provide less impact cushioning.

Collision damage, even from seemingly minor fender-benders, often affects the steering knuckle. Any front-end impact that’s severe enough to require bumper or fender repair should trigger a thorough inspection of the knuckles and suspension components. The forces that crumple sheet metal can easily bend or crack the more rigid knuckle structure.

Off-road rock strikes present unique challenges for vehicles used in challenging terrain. Sharp impacts from rocks can chip cast iron knuckles or create stress risers (concentrated stress points) that lead to crack propagation. This is why serious off-road vehicles often upgrade to forged steel knuckles.

Damage patterns vary by impact type. A bent steering arm throws off alignment by changing the effective tie rod connection point. Cracked knuckle bodies often develop hairline cracks that are invisible to casual inspection but weaken structural integrity. Distorted ball joint tapers create excessive play in the ball joint connection. Broken mounting ears or bosses prevent proper component attachment.

Some damage is immediately catastrophic – a completely broken knuckle prevents driving. Other damage is progressive, weakening the structure over time until final failure occurs, potentially at highway speeds. This delayed failure mode is why professional inspection after any significant impact is crucial.

Warning Signs and Symptoms

Recognizing steering knuckle problems requires attention to multiple symptom categories. The challenge is that many symptoms overlap with other suspension and steering issues, which is why professional diagnosis is important for definitive identification.

Alignment problems provide the most common early warning signs. If one wheel appears visibly tilted inward or outward (camber change) compared to the other side, knuckle damage is a likely cause. The steering wheel pointing off-center when driving straight suggests that one knuckle has shifted position. Persistent pulling to one side, especially if alignment adjustments don’t correct the problem, indicates structural damage affecting suspension geometry. Rapid tire wear concentrated on the inside or outside edge of one tire often results from the camber changes created by a bent knuckle. Most tellingly, if a professional alignment technician reports that alignment cannot be adjusted to specification on one side, knuckle damage is a primary suspect.

Steering feel issues manifest in several ways. A steering wheel that doesn’t return to center after turns suggests binding or resistance in the knuckle pivots. Delayed steering response – a lag between steering input and wheel direction change – can indicate looseness in the knuckle connections. Steering that feels loose or imprecise, requiring constant corrections to maintain straight-line travel, often results from play in the ball joint tapers caused by knuckle distortion. Vibration through the steering wheel, particularly at highway speeds, can indicate knuckle imbalance or improper hub mounting caused by knuckle bore damage.

Noise symptoms vary by damage type and severity. Clunking during turns, particularly at low speeds in parking lots, suggests excessive play in the ball joint connections – often caused by elongated or distorted taper holes in the knuckle. Squealing or groaning when steering points to binding in the knuckle pivots or inadequate lubrication in ball joints affected by knuckle distortion. Creaking sounds over bumps indicate movement between components that should be rigidly connected – the knuckle and its attached components flexing abnormally. Metallic scraping represents advanced wear or damage where components are making contact they shouldn’t.

Visual indicators require wheel removal for proper inspection. Visible cracks in the knuckle body, particularly around the ball joint bosses or steering arm, indicate structural failure. Watch for rust or corrosion flaking, which often indicates stress cracks forming beneath the surface oxidation – the stress crack breaks the protective rust layer, exposing fresh metal that immediately oxidizes. Flattened or dented areas from impact are obvious signs of damage. Uneven gaps between the knuckle and connected components suggest structural distortion.

Corrosion and Material Degradation

While less dramatic than impact damage, corrosion can severely compromise steering knuckle integrity, particularly in regions with harsh winters where road salt is used extensively.

Surface rust on the knuckle body is generally cosmetic and doesn’t affect structural integrity. However, pitting corrosion – where rust creates small craters in the metal surface – can weaken critical areas. These pits act as stress concentration points where cracks can initiate under load.

The most serious corrosion problem is “rust jacking” in the ball joint bores. As corrosion products form between the ball joint taper and the knuckle’s taper hole, the expanding rust actually deforms the hole from circular to oval. This creates excessive play in the ball joint connection even with a new ball joint installed. Once the taper hole is significantly distorted, the only solution is knuckle replacement.

