The art of driving a manual transmission—once the standard for every vehicle—is becoming a specialized skill in today’s automotive landscape. While less than 2.5% of new cars sold in the United States feature manual transmissions, understanding how these mechanical marvels work remains valuable for enthusiasts, DIYers, and anyone who appreciates the direct connection between driver and machine. Whether you’re learning to drive stick shift, maintaining your manual transmission vehicle, or simply curious about automotive engineering, this comprehensive guide demystifies the mechanics, operation, and care of manual transmissions.

Manual transmissions represent one of the most reliable and engaging drivetrain configurations ever developed. Unlike automatic transmissions that handle gear selection automatically, or CVT transmissions that provide infinitely variable ratios, manual transmissions put you in complete control of gear selection. This direct mechanical connection between engine and wheels, mediated only by your decisions and inputs, creates a driving experience that many enthusiasts consider irreplaceable.

Manual Transmission Fundamentals

What Is a Manual Transmission?

A manual transmission is a gearbox that enables the driver to manually select different gear ratios to match engine power delivery with driving conditions. The fundamental principle is elegantly simple: the transmission allows the engine to operate within its optimal power band while providing the torque and speed characteristics needed for different situations. Lower gears provide more torque but less speed—essential for starting from a standstill or climbing steep grades. Higher gears reduce torque multiplication but allow higher speeds while keeping engine RPM reasonable for fuel efficiency and longevity.

The problem manual transmissions solve stems from the physics of internal combustion engines. Every engine has a redline—a maximum RPM value above which the engine cannot safely operate. Engines also produce their maximum horsepower and torque within narrow RPM ranges, typically between 3,000 and 6,500 RPM depending on design. Without a transmission, a vehicle would need enormous engine displacement to provide adequate torque for acceleration while also achieving highway speeds. The manual transmission’s multiple gear ratios allow a modestly sized engine to deliver strong acceleration when needed and efficient cruising when conditions permit.

The Manual vs. Automatic Question

The debate between manual and automatic transmissions has evolved significantly over the past decade. Historically, manual transmissions offered clear advantages in fuel efficiency, lower cost, and engaging driving dynamics. Modern technology has narrowed or eliminated many of these gaps, but fundamental differences remain.

Performance and Control: Manual transmissions provide complete control over gear selection and engine RPM. Skilled drivers can execute perfectly timed shifts, maintain specific engine speeds for performance driving, or select lower gears for engine braking on descents. Dual-clutch transmissions offer faster shift times than any human driver, but they can’t match the anticipatory gear selection of an experienced manual transmission driver who knows exactly when to downshift before a corner.

Fuel Efficiency Reality: The long-standing belief that manual transmissions are more fuel efficient than automatics is now outdated. Modern automatic transmissions with eight, nine, or ten forward gears, combined with sophisticated electronic controls, often achieve equal or superior fuel economy compared to their manual counterparts. The efficiency advantage manual transmissions once enjoyed came from lighter weight and more direct mechanical connection, but advances in automatic transmission technology—including lockup torque converters and wide-ratio gear sets—have closed this gap.

Cost Considerations: Manual transmission vehicles typically cost $1,000 to $1,500 less than equivalent automatic models at purchase. However, this advantage is offset by eventual clutch replacement costs, which range from $700 to $1,200 depending on the vehicle. Clutches typically require replacement every 60,000 to 100,000 miles with normal driving, though aggressive driving can reduce this significantly. Automatic transmissions generally last longer without major service but cost considerably more to repair when problems occur.

Driving Experience: For many enthusiasts, the engagement and connection provided by manual transmissions represents their primary appeal. The mechanical feedback through the shift lever, the coordination required between clutch, shifter, and throttle, and the sense of being an active participant rather than a passenger in the driving process creates satisfaction that automated systems cannot replicate. This intangible quality explains why manual transmissions persist in sports cars and performance vehicles despite the measurable advantages of modern automatics.

Core Components and Architecture

Understanding how manual transmissions work begins with recognizing the elegantly simple three-shaft architecture at their core. While automatic transmissions rely on complex planetary gearsets and valve bodies, manual transmissions use a straightforward arrangement of parallel shafts with constantly-meshed gears.

The Three-Shaft System

Input Shaft: The input shaft connects directly to the engine through the clutch assembly and flywheel. When the clutch is engaged (pedal released), the input shaft spins at the same speed as the engine’s crankshaft. This shaft carries engine power into the transmission and meshes with the countershaft. The input shaft’s speed varies constantly based on engine RPM—idling around 800 RPM, cruising at 2,500 RPM, and potentially reaching 6,000+ RPM under acceleration.

Countershaft (Layshaft): The countershaft represents the transmission’s workhorse component. It remains constantly meshed with the input shaft through a fixed gear pair, meaning it spins whenever the engine runs and the clutch is engaged. The countershaft contains multiple gears of different sizes—typically five or six for forward motion plus one for reverse. These gears spin freely on the countershaft but don’t directly drive anything. The manual gearbox design ensures all these gears are always available for selection.

