Imagine accelerating from a stoplight on a rain-slicked road. While other vehicles struggle for grip, wheels spinning uselessly, your car surges forward smoothly and confidently. This isn’t magic—it’s the result of an all-wheel drive system working behind the scenes, intelligently distributing power to all four wheels to maximize traction exactly when you need it.

All-wheel drive technology has evolved from a niche feature in off-road vehicles to a mainstream expectation in everything from family crossovers to high-performance sports cars. Yet despite its popularity, many drivers don’t understand how AWD actually works, when they truly need it, or how to maintain these sophisticated systems properly. The confusion between AWD and 4WD alone causes countless misunderstandings about capabilities and limitations.

Understanding AWD mechanics matters because these systems significantly affect your vehicle’s safety, performance characteristics, and maintenance costs. Whether you’re considering an AWD vehicle purchase, maintaining your current system, or simply curious about the technology working beneath your feet, this comprehensive guide will explain exactly how AWD systems distribute power, what components make them function, and what you need to know to keep them operating reliably. You’ll learn to distinguish between different AWD types, recognize warning signs of problems, and understand when professional service becomes necessary.

What Is an AWD System? Core Concepts and Operation

All-wheel drive (AWD) is a sophisticated drivetrain system that automatically distributes engine power to all four wheels of a vehicle, enhancing traction, stability, and control across various driving conditions. Unlike traditional two-wheel drive systems that send power exclusively to either the front or rear axle, AWD continuously monitors road conditions and adjusts power distribution to maximize grip wherever it’s needed most. The system operates largely without driver intervention, using computer controls and sensors to make split-second decisions about where torque should flow.

At its foundation, AWD relies on a center differential that splits engine torque between the front and rear axles. This differential allows the front and rear wheels to rotate at different speeds—essential when turning corners, as the outer wheels travel farther than the inner wheels. Without this capability, the drivetrain would bind up during turns, causing excessive tire wear and mechanical stress. The center differential represents the fundamental distinction between AWD and simpler drivetrain configurations.

Full-Time AWD: Always Engaged, Always Ready

Full-time AWD systems deliver power to all four wheels continuously, regardless of road conditions or driver input. These systems never operate in two-wheel drive mode; instead, they constantly monitor and adjust the torque split between axles based on traction needs. Subaru’s Symmetrical AWD and Audi’s Quattro system exemplify this approach, providing confidence in all weather conditions without requiring the driver to activate anything.

The advantage of full-time AWD lies in its immediate response to changing conditions. Because power already flows to all wheels, there’s no delay when traction suddenly diminishes—the system simply adjusts the distribution ratios. This makes full-time AWD particularly well-suited for areas with unpredictable weather or drivers who frequently encounter varying road surfaces. However, the constant engagement comes at a cost: slightly lower fuel economy compared to part-time systems, as all drivetrain components remain active all the time.

Part-Time AWD: Efficiency Meets Capability

Part-time AWD systems, far more common in modern crossovers and SUVs, operate most of the time in either front-wheel drive or rear-wheel drive mode. The system only engages all four wheels when sensors detect wheel slip or anticipate the need for additional traction. This on-demand approach offers better fuel economy than full-time systems, as the vehicle can operate efficiently in two-wheel drive during normal conditions while maintaining the capability to engage AWD when circumstances demand it.

Modern part-time systems have become remarkably sophisticated. Rather than simply reacting to wheel slip after it occurs, advanced systems use predictive algorithms that analyze steering angle, throttle position, and acceleration patterns to engage AWD before wheels lose traction. This proactive approach eliminates the slight delay inherent in reactive systems, providing a driving experience that feels nearly identical to full-time AWD while preserving the efficiency benefits of part-time operation.

The electronic stability control system works closely with AWD to enhance vehicle dynamics. While AWD manages power distribution for traction, ESC uses individual wheel braking and throttle modulation to maintain vehicle stability during aggressive maneuvers or emergency situations. Together, these systems create a comprehensive safety net that helps drivers maintain control even when conditions deteriorate rapidly.

AWD vs 4WD: Understanding Critical Differences

The terms “all-wheel drive” and “four-wheel drive” are frequently used interchangeably, but they describe fundamentally different systems designed for distinct purposes. Understanding these differences helps you choose the right system for your needs and operate it safely within its intended parameters.

AWD systems are engineered primarily for on-road use, with automatic operation that requires no driver input. They use a center differential to allow front and rear axles to rotate at different speeds, enabling normal operation on dry pavement without drivetrain binding. The system’s computer continuously monitors conditions and adjusts power distribution accordingly, making AWD ideal for daily driving in varying weather conditions—rain, snow, ice, or dry roads.

Four-wheel drive systems, in contrast, are designed for serious off-road use and typically require manual engagement by the driver through a button, switch, or lever. Most 4WD systems use a transfer case that locks the front and rear driveshafts together, forcing them to rotate at the same speed. This locked configuration provides maximum traction in extreme conditions like deep mud, steep rocky trails, or deep snow, but it cannot be used on dry pavement due to the drivetrain binding that occurs when the system tries to turn corners with locked axles.

Professional mechanics emphasize a critical safety point: Part-time 4WD systems should never be engaged on dry pavement. The locked driveshafts create tremendous mechanical stress during turns, potentially damaging transfer cases, differentials, and axles. This binding also makes the vehicle difficult to steer and can cause dangerous handling characteristics. AWD systems avoid this problem entirely through their center differential design, making them safe for use in all conditions.

Key AWD Components and Mechanical Operation

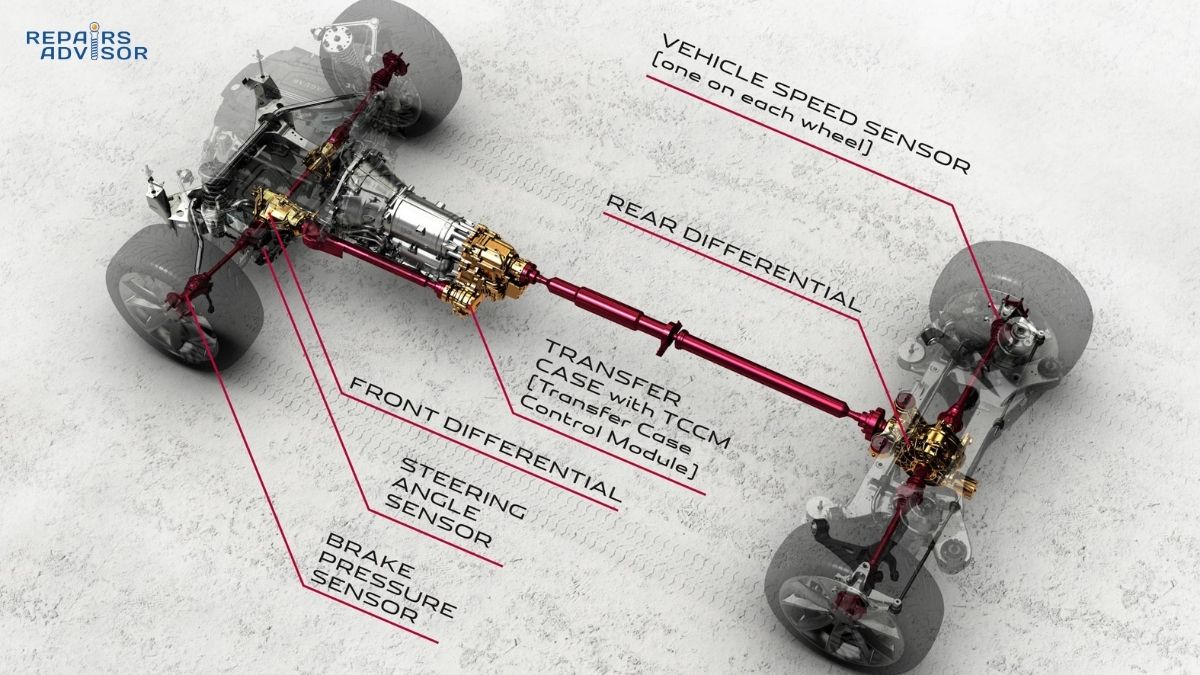

The mechanical heart of any AWD system consists of several key components working in concert to distribute power effectively. Understanding these components illuminates how AWD systems achieve their impressive balance of capability and drivability.