Ball joint bore damage from corrosion follows a progressive pattern. Initial corrosion creates microscopic surface roughness. As corrosion continues, the taper hole loses its precise geometry. Eventually, the distortion becomes severe enough that ball joints develop play immediately after installation. This is why experienced mechanics in northern climates often replace knuckles preventively during major suspension work on high-mileage vehicles – the cost of knuckle replacement is less than the labor cost of removing and reinstalling components multiple times.

Wheel Bearing and Hub Issues Related to Knuckle

While technically separate components, wheel bearings and hubs can create problems that require knuckle replacement. Press-fit wheel bearings can corrode in place within the knuckle bore, particularly on high-mileage vehicles (150,000+ miles) in corrosive environments. When bearings seize in the knuckle, extraction becomes extremely difficult. Attempting to press out a seized bearing can crack the knuckle, and using excessive force with bearing pullers risks structural damage. If a bearing absolutely cannot be removed, the entire knuckle must be replaced.

Bearing bore wear, though rare, occurs when the press-fit between the bearing outer race and the knuckle bore loosens, allowing the bearing to spin in the knuckle. This damages the precision-machined bore surface, preventing proper bearing retention. Once the bore is damaged, no amount of force will make a bearing fit correctly, necessitating knuckle replacement.

ABS sensor mounting damage presents another knuckle-related issue. If the sensor mounting tab breaks off the knuckle, proper sensor positioning becomes impossible. While some aftermarket solutions exist for certain applications, many vehicles require knuckle replacement to restore proper ABS function.

Safety Critical Warning

⚠️ SAFETY WARNING: Never continue driving with a suspected damaged steering knuckle. A failed steering knuckle can cause complete loss of steering control, wheel separation from the vehicle, catastrophic brake failure, or uncontrolled vehicle direction changes – all potentially fatal scenarios.

If you experience multiple symptoms simultaneously – particularly combining alignment problems with unusual noises and steering feel issues – have the vehicle inspected immediately by a qualified technician. Do not attempt to drive to a repair facility if you hear loud clunking from the front suspension or feel severe steering looseness. In these cases, have the vehicle towed for inspection.

The steering knuckle is a safety-critical component with zero fault tolerance. Unlike brake pads that wear gradually with warning signs, a cracked knuckle can fail suddenly and catastrophically. Professional diagnosis after any front-end impact or when symptoms appear isn’t optional – it’s essential for your safety and the safety of other road users.

Steering Knuckle Replacement and Professional Considerations

Replacement Complexity and Required Expertise

Steering knuckle replacement falls into the advanced DIY to professional skill category. While mechanically capable enthusiasts with proper tools can successfully complete this repair, several factors make professional service the recommended choice for most people.

The complexity begins with the disassembly process. Separating ball joints and tie rod ends from the knuckle requires special tools – ball joint separators or “pickle forks” – and technique to avoid damaging protective boots on the new components. The wheel bearing and hub must often be pressed out of the old knuckle and into the new one, requiring a hydraulic press and proper support fixtures. Brake components must be carefully suspended to avoid damaging flexible brake hoses. On many modern vehicles, ABS sensors, brake lines, and wiring harnesses have limited service loops, making removal challenging without proper techniques.

Torque specifications are critical and vehicle-specific. Ball joint nuts typically require 70-100 ft-lbs, tie rod end nuts need 40-60 ft-lbs, and strut-to-knuckle bolts often specify 75-150 ft-lbs. These specifications must be followed precisely – undertorquing allows components to work loose, while overtorquing can damage threads or distort components.

The most critical reason for professional service is the mandatory wheel alignment after installation. Replacing a steering knuckle changes the reference points for suspension geometry, making precise alignment essential. Without proper alignment, the vehicle will handle poorly, wear tires rapidly, and potentially create dangerous handling characteristics. Professional alignment requires specialized equipment that measures camber, caster, toe, and other angles, then adjusts them to manufacturer specifications.

DIY considerations for experienced intermediate mechanics: Budget 3-5 hours for first-time replacement on a side you haven’t worked on before. You’ll need jack stands (never trust a floor jack alone for safety), a torque wrench calibrated to the appropriate range, ball joint separator tools, and potentially a spring compressor if working on strut-type suspension. Online factory service manuals provide vehicle-specific procedures and torque specifications. Even with successful DIY replacement, you must have the vehicle professionally aligned before driving at highway speeds.