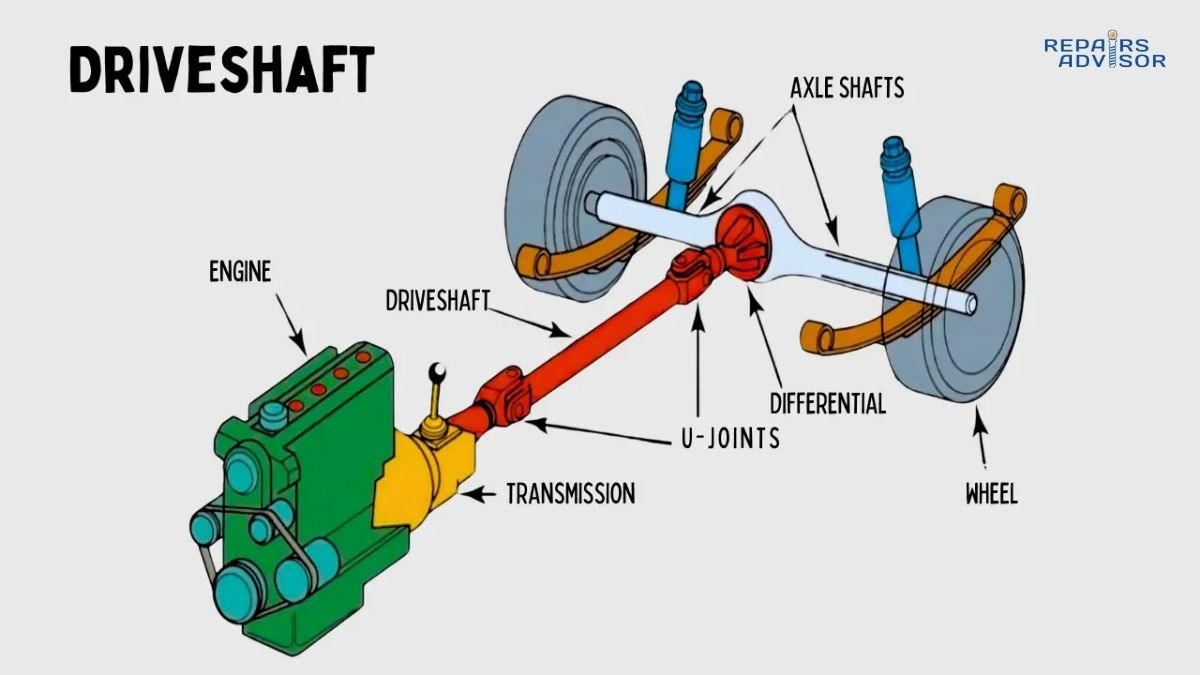

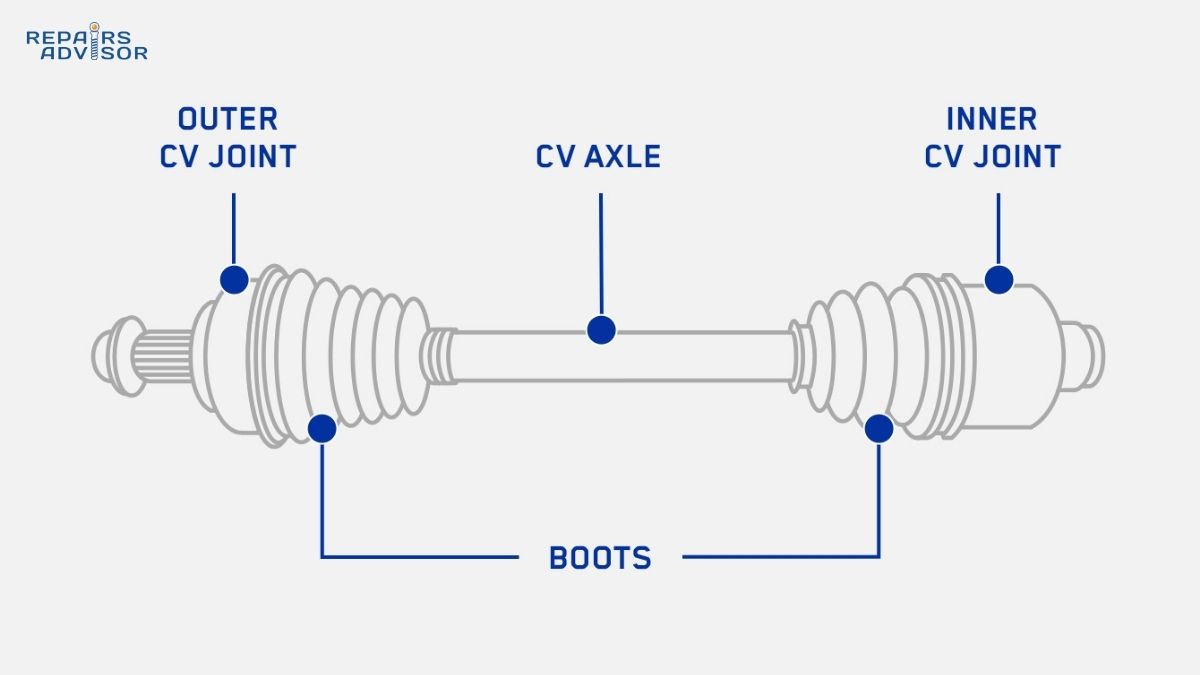

Output Shaft: The output shaft connects to the driveshaft and ultimately the wheels. It contains synchronizer collars (also called dog clutches) that can slide along the shaft to engage with different gears. The output shaft’s speed determines vehicle speed. When you select a gear by moving the shift lever, you’re commanding a synchronizer collar on the output shaft to engage with a specific gear, locking that gear’s rotation to the output shaft’s rotation. This is where the magic of different gear ratios manifests—the output shaft can spin much slower than the input shaft (low gears) or nearly the same speed (high gears) depending on which gear is engaged.

Essential Transmission Components

Clutch Assembly: The clutch assembly mediates the connection between engine and transmission. The hydraulic clutch system or mechanical clutch cable translates your foot pressure on the clutch pedal into mechanical force that separates the clutch disc from the flywheel. When engaged (pedal up), the pressure plate clamps the clutch disc against the flywheel with tremendous force—often 2,000+ pounds of clamping pressure. This friction connection allows engine power to flow into the transmission. When you press the clutch pedal, a clutch release bearing (also called a throwout bearing) pushes against the pressure plate’s release fingers, relieving clamping force and allowing the clutch disc to spin freely from the flywheel. This disconnection is essential for smooth gear changes.

Synchronizers (Synchromesh): Manual transmission synchronizers represent one of the most important innovations in transmission design. Before synchronizers, drivers had to perform double-clutching or rev-matching to change gears smoothly. Synchronizers solve this problem elegantly. Each synchronizer consists of a brass or bronze cone that makes friction contact with the gear before the dog teeth engage. When you move the shift lever to select a gear, the synchronizer collar slides toward that gear. The cone makes contact first, using friction to speed up or slow down the gear until it matches the output shaft’s speed. Only after speeds are synchronized do the internal dog teeth engage, locking the gear to the shaft. This synchromesh design allows smooth, quiet gear changes using only the clutch pedal.

The synchronizer’s brass or bronze construction is deliberate—these softer metals absorb the energy of speed matching through friction and heat, protecting the harder steel gears from damage. However, this means synchronizers are wear items. Aggressive shifting, incomplete clutch depression, or attempting to shift into gear at wildly mismatched speeds causes excessive synchronizer wear. You’ll recognize worn synchronizers by grinding noises during shifts or difficulty engaging specific gears.

Shift Forks and Collars: The mechanical linkage between your hand on the shift lever and the internal synchronizer collars consists of shift forks and selector rods. When you move the shift lever in its H-pattern (or other pattern depending on the vehicle), you’re rotating or sliding selector rods inside the transmission. These rods have shift forks attached—typically three forks in a five-speed transmission, each controlling two gears. The fork physically pushes a synchronizer collar left or right to engage different gears. This simple mechanical linkage provides the direct, tactile feedback that manual transmission enthusiasts value—you can literally feel the synchronizer engaging through the shift lever.

How Manual Transmissions Work – Step by Step

Understanding the sequence of events during gear changes reveals the elegant simplicity of manual transmission operation. Every shift follows the same fundamental process, whether you’re accelerating from first to second gear or downshifting for a corner.

The Clutch Operation Cycle

Stage 1 – Clutch Engaged (Normal Driving): When you’re driving with your foot off the clutch pedal, the clutch is fully engaged. The pressure plate clamps the clutch disc firmly against the flywheel with tremendous force. Engine power flows through this friction connection into the transmission input shaft. The currently selected gear’s synchronizer collar locks that gear to the output shaft, and power flows through the meshed gears to the wheels. This is the transmission’s power-transmitting state—all components are locked together and rotating as a unified system.

Stage 2 – Clutch Disengagement Begins: When you press the clutch pedal, your foot pressure transmits through either a hydraulic system (master cylinder to slave cylinder) or mechanical cable to the release fork. The release fork pushes the throwout bearing against the pressure plate’s release fingers. As the throwout bearing moves, it forces the pressure plate to back away from the clutch disc, gradually reducing clamping force. During this transition, the clutch disc begins slipping relative to the flywheel—engine speed and transmission input shaft speed start to diverge.

Stage 3 – Full Clutch Disengagement: With the clutch pedal fully depressed, the pressure plate completely releases the clutch disc. The clutch disc now spins freely, disconnected from both the flywheel and pressure plate. Engine power no longer reaches the transmission. The engine can rev freely without affecting the transmission, and the transmission input shaft begins to slow down as friction and residual connections gradually reduce its speed. This disconnection is absolutely essential for the next stage—you cannot change gears smoothly with the clutch engaged because the transmission components are rotating at incompatible speeds.

Stage 4 – Gear Selection: With the clutch fully disengaged, you move the shift lever to select your desired gear. This movement slides a synchronizer collar along the output shaft toward the target gear. The synchronizer’s brass friction cone first makes contact with the gear, using friction to match their speeds. This speed-matching happens quickly—within a fraction of a second. Once speeds are synchronized, the dog teeth on the collar engage with matching teeth on the gear, positively locking that gear to the output shaft. Different gear ratios provide different relationships between input shaft and output shaft speeds.

