Information provided for reference only. Always consult manufacturer specifications and professional guidance for safety-critical ignition system work. Repairs Advisor provides technical documentation and educational content – not direct repair services.

Spark plugs are the critical ignition components that transform high-voltage electrical energy into the precisely timed combustion events that power your engine. Understanding how spark plugs function, their heat range characteristics, and electrode gap requirements empowers both DIY enthusiasts and professional mechanics to maintain optimal engine performance and reliability.

Why Spark Plugs Are Critical for Electrical Function

Spark plugs serve as the essential bridge between your vehicle’s ignition system and the combustion process within each cylinder. These precision-engineered components must operate reliably under extreme conditions, withstanding temperatures exceeding 2,500°F while maintaining consistent ignition energy delivery across thousands of firing cycles per minute.

The spark plug’s role in electrical function extends beyond simple spark generation. Each plug must properly ground electrical energy, resist fouling from combustion byproducts, and maintain optimal heat range characteristics to prevent pre-ignition or misfiring. Modern engines rely on precise ignition timing controlled by the engine management system, making spark plug condition critical for overall engine performance and emissions compliance.

Professional mechanics recognize that spark plug selection affects not only ignition reliability but also fuel efficiency, emissions output, and engine longevity. The integration between spark plugs and ignition coils determines the quality and consistency of combustion events, directly impacting drivability and performance characteristics that customers experience daily.

Spark Plug Parts and Construction Explained

Understanding spark plug construction reveals why these seemingly simple components require precise engineering and material selection. The center electrode forms the core of the spark plug’s functionality, typically constructed from nickel alloy, platinum, or iridium depending on performance requirements and service life expectations.

The center electrode extends through a ceramic insulator that provides electrical isolation while withstanding extreme thermal stress. This insulator material must resist cracking under rapid temperature changes while maintaining electrical integrity across the operating voltage range. High-performance applications often utilize alumina ceramic insulators with specific thermal expansion characteristics.

The ground electrode, also called the side electrode, provides the spark gap terminus and completes the electrical circuit. Ground electrode materials and configurations vary significantly between standard and performance applications. Some designs feature multiple ground electrodes or specialized alloy tips to enhance durability and maintain consistent electrode gap over extended service intervals.

The threaded shell houses all internal components and provides both mechanical attachment to the cylinder head and heat transfer pathway. The shell design includes specific reach dimensions and heat range characteristics that must match engine requirements. ECU systems monitor ignition performance through various sensors, making proper spark plug specification critical for optimal operation.

Internal resistor elements, typically ceramic-based, suppress electromagnetic interference that could affect vehicle electronics and radio reception. This resistor function becomes increasingly important in modern vehicles with extensive electronic systems and sensitive communication networks.

How Spark Plugs Work: Step-by-Step Operation

The spark plug ignition process begins when the ignition coil delivers high-voltage energy, typically 15,000-40,000 volts, across the center electrode. This voltage buildup occurs during the coil’s primary winding saturation phase, controlled by the engine management system’s dwell time calculations.

As voltage increases beyond the breakdown threshold, electrical energy jumps across the electrode gap, creating an ionized plasma channel. This plasma formation occurs in microseconds, generating temperatures exceeding 60,000°F – sufficient to ignite the compressed air-fuel mixture. The spark duration, typically 1-2 milliseconds, must provide adequate ignition energy while avoiding electrode erosion.

Heat range characteristics determine how effectively the spark plug transfers combustion heat to the cylinder head cooling system. Cold heat range plugs transfer heat rapidly, preventing electrode overheating in high-performance applications. Hot heat range plugs retain more heat, promoting self-cleaning in lower-temperature operating conditions or vehicles with frequent short-trip usage patterns.

The ignition energy must overcome various factors including compression pressure, air-fuel mixture density, and electrode gap dimension. Modern fuel injection systems create more consistent air-fuel mixtures, allowing spark plugs to operate more efficiently across varying load conditions.

Electrode gap spacing directly affects ignition energy requirements and flame kernel formation. Wider gaps require higher voltage but create larger flame kernels for improved combustion initiation. Narrower gaps reduce voltage requirements but may limit combustion efficiency. Professional installers always verify gap specifications against manufacturer requirements.

Spark Plug Location and Access Guide

Safety Warning: Spark plug replacement involves working with high-voltage ignition systems and hot engine components. Allow engines to cool completely before attempting service. Individuals without automotive electrical experience should consult qualified professionals.

Spark plug locations vary significantly between engine configurations, with inline engines typically providing straightforward access while V-type engines may require removal of intake components or ignition coil covers. Modern engines often integrate coil-on-plug designs that eliminate traditional spark plug wires, requiring coil removal before plug access.