Center Differential: The Power Distribution Hub

The center differential serves as the primary power-splitting mechanism in AWD systems, dividing engine torque between the front and rear axles. This component sits between the transmission and the drive shafts, receiving input from the engine and transmission before distributing that power to both ends of the vehicle. Unlike the front and rear differentials that allow left and right wheels to rotate at different speeds, the center differential enables the front and rear axles to turn at different rates—essential for navigating corners without drivetrain binding.

Center differentials come in several designs, each with distinct characteristics. Open differentials split power evenly between axles under normal conditions but can send torque to the axle with less resistance when traction differs. Limited-slip differentials use clutch packs or other mechanisms to maintain more balanced power delivery even when one axle loses traction, preventing the common open-differential problem where all power flows to the slipping wheel.

Electronically controlled center differentials represent the most advanced approach, using computer-controlled clutches to continuously adjust the torque split based on driving conditions. These systems can vary the front-to-rear distribution from 100:0 to 0:100 in milliseconds, placing power exactly where it’s needed. Some performance AWD systems maintain a rear-biased distribution (60 percent rear, 40 percent front, for example) under normal driving for more dynamic handling characteristics, then shift toward even splits or front-biased distributions when traction becomes limited.

Viscous Coupling: Simple Fluid-Based Power Transfer

Viscous coupling systems represent one of the earliest automatic AWD technologies, and many remain in service today due to their simplicity and reliability. These systems use a sealed housing filled with silicone-based fluid and two sets of plates—one connected to the front axle and one to the rear. Under normal driving, the plates rotate at similar speeds and the fluid offers little resistance. When one axle begins spinning faster than the other (indicating wheel slip), the speed difference causes the fluid to heat up and thicken, effectively linking the plates together and transferring torque to the slower-rotating axle.

This fluid-based approach provides progressive engagement—the greater the speed difference, the more torque gets transferred. The system requires no electronic controls, sensors, or driver input, making it mechanically simple and reliable. However, viscous couplings have inherent limitations. The fluid must heat up before it can transfer significant torque, creating a slight delay in response. Additionally, these systems can overheat during sustained wheel slip, temporarily reducing their effectiveness until the fluid cools.

Despite these limitations, viscous couplings remain popular in many AWD applications due to their low cost, compact size, and proven durability. They work particularly well in vehicles where AWD serves primarily as a bad-weather safety feature rather than a performance enhancement.

Multi-Plate Clutch: Precision Electronic Control

Multi-plate clutch systems have become the dominant AWD technology in modern vehicles, offering precise electronic control and rapid response times. These systems use a hydraulically or electrically actuated clutch pack to connect the front and rear axles. Computer control allows the system to adjust clutch engagement pressure continuously, varying the amount of torque transferred based on real-time driving conditions.

The clutch pack consists of alternating friction plates—some connected to the front axle and others to the rear. When the system’s control module detects the need for AWD engagement, it applies pressure to compress these plates together, mechanically linking the axles and allowing torque transfer. By varying the pressure, the system can send anywhere from zero to 100 percent of available torque to either axle.

This electronic control enables sophisticated AWD behavior. The system can engage preemptively based on throttle position, steering angle, and other inputs, eliminating the response delay inherent in reactive systems. Multi-plate clutches also allow for more precise control than viscous couplings, distributing exactly the right amount of torque to maintain optimal traction without over-engaging and wasting energy. Honda’s Real Time AWD and Nissan’s Intelligent AWD both utilize advanced multi-plate clutch systems with predictive engagement algorithms.

The electronic control systems managing these clutches have become increasingly sophisticated. Modern AWD computers process inputs from dozens of sensors, considering factors like individual wheel speeds, throttle position, steering angle, lateral acceleration, and even outside temperature to determine the optimal torque distribution for current conditions. This level of integration allows AWD systems to enhance both safety and performance simultaneously.

Haldex Coupling: Advanced Electro-Hydraulic Integration

Haldex couplings represent a specialized AWD technology commonly used in vehicles with transversely mounted engines (typical in front-wheel-drive-based platforms). These systems integrate an electronically controlled hydraulic pump with a multi-plate clutch mechanism, providing rapid response and precise torque control in a compact package. Volkswagen Group vehicles (VW, Audi transverse models, Škoda, SEAT) frequently employ Haldex systems, as do some Volvo and Land Rover models.

The Haldex system’s hydraulic pump actively builds pressure to engage the clutch pack rather than relying on passive mechanical or viscous mechanisms. This active design enables extremely fast response—the system can engage full AWD capability in milliseconds when needed. The electronic control unit continuously monitors vehicle dynamics and can modulate clutch engagement pressure hundreds of times per second, providing seamless power distribution that adapts to changing conditions.

However, Haldex systems require more maintenance attention than some other AWD designs. The hydraulic fluid and internal filter must be serviced regularly—typically every 20,000 to 40,000 miles, depending on the generation and application. Neglecting this maintenance can lead to reduced performance, erratic engagement, or complete system failure. The complexity also means that Haldex repairs generally require specialized knowledge and diagnostic equipment. Understanding hydraulic systems fundamentals helps appreciate how these sophisticated couplings manage power transfer.

Drive Shafts and CV Joints: Power Delivery to Wheels

Once the center differential or coupling system distributes power between front and rear axles, that energy must travel to the wheels through drive shafts and CV (constant velocity) joints. In AWD vehicles, these components face greater stress than in two-wheel-drive configurations, as they must handle continuously varying loads and speeds.

Drive shafts transmit rotational force from the transfer case or center differential to the front and rear differentials. These shafts must be precisely balanced to avoid vibrations at highway speeds, and they typically incorporate universal joints or CV joints to accommodate the suspension’s vertical movement while maintaining power delivery. In many AWD systems, the rear drive shaft includes a center support bearing that must be inspected periodically for wear.

CV joints allow the drive shafts to transfer power while accommodating steering movement and suspension travel. These joints consist of precision ball bearings contained within protective rubber boots filled with specialized grease. The boots keep contaminants out while retaining lubricant—they represent the most common failure point in AWD drivetrain systems. A torn CV boot allows grease to escape and dirt to enter, leading to rapid joint wear. The classic symptom of a failing CV joint is a clicking or popping sound during turns, especially under acceleration.

Regular inspection of CV boots and drive shaft components should be part of any AWD maintenance routine. Catching a torn boot early allows for simple boot replacement, while ignoring the issue typically necessitates complete joint replacement at significantly higher cost.

Electronic Control and Sensors: The Intelligence Behind AWD

Modern AWD systems rely on an extensive network of sensors and electronic controls to make real-time decisions about power distribution. This electronic intelligence transforms mechanical hardware into a responsive, adaptive system capable of optimizing both safety and performance.

Wheel Speed Sensors: Detecting Traction Loss

Individual wheel speed sensors form the foundation of AWD electronic control. These sensors, typically magnetic or Hall-effect devices mounted at each wheel, measure the rotational speed of each tire dozens of times per second. The AWD control module continuously compares these speeds—when one or more wheels rotate faster than the others, the system recognizes wheel slip and responds accordingly.

These same wheel speed sensors serve double duty, also providing critical data to the ABS system for anti-lock braking functionality. This integration allows the AWD control module to work cooperatively with the ABS controller, sharing information and coordinating responses to maximize both traction and stability. When a wheel speed sensor fails, it typically triggers warning lights for both systems and may cause the AWD system to default to a safe mode or disengage entirely.

The precision of wheel speed measurement has improved dramatically over the years. Modern sensors can detect speed differences as small as a fraction of a revolution, allowing AWD systems to respond to incipient wheel slip before it becomes significant. This capability enables the predictive engagement strategies that characterize the most advanced AWD systems.