Stage 5 – Clutch Re-engagement: As you gradually release the clutch pedal, the pressure plate moves back toward the clutch disc, beginning to apply clamping force. The clutch disc starts to make friction contact with both the flywheel (engine side) and pressure plate (transmission side). During this critical phase, the clutch slips intentionally—engine speed and transmission speed aren’t yet matched. Your throttle input during re-engagement determines how quickly speeds match. Release too quickly and the engine’s momentum tries to instantly accelerate the vehicle, causing a lurch or even a stall. Release too slowly while applying throttle and you generate excessive heat in the clutch disc, accelerating wear. Smooth clutch control requires feeling the “bite point”—the pedal position where friction engagement begins—and coordinating release speed with throttle input.

Gear Ratio Mechanics

The different gear ratios in a manual transmission aren’t arbitrary—they’re carefully calculated to provide optimal engine operation across the vehicle’s speed range. Understanding how these ratios work reveals why you shift when you do.

First Gear (Typical Ratio 3.166:1): First gear represents the transmission’s maximum torque multiplication. The input shaft drives a small gear on the countershaft, which in turn drives the largest gear on the output shaft. With a 3.166:1 ratio, the engine must rotate 3.166 times for the output shaft to rotate once. This dramatic reduction means massive torque multiplication—if your engine produces 150 lb-ft of torque, first gear might deliver 475 lb-ft to the wheels (before final drive multiplication). This tremendous torque is essential for overcoming the vehicle’s inertia and getting it moving from a standstill. However, first gear severely limits speed—trying to drive in first gear at 40 mph would require engine RPM well beyond the redline.

Second Through Fourth Gears: Each successive gear provides a progressively higher ratio, meaning less torque multiplication but higher possible speeds. Second gear might be 1.882:1, third gear 1.296:1, and fourth gear 1.00:1 (direct drive, where input and output shafts rotate at the same speed). These intermediate ratios allow the engine to remain within its optimal power band while the vehicle accelerates. When you hear your engine approaching high RPM in second gear, you shift to third. This drops engine RPM back down but maintains vehicle speed because third gear’s higher ratio allows higher road speed at the same engine RPM. Each upshift sacrifices some torque multiplication but gains speed capability.

Fifth/Sixth Gear (Overdrive): Most modern manual transmissions include at least one overdrive gear—a ratio less than 1:1, such as 0.80:1 or 0.75:1. In overdrive, the output shaft rotates faster than the input shaft. If you’re cruising at 70 mph in fifth gear with a 0.80:1 ratio, your engine might only be turning 2,200 RPM. This reduces fuel consumption, engine wear, and noise. However, overdrive gears provide minimal torque multiplication—they’re strictly for efficiency during steady-state cruising. Attempting to accelerate hard in top gear often requires downshifting to a lower gear where the engine can develop more power.

Reverse Gear: Reverse gear operates differently from forward gears. An idler gear positioned between the countershaft and output shaft reverses the rotation direction. This idler gear slides into mesh when you select reverse, creating a power path that rotates the output shaft backward. Reverse gear is not synchronized—the brass friction cones that enable smooth forward gear engagement aren’t present on reverse. This is why attempting to shift into reverse while moving forward produces horrible grinding noises. The unsynchronized dog teeth clash violently when speeds don’t match. You must come to a complete stop before selecting reverse.

Neutral and Power Flow

When the transmission is in neutral, none of the synchronizer collars are engaged with any gears. All the gears on both the countershaft and output shaft spin freely—they’re rotating because they’re meshed with other spinning gears, but they’re not locked to their respective shafts. The countershaft gears spin with the countershaft (which is driven by the constantly-rotating input shaft when the clutch is engaged), but the output shaft gears simply spin freely on the output shaft. No power flows to the wheels. This is why you can safely start your engine in neutral—the engine can run, the input shaft and countershaft can spin, but the output shaft and wheels remain stationary because no gear is locked to transmit power.

Hydraulic vs. Cable Clutch Systems

The clutch actuation system—the mechanism that translates your foot movement on the clutch pedal into mechanical force that disengages the clutch—has evolved significantly over automotive history. Understanding these systems helps diagnose problems and perform proper maintenance.

Hydraulic Actuation

Modern vehicles predominantly use hydraulic clutch systems due to their superior performance characteristics. The system consists of a master cylinder (attached to the clutch pedal), hydraulic lines filled with brake fluid, and a slave cylinder (which pushes the release fork). When you press the clutch pedal, the master cylinder’s piston pressurizes hydraulic fluid. This pressure transmits through the lines to the slave cylinder, whose piston extends and pushes the release fork, which in turn pushes the throwout bearing against the pressure plate.

Hydraulic systems provide several advantages. First, they’re self-adjusting—as the clutch disc wears and becomes thinner, the system automatically compensates without requiring manual adjustment. Second, they provide consistent pedal feel regardless of temperature, cable stretch, or routing complexity. Third, they eliminate the friction and binding that can affect cable systems. The hydraulic advantage is the same principle that makes brake systems reliable—incompressible fluid transmits force precisely and consistently.

However, hydraulic systems require proper maintenance. The hydraulic fluid can absorb moisture over time, reducing boiling point and causing corrosion in cylinders. Air in the system creates a spongy pedal feel and incomplete clutch disengagement. Bleeding the system—removing air bubbles—requires the same procedure used for brake bleeding. Seals in both master and slave cylinders eventually deteriorate, causing fluid leaks and system failure. A telltale sign of a failing clutch master cylinder is decreasing pedal resistance or fluid loss from the reservoir.

Concentric Slave Cylinders: Many modern vehicles use concentric slave cylinders (CSCs), also called internal slave cylinders. Instead of an external slave cylinder pushing a release fork, the CSC mounts directly around the transmission input shaft inside the bellhousing. It acts as both the slave cylinder and throwout bearing in a single integrated unit. CSCs provide more compact packaging and eliminate the release fork, reducing complexity and potential wear points. However, they’re more difficult to service—replacing a CSC typically requires transmission removal. Proper pre-installation shimming is critical with CSCs to ensure adequate travel distance for complete clutch release.

Cable Actuation (Legacy Systems)

Older vehicles and some budget models use mechanical clutch cables for actuation. A steel cable in a housing runs from the clutch pedal to the release fork. When you press the pedal, the cable pulls the release fork, which pushes the throwout bearing. Cable systems are mechanically simple, relatively inexpensive, and easy to understand for DIY repairs.

However, cable systems have significant disadvantages. Cables stretch over time, requiring periodic adjustment to maintain proper clutch operation. The adjustment procedure varies by vehicle but typically involves turning adjustment nuts at either the pedal end or transmission end to change cable tension. Cables can bind in their housings if the routing creates sharp bends or if the housing becomes contaminated with dirt or corrosion. Cold weather can make cables stiff, resulting in heavy pedal effort. Cables can also fray or break, causing sudden complete clutch failure—a scenario that leaves you stranded because you can’t change gears.

Despite these limitations, cable clutch systems remain serviceable and reliable when properly maintained. They provide direct mechanical feedback through the pedal, which some drivers prefer over hydraulic systems’ cushioned feel. Regular lubrication of the cable and housing, periodic adjustment, and proactive replacement before failure can maintain excellent cable system performance.

Manual Transmission Fluid and Lubrication

Manual transmissions rely entirely on their lubricating fluid to prevent wear, dissipate heat, and ensure smooth operation. Unlike automatic transmissions that use fluid for both hydraulic control and lubrication, manual transmission fluid serves purely mechanical lubrication functions. Understanding proper fluid selection and maintenance is essential for transmission longevity.