Replacement Cost Breakdown

Understanding cost components helps you evaluate quotes and make informed decisions about OEM versus aftermarket parts.

Parts costs vary significantly by vehicle type and parts choice. OEM steering knuckles from the vehicle manufacturer typically cost $150-$500, with luxury and European vehicles at the higher end of that range. Aftermarket knuckles from reputable manufacturers like Moog, Dorman, or Detroit Axle range from $80-$300. Keep in mind that steering knuckle replacement often requires additional parts: ball joints ($30-$150), wheel hub and bearing assemblies ($80-$200), and tie rod ends ($25-$75). If the brake caliper mounting threads are damaged, you might also need new caliper mounting hardware.

Labor costs reflect the complexity and time required. A standard steering knuckle replacement typically takes 2-4 hours of professional shop time at rates ranging from $100-$150 per hour in most markets, resulting in labor costs of $200-$400. Complex vehicles with more sophisticated suspension designs (luxury vehicles, performance cars, AWD systems) may require 4-6 hours, pushing labor costs to $400-$600. This labor time includes knuckle removal and installation, component transfer (pressing bearings, installing ABS sensors, attaching brake components), and preliminary suspension checks.

The total cost range for steering knuckle replacement typically falls between $450-$900 for standard passenger vehicles, with luxury and performance vehicles potentially reaching $1,200-$1,500. This estimate includes parts and labor but not the mandatory wheel alignment.

Wheel alignment adds $75-$150 to the total cost but is absolutely necessary for safe vehicle operation. Some shops include basic alignment in the replacement quote, while others charge it separately. Confirm alignment costs when receiving quotes to avoid surprise charges.

OEM vs. Aftermarket Parts Decision

The choice between OEM and aftermarket steering knuckles involves balancing cost, quality assurance, and risk tolerance for a safety-critical component.

OEM advantages include guaranteed fitment – factory parts are manufactured to the exact specifications and tolerances as the original equipment, eliminating fit issues. Material specifications match the original component, providing equivalent strength and durability. OEM parts typically include warranty coverage (12 months/12,000 miles is standard) and have the confidence of being the same part the vehicle was engineered around. For safety-critical components like steering knuckles, many professional mechanics recommend OEM parts to eliminate any uncertainty about quality or performance.

Aftermarket considerations center on cost savings – quality aftermarket knuckles cost 40-60% less than OEM equivalents, potentially saving $100-$300 on parts alone. However, quality varies dramatically by manufacturer. Reputable brands like Moog, TRW, and Dorman maintain high quality standards and often match or exceed OEM specifications. Some aftermarket manufacturers even offer upgraded materials, such as forged steel replacements for original cast iron knuckles. Unknown or ultra-cheap brands may use inferior materials or imprecise manufacturing, creating safety risks.

Before purchasing aftermarket parts, research the manufacturer’s reputation through professional mechanic forums and consumer reviews. Look for brands that specify material composition and provide warranty coverage comparable to OEM parts. Be especially cautious about extremely low-priced options – a steering knuckle that costs half the going rate for aftermarket parts is likely using substandard materials or manufacturing processes.

Professional recommendation: For steering knuckles and other safety-critical suspension components (ball joints, tie rod ends, control arms), the cost difference between quality aftermarket and OEM parts is relatively small compared to the labor cost and safety implications. Many professionals default to OEM parts for these components to eliminate any quality uncertainty.

Related Components to Inspect and Replace

When replacing a steering knuckle, professional mechanics recommend inspecting and potentially replacing several related components. Since much of the labor cost involves disassembly to access the knuckle, replacing wear items simultaneously saves money compared to addressing them separately later.

Ball joints should always be inspected during knuckle replacement, and many professionals recommend replacement if the vehicle has over 100,000 miles. The labor to replace ball joints after knuckle installation is nearly the same as the knuckle replacement itself, making concurrent replacement economical.

Wheel hub and bearing assemblies often must be pressed out of the old knuckle and into the new one. If the bearing shows any signs of roughness, noise, or play, replace it during this service. The press work is already being performed, so the only additional cost is the bearing itself.

Tie rod ends connect directly to the steering knuckle and must be disconnected for replacement. Inspect them carefully for play in the ball socket and boot damage. Replacing a worn tie rod end during knuckle service adds minimal labor cost.