AWD Control Module: The System Brain

The AWD control module serves as the central computer that processes sensor inputs and commands actuators to engage or disengage AWD components. This module receives data from wheel speed sensors, throttle position sensors, steering angle sensors, lateral accelerometers, and numerous other inputs. Using sophisticated algorithms, it determines the optimal power distribution for current conditions and sends commands to clutch actuators, valve bodies, or other control mechanisms.

Modern AWD control modules integrate with virtually every other vehicle system. They communicate with the engine control unit to modulate throttle response when necessary, coordinate with the traction control system to manage wheel slip through braking intervention, and work with electronic stability control to maintain vehicle dynamics during aggressive maneuvers. This integration creates a comprehensive vehicle dynamics management system where AWD represents just one tool in a larger safety and performance toolkit.

The control module also monitors system health, watching for sensor failures, mechanical problems, or abnormal operating conditions. When it detects an issue, it illuminates the AWD warning light on the dashboard and typically stores diagnostic trouble codes that technicians can retrieve during service. In some cases, the module may command the system into a safe mode—often front-wheel or rear-wheel drive only—to prevent damage while allowing continued operation.

Torque Vectoring: Next-Level Power Distribution

Torque vectoring represents an advanced AWD capability found primarily in performance-oriented vehicles. While conventional AWD systems can only vary power distribution between front and rear axles, torque vectoring systems add the ability to adjust power between the left and right wheels on an axle. This additional dimension of control enables dramatic improvements in cornering performance and handling dynamics.

Systems like Acura’s Super Handling All-Wheel Drive (SH-AWD) and BMW’s xDrive with torque vectoring use electronically controlled clutches on the rear axle to route more power to the outside rear wheel during cornering. This actively rotates the vehicle into the turn, reducing understeer and allowing higher cornering speeds. The effect is particularly noticeable in enthusiastic driving—the car feels more agile and responsive, with the ability to adjust its line mid-corner through power modulation.

Implementing torque vectoring requires additional hardware complexity and sophisticated control algorithms. The system must consider steering angle, lateral acceleration, yaw rate, individual wheel speeds, and throttle position to determine the optimal torque distribution. Professional mechanics emphasize that these advanced systems require specialized diagnostic equipment and should only be serviced by technicians with specific training in these technologies.

Predictive AWD Algorithms: Anticipating Need

The most sophisticated AWD systems have evolved beyond simply reacting to wheel slip—they now predict when additional traction will be needed and engage proactively. Honda’s Real Time AWD exemplifies this approach, using inputs from the accelerator pedal, steering wheel, and throttle body to anticipate scenarios where AWD will benefit the driver.

For example, when the system detects the driver depressing the accelerator pedal while the vehicle is stationary or moving slowly, it assumes the driver intends to accelerate and preemptively engages the rear wheels. This eliminates any delay or initial wheel spin that might occur with purely reactive engagement. Similarly, when sensors detect the vehicle approaching a curve based on steering input, the system can pre-position power distribution to optimize stability and traction through the turn.

These predictive strategies require extensive calibration and testing to avoid false positives that would waste energy or create unwanted engagement. However, when properly implemented, they provide a driving experience where AWD feels seamlessly integrated—the system becomes invisible to the driver, working behind the scenes to optimize traction in all conditions.

AWD System Benefits and Performance Advantages

The popularity of AWD systems stems from their ability to enhance vehicle capability across multiple dimensions. Understanding these benefits helps drivers appreciate what AWD provides—and equally important, what it doesn’t.

Improved Traction in Adverse Conditions

The most obvious and widely appreciated benefit of AWD is enhanced traction in slippery conditions. Snow, ice, rain, wet leaves, gravel, mud—any surface that limits tire grip becomes more manageable with AWD engaged. While a two-wheel-drive vehicle struggles to transfer power through two tires that may be spinning, an AWD vehicle distributes that same power across four tires, effectively doubling the contact patches contributing to forward motion.

This traction advantage is most dramatic during acceleration from a stop. Watch vehicles at a stoplight on a snowy day, and the AWD-equipped cars typically pull away smoothly while front-wheel and rear-wheel drive vehicles spin their tires trying to find grip. The difference becomes even more pronounced on hills, where AWD systems help vehicles climb grades that would leave two-wheel-drive cars helplessly spinning in place.

However, a critical safety point must be emphasized: AWD helps with acceleration, not braking or cornering. All vehicles, regardless of drivetrain configuration, brake and turn using the same four tires with the same contact patches. AWD provides zero benefit when trying to stop on ice or negotiate a slippery curve. Many accidents occur when AWD drivers, emboldened by their enhanced acceleration capability, drive too fast for conditions and discover that their braking and cornering limits remain unchanged.

Enhanced Stability and Handling Characteristics

Beyond raw traction, AWD systems contribute to improved vehicle stability and more predictable handling characteristics. By distributing power to all four wheels, AWD helps balance the forces acting on the vehicle during acceleration, reducing weight transfer and helping maintain neutral handling characteristics. This proves particularly valuable in front-heavy vehicles, where AWD mitigates the tendency toward understeer that plagues powerful front-wheel-drive cars.

The stability benefits extend to high-speed driving as well. With power flowing to all four corners, AWD vehicles feel more planted and composed at highway speeds, especially during lane changes or when encountering crosswinds. The system continuously makes micro-adjustments to power distribution, helping keep the vehicle tracking straight and responding predictably to steering inputs.

The integration between AWD and electronic stability control creates a powerful safety partnership. ESC systems use individual wheel braking to help maintain vehicle stability, while AWD uses power distribution for the same goal. Together, these systems provide multiple tools to keep the vehicle under control, significantly reducing the likelihood of losing control during emergency maneuvers or unexpected traction loss.

Performance Applications: When Every Wheel Counts

High-performance vehicles increasingly adopt AWD not for all-weather capability, but for the pure performance advantages it provides. Supercars like the Audi R8, Nissan GT-R, and Porsche 911 Turbo use sophisticated AWD systems to deploy their prodigious horsepower effectively, putting power to the ground that would overwhelm any two-wheel-drive configuration.

The performance advantage is straightforward: More tires contributing to acceleration means faster launches and more effective power delivery at any speed. AWD supercars can achieve 0-60 mph times previously impossible for even the most powerful rear-wheel-drive machines, simply because all four contact patches work together to overcome inertia. Launch control systems in these vehicles manage AWD engagement along with throttle, clutch, and other parameters to achieve repeatable maximum-acceleration launches.

Beyond straight-line performance, well-engineered AWD systems enhance cornering ability by allowing drivers to apply power earlier in a turn. While a rear-wheel-drive car might require trailing throttle or gentle acceleration through a corner to avoid oversteer, an AWD vehicle can often accelerate aggressively even before the apex, using all four wheels to pull through the turn with minimal drama. Performance-oriented AWD systems typically maintain a rear-wheel bias under normal conditions to preserve the engaging rear-drive feel, shifting toward even or front-biased distributions only when wheel slip is detected.

Light Off-Road Capability Without 4WD Compromise

AWD systems provide meaningful off-pavement capability for drivers who occasionally venture off paved roads but don’t need dedicated 4WD systems. Gravel roads, dirt trails, campsite access, boat launches, and similar light off-road scenarios all benefit from AWD traction without the compromises inherent in 4WD systems—compromises like poor on-road fuel economy, coarse handling, and the need for manual engagement and disengagement.

The key distinction is one of degree rather than kind. AWD excels on surfaces that still offer reasonable traction but would challenge two-wheel-drive vehicles—muddy tracks after rain, sandy trails, shallow water crossings, and moderate hills with loose surfaces. These represent the scenarios most drivers actually encounter, making AWD a practical solution that adds capability without significant daily-driving penalties.

However, serious off-roading remains 4WD territory. AWD systems lack the low-range gearing, locking differentials, and robust construction needed for rock crawling, deep mud, steep technical trails, or serious overlanding. Ground clearance limitations in most AWD vehicles compound this limitation. Professional guidance suggests assessing your actual usage patterns honestly—if you regularly need capabilities beyond what AWD provides, invest in a proper 4WD vehicle rather than attempting to push an AWD system beyond its design parameters.