Fluid Types and Specifications

The variety of fluids specified for manual transmissions can be confusing, but each type serves specific design requirements. Always consult your owner’s manual or transmission specifications before adding or changing fluid—using incorrect fluid can cause immediate and severe damage.

Manual Transmission Oil (Gear Oil): Heavy-weight gear oils, typically SAE 75W-90 or 80W-90, represent the traditional manual transmission lubricant. These oils contain extreme pressure (EP) additives that protect gears under the immense contact pressures generated where gear teeth mesh. The high viscosity provides thick protective films between metal surfaces. Most truck transmissions, older car transmissions, and heavy-duty applications specify gear oil. However, gear oil’s thickness can make cold-weather shifting difficult—the oil becomes even thicker in cold temperatures, creating resistance that makes gear engagement notchy or difficult until the transmission warms up.

Automatic Transmission Fluid (ATF): Surprisingly, some manual transmissions specify ATF, particularly certain Chrysler vehicles from the 1970s-90s. Engineers specified ATF to solve cold-shift complaints—ATF’s lower viscosity flows more easily in cold weather, providing immediate smooth shifting even at low temperatures. Some modern manual transmissions also specify synthetic ATF for its superior low-temperature properties and friction characteristics that work well with modern synchronizer designs. Using ATF in transmissions designed for it is not a compromise—it’s the correct specification.

Motor Oil: Some modern manual transmissions specify regular motor oil, typically 5W-30 or similar grades. Honda, in particular, often specifies motor oil for their manual transmissions. These transmissions are designed with this lower-viscosity fluid in mind, and using heavier gear oil can actually cause problems. The lower viscosity provides easier shifting and better fuel economy through reduced parasitic drag, while modern oil formulations provide adequate protection for transmission gears.

Synthetic Options: Synthetic versions of all these fluid types offer advantages: improved low-temperature flow, better high-temperature protection, longer service intervals, and enhanced wear protection. Many enthusiasts and mechanics prefer synthetic fluids for manual transmissions, especially in performance applications or extreme climates. However, synthetic fluids cost significantly more than conventional fluids, and the benefits may not justify the expense for vehicles with normal use patterns and moderate climates.

Lubrication System Functions

Manual transmission fluid performs multiple critical functions simultaneously. During operation, gear teeth mesh and unmesh thousands of times per minute under tremendous pressure—often exceeding 100,000 psi at the contact point. The fluid must maintain a protective film between these surfaces despite the pressure trying to squeeze it out. This requires both appropriate viscosity and extreme pressure additives.

Heat dissipation represents another crucial function. Gear meshing generates significant heat through friction. The transmission case acts as a heat exchanger, with internal fluid absorbing heat and transferring it to the case, which radiates it to the surrounding air. Synchronizer operation generates additional heat—the friction that matches gear speeds converts kinetic energy to thermal energy. Adequate fluid level is essential for heat dissipation; low fluid levels lead to overheating and rapid wear.

Synchronizer performance depends heavily on fluid characteristics. The brass or bronze synchronizer cones require a specific coefficient of friction with the fluid present. Too little friction and the synchronizer cannot effectively speed-match; too much friction and shift quality suffers. This is why using incorrect fluid can immediately affect shift feel—the wrong fluid changes synchronizer friction characteristics.

Corrosion protection and detergent properties keep internal components clean and protected during storage and operation. Unlike engine oil, manual transmission fluid doesn’t become contaminated with combustion byproducts, but it does accumulate metal particles from normal gear wear. Importantly, manual transmissions typically have no filtration system—whatever particles the fluid accumulates remain in circulation until fluid changes.

Service Intervals and Warning Signs

Conventional wisdom suggests changing manual transmission fluid every 30,000 to 60,000 miles for normal driving conditions. However, service intervals should be adjusted based on use. Performance driving, towing, racing, or frequent stop-and-go traffic accelerates fluid degradation—consider 15,000-mile intervals for severe service. Some manufacturers claim “lifetime” fluid fills, but this typically means the expected vehicle lifetime, not truly permanent. Changing fluid at least once during vehicle ownership provides insurance against accelerated wear and gives you an opportunity to inspect the old fluid for warning signs.

Warning signs that fluid needs attention include:

- Notchy or Difficult Shifting: Increased resistance when moving the shift lever, particularly when cold, suggests fluid viscosity has increased or synchronizer function has degraded

- Grinding Noises During Shifts: Grinding in specific gears indicates synchronizer wear, but contaminated or degraded fluid can accelerate this process

- Gear Clash: Difficulty engaging first gear from a stop or reverse gear suggests clutch or synchronizer problems, but fluid condition should be checked first

- Visible Leaks: Puddles under the vehicle or visible fluid on the transmission case indicate seal failure requiring immediate attention

- Burnt Smell: Overheated transmission fluid develops a distinctive burnt odor, indicating severe overheating or excessive clutch slip

Safety Warning: Using incorrect fluid type can damage synchronizers within minutes of operation, causing permanent grinding and difficult shifts. Wrong fluid viscosity can lead to inadequate lubrication and catastrophic gear failure. Always verify the correct fluid specification for your specific transmission before service. When in doubt, consult a transmission specialist—fluid is cheap compared to transmission repair.

Common Problems and Troubleshooting

Manual transmissions are remarkably reliable when properly operated and maintained, but certain problems occur with predictable frequency. Understanding symptoms, causes, and appropriate responses helps you make informed decisions about repairs and when to seek professional help.

Clutch-Related Issues

Slipping Clutch: A slipping clutch manifests as engine RPM increasing without corresponding vehicle acceleration, particularly when accelerating hard or climbing grades. You may notice a burnt smell resembling burning paper or toast—this is the clutch disc friction material overheating. Slipping occurs when the clutch disc can no longer transmit full engine torque to the transmission. Causes include worn clutch disc friction material (normal wear after 60,000-150,000 miles), oil contamination of the friction surface (from engine or transmission leaks), or weak pressure plate springs that cannot maintain adequate clamping force.

A slipping clutch requires complete clutch assembly replacement—there are no partial fixes or adjustments that can restore friction material. The repair involves removing the transmission to access the clutch assembly, inspecting the flywheel for damage or excessive heat, and installing new clutch disc, pressure plate, and throwout bearing as a complete kit. Professional installation is strongly recommended because improper installation can cause immediate failure or drastically reduced clutch life.

Dragging Clutch: A dragging clutch occurs when the clutch disc doesn’t completely separate from the flywheel despite full clutch pedal depression. Symptoms include difficulty engaging first gear from a stop, grinding when shifting into reverse, and sometimes all gears being difficult to engage. The underlying problem is incomplete clutch disengagement—the clutch disc continues spinning even with the pedal fully depressed, and this residual rotation prevents smooth synchronizer engagement.

Causes of clutch drag include air in hydraulic clutch lines (creating spongy pedal feel and inadequate slave cylinder travel), improperly adjusted clutch cable (cable too loose, allowing insufficient throwout bearing travel), transmission misalignment (allowing clutch disc to bind even when pressure is released), or warped clutch disc or pressure plate. Hydraulic system bleeding often resolves dragging caused by air in the lines. Cable adjustment can restore proper operation in cable systems. However, warped components or misalignment require transmission removal for proper diagnosis and correction.

Clutch Chatter: Clutch chatter produces vibration or shuddering during engagement, particularly when starting from a stop. The clutch engagement feels inconsistent—grabbing, releasing, grabbing again in rapid succession rather than providing smooth progressive engagement. While worn clutch components can cause chatter, the problem often originates elsewhere.

Common non-clutch causes include contaminated clutch disc (oil or grease on friction material), glazed flywheel surface (from excessive heat creating a hard, smooth surface that doesn’t grip well), engine or transmission mounting problems (worn mounts allowing excessive movement), transmission misalignment (often from missing or worn bellhousing dowel pins), or worn pressure plate causing uneven clamping force. Diagnosing chatter requires systematic inspection. Professional mechanics can often identify the cause through test drives and visual inspection during clutch removal.

Transmission Internal Issues

Grinding Gears: The unmistakable grinding noise when shifting gears indicates metal-on-metal contact between dog teeth—the synchronizer has failed to properly match speeds before the collar engages the gear. This is perhaps the most serious warning sign because continued operation causes rapid damage. Early-stage grinding might only occur in specific gears (often second or third, which experience the most use) or only when cold. Advanced grinding occurs consistently and may eventually prevent the gear from engaging at all.

Worn synchronizers represent the primary cause of grinding. The brass friction cones wear down through normal use, but aggressive shifting (speed-shifting without full clutch depression, slamming into gear) dramatically accelerates wear. Attempting to shift into gear at wildly mismatched speeds (high-speed downshifts without rev-matching) overworks synchronizers. Incorrect transmission fluid can also contribute—fluid that’s too thin or too thick changes synchronizer friction characteristics, and contaminated fluid accelerates wear.

Once grinding begins, it progressively worsens. The damaged dog teeth and synchronizer cone damage each other further with each shift. Temporary relief might come from double-clutching (blipping throttle during the shift to manually match speeds), but this is a stopgap measure. Proper repair requires transmission disassembly to replace worn synchronizers. This is a complex repair requiring specialized knowledge and tools—definitely a job for transmission specialists rather than general repair shops.

Popping Out of Gear: When a transmission spontaneously disengages from a selected gear and returns to neutral, you’re experiencing one of the most dangerous transmission problems. This typically occurs under load—accelerating or climbing grades—and can happen suddenly without warning. The transmission simply “pops” into neutral, causing immediate loss of power to the wheels. This is especially dangerous on highways or while overtaking.

Causes include worn shift fork engagement (the fork can’t hold the synchronizer collar firmly in the locked position), damaged detent mechanism (spring-loaded balls that hold selector rods in position become worn), worn dog teeth on gears or synchronizers (allowing disengagement under load), or worn bearings causing shaft misalignment. Sometimes chronic popping out occurs in just one gear (often second or third), indicating specific component wear.

This problem requires immediate professional diagnosis. Continuing to drive with a transmission that pops out of gear is genuinely unsafe—you could lose power at a critical moment. Diagnosis usually requires transmission removal and disassembly to identify the specific worn components. This is not a repair that can be attempted by anyone without professional transmission rebuilding experience.

Hard Shifting: Difficulty moving the shift lever, requiring excessive force to engage gears, or a notchy, grinding feel during shifts indicates problems preventing smooth synchronizer operation. Unlike grinding gears where you hear damage occurring, hard shifting simply makes gear engagement difficult but might not produce obvious noises.

The most common and easily remedied cause is incorrect transmission fluid. Using fluid of the wrong viscosity, contaminated fluid, or grossly old fluid can make shifting difficult, particularly when cold. Simply draining and refilling with the correct fluid specification often completely resolves hard shifting. Beyond fluid issues, worn synchronizers cause progressively harder shifting as their friction cones wear down. External linkage problems—worn bushings, binding cables, or misadjusted shifter cables—can create resistance. Clutch problems preventing complete disengagement make all shifts difficult.

Diagnosis should always start with fluid inspection. Check the fluid level (low fluid doesn’t provide adequate lubrication), examine its condition (burnt smell, metallic particles, or milky appearance indicating water contamination), and verify the correct fluid type is installed. If fluid service doesn’t resolve hard shifting, professional diagnosis can identify whether internal wear or external linkage problems are responsible.

External Problems

Fluid Leaks: Manual transmission fluid leaks most commonly occur at shaft seals—the input shaft seal where it enters the transmission from the clutch, the output shaft seal where it exits to the driveshaft, and the shifter shaft seals where selector rods penetrate the case. Small seepage (slight dampness) at seals is relatively common in older transmissions and doesn’t necessarily require immediate action. However, active dripping or puddle formation indicates seal failure requiring prompt attention.

Low fluid level from leaks causes immediate problems: inadequate lubrication leads to accelerated wear, heat dissipation suffers, and synchronizer operation deteriorates. Visible fluid under the vehicle should always be investigated—identify the leak source, assess severity, and verify fluid level. Even if the leak seems minor, checking fluid level regularly prevents running the transmission low, which causes expensive internal damage far exceeding seal replacement cost.

Replacing input shaft seals requires transmission removal because the seal is located behind the clutch. Output shaft seals can sometimes be replaced without full transmission removal, depending on vehicle configuration and access. Shifter shaft seals are typically accessible without transmission removal. Professional diagnosis determines the appropriate repair approach based on leak location and severity.

Linkage and Cable Problems: The external shift linkage connecting your shift lever to the transmission’s internal selector rods can develop problems that affect shift quality without indicating internal transmission damage. Symptoms include vague or sloppy shift feel, inability to select certain gears, or shift lever positions that don’t match actual gear engagement.

Worn bushings in the shift linkage create excessive play, making the shifter feel imprecise. Stretched shifter cables (in cable-shifted transmissions) cause misalignment between lever position and internal selector rod position. Loose or misadjusted linkage rods produce similar symptoms. These external problems often produce symptoms that mimic internal transmission issues, but they’re much less expensive to repair and frequently within DIY capability.

Diagnosis involves inspecting the external linkage while someone moves the shifter. Look for loose connections, worn bushings, or binding in cables. Many shifter assemblies include adjustment provisions to compensate for wear or cable stretch. Replacing worn bushings and adjusting cables often completely restores crisp shift feel. This is maintenance rather than repair—addressing external linkage issues before they cause you to force shifts (which can damage internal components) is good preventive practice.

For complex transmission problems or symptoms that don’t clearly point to external causes, consulting transmission diagnostic codes through the vehicle’s computer system can provide valuable insights into electronic components or sensors related to transmission operation.

Maintenance Best Practices

Proper manual transmission maintenance extends far beyond periodic fluid changes. Your driving habits have enormous impact on clutch and transmission longevity. Understanding which practices preserve components and which accelerate wear empowers you to maximize your transmission’s lifespan.

Driving Habits That Extend Transmission Life

Avoid “Riding the Clutch”: One of the most common bad habits is resting your foot on the clutch pedal while driving. Even slight pedal pressure partially compresses the throwout bearing against the pressure plate release fingers. This creates constant load on the throwout bearing, causing premature wear. The throwout bearing isn’t designed for continuous operation—it’s meant to engage only during gear changes and then retract completely. Additionally, partial pedal pressure can create slight clutch slip even though you’re not consciously slipping the clutch, generating heat and accelerating clutch disc wear.

The solution is simple but requires conscious attention: rest your left foot on the floor or on a dead pedal (the footrest to the left of the clutch pedal), not on the clutch pedal itself. Some drivers argue they’re “ready to shift” with their foot on the pedal, but this readiness comes at the expense of clutch life. Train yourself to move your foot to the clutch only when you’re actually shifting.

Complete Clutch Depression: Always depress the clutch pedal completely to the floor when shifting. Partial clutch depression doesn’t fully disengage the clutch disc from the flywheel, meaning the input shaft continues spinning—just more slowly than before. When you attempt to shift with the clutch partially engaged, the synchronizers must work much harder to match speeds, and they may not fully succeed. The result is accelerated synchronizer wear, potential grinding, and damaged dog teeth.

Some drivers develop the habit of “feathering” the clutch during shifts, believing this provides smoother operation. In reality, proper shift technique requires full clutch depression, smooth deliberate shifter movement, and complete clutch re-engagement. Developing smooth, consistent technique with full pedal travel provides the best shift quality and longest component life.

Don’t Hold on Hills with Clutch: When stopped on an incline, don’t hold position by balancing clutch engagement against brake pedal. This “hill-holding” technique keeps the clutch partially engaged—the clutch disc is slipping against the flywheel and pressure plate, generating tremendous heat. Even 30 seconds of hill-holding can generate enough heat to glaze the clutch disc surface, reducing its effective life by thousands of miles.

Proper technique uses the foot brake or parking brake to hold position. When ready to proceed, fully depress the clutch, engage first gear, then smoothly release the clutch while simultaneously applying throttle and releasing the brake. Some vehicles with electronic parking brakes include “hill-hold” features that automatically hold brake pressure for a few seconds after you release the brake pedal, giving you time to transition to clutch engagement without rollback.

Avoid Money Shifting: “Money shifting” refers to accidentally selecting the wrong gear—typically a gear that’s two steps away from the current gear rather than one step away. The classic example is attempting to shift from third to fourth but accidentally hitting second. At highway speeds, this forces the engine to suddenly rev far beyond its redline, potentially causing immediate catastrophic engine damage (valve float, broken valves, damaged pistons) and transmission damage from shock loads. The term “money shifting” comes from the expensive repair bills that follow.

Prevention requires attention and smooth, deliberate shifting. Don’t rush shifts or slam the lever into position. Feel the gear engage and verify you’re in the intended gear before releasing the clutch. On vehicles with difficult-to-differentiate shift gates (some six-speed patterns are particularly challenging), extra care is warranted. If you’ve accidentally selected the wrong gear, you’ll typically feel unusual resistance as the synchronizer tries to match wildly incompatible speeds—stop the shift, return to neutral, and try again.

Don’t Downshift to Slow Down: Many drivers believe downshifting through the gears while decelerating saves brake wear. While technically true, this practice transfers wear from inexpensive, easily serviceable brake pads to expensive, difficult-to-access clutch and transmission components. Every downshift requires clutch disengagement and re-engagement, adding cycles to clutch life. Each gear engagement adds wear cycles to synchronizers.

Modern brake systems are designed for stopping duty, with large, ventilated rotors and high-quality pads that provide hundreds of thousands of stops before requiring service. Brake pad replacement is cheap and straightforward compared to clutch replacement. The appropriate use of engine braking is on extended descents (mountain roads, long hills) where continuous braking would overheat the brakes. For normal deceleration and stopping, simply brake in your current gear until you need to accelerate again or until you approach stalling speed (below ~15 mph), then shift to the appropriate gear for your speed.

Scheduled Maintenance

Regular Fluid Checks: Incorporate transmission fluid inspection into your routine maintenance schedule. Every time you change your engine oil, take an extra minute to check for transmission fluid leaks. Look for wet spots or drips around the transmission case, particularly at seal locations. Check under the vehicle after it’s been parked overnight—fresh spots indicate active leaks requiring attention.

If you notice shifting difficulties, check the fluid level. While many manual transmissions have limited capacity and rarely drop significantly unless there’s a major leak, low fluid can cause immediate problems. Some transmissions have easily accessible fill plugs; others require working underneath the vehicle. Consult your repair manual for the correct checking procedure—some require the vehicle to be level, others have specific temperature requirements.

Fluid Changes: Follow your manufacturer’s recommended fluid change intervals as documented in your owner’s manual. Don’t assume manual transmissions never need fluid service—that “lifetime fill” typically means the expected vehicle lifetime, not genuinely permanent. As discussed previously, fluid accumulates metal particles from normal wear, and these particles accelerate further wear. Periodic fluid changes remove these contaminants.

For vehicles used in severe service conditions—frequent towing, track days, aggressive driving, stop-and-go traffic in hot climates, or off-road use—reduce service intervals by 30-50%. The additional cost of more frequent fluid changes is trivial compared to transmission repair or rebuilding costs.

When changing fluid, use the exact specification called for in your owner’s manual. Resist the urge to “upgrade” to heavier-weight fluid or use whatever is on sale—transmission engineers specified particular fluid characteristics for good reasons related to synchronizer function, gear protection, and shift quality. Using incorrect fluid can immediately alter shift feel and potentially cause long-term damage.

External Inspection: Periodically inspect external components for wear or damage. Check shifter linkage bushings for play or deterioration. Examine shifter cables for fraying or binding. Verify that rubber boots protecting shift lever and cable entry points aren’t torn or deteriorated—these boots keep contaminants out of the transmission. Look at hydraulic clutch lines for damage, leaks, or deterioration. Inspect the clutch master cylinder reservoir fluid level and condition.

These external inspections take only a few minutes but can identify developing problems before they become serious failures. A fraying shifter cable caught early can be replaced for modest cost; waiting until it breaks can leave you stranded in a single gear or unable to shift at all.

Professional Inspection: Consider having a transmission specialist inspect your transmission annually or every 15,000-20,000 miles, particularly if you’re driving an older vehicle or one with high mileage. Professional inspection can identify developing problems—slight gear mesh noise, bearing wear, seal seepage, or clutch wear approaching the point where replacement is advisable. Early identification allows you to plan and budget for repairs rather than facing unexpected catastrophic failure.

Professional inspection is particularly valuable before long trips or if you’re planning to keep the vehicle for many more years. A transmission specialist can assess remaining clutch life, identify any fluid leaks requiring attention, and verify that all systems are operating within normal parameters. This preventive approach often identifies minor problems that are inexpensive to address before they cause major component damage.

For more comprehensive vehicle maintenance guidance, explore the Vehicle Care Tips section which covers systematic approaches to preventive maintenance across all vehicle systems.

When to Consult a Professional

Understanding when to attempt DIY repairs versus when to consult professionals is crucial for safety, cost management, and ensuring proper repairs. Manual transmissions have clear boundaries between serviceable external components and complex internal systems requiring specialized expertise.

Immediate Professional Attention Required

Certain symptoms indicate serious problems requiring immediate professional diagnosis and repair. Don’t continue driving extensively if you experience:

Grinding Noise During Normal Shifts: While occasional grinding during rushed or poorly-executed shifts might not indicate immediate danger, consistent grinding during careful shifts signals worn synchronizers or damaged dog teeth. Continued driving accelerates damage, potentially causing complete transmission failure. The parts are already worn—additional grinding doesn’t make them “worse” in the sense of moving from “slightly worn” to “very worn,” but rather from “repairable” to “complete rebuild required.”

Transmission Jumping Out of Gear: This is a genuine safety issue. Loss of power to the wheels during acceleration, on grades, or at highway speeds creates hazardous situations. The underlying problem—worn shift forks, detent mechanisms, or dog teeth—will not improve and typically worsens rapidly. Schedule professional diagnosis immediately and consider alternative transportation until repairs are completed.

Major Fluid Leaks: Active dripping or puddle formation indicates seal failure requiring prompt repair. Low fluid levels cause catastrophic internal damage within a short time—hours or days rather than weeks. If you notice a major leak, check the fluid level immediately. If it’s low, don’t drive the vehicle. Have it towed to a repair facility rather than risking complete transmission destruction by driving with inadequate lubrication.

Complete Inability to Select Gears: If you can’t engage any gears with the engine running and the clutch depressed, the problem could be severe clutch drag, completely failed clutch hydraulics, or internal transmission problems. Attempting to force gears into engagement can cause immediate internal damage. Professional diagnosis is essential to identify the root cause and appropriate repair.

Burning Smell from Transmission Area: A distinct burning smell combined with difficulty shifting, grinding, or unusual heat from the transmission case indicates serious overheating, clutch problems, or catastrophic internal failure. Don’t continue driving—overheating can warp components, contaminate fluid, and escalate a potentially repairable problem into a complete transmission replacement situation.

Schedule Professional Diagnosis

Some situations aren’t immediate emergencies but warrant professional attention within days or weeks:

Progressive Increase in Shift Effort: If the force required to move the shift lever gradually increases over weeks or months, something is progressively wearing or binding. This might be external linkage wear (relatively inexpensive to repair) or internal synchronizer wear (expensive to repair). Early diagnosis allows you to address the problem before it progresses to grinding or gear selection failure.

Clutch Engagement Point Changing: If the point where the clutch begins engaging moves significantly higher or lower on the pedal travel, clutch wear is advancing. This isn’t an emergency, but it indicates approaching clutch replacement time. Planning for clutch replacement is preferable to waiting for complete clutch failure, which always occurs at the most inconvenient time.

Subtle Grinding in Specific Gears: If one particular gear (often second or third) produces slight grinding during careful shifts while other gears remain smooth, that gear’s synchronizer is worn but not yet failed. Addressing this while it’s still minor might allow synchronizer replacement without complete transmission disassembly, depending on the transmission design.

Unusual Noises During Operation: Whining, humming, or growling noises from the transmission while driving (not just during shifts) indicate bearing wear or gear problems. These noises typically start subtle and gradually increase in volume over weeks or months. Early diagnosis can identify the specific failing component and allow replacement before the failure damages other components through metal contamination or cascading damage.

DIY vs. Professional Repair Boundaries

Appropriate for DIY (with proper tools and knowledge):

- Manual transmission fluid changes

- External linkage adjustment and bushing replacement

- Shifter cable replacement (in cable-shifted transmissions)

- Clutch hydraulic system fluid changes

- Basic hydraulic system bleeding (with proper technique)

- External seal replacement where accessible without transmission removal

Requires Professional Service:

- Clutch assembly replacement (requires transmission removal and specialized alignment tools)

- Internal synchronizer replacement or repair

- Bearing replacement inside the transmission

- Any work requiring transmission disassembly

- Clutch hydraulic master cylinder or slave cylinder replacement (requires proper bleeding and often special tools)

- Transmission removal and installation

- Concentric slave cylinder replacement

Gray Area (Possible DIY for Experienced Home Mechanics with Proper Tools):

- Output shaft seal replacement (depends on vehicle configuration)

- External shifter mechanism service and adjustment

- Clutch hydraulic line replacement

- Advanced hydraulic system bleeding using pressure or vacuum methods

Critical Safety Reminder: Manual transmission repair, particularly clutch replacement and internal transmission work, requires specialized knowledge, proper tools, and safety equipment. Improper clutch installation can cause immediate failure when you first attempt to drive. Incomplete transmission assembly can cause catastrophic failure at highway speeds. Transmission removal requires proper support—the transmission weighs 60-150 pounds depending on vehicle type, and dropping it can cause severe injury. When in doubt about your ability to perform a repair safely and correctly, consult qualified transmission specialists. The cost of professional service is far less than the cost of botched DIY repairs, replacement of damaged components, or medical treatment for injuries.

Manual Transmission Variants

While synchronized manual transmissions represent the standard configuration, several specialized variants exist for particular applications. Understanding these alternatives provides context for how manual transmission technology has evolved and continues to serve specialized purposes.

Synchronized vs. Unsynchronized Transmissions

Synchronized Transmissions (Modern Standard): Virtually all modern passenger car and light truck manual transmissions use synchromesh design, where brass or bronze friction cones facilitate smooth gear engagement. As discussed throughout this guide, synchronizers enable shifting using only the clutch pedal—no double-clutching or rev-matching required. The synchronizer matches the speed of the target gear to the output shaft speed before the dog teeth engage, providing quiet, smooth shifts that any driver can accomplish with minimal training.

Synchronized transmissions dominate the market because they’re user-friendly, reliable, and adequately durable for normal driving conditions. The synchronizer’s brass friction material does represent a wear item, but typical lifespan ranges from 100,000 to 200,000+ miles with proper operation. For the vast majority of applications, synchronized transmissions represent the optimal balance of ease of use and durability.

Unsynchronized Transmissions (Heavy-Duty/Racing): Unsynchronized transmissions, also called “crash boxes,” require the driver to manually match engine speed to transmission speed before shifting. This is accomplished through double-clutching (clutch in, shift to neutral, clutch out, blip throttle to match engine speed to target gear speed, clutch in, shift to gear) or by rev-matching during clutch-in shifting. Getting this right requires skill and practice; getting it wrong produces horrible grinding noises as dog teeth clash at mismatched speeds.

Why would anyone want this more difficult design? Unsynchronized transmissions offer advantages for specific applications. The absence of brass synchronizer cones means steel-on-steel engagement—much more durable under extreme loads. Heavy commercial trucks traditionally used unsynchronized transmissions because durability trumped ease of use. Racing applications sometimes prefer unsynchronized designs because properly executed shifts can be faster without waiting for synchronizer action, and the transmissions tolerate repeated hard shifts better.

Modern heavy trucks increasingly use synchronized transmissions or automated manual transmissions that electronically manage the required rev-matching. Unsynchronized transmissions persist primarily in vintage commercial equipment and some racing applications where their specific advantages outweigh the driver skill requirements.

Sequential Gearboxes

Sequential manual transmissions eliminate the H-pattern shift gate entirely. Instead, you shift forward for upshifts and backward (or pull toward you, depending on design) for downshifts. You progress through the gears in order—first, second, third, fourth—with no way to skip gears. There’s no neutral position between gears; shifting through neutral happens instantaneously during gear changes.

Sequential gearboxes originated in motorcycle transmissions but have found applications in racing cars, rally cars, and some high-performance road cars. The sequential design enables extremely fast shifts—often much faster than H-pattern transmissions—because the shorter shifter movement and linear action allow quicker actuation. Race drivers can shift without removing their hand from the steering wheel by using paddle shifters or steering wheel-mounted buttons connected to sequential actuators.

The racing pedigree explains sequential transmissions’ limited road car adoption. They’re expensive to manufacture, sometimes produce more gear noise than conventional transmissions, and the linear shift pattern feels unfamiliar to drivers accustomed to H-pattern boxes. Some performance motorcycles converted to car applications use sequential boxes, and certain racing-derived supercars offer sequential transmissions, but they remain rare in mainstream vehicles.

Semi-Automatic Manual Transmissions

Semi-automatic manual transmissions bridge the gap between fully manual and fully automatic operation. These systems use a conventional manual transmission internal design but automate the clutch actuation and, in some implementations, gear selection. The driver might use a conventional H-pattern shifter, paddle shifters, or sequential buttons to command gear changes, but the system handles the clutch operation through computer-controlled actuators.

Early implementations appeared in Formula 1 racing in the 1990s and gradually migrated to exotic sports cars. Systems like Ferrari’s F1 transmission, Lamborghini’s e-gear, and various manufacturer-specific names all work on similar principles: electronically controlled hydraulic actuators operate the clutch and shift mechanisms based on driver commands and sensor inputs. The computer can execute shifts faster and more consistently than human drivers, potentially rev-matching on downshifts and modulating clutch engagement for smooth starts.