Access procedures typically begin with removing engine covers and identifying individual ignition coils or spark plug wire connections. Label or photograph wire routing before disconnection to ensure proper reassembly. Some vehicles require removing air filter assemblies or throttle body components for adequate clearance.

Professional mechanics use specialized tools including spark plug sockets with rubber inserts, torque wrenches, and gap gauges for proper installation. Socket depth must accommodate spark plug reach while providing adequate grip on the hexagonal portion. Magnetic or rubber-lined sockets prevent plug damage during removal and installation.

Thread engagement requires careful attention to avoid cross-threading aluminum cylinder heads. Hand-start all plugs several turns before using tools, and apply manufacturer-specified torque values. Over-tightening can damage threads or crack ceramic insulators, while under-tightening allows heat loss and potential engine damage.

Installation procedures should include verification of proper gap dimensions using feeler gauges or gap tools. Never assume pre-gapped plugs meet specifications, as shipping and handling can alter gap settings. Document installation dates and specifications for future maintenance reference.

Professional Consultation Recommended: Complex ignition system diagnosis, cylinder head thread repair, or vehicles with difficult access configurations may require specialized tools and expertise beyond typical DIY capabilities.

Related Component Articles

For comprehensive understanding of ignition system operation, explore these related technical guides:

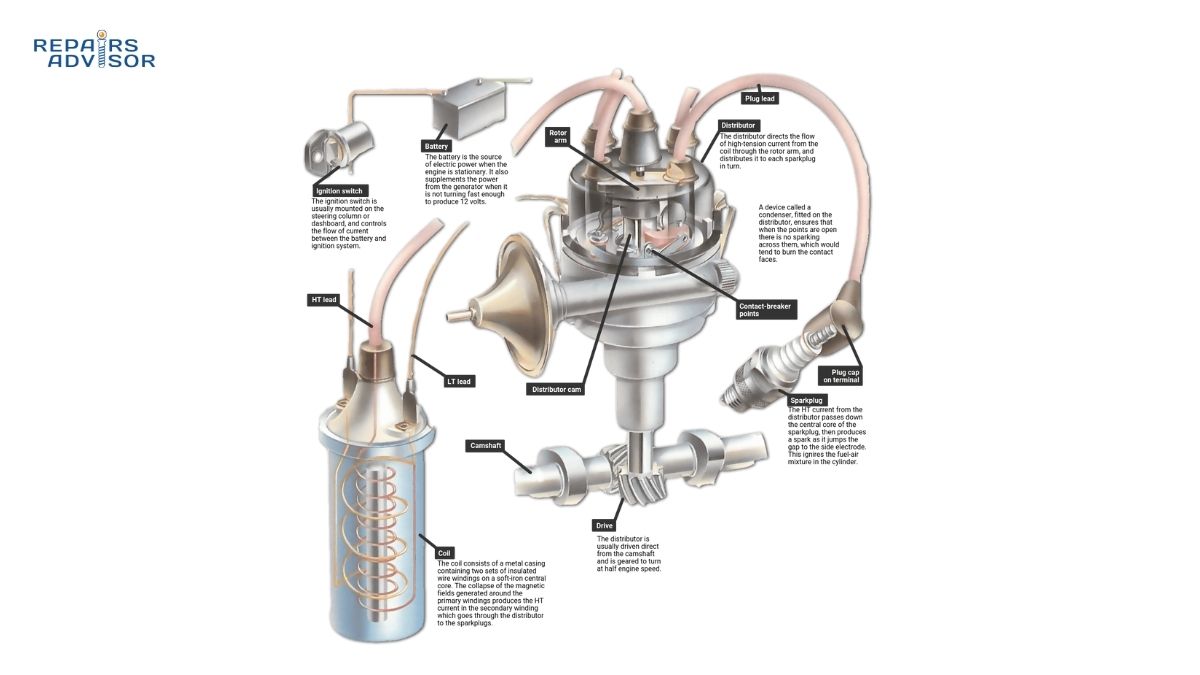

- How Ignition Systems Work – Complete ignition system integration and timing control

- How Ignition Coils Work – High voltage generation and coil-on-plug technology

- How Engine Management Systems Work – ECU control of ignition timing and dwell

- How Combustion Works – Otto and diesel cycle fundamentals

- How Fuel Injection Systems Work – Precision fuel delivery for optimal combustion

- How Distributors Work – Classic ignition timing systems

- How ECUs Work – Automotive computer control systems

- How Engine Blocks Work – Foundation components housing ignition systems

Support Resources

For technical assistance with spark plug specifications, ignition system troubleshooting, or access to manufacturer service documentation, contact our technical support team at [email protected] or visit our Help Center for comprehensive troubleshooting guides.

Disclaimer: This information is provided for educational reference only. Repairs Advisor does not provide direct repair services or warranty any repair outcomes. Always follow manufacturer specifications and consult qualified professionals for safety-critical ignition system work.