AWD System Maintenance Requirements and Service Intervals

AWD systems add complexity to your vehicle’s drivetrain, and that complexity brings additional maintenance requirements. Proper service extends system life, prevents expensive failures, and ensures reliable operation when you need it most.

Differential Fluid Service: The Foundation of AWD Longevity

Every AWD vehicle has at least three differentials requiring periodic fluid service—front, center, and rear. Some vehicles have more, depending on configuration. Unlike engine oil, differential fluid operates in a sealed environment without filtration, meaning contaminants remain in the system until the fluid is changed. Metal shavings from normal gear wear accumulate over time, gradually degrading the fluid’s lubricating properties and potentially causing accelerated component wear.

Most manufacturers recommend differential fluid changes every 30,000 to 60,000 miles under normal driving conditions, with more frequent service recommended for severe use—towing, off-roading, or track driving. The cost typically ranges from $200 to $300 to service all three differentials, representing a modest investment in preventing failures that can cost thousands to repair. Professional mechanics note that differentials rarely fail catastrophically if properly maintained, making fluid service one of the most cost-effective preventive measures available.

The service process requires proper equipment and knowledge. Each differential must be filled to a specific level with the exact fluid type specified by the manufacturer. Using incorrect fluid or improper fill levels can cause noise, excessive wear, or even complete failure. Many differential plugs require specific tools and torque specifications for removal and installation. While experienced DIY mechanics can perform differential service, most owners benefit from having this work done by professionals who have the proper equipment and access to manufacturer service data.

Transfer Case Maintenance: Protecting the Power Hub

Vehicles with separate transfer cases—typically those with more traditional 4WD-style layouts rather than transaxle-based designs—require transfer case fluid service as well. Service intervals vary widely depending on the system, ranging from 25,000 to 60,000 miles or even longer in some applications. The transfer case serves as the power distribution hub in these configurations, making its proper maintenance critical to overall system function.

Transfer cases endure significant mechanical stress, particularly in vehicles used for towing or off-roading. The fluid lubricates chains or gears that distribute power between front and rear axles while also keeping seals pliable and preventing corrosion. Leak inspection forms an essential part of transfer case maintenance—fluid weeping past seals indicates wear that will worsen if not addressed promptly.

Severe-use conditions dramatically accelerate transfer case fluid degradation. If you regularly tow heavy loads, drive in deep water, operate in extreme heat or cold, or frequently engage in off-road driving, consider halving the recommended service interval. The relatively low cost of fluid changes provides cheap insurance against the expense and inconvenience of transfer case failure.

Critical Tire Maintenance for AWD Systems

Tire maintenance takes on heightened importance with AWD vehicles due to the way these systems operate. AWD systems continuously monitor individual wheel speeds and adjust power distribution accordingly—they fundamentally assume that all tires are similar sizes and rolling at comparable rates. When tire diameters differ significantly due to uneven wear, the system interprets this as continuous wheel slip and responds by constantly engaging or modulating power distribution in an attempt to correct a problem that doesn’t actually exist.

The mechanical consequence of mismatched tires can be severe. AWD systems working continuously to compensate for tire diameter differences generate excessive heat in clutches, couplings, and differentials. This premature wear can destroy expensive AWD components, often requiring complete replacement. Many manufacturers specify that all four tires must be within 2/32nds of an inch in tread depth difference. Some systems are even more stringent.

This requirement creates a practical problem: If you suffer irreparable tire damage on a vehicle with significantly worn remaining tires, you may need to replace all four tires rather than just the damaged one. While this seems expensive compared to replacing a single tire, it’s far cheaper than replacing an AWD coupling or differential destroyed by mismatched tire diameters. Some tire dealers offer shaving services that can remove tread from a new tire to match existing worn tires, potentially avoiding four-tire replacement costs.

Regular tire rotation becomes essential for AWD vehicles—even more so than with two-wheel-drive configurations. Rotating tires every 5,000 to 8,000 miles helps ensure even wear across all four positions, maximizing tire life while minimizing the risk of developing diameter differences large enough to stress the AWD system. Wheel alignment should also be maintained properly, as misalignment causes uneven wear that creates the same diameter differences the system can’t tolerate.

Drive Shaft and CV Joint Inspection

The drive shafts and CV joints connecting your AWD system’s differentials to the wheels represent critical wear points requiring regular inspection. CV joints are protected by rubber boots that keep lubricant in while keeping contaminants out. These boots face harsh conditions—road salt, rocks, oil, extreme temperatures—and eventually crack or tear. Once compromised, a CV joint will fail within a few thousand miles as grease escapes and contaminants enter.

Inspecting CV boots during oil changes or tire rotations takes only moments but can prevent expensive repairs. Look for any tears, cracks, or grease leaking from the boots. If you notice CV boot damage, replace the boot immediately—before the joint itself sustains damage. Many vehicles allow boot replacement without removing the entire axle, making this a relatively inexpensive repair. Waiting until the joint fails typically requires complete axle replacement at several times the cost.

Listen for unusual noises that may indicate CV joint or drive shaft problems. Clicking or popping sounds during turns, especially under acceleration, typically indicate a failing outer CV joint. Clunking during acceleration or deceleration may point to inner CV joint wear or u-joint issues. Vibrations that vary with speed often stem from driveshaft imbalance or worn center support bearings. Any of these symptoms deserves prompt professional attention to diagnose and repair before minor issues become major failures.

Long-Term Cost Considerations

The total cost of AWD ownership extends beyond the vehicle’s purchase price. Annual fuel costs typically run $150 to $300 higher than equivalent two-wheel-drive models due to the additional weight and mechanical friction of AWD components. Tire replacement costs more since you may need to replace all four tires rather than just two. Maintenance expenses add $200 to $500 every few years for differential and transfer case services that don’t apply to simpler drivetrains.

As vehicles age and accumulate mileage, AWD systems face increasing repair costs. Components like transfer cases, center differentials, and AWD couplings can require expensive repairs or replacement—often $1,500 to $3,500 depending on the vehicle and specific failure. While proper maintenance significantly reduces the likelihood of such failures, the complexity inherent in AWD systems means more potential failure points compared to two-wheel-drive configurations.

For many drivers, these costs represent worthwhile investments for the safety, capability, and confidence AWD provides. However, honest assessment of your actual needs helps determine whether AWD’s benefits justify its expenses. If you live in a warm climate with minimal precipitation and rarely leave paved roads, AWD may provide little practical benefit despite its ongoing costs. Conversely, drivers in areas with harsh winters or those who regularly need to navigate challenging road conditions typically find AWD’s advantages easily justify the additional expenses.

Common AWD Problems and Diagnostic Warning Signs

Understanding common AWD failures and recognizing their symptoms enables early intervention before minor issues cascade into expensive repairs. While modern AWD systems generally prove reliable with proper maintenance, certain problems occur frequently enough that all AWD owners should know what to watch for.

AWD Warning Light Activation: Don’t Ignore the Signal

The AWD warning light on your dashboard serves as the system’s primary communication channel with you. When this light illuminates—whether solid or flashing—it indicates the control module has detected a problem. The specific issue could range from a simple sensor malfunction to a serious mechanical failure, but all deserve attention. Ignoring an AWD warning light allows potential problems to worsen, often resulting in more expensive repairs or even safety hazards.

Common causes of AWD warning light activation include wheel speed sensor failures, which prevent the system from accurately monitoring individual wheel speeds. These sensors face harsh conditions—road debris, salt, temperature extremes—and occasionally fail or develop intermittent connections. A failed wheel speed sensor typically illuminates both the AWD warning light and the ABS light, as both systems rely on the same sensors. Professional diagnostic equipment can quickly identify which sensor has failed.

In Subaru vehicles specifically, a peculiar cause of AWD light activation involves the FWD fuse in the fuse box. This fuse slot allows temporary conversion to front-wheel-drive only mode for certain situations (like using a temporary spare tire or performing rolling road diagnostics). If someone accidentally inserts a fuse in this location, the AWD system disables itself and illuminates the warning light. Removing the fuse immediately restores AWD function.

More serious issues can also trigger the warning light. Internal mechanical problems within the transfer case, center differential, or coupling mechanism may cause the control module to detect abnormal operation and disable the system to prevent damage. Electronic control module failures, though less common, can cause erratic behavior or complete system shutdown. When the warning light activates, professional diagnostic scanning should be your first step—trying to guess the problem rarely succeeds, and proper diagnosis saves time and money.

Unusual Drivetrain Noises: Listening for Trouble

Abnormal sounds emanating from your AWD system often provide early warning of developing problems. Learning to recognize and locate these noises helps identify issues before they progress to failure. Grinding or whining noises typically indicate bearing wear within the transfer case, differentials, or wheel hubs. These sounds often vary with vehicle speed and may change pitch during turns. As bearings wear, they develop increased clearance that allows components to move excessively, creating noise and vibration.

Clunking sounds during acceleration or deceleration frequently point to worn CV joints or U-joints in the driveshaft. CV joints typically produce clicking or popping sounds that intensify during turns and under power—the classic symptom of a worn outer CV joint. Inner CV joints and U-joints often create more of a clunking sensation that you may feel through the vehicle structure as much as hear. These worn joints create excessive play in the drivetrain, and that play manifests as clunks when power delivery changes direction.

In vehicles with viscous coupling AWD systems, a particularly concerning noise is the sound of the coupling itself beginning to fail. As the viscous fluid breaks down or the coupling’s internal components wear, you may hear a howling or moaning sound that changes with vehicle speed. This often accompanies a symptom where the vehicle feels like it’s in four-wheel drive all the time, creating handling difficulties and increased tire wear. A failing viscous coupling typically requires complete replacement, as they’re sealed units that can’t be serviced.

Professional mechanics emphasize that unusual noises should never be ignored, especially in AWD systems. The same failures that create noise often generate excessive heat and metal-to-metal contact that accelerates damage. What might be a $300 repair if addressed immediately can balloon into a $2,000 replacement if deferred until complete failure.

Binding or “Bucking” Behavior During Turns

If your AWD vehicle exhibits binding, resistance, or bucking behavior when making tight turns—particularly in parking lots or during low-speed maneuvering—the system has a serious problem requiring immediate attention. This symptom indicates the AWD system cannot properly allow the front and rear axles to rotate at different speeds, forcing the tires to fight each other during turns.

In AWD systems, this typically stems from a failed center differential or a coupling mechanism that has become stuck in engaged position. The mechanical limitation prevents the front and rear wheels from rotating at their naturally different speeds during turns, creating tire scrub and excessive mechanical stress. Continued driving in this condition can damage tires, axles, differentials, and the coupling mechanism itself.

In 4WD vehicles, this binding is normal and expected when four-wheel drive is engaged on dry pavement—which is precisely why professional mechanics repeatedly emphasize that part-time 4WD should never be used on surfaces with good traction. However, if an AWD system exhibits this behavior, it represents a malfunction. The system should seamlessly allow different rotational speeds between axles under all conditions.

This symptom demands immediate professional diagnosis. Continuing to drive with a binding AWD system risks exponentially increasing repair costs as additional components suffer damage from the abnormal operating conditions. In some cases, the problem may be as simple as an electronic control failure that has locked a clutch pack closed—a relatively affordable repair. Delaying diagnosis allows what might be electrical issues to cause mechanical damage that requires component replacement.

Fluid Leaks: The Slow Path to Catastrophic Failure

Fluid leaks from any AWD component—differential, transfer case, or coupling—represent red flags requiring prompt attention. Unlike oil leaks from the engine that may be tolerated temporarily (though they shouldn’t be), drivetrain fluid leaks can quickly lead to catastrophic failures with no warning. AWD components operate with relatively small fluid capacities, meaning even modest leaks can deplete lubricant to dangerously low levels within weeks or even days.

Differential leaks typically manifest as dark, often gear-oil-smelling fluid accumulating on the differential housing or dripping onto the ground beneath the vehicle. These leaks usually develop at axle seals, pinion seals, or cover gaskets. While small seepage may not immediately threaten component integrity, any leak that produces visible drips or puddles requires repair. Operating a differential with low fluid levels generates excessive heat that quickly destroys bearings and gears—failures that necessitate complete differential replacement or rebuild at costs ranging from $1,000 to $2,500 or more.

Transfer case leaks follow similar patterns, with fluid escaping past seals, gaskets, or worn drive shaft connections. The fluid may appear similar to differential oil—typically dark and with a characteristic gear oil smell. Some transfer cases share fluid with the transmission, in which case you may notice both low transmission fluid levels and transfer case leakage simultaneously. This dual problem requires rapid attention, as running low on transmission fluid can destroy the transmission while low transfer case fluid damages the AWD system.

Haldex coupling leaks deserve special mention, as these systems use specific hydraulic fluid that differs from standard differential or transmission fluids. Haldex fluid is typically light in color—pink or amber—and may initially be confused with transmission fluid. These leaks usually occur at seals or from the coupling housing itself. Because Haldex systems require proper fluid levels and quality to function correctly, leaks should be addressed promptly.

Regular inspection for leaks should be part of your maintenance routine. When the vehicle is parked after driving, look underneath for any fresh fluid. Check differential covers, transfer cases, and any visible joints or connections in the AWD system for wetness or fluid accumulation. Catching leaks early—when they’re mere seepage—often allows simple seal replacement before significant fluid loss causes internal damage.

Vibrations During Acceleration: Tracking Down Drivetrain Issues

Vibrations that occur during acceleration often stem from AWD drivetrain components and shouldn’t be dismissed as minor annoyances. These vibrations may indicate problems with driveshaft balance, worn universal joints, failing CV joints, or damaged center support bearings. The specific characteristics of the vibration—when it occurs, where you feel it, and how it changes with speed—provide important diagnostic clues.

Driveshaft vibrations typically manifest at specific speed ranges, often becoming most noticeable around 40-50 mph or during acceleration through that range. If the vibration smooths out at higher speeds, driveshaft balance is the likely culprit. Balance can be disrupted by lost balance weights, mud buildup, or dents from road debris. Sometimes the vibration is present constantly above a certain speed, indicating more significant driveshaft problems like a bent tube or worn center support bearing.

CV joints typically produce vibrations that feel more localized to the front of the vehicle and may be accompanied by clicking or popping sounds during turns. As CV joints wear, they develop play that allows the axle to move slightly within the joint, creating a cyclic vibration that usually worsens with acceleration force. Severely worn CV joints can create quite dramatic vibrations and may even cause the vehicle to shudder during hard acceleration.

Center support bearings, used in longer driveshafts that require midpoint support, can develop wear that allows the driveshaft to wobble. This typically creates a vibration or rumble that’s most noticeable during acceleration and may change character with different load conditions. These bearings are often easy to replace once diagnosed, but identifying them as the source requires systematic evaluation of the drivetrain.

Professional mechanics approach vibration diagnosis methodically, often using specialized equipment to measure vibration frequencies and amplitudes. Attempting to diagnose vibrations without proper experience often leads to unnecessary parts replacement—many DIYers have replaced multiple components trying to chase down vibrations that a professional could have identified immediately. When vibrations develop, professional diagnosis typically saves money despite the diagnostic fee.

Decreased Fuel Economy: An Efficiency Warning

While fuel economy varies based on numerous factors, a sudden or unexplained decrease in efficiency can indicate AWD system problems. Several AWD malfunctions manifest as reduced fuel economy before creating more obvious symptoms. A coupling or clutch mechanism stuck in partial or full engagement forces the AWD system to operate continuously, even when not needed. This constant engagement creates parasitic losses that increase fuel consumption.

Binding components in differentials or transfer cases increase rolling resistance, requiring more engine power to maintain speed. This mechanical drag shows up as reduced fuel economy and may be accompanied by increased operating temperatures in the affected components. If you notice the fuel economy declining while also detecting any heat, noise, or smell from drivetrain components, these symptoms together strongly suggest mechanical problems requiring diagnosis.

Electronic control problems can also impact fuel economy. If the AWD control module receives incorrect sensor inputs or develops internal faults, it may command inappropriate AWD engagement patterns. The system might engage AWD unnecessarily or maintain engagement longer than required, wasting energy. These issues typically trigger warning lights or diagnostic codes, though not always immediately.

Tracking fuel economy provides a useful baseline for detecting potential problems. Most vehicles’ trip computers display average fuel economy over various timeframes. Monitoring these numbers and watching for significant unexplained changes helps you catch problems early. Of course, fuel economy naturally varies with driving conditions, weather, tire pressure, and load—but sudden drops of 10 percent or more without obvious explanation deserve investigation.

AWD System Location and Access Points

Understanding where AWD components are located and how to access them helps vehicle owners perform basic inspections and assists in communicating with service technicians about repairs.

Physical Component Layout

The center differential in most AWD systems resides within the transmission housing or in a separate transfer case positioned immediately behind the transmission. In transverse-engine vehicles (most modern AWD cars and crossovers based on front-wheel-drive platforms), the center differential and associated coupling mechanisms are integrated into the transaxle assembly. This compact integration saves space and weight but makes service more complex, as accessing these components often requires significant transmission disassembly.

Vehicles with longitudinal engine layouts (typical in rear-wheel-drive-based platforms) generally use a more traditional transfer case configuration. This separate housing mounts behind the transmission, with a short driveshaft connecting them. The transfer case then sends power forward to the front differential via another driveshaft and rearward to the rear differential through a longer prop shaft. This configuration allows easier service access but occupies more space and adds weight compared to integrated designs.

The rear differential on all AWD vehicles mounts at the center of the rear axle, clearly visible from underneath the vehicle. It resembles a large metallic pumpkin-shaped housing with drive shafts (or CV axles) extending to each rear wheel. The front differential’s location varies based on drivetrain design—in front-wheel-drive-based AWD systems, it integrates into the transaxle along with the center differential. In rear-wheel-drive-based AWD configurations, the front differential may be a separate unit positioned at the front axle center, similar to the rear differential’s layout.

Service Access Requirements

Performing any significant work on AWD components requires lifting the entire vehicle, as virtually all drivetrain components are accessible only from underneath. A hydraulic lift provides the safest and most convenient access, though sturdy jack stands can suffice for basic inspections if properly positioned on the vehicle’s rated lift points. Never work under a vehicle supported only by a floor jack—these can fail without warning, causing serious injury or death.

Differential service requires specific tools beyond basic mechanic’s supplies. Most differentials use square or hex-head fill and drain plugs requiring special sockets or wrenches. The fill plug must be removed before the drain plug to ensure you can refill the differential—discovering a seized fill plug after draining the fluid creates a serious problem. A fluid pump or squeeze bottle designed for gear oil makes filling differentials much easier, as the fill holes are typically positioned such that gravity-feeding oil is impossible.

Proper torque specifications are critical when servicing differentials and transfer cases. Fill and drain plugs must be tightened to specific values—too loose and they’ll leak; too tight and you risk stripping threads or cracking housings. Differential cover bolts follow specific torque sequences to ensure even gasket compression and prevent leaks. Professional service manuals provide these specifications, and investing in a quality torque wrench is essential for proper service.

Vehicle Configuration Variations

Front-wheel-drive-based AWD systems pack the center differential, front differential, transmission, and sometimes the coupling mechanism into a single transaxle housing mounted transversely (perpendicular to the vehicle’s length). This compact packaging saves space and weight but creates service challenges. Accessing internal components often requires removing the transaxle from the vehicle—a major undertaking beyond most DIY capabilities. External components like CV axles remain serviceable, but internal clutch packs, center differentials, and transfer gears require professional equipment and expertise.

Rear-wheel-drive-based AWD layouts use more traditional component placement. The transmission mounts longitudinally (aligned with the vehicle’s length), with the transfer case behind it. This configuration allows easier access to individual components and often permits servicing the transfer case without transmission removal. The front differential may be a separate unit accessed from underneath, making its service more straightforward than in integrated designs.

Some manufacturers blend these approaches. Audi’s longitudinal-engine Quattro system, for example, integrates the center differential into the transmission but uses traditional front and rear differential arrangements. BMW’s xDrive similarly incorporates AWD components into the transmission while maintaining service access through removable covers and pans. Understanding your specific vehicle’s configuration helps set realistic expectations for service complexity and costs.

Professional Service Indicators and Requirements

Certain AWD repairs and maintenance tasks demand professional service regardless of your mechanical aptitude. Electronic system diagnosis requires expensive scan tools capable of communicating with AWD control modules and reading manufacturer-specific diagnostic codes. Interpreting these codes and performing proper diagnostic procedures requires training and experience—guessing at repairs based on symptoms rarely succeeds and often leads to unnecessary parts replacement.

Alignment specifications become critical with AWD vehicles, as improper alignment creates uneven tire wear that stresses the AWD system. Professional alignment equipment measures camber, caster, toe, and thrust angle with precision impossible using DIY methods. After any suspension work or component replacement that could affect alignment, professional alignment service is essential to protect your AWD system from premature wear.

Advanced AWD systems with torque vectoring capability require calibration procedures after certain repairs. These calibrations ensure the control module correctly interprets sensor inputs and commands appropriate responses. Performing these calibrations requires manufacturer-specific diagnostic equipment and procedures—attempting repairs without proper calibration may leave the system non-functional or operating incorrectly.

Transfer case and differential rebuilds, while theoretically within the scope of experienced DIY mechanics, require specialized knowledge and often manufacturer-specific tools. The precise shim selections, bearing preloads, and gear mesh patterns necessary for proper operation take significant experience to achieve. Unless you have specific training in differential work, these repairs are best left to specialists. The risk of improper assembly leading to premature failure or even dangerous mechanical breakage far outweighs the labor cost savings of DIY repairs.

When to Choose AWD vs Alternative Drivetrains

Making an informed decision about whether AWD suits your needs requires honest assessment of your driving conditions, usage patterns, and priorities. AWD provides clear benefits in specific scenarios while imposing costs and compromises that may be unjustified for drivers who rarely encounter conditions where AWD helps.

AWD Provides Maximum Value When:

Winter weather dominates your local climate. If you regularly encounter snow, ice, or freezing rain, AWD significantly improves safety and reduces stress during daily driving. The enhanced traction during acceleration prevents getting stuck and helps when climbing snowy hills or navigating icy parking lots. This represents the primary justification for AWD ownership for most drivers—the confidence and capability it provides during several months of challenging weather.

Mountain driving forms part of your regular routine. Steep grades combined with variable weather conditions—common in mountainous regions—make AWD valuable even during seasons when snow isn’t a factor. Summer thunderstorms can create slippery conditions on mountain roads, and the enhanced traction AWD provides helps maintain control during these scenarios. Additionally, the power distribution helps manage the increased loads inherent in mountain driving.

You value performance and handling dynamics. For driving enthusiasts, AWD’s ability to deploy power effectively and enhance cornering capability justifies its adoption regardless of weather considerations. The feeling of all four wheels working together to accelerate out of corners or the confidence to apply power earlier in a turn appeals to those who enjoy spirited driving. Performance AWD systems transform how a powerful car drives, making capabilities accessible that would be unusable in rear-wheel-drive configurations.

Light off-road use suits your recreational activities. Weekend camping trips, boat launches, accessing trailheads, or recreational property with unpaved access roads all benefit from AWD capability. These scenarios don’t require dedicated off-road vehicles, but two-wheel drive would struggle or require overly conservative approach speeds. AWD provides adequate capability for occasional adventure without the daily-driving compromises of a serious 4WD truck.