More mundane applications include some commercial vehicles and accessibility adaptations that retain manual transmission efficiency while eliminating the physical demands of clutch pedal operation. Some manual transmission enthusiasts view these systems as compromising the “pure” manual driving experience, while others appreciate the blend of manual control with automated execution.

Modern electric vehicles like the single-speed units described in EV transmission systems represent a completely different approach to power transmission, eliminating the need for multiple gear ratios entirely through electric motor characteristics.

Conclusion

Manual transmissions represent one of automotive engineering’s most elegant solutions—a purely mechanical system that allows direct driver control over power delivery while maintaining engine operation within optimal parameters. Understanding the three-shaft architecture, synchronizer operation, clutch actuation, and proper maintenance empowers you to maximize transmission longevity and driving enjoyment.

The fundamental principles haven’t changed significantly since the introduction of synchronized transmissions in the 1920s: multiple gear ratios multiply engine torque for various driving conditions, a clutch disconnects the engine during gear changes, and synchronizers enable smooth engagement. This mechanical simplicity contributes to manual transmissions’ legendary reliability—properly operated manual transmissions regularly exceed 200,000 miles without major repairs, with clutch replacement being the only significant service required.

Your driving habits profoundly impact transmission and clutch longevity. Avoiding common mistakes—riding the clutch, forcing shifts without complete clutch disengagement, hill-holding with the clutch, and unnecessary downshifting—can double or triple clutch life and virtually eliminate premature synchronizer wear. Regular fluid maintenance, using the correct fluid specification, and addressing minor problems before they escalate prevents expensive repairs.

The Future of Manual Transmissions

The trajectory is clear: manual transmissions are disappearing from most mainstream vehicles, particularly in North America where they represent less than 2.5% of new car sales. Automatic transmissions now match or exceed manuals in fuel efficiency while offering superior convenience. Most manufacturers have eliminated manual options from their lineups entirely, concentrating remaining offerings in performance vehicles where driving engagement justifies the niche appeal.

However, manual transmissions will persist in certain markets and applications. European and Asian markets maintain higher manual transmission adoption rates due to different driving cultures, fuel costs, and training requirements. Performance and sports cars continue offering manual transmissions as enthusiast options—manufacturers recognize that a subset of buyers specifically seeks the engagement and control that manuals provide. Some truck applications, particularly heavy commercial vehicles internationally, retain manual transmissions for durability and driver control in challenging conditions.

Electric vehicles fundamentally change the transmission paradigm. Electric motors produce maximum torque from zero RPM and operate efficiently across enormous speed ranges, eliminating the need for multiple gear ratios. Most EVs use single-speed reduction gearboxes rather than multi-speed transmissions. As EVs proliferate, manual transmission operation will become an increasingly specialized skill rather than basic driving knowledge.

Final Recommendations

For current manual transmission owners, maintain your vehicle properly and drive it thoughtfully. Manual transmissions are among the most reliable automotive components when respected. Change the fluid at appropriate intervals with the correct specification. Avoid bad habits that accelerate wear. Address problems promptly before they escalate. Your manual transmission can easily outlast the rest of the vehicle if given basic care.

For those learning to drive manual transmissions, focus on developing smooth, consistent technique. Fully depress the clutch for every shift. Feel the synchronizer engagement rather than forcing the shifter. Release the clutch progressively, feeling the engagement point. With practice, these movements become automatic, and the mechanical sympathy you develop benefits the transmission throughout its life.

For anyone experiencing transmission problems, understanding the symptoms and their implications helps you communicate effectively with repair professionals and make informed decisions about repairs. Grinding during shifts indicates worn synchronizers. Slipping clutches produce burning smells and high engine RPM without acceleration. Jumping out of gear signals worn internal components requiring immediate attention. Early diagnosis and repair invariably costs less than allowing problems to progress to complete failure.

Professional Consultation Reminder: For any significant transmission concerns—unusual noises, difficult shifting, grinding, or jumping out of gear—consult a qualified transmission specialist immediately. Manual transmission internal repairs require specialized knowledge, proper tools, and experience. Attempting complex transmission repairs without appropriate expertise can cause additional damage, create safety hazards, and ultimately cost more than professional service. When in doubt, seek professional help.

Understanding the Complete Drivetrain

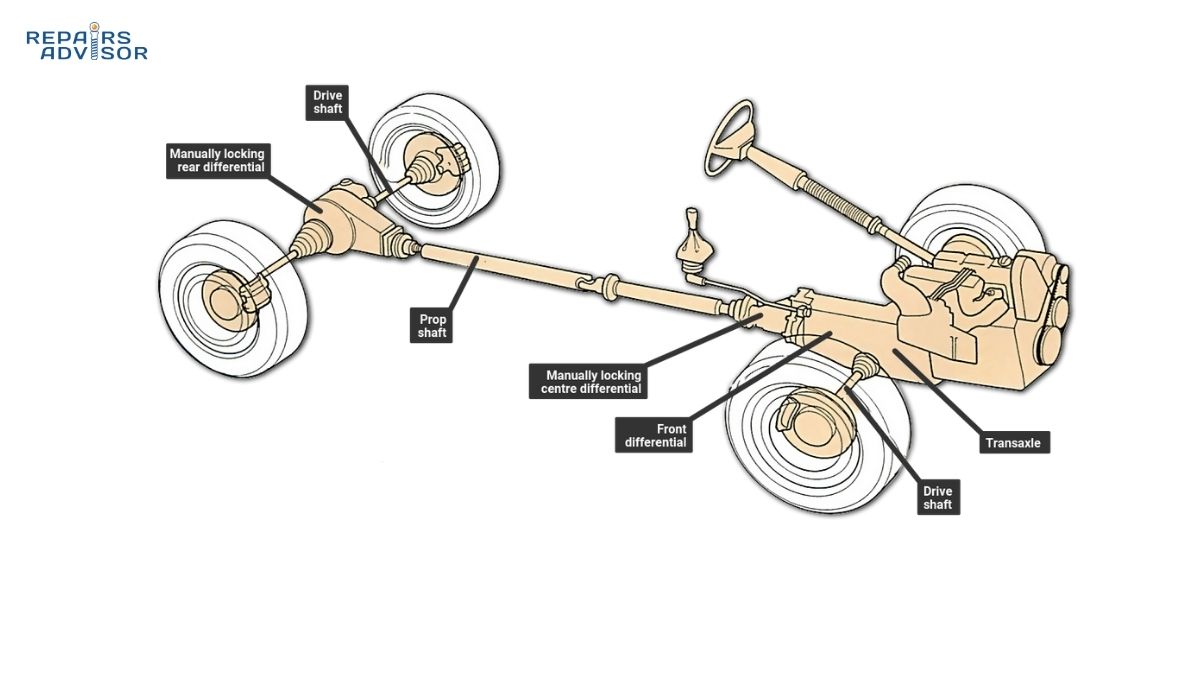

Manual transmissions don’t operate in isolation—they’re one component in a complex drivetrain system. Understanding how power flows from the engine, through the transmission, to the drive shaft, through the differential, and finally to the wheels provides complete context for how your vehicle converts engine power into forward motion. For comprehensive coverage of all vehicle systems, explore the Vehicle Systems & Parts Explained section.

Manual transmissions may be fading from the automotive mainstream, but their mechanical simplicity, driver engagement, and reliability ensure they’ll remain relevant for enthusiasts and specialized applications for years to come. Whether you drive a manual by choice or necessity, understanding how these systems work transforms abstract mechanical operation into comprehensible engineering—knowledge that enhances both appreciation and proper care.