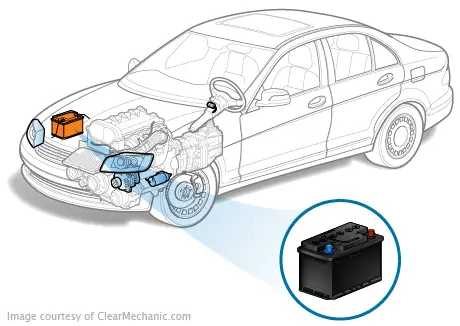

If you drive a gasoline-powered car, its battery is the powerhouse that delivers the initial surge of energy to turn your starter motor, crank the engine, and get it running. Beyond starting, it also fuels essential components like your car’s onboard computers, clocks, radio presets, and alarm systems when the engine is switched off.

Car batteries are relatively compact and affordable, providing a strong burst of current to fire up your engine in various weather conditions. However, they are wear items – meaning they don’t last forever. Their lifespan can be shortened by factors like extreme cold, accidentally leaving lights on, or consistently driving only short distances. Let’s delve into how a battery works and the common issues that can cause it to fail.

What Is a Car Battery and How Does It Work?

Car Battery Definition and Core Function

The car battery serves as your vehicle’s electrical energy storage system, providing the high-amperage power burst needed to start the engine and supplying electricity when the engine is off or when electrical demand exceeds alternator output. Unlike the alternator which generates electricity while the engine runs, the battery stores chemical energy and converts it to electrical energy on demand.

The car battery performs three critical functions:

- Provides starting power to crank the engine and ignition systems

- Supplies electricity for lights, radio, and accessories when the engine is off

- Acts as a voltage stabilizer and electrical surge protector for sensitive electronics

This electrochemical powerhouse operates on the principle of reversible chemical reactions, where lead and sulfuric acid interact to produce electrical current. When you turn the key, the battery instantly delivers hundreds of amps to power the starter motor, which requires far more current than the alternator alone can provide.

Battery Chemistry and Construction

Understanding your car battery’s internal construction helps you better maintain it and recognize problems before they leave you stranded.

Lead-Acid Battery Fundamentals Modern automotive batteries use lead-acid chemistry, a technology proven reliable for over 150 years. This system uses lead dioxide (positive plates), sponge lead (negative plates), and sulfuric acid electrolyte to create and store electrical energy through predictable chemical reactions.

Positive and Negative Plates Each battery cell contains alternating positive and negative lead plates separated by insulating material. Positive plates are coated with lead dioxide (PbO2), while negative plates consist of porous sponge lead (Pb). These plates provide the surface area where chemical reactions occur during charging and discharging.

Electrolyte Solution The electrolyte is a mixture of sulfuric acid and distilled water, typically with a specific gravity of 1.265 when fully charged. This solution facilitates the chemical reactions between the lead plates and stores energy in chemical form. The concentration and condition of the electrolyte directly affects battery performance and lifespan.

Cell Construction and 6-Cell Configuration Automotive batteries contain six individual cells connected in series, with each cell producing approximately 2.1 volts when fully charged. This configuration delivers the 12.6 volts needed for automotive electrical systems. Each cell operates independently, though the failure of one cell affects the entire battery’s performance.

Battery Case and Terminal Design The battery case, typically made of polypropylene plastic, protects internal components from physical damage and contains any electrolyte spills. Terminals provide the electrical connection points, with positive and negative posts designed to prevent reverse polarity connections that could damage electrical systems.

How Battery Storage and Discharge Works

The car battery’s ability to store and release electrical energy depends on reversible electrochemical reactions that convert chemical energy to electrical energy and back again.

Electrochemical Reaction Principles During discharge, the lead dioxide positive plates react with sulfuric acid to form lead sulfate, water, and electrical current. Simultaneously, the sponge lead negative plates also convert to lead sulfate. This process releases electrons that flow through the external circuit, powering your vehicle’s electrical systems.

Charge and Discharge Cycles When the alternator charges the battery, electrical current reverses the discharge reaction, converting lead sulfate back to lead dioxide and sponge lead while restoring the sulfuric acid concentration. This cyclical process allows the battery to store and release energy repeatedly throughout its service life.

Capacity Measurement Battery capacity is measured in amp-hours (Ah) and cold cranking amps (CCA). Amp-hours indicate how much current the battery can deliver over a specific time period, while CCA measures the battery’s ability to deliver high current for engine starting in cold conditions. These ratings help you select the right battery for your vehicle’s needs.

Voltage Characteristics During Operation A fully charged battery measures 12.6-12.8 volts at rest. During starting, voltage typically drops to 9-10 volts under the heavy load of the starter motor. After starting, the alternator should maintain system voltage at 13.5-14.5 volts to properly charge the battery and power electrical systems.

Temperature Effects on Performance Battery performance decreases significantly in cold weather, with capacity dropping by 20% at 32°F and 50% at 0°F. Chemical reactions slow down in cold temperatures, reducing the battery’s ability to deliver starting power when you need it most. Understanding this helps explain why batteries often fail during winter months.

Types of Automotive Batteries

Choosing the right battery type for your vehicle depends on your driving patterns, climate, and electrical demands. Modern vehicles offer several battery technologies, each with distinct advantages and applications.

Conventional Flooded Lead-Acid Batteries

Traditional Wet Cell Construction Conventional flooded batteries contain liquid electrolyte that freely flows around the lead plates. These batteries have removable caps that allow access to individual cells for maintenance and electrolyte level checking. They represent the most basic and affordable battery technology available.