Front-Wheel Drive Suffices When:

Your climate features mild winters with minimal snow or ice. If winter weather is rare or limited to a few storms per year, the substantial cost premium for AWD may be unjustified. Modern front-wheel drive vehicles with electronic stability control and traction control perform surprisingly well in occasional snow, especially with appropriate winter tires. The money saved by avoiding AWD could be better invested in quality tires, which often provide more benefit than AWD with mediocre all-season tires.

Budget considerations drive your purchase decision. AWD adds significant cost—typically $1,500 to $3,000 at purchase plus $300 to $600 annually in operation. For budget-conscious buyers, particularly those purchasing used vehicles, avoiding AWD preserves capital for other priorities while still providing reliable transportation. Front-wheel drive vehicles also generally offer more interior space in a given footprint, as they lack the central driveshaft tunnel AWD requires.

Maximum fuel efficiency is your priority. Front-wheel drive vehicles achieve the best fuel economy in any given model line, sometimes by several miles per gallon compared to AWD equivalents. For high-mileage drivers or those simply prioritizing efficiency, this difference adds up substantially over years of ownership. The weight savings of eliminating AWD components also benefits handling and acceleration, though these effects are subtle.

Rear-Wheel Drive Appeals When:

Driving dynamics and engagement matter more than all-weather capability. Enthusiast drivers often prefer rear-wheel drive’s more engaging feedback and classic sports car feel. Without the understeer tendency that plagues front-wheel drive in enthusiastic driving, rear-wheel drive cars offer more neutral handling and the ability to adjust cornering lines with throttle. For those living in climates where winter traction isn’t a concern, rear-wheel drive often represents the sweet spot of engagement and capability.

Towing forms a regular requirement. Rear-wheel drive’s weight distribution and stronger drivetrain construction (compared to front-wheel drive) make it better suited for regular towing duties. Many trucks and body-on-frame SUVs use rear-wheel drive as their base configuration specifically because this layout handles heavy tongue weights and sustained towing loads more effectively than front-wheel drive architectures.

Four-Wheel Drive Justifies Its Compromises When:

Serious off-roading defines your vehicle usage. If you regularly tackle technical trails, deep mud, rock crawling, or other extreme off-road scenarios, proper 4WD with low-range gearing and locking differentials becomes necessary. AWD systems simply lack the robust construction and gearing range needed for serious off-road work. The compromises inherent in 4WD—poorer on-road fuel economy, coarse handling, and manual engagement requirements—become acceptable given the capability they enable.

Heavy-duty work demands drive your needs. Towing large trailers, hauling heavy loads, or using your vehicle as a work platform all favor traditional 4WD trucks and SUVs. These vehicles’ chassis, suspension, and drivetrain are engineered for sustained heavy use in ways passenger-car-based AWD systems cannot match. If your vehicle regularly operates at or near its gross vehicle weight rating, 4WD’s superior strength and capability justify choosing it over AWD.

Agricultural, construction, or commercial use defines your application. Professional users operating on job sites, farms, or construction areas need the ground clearance, durability, and low-range gearing that 4WD provides. While these vehicles may spend significant time on-road, their off-road work requirements dictate 4WD selection despite its on-road compromises.

Hybrid and Electric AWD: The New Alternative

Electric vehicles and hybrids introduce a fundamentally different AWD approach—dual motors providing independent power to front and rear axles without mechanical connection. A front motor drives the front wheels while a rear motor powers the rears, with the vehicle’s computer managing power distribution. This configuration offers several advantages: instant torque delivery, independent control of each axle, and no parasitic losses from mechanical transfer cases or drive shafts.

Dual-motor EVs demonstrate that AWD can actually improve efficiency in electric vehicles, contrary to the efficiency penalty AWD imposes in gasoline vehicles. The ability to use just one motor when possible, or to bias power to whichever motor is most efficient at the moment, makes dual-motor EVs often more efficient in real-world driving than single-motor versions. The instant torque distribution also provides traction benefits that exceed mechanical AWD systems in many scenarios.

As electric vehicles become more common, this new form of AWD will likely become dominant in the long term. The mechanical simplicity, packaging advantages, and performance characteristics of dual-motor AWD make it ideal for EVs. However, during the transition period, traditional mechanical AWD systems will remain relevant in the gasoline and hybrid vehicles that still constitute the majority of new vehicle sales. Understanding electric motor technology provides insight into how these next-generation AWD systems function.

Brand-Specific AWD Technologies and Characteristics

While AWD systems all share the same basic goal—distributing power to all four wheels—manufacturers have developed distinct implementations with different characteristics. Understanding these variations helps when shopping for vehicles or servicing systems.

Subaru Symmetrical AWD: The Longitudinal Layout Advantage

Subaru has built its brand reputation around AWD, making it standard on nearly every model (the BRZ sports car is the sole exception). The company’s Symmetrical AWD name references its longitudinal engine and transmission layout, which positions the drivetrain along the vehicle’s centerline for balanced weight distribution. This layout allows a direct, efficient power path from engine to all four wheels, minimizing the power losses that plague some transverse-engine AWD implementations.

Subaru offers several AWD system variants across its lineup. Base models typically use viscous coupling center differentials that provide fully automatic operation without electronic intervention. Performance models like the WRX employ electronically controlled systems with driver-selectable modes that adjust power distribution patterns. The WRX STI features a sophisticated system with driver-controlled center differential locking and torque biasing, allowing enthusiast drivers to tailor AWD behavior to driving conditions and personal preference.

The reliability and effectiveness of Subaru’s AWD systems have earned them strong reputations in areas with harsh winters. The company’s engineering focus on AWD as a core technology rather than an add-on option shows in the systems’ robustness and integration with other vehicle dynamics controls. For drivers prioritizing AWD capability, Subaru merits serious consideration. Subaru-specific repair manuals provide detailed maintenance and service information for these systems.

Audi Quattro: Performance-Oriented Sophistication

Audi pioneered modern AWD in passenger cars with its Quattro system, introduced in the 1980s. The name Quattro has become synonymous with advanced AWD technology, and Audi continues to develop increasingly sophisticated implementations across its model range. Early Quattro systems used Torsen (torque-sensing) differentials—purely mechanical devices that automatically adjust power distribution based on traction conditions without requiring electronic controls.

Modern Audi vehicles employ various Quattro implementations depending on engine layout and platform. Longitudinal-engine models (most Audis) use evolved versions of the Torsen differential system, now enhanced with electronic controls for even more precise power management. Transverse-engine models (some A3 and Q3 variants) use Haldex coupling systems similar to other VAG (Volkswagen Auto Group) products. These different implementations share the Quattro name but feature distinct operating characteristics.

Audi’s performance models, particularly RS variants, feature sport-tuned Quattro systems with rear-biased power distribution to enhance driving dynamics. These systems maintain a 40/60 front/rear torque split under normal conditions, providing rear-drive-like handling characteristics while retaining AWD’s capability when needed. The integration between Quattro and other vehicle systems—engine management, electronic stability control, torque vectoring—creates comprehensive dynamics management that helps explain Audi’s strong performance reputation. Audi repair information documents these sophisticated systems in detail.

Honda Real Time AWD: Predictive Efficiency

Honda’s Real Time AWD system represents a different philosophy—prioritizing efficiency while providing AWD capability when needed. The system uses an electronically controlled hydraulic multi-plate clutch to engage the rear wheels, with the vehicle operating in front-wheel drive the majority of the time. What distinguishes Honda’s implementation is its predictive engagement strategy that activates AWD before wheel slip occurs.

The Real Time AWD system monitors accelerator pedal position, steering angle, throttle opening, and other parameters to anticipate when AWD will benefit the driver. For example, when starting from a stop, the system engages the rear wheels preemptively to prevent any front wheel spin, then gradually releases them as forward motion is established and full traction is no longer needed. During cornering, it can engage the outside rear wheel to enhance stability and reduce understeer.

