Modern ignition coils are sophisticated electromagnetic transformers that convert your vehicle’s 12-volt battery power into the thousands of volts needed for reliable spark generation. Understanding how ignition coils work empowers DIY enthusiasts to diagnose common ignition problems, while helping professionals optimize their troubleshooting efficiency. As the critical link between engine management systems and spark plugs, these components must deliver precise energy transfer at exactly the right moment in the combustion cycle.

Safety Note: Working with ignition systems involves high voltage components that can deliver dangerous electrical shocks. Always disconnect the battery, use insulated tools, and wear safety glasses when inspecting ignition coils. If you’re uncomfortable working with electrical systems, consult a qualified professional.

Why Ignition Coils Are Critical for Electrical Function

Ignition coils serve as the electrical heart of your engine’s combustion process, transforming low-voltage battery power into the high-voltage energy required for spark generation. Without properly functioning coil-on-plug systems, even the most sophisticated fuel injection systems cannot complete the combustion cycle effectively.

The precision energy transfer provided by modern ignition coils directly impacts engine performance, fuel economy, and emissions control. Professional mechanics understand that coil-on-plug designs offer superior diagnostic capabilities compared to older distributor systems, enabling faster troubleshooting and more accurate problem identification. For intermediate DIY enthusiasts, recognizing the symptoms of failing ignition coils such as engine misfires, rough idle, or poor acceleration can prevent more costly engine damage.

Modern vehicles rely on precisely controlled dwell time to optimize spark energy delivery. The ECU calculates the exact moment to begin charging each coil’s primary winding, ensuring maximum energy transfer when the spark plug fires. This coordination between the ignition coils and the broader ignition system demonstrates the critical role these components play in overall engine management.

Beginner Tip: If your engine runs roughly or struggles to start, ignition coils are often among the first components to check. Unlike older distributor-based systems, modern coil-on-plug designs allow you to swap coils between cylinders to quickly identify failing units.

Ignition Coils Parts and Construction Explained

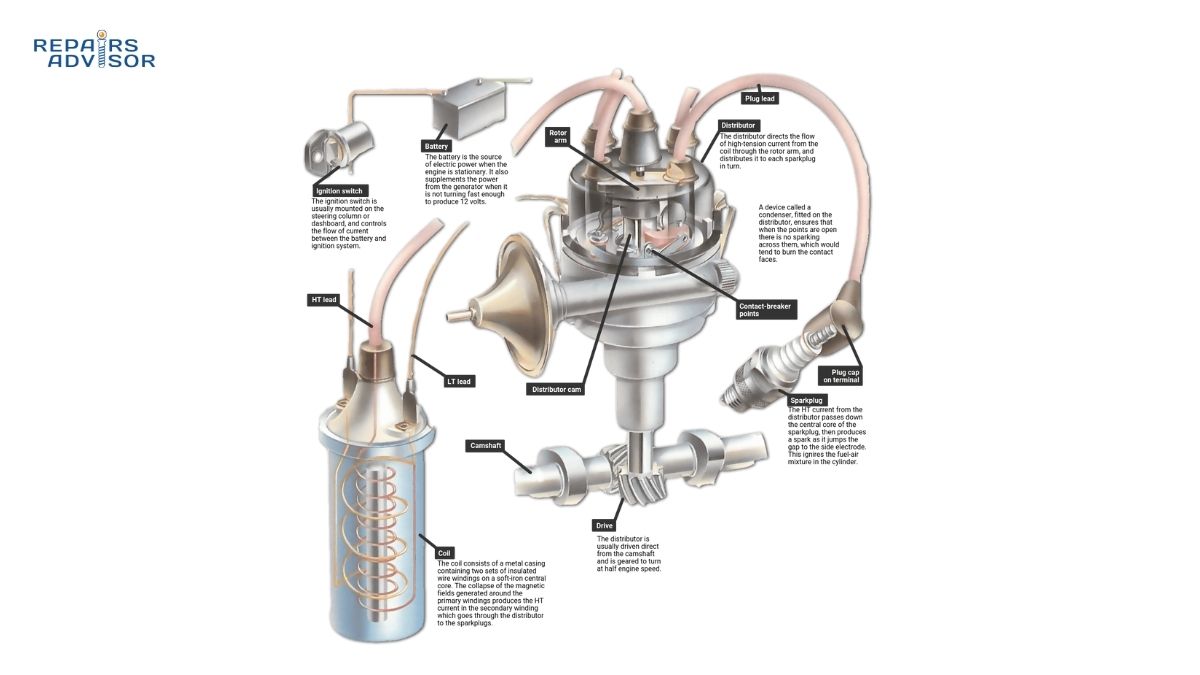

The internal construction of ignition coils reveals the sophisticated engineering required for efficient energy transfer. At the core lies an iron-based laminated structure that concentrates magnetic flux and minimizes energy losses during the transformation process. The primary winding consists of relatively few turns of heavy-gauge copper wire, designed to handle the substantial current flow from the vehicle’s electrical system.

Surrounding the iron core, the secondary winding contains thousands of turns of fine copper wire, creating the step-up transformer ratio necessary for high-voltage generation. Professional mechanics know that the exact turns ratio varies by manufacturer and application, but typically ranges from 100:1 to 150:1. This means 12 volts from the battery becomes 15,000 to 25,000 volts at the spark plug.

The coil driver circuit, integrated into modern ignition systems, precisely controls the dwell control process. During the dwell period, current flows through the primary winding, building magnetic energy in the iron core. When the ECU interrupts this current flow, the collapsing magnetic field induces high voltage in the secondary winding through electromagnetic induction.

Intermediate Insight: The saturation point of the iron core determines maximum energy storage. Once saturated, additional dwell time doesn’t increase spark energy but does generate unnecessary heat. This is why modern engine management systems carefully calculate optimal dwell time based on engine speed and load conditions.

Advanced coil-on-plug designs incorporate additional features for enhanced performance and diagnostics. Many include integrated ignition modules that provide local switching control, reducing the electrical load on the main ECU. Temperature compensation circuits adjust timing and energy delivery based on operating conditions, ensuring consistent performance across a wide range of environments.

The housing design protects internal components while providing proper heat dissipation. High-quality ignition coils feature robust insulation systems that prevent voltage breakdown under extreme conditions. Professional-grade diagnostic equipment can measure primary and secondary resistance values to assess coil health, making these components relatively straightforward to test compared to other ignition system elements.

How Ignition Coils Work: Step-by-Step Operation

The ignition coil operation cycle begins when the ECU determines the optimal time to start building magnetic energy for the next firing event. Based on inputs from the crankshaft position sensor and other engine sensors, the engine management system initiates the dwell time by energizing the primary winding through the coil driver circuit.

During the energy charging phase, current flows through the primary winding, creating a magnetic field that saturates the iron core. The dwell time typically ranges from 2-6 milliseconds, depending on engine speed and coil characteristics. Professional mechanics understand that insufficient dwell time results in weak spark energy, while excessive dwell time wastes battery power and generates unnecessary heat.

The actual energy transfer occurs when the ECU abruptly interrupts primary current flow. This sudden change creates a rapidly collapsing magnetic field, which induces high voltage in the secondary winding through electromagnetic induction. The step-up transformer effect multiplies the 12-volt input by the turns ratio, generating the thousands of volts needed for reliable spark plug operation.

Professional Tip: The rate of current change during coil cutoff directly affects spark energy. Sharp, clean current interruption produces more powerful sparks than slow or irregular cutoff patterns. This is why quality coil drivers use fast-switching transistors rather than mechanical contact points.

Modern coil-on-plug systems coordinate this process across multiple cylinders with precise timing control. The ECU staggers firing events to match the engine’s firing order while optimizing dwell time for each individual coil. This level of coordination requires sophisticated communication between the ignition coils and other engine management components, including the fuel injection system and emission control devices.

The energy delivery phase completes when high voltage jumps the spark plug gap, creating the plasma channel needed for combustion initiation. Any remaining energy in the coil dissipates through the spark duration, which typically lasts 1-2 milliseconds. Understanding this complete cycle helps diagnostic technicians identify whether ignition problems stem from the coils themselves or from related systems like fuel pumps or engine sensors.

Ignition Coils Location and Access Guide

Locating ignition coils in modern vehicles requires understanding the transition from older distributor-based systems to contemporary coil-on-plug designs. In coil-on-plug applications, each cylinder has its own dedicated ignition coil mounted directly above the spark plug, eliminating the need for spark plug wires and distributors. This configuration provides more precise timing control and easier diagnostic access.

For DIY enthusiasts, identifying ignition coils typically involves locating cylindrical or rectangular components mounted on the engine’s valve cover or cylinder head. Each coil connects directly to a spark plug through a rubber boot and spring connector system. Professional mechanics appreciate this design because it allows individual coil testing and replacement without disturbing other cylinders.

Safety Reminder: Before accessing ignition coils, always disconnect the negative battery terminal and allow the engine to cool completely. Ignition coils can retain high voltage charges even after the engine is turned off, presenting a shock hazard during service.

Access procedures vary significantly between vehicle manufacturers and engine configurations. In many applications, removing the engine cover provides direct access to all ignition coils. However, some designs require removing air intake components, fuel rails, or other engine accessories to reach certain coils. Always consult manufacturer-specific service information before beginning any ignition system work.

The electrical connections to each coil typically include a main power feed from the vehicle’s electrical system and a control signal from the ECU. Many coil-on-plug designs use individual connectors for each coil, while some systems employ a single harness that distributes power and control signals to multiple coils. Understanding these connection patterns helps technicians diagnose whether problems affect individual coils or the entire ignition system.

Beginner Guide: When working on ignition coils, take photos of connector orientations and wire routing before disassembly. Modern vehicles often have similar-looking connectors that can be confused during reassembly. Proper documentation prevents electrical connection errors that could damage expensive electronic components.

Professional diagnostic procedures often involve swapping coils between cylinders to isolate failures. This technique works because most ignition-related misfires will follow the coil to its new cylinder location. Combined with OBD-II diagnostic codes and professional scan tools, coil swapping provides definitive identification of failed components without expensive test equipment.

For vehicles requiring more complex access procedures, consider the relationship between ignition coil service and other maintenance items. Many technicians recommend replacing spark plugs during ignition coil service, as both components affect combustion quality and are often accessible through the same service procedures. This approach maximizes efficiency while ensuring optimal ignition system performance.

Technical Insight: When accessing ignition coils in tight engine compartments, professional mechanics often use specialized tools designed for coil removal and installation. These tools prevent damage to rubber boots and electrical connectors while providing adequate leverage in confined spaces. Investing in quality tools pays dividends in reduced service time and fewer comeback repairs.

For comprehensive repair manuals covering specific vehicle makes and models, explore our extensive collection of Ford repair manuals, Toyota service guides, and Honda technical documentation. Professional mechanics and DIY enthusiasts can also reference our automotive electrical systems section for additional diagnostic resources and troubleshooting guides.

Disclaimer: This information is provided for educational reference only. Always consult manufacturer specifications and professional guidance when working on vehicle ignition systems. Repairs Advisor provides technical manuals and documentation but does not offer direct repair services or warranty guarantees on repair outcomes.