Control arm bushings should be inspected while the suspension is disassembled. Worn bushings affect alignment and handling, and replacing them later requires repeating much of the disassembly work.

Brake caliper mounting hardware including bolts, clips, and anti-rattle shims should be inspected and replaced if corroded or damaged. These small components are inexpensive but critical for proper brake function.

ABS wheel speed sensors should be carefully inspected during removal. The sensor or its wiring can be damaged if not properly supported during knuckle removal. Test the sensor’s resistance and inspect the sensor tip and tone ring for damage.

The cost-saving strategy is clear: address wear items together to minimize future labor costs. Spending an additional $200 in parts during knuckle replacement is more economical than paying another $400 in labor six months later to replace a component that was accessible during the knuckle work.

Post-Replacement Requirements

After steering knuckle installation, several critical steps ensure safe and proper vehicle operation.

Wheel alignment must be performed within 24 hours of knuckle replacement and before any highway driving. The new knuckle changes the reference points for suspension geometry, and even if installed perfectly, alignment angles will be incorrect. Driving on misaligned suspension causes rapid tire wear, poor handling, and potential safety issues.

Professional test drive allows an experienced technician to verify steering feel, handling characteristics, and absence of unusual noises. The mechanic can detect subtle issues that might not be apparent to vehicle owners unfamiliar with how their specific vehicle should handle.

Re-torque check of critical fasteners should occur after 50-100 miles of driving. Some manufacturers specify this as a requirement, particularly for strut-to-knuckle bolts and ball joint nuts. The initial driving period allows components to seat fully, and re-torquing ensures no loosening has occurred.

Break-in period for new components typically spans the first 500 miles. During this time, avoid aggressive driving, extreme braking, or rough road use that could stress new components before they’ve fully seated. This is particularly important if new ball joints or wheel bearings were installed with the knuckle.

Professional Consultation Reminder

If you’re uncomfortable with any aspect of steering knuckle service, seek professional assistance without hesitation. This is a safety-critical component where improper installation, incorrect torque specifications, or skipped alignment can lead to loss of vehicle control. The cost of professional service is minimal compared to the potential consequences of improper repair.

Professional mechanics have the specialized tools, experience with vehicle-specific procedures, and quality control processes to ensure the job is done correctly the first time. They can also identify related component wear that might not be obvious to DIY mechanics, potentially saving you from additional failures and repair costs.

Conclusion

The steering knuckle serves as the critical structural hub where your vehicle’s steering, suspension, braking, and wheel rotation systems converge. This heavy-duty forged or cast component withstands thousands of pounds of force daily while maintaining the precise geometry necessary for safe vehicle control. Understanding how steering knuckles work helps you recognize potential problems before they escalate into dangerous failures.

Most steering knuckle damage results from impact events – curb strikes, pothole impacts, or collision damage – rather than normal wear. The warning signs include persistent alignment problems that can’t be corrected, steering feel abnormalities, unusual noises during turns or over bumps, and visible damage discovered during routine service. Because the steering knuckle is a safety-critical component with zero fault tolerance, any suspected damage requires immediate professional inspection.

Replacement involves significant complexity including ball joint separation, wheel bearing transfer, precise torque specifications, and mandatory wheel alignment. While experienced DIY mechanics can successfully complete this repair, professional service is recommended for most vehicle owners due to the safety implications and specialized equipment requirements. Costs typically range from $450-$900 including parts and labor, with wheel alignment adding another $75-$150.

When replacement becomes necessary, carefully consider the OEM versus aftermarket parts decision. Quality matters tremendously for safety-critical components – this isn’t the place to choose the cheapest available option. Reputable aftermarket brands can provide excellent value, but unknown manufacturers may compromise safety through inferior materials or manufacturing tolerances.

The steering knuckle exemplifies how seemingly simple mechanical components perform incredibly demanding jobs. What appears to be just a heavy chunk of metal is actually a precisely engineered structure that must simultaneously support vehicle weight, enable steering precision, accommodate suspension movement, and anchor brake components – all while withstanding impact forces and extreme operating temperatures. Respect the engineering that goes into this critical component, and never compromise on proper inspection, quality parts, or professional service when safety is at stake.

For vehicle-specific repair procedures, torque specifications, and complete service information, consult your vehicle’s factory service manual available through Ford, Toyota, Honda, or your specific manufacturer.