This predictive approach provides a driving experience closer to full-time AWD while maintaining the efficiency benefits of a part-time system. The elimination of response delay makes the engagement feel transparent—drivers simply experience the enhanced capability without awareness of system activation. Honda offers Real Time AWD on most of its crossover and SUV lineup, making it one of the most commonly encountered AWD systems in the market. Honda-specific manuals explain maintenance requirements for these systems.

Toyota and Lexus Dynamic AWD: Variable Solutions

Toyota and Lexus offer various AWD implementations across their extensive model ranges. More basic systems use simple mechanical AWD with viscous coupling, while advanced implementations feature electronically controlled clutch systems with sophisticated control algorithms. Recent models increasingly feature Dynamic Torque Control, which can completely disconnect the rear driveshaft for improved efficiency, then reengage it in milliseconds when AWD is needed.

The Dynamic Torque Vectoring AWD system available on some models adds the ability to distribute torque between the rear wheels independently, similar to torque vectoring systems from luxury brands. This enhances both performance and capability, providing better traction in challenging conditions while improving cornering dynamics on dry pavement. The system integrates with vehicle stability control to coordinate braking and power delivery for optimal vehicle control.

Lexus models often receive more sophisticated AWD calibrations tuned for luxury and refinement rather than maximum performance. The focus on smooth, transparent operation results in systems that work unobtrusively in the background, enhancing capability without drawing attention to their operation. Toyota repair documentation provides service information across the company’s diverse AWD applications.

BMW xDrive: Sport-Tuned Intelligence

BMW’s xDrive system prioritizes the company’s performance and handling reputation while adding all-weather capability. The system uses an electronically controlled multi-plate clutch in the transfer case to vary power distribution, with rear-biased default settings that maintain BMW’s characteristic rear-drive feel. Under normal driving, xDrive typically sends about 40 percent of power to the front wheels and 60 percent to the rear, but it can adjust this ratio continuously based on traction needs.

The integration between xDrive and BMW’s Dynamic Stability Control allows sophisticated coordination of AWD power distribution and individual wheel braking intervention. In performance models, xDrive works with the limited-slip rear differential and, on some models, torque vectoring to create comprehensive dynamics management that enhances both safety and performance. The system can send virtually all power to whichever axle has the most traction when conditions demand it.

BMW offers various xDrive calibrations across its model range, with sport models receiving more aggressive tuning that emphasizes performance over efficiency. Some M performance models include drift modes that bias power rearward to enable controlled oversteer, satisfying enthusiast drivers while retaining AWD’s capability for daily driving. The sophistication comes at a cost—xDrive systems require proper maintenance and can be expensive to repair if problems develop. BMW-specific information details these premium AWD systems.

Ford Intelligent AWD: Mass-Market Capability

Ford’s Intelligent AWD represents the mainstream implementation common in family crossovers and SUVs. The system uses electronically controlled coupling with multiple sensors monitoring driving conditions to determine when AWD engagement benefits the driver. Ford has developed various generations of Intelligent AWD with progressively more sophisticated control algorithms and faster response times.

Recent versions include disconnect functionality that completely disengages the rear axle drive shaft during highway cruising, eliminating parasitic losses and improving fuel economy. When the system senses conditions where AWD might be needed—deceleration, wet roads, low temperatures—it reconnects the driveshaft in milliseconds, making the engagement completely transparent to the driver. Some models offer selectable drive modes that alter AWD behavior, with settings optimized for different conditions like sand, mud, or snow.

The emphasis on efficiency and ease of use makes Ford’s Intelligent AWD well-suited to its typical customer base—families needing occasional AWD capability but primarily driving on paved roads. The system provides confidence in winter weather without imposing significant fuel economy penalties or requiring driver expertise to operate effectively. Ford repair manuals document service procedures for these systems across Ford’s diverse vehicle lineup.

Conclusion: Understanding AWD for Informed Decisions

All-wheel drive technology has evolved from a specialized capability to a mainstream expectation, available on vehicles ranging from compact cars to luxury performance machines. Understanding how AWD systems function, what benefits they provide, and what maintenance they require enables informed decisions about whether AWD suits your needs and how to maintain these sophisticated systems properly.

The fundamental principle remains consistent across all implementations: AWD distributes engine power to all four wheels, enhancing traction and stability when road conditions limit grip. Whether using a simple viscous coupling, a sophisticated electronically controlled multi-plate clutch, or dual electric motors in an EV, the goal is the same—maximize the available contact patch contributing to forward motion. The mechanical and electronic sophistication behind this simple goal continues to advance, with modern systems providing increasingly transparent operation that works seamlessly in the background.

Critical Takeaways for AWD Owners

Regular maintenance represents the single most important factor in AWD system longevity. Differential fluid changes every 30,000 to 60,000 miles prevent premature wear and expensive failures. Transfer case service according to manufacturer specifications keeps these critical components functioning properly. Most important, maintaining matched tire tread depths across all four positions protects the AWD system from damage caused by continuously compensating for diameter differences. These maintenance tasks cost relatively little but provide insurance against repairs that can reach thousands of dollars.

Understanding AWD’s limitations proves as important as appreciating its capabilities. AWD helps with acceleration and traction, but it provides zero benefit for braking or cornering. The enhanced capability AWD provides during acceleration can create false confidence that leads to excessive speeds for conditions. Remember that when you need to stop or turn, all vehicles rely on the same four contact patches regardless of drivetrain configuration. Drive according to conditions, not according to your drivetrain’s capabilities.

Recognizing When Professional Help Is Needed

AWD systems’ electronic complexity and mechanical precision place most repairs beyond DIY capabilities, even for experienced home mechanics. When the AWD warning light illuminates, professional diagnostic scanning should be your first step. The specialized scan tools required to communicate with AWD control modules and interpret manufacturer-specific codes represent substantial investments that only professionals justify. Attempting repairs based on symptoms or generic advice rarely succeeds and often leads to unnecessary parts replacement.

Any unusual noises from the drivetrain deserve immediate professional attention—grinding, whining, clunking, or clicking all indicate developing problems that worsen rapidly if ignored. Binding behavior during turns, fluid leaks, or vibrations similarly demand professional diagnosis before minor issues cascade into major failures. The cost of proper diagnosis pales in comparison to the expense of repairing damage that occurs when problems go unaddressed.

Modern AWD systems integrate with virtually every other vehicle system—engine management, transmission control, stability control, traction control, and more. This integration means that AWD issues can cause symptoms in seemingly unrelated systems, and problems elsewhere can manifest as AWD malfunctions. Professional technicians have the training, experience, and equipment to navigate these complex interactions and identify root causes efficiently.

Maintenance Priorities Moving Forward

If you own an AWD vehicle, establish a maintenance schedule that addresses system-specific requirements beyond typical service. Mark your calendar or set reminders for differential fluid changes at the appropriate intervals—don’t wait for problems to appear before servicing these components. Inspect CV boots during every oil change or tire rotation, looking for tears, cracks, or grease leakage. Address any boot damage immediately, before the joint itself sustains damage requiring complete axle replacement.

Maintain meticulous attention to tire maintenance. Rotate tires regularly to promote even wear across all four positions. Check and adjust tire pressures monthly—underinflated tires wear faster on the outer edges, creating diameter differences that stress the AWD system. When replacing tires, verify that the new tires’ tread depth matches the remaining tires within your vehicle’s specifications, or plan to replace all four simultaneously. This discipline prevents the costly component damage that mismatched tires can cause.

Monitor your AWD system’s behavior and performance. Familiarize yourself with how your system normally feels and sounds during operation, so you can recognize changes that might indicate developing problems. Pay attention to dashboard warning lights and address them promptly rather than hoping they’ll go away. This proactive awareness allows you to catch problems early when they’re least expensive to address.

Related Systems and Further Learning

Understanding AWD systems provides foundation knowledge that connects to numerous related automotive systems. The differentials that enable AWD operation use the same principles whether in the center differential or the front and rear units. Transfer cases in 4WD systems share components and concepts with AWD systems despite their different engagement methods and intended applications.