Maintenance Requirements and Electrolyte Checking Flooded batteries require periodic maintenance, including checking electrolyte levels and adding distilled water as needed. The electrolyte level should cover the plates by approximately 1/2 inch. Regular maintenance ensures optimal performance and extends battery life, though many vehicle owners prefer maintenance-free alternatives.

Ventilation Needs and Gas Emission During charging, flooded batteries emit hydrogen and oxygen gases that must be properly vented to prevent accumulation. These gases are explosive in sufficient concentrations, requiring adequate ventilation in the battery compartment. Never smoke or create sparks near a charging battery.

Cost Advantages and Widespread Availability Flooded batteries typically cost 20-40% less than advanced technologies, making them attractive for budget-conscious consumers. Their simple construction also means they’re widely available and easily recycled, with established infrastructure for manufacturing and disposal.

Performance Characteristics and Limitations While affordable, conventional batteries are sensitive to deep discharge cycles and may not perform well in extreme temperatures. They also require upright installation and regular maintenance, making them less suitable for some modern vehicle applications.

Maintenance-Free and Low-Maintenance Batteries

Sealed Construction Benefits Maintenance-free batteries feature sealed construction that prevents electrolyte loss and eliminates the need for regular water additions. Internal design improvements reduce gassing during normal operation, allowing these batteries to operate for their entire service life without maintenance.

Calcium-Enhanced Plates Lead plates in maintenance-free batteries often contain calcium additives that reduce water loss and improve charge retention. This technology allows batteries to maintain proper electrolyte levels throughout their service life while providing better resistance to overcharging.

Reduced Water Loss Technology Advanced grid designs and manufacturing processes minimize electrolyte evaporation during charging and discharging cycles. This technology extends the time between maintenance intervals and improves overall reliability compared to conventional flooded batteries.

Service Interval Differences While labeled “maintenance-free,” these batteries still benefit from periodic inspection and cleaning of terminals and connections. However, they eliminate the need for electrolyte level checking and water additions that conventional batteries require every few months.

Performance and Longevity Improvements Maintenance-free batteries typically last 20-30% longer than conventional flooded batteries due to improved internal design and reduced maintenance requirements. They also provide more consistent performance throughout their service life.

Advanced Battery Technologies

Absorbed Glass Mat (AGM) Batteries AGM batteries use fiberglass matting to absorb the electrolyte, creating a spill-proof design that can be mounted in any orientation. This technology provides superior vibration resistance, faster charging, and better performance in extreme temperatures. AGM batteries are ideal for vehicles with start-stop systems or high electrical demands.

Gel Cell Battery Construction Gel batteries use silica gel to immobilize the electrolyte, creating a maintenance-free, spill-proof design with excellent deep-cycle capability. While more expensive than conventional batteries, gel cells provide superior performance in applications requiring frequent deep discharging, such as RVs or marine applications.

Enhanced Flooded Battery (EFB) Technology EFB batteries represent a middle ground between conventional flooded and AGM technologies. They feature enhanced positive plates and improved electrolyte circulation, providing better cycling performance than conventional batteries at lower cost than AGM technology.

Lithium-Ion Automotive Applications While primarily used in electric and hybrid vehicles, lithium-ion technology is beginning to appear in some high-end conventional vehicles. These batteries offer significant weight savings and longer life but require sophisticated battery management systems and carry higher replacement costs.

Performance Comparisons and Cost Considerations Advanced battery technologies typically cost 50-200% more than conventional batteries but provide improved performance, longer life, and better reliability. Consider your vehicle’s electrical demands, climate conditions, and driving patterns when evaluating the cost-benefit ratio of advanced battery technologies.

Signs of a Failing Car Battery

Recognizing early warning signs of battery failure helps prevent unexpected breakdowns and allows for planned replacement at convenient times. For detailed troubleshooting guidance, refer to our comprehensive guide on why your car battery dies and what to do about it.

Starting System Symptoms

Slow or Labored Engine Cranking When your battery begins to fail, you’ll often notice the engine cranking more slowly than normal, especially during cold weather. The starter motor requires significant current to turn the engine over, and a weak battery cannot deliver adequate power for normal cranking speed.

Clicking Sounds from Starter A rapid clicking noise when you turn the key typically indicates insufficient battery power to engage the starter motor fully. The starter solenoid attempts to engage but cannot maintain contact due to voltage drop under load, creating the characteristic clicking sound.

Complete Failure to Start Total starting failure often indicates severe battery discharge or internal battery failure. However, distinguish between battery problems and other starting system issues by checking lights and electrical accessories – if they work normally, investigate the starting system rather than assuming battery failure.

Intermittent Starting Problems Batteries that start the engine sometimes but fail other times often have internal cell damage or loose connections. These inconsistent symptoms can be frustrating but typically worsen over time until complete failure occurs.

Dashboard Warning Lights Modern vehicles monitor battery voltage and will illuminate warning lights when voltage drops below acceptable levels. Pay attention to battery, charging system, or generic electrical system warning lights that may indicate developing battery problems.

Electrical System Indicators

Dim or Flickering Headlights Headlights that dim when you turn on accessories like air conditioning or radio indicate the battery cannot maintain proper voltage under electrical load. This symptom becomes more noticeable at idle when the alternator produces less current.

Weak Interior Lighting Dome lights, dashboard illumination, and other interior lighting that appears dimmer than normal often indicate battery voltage drop. This symptom is particularly noticeable when the engine is off and the battery is supplying all electrical power.

Radio and Electronic Malfunctions Modern vehicle electronics are sensitive to voltage fluctuations. A failing battery may cause radio presets to reset, navigation systems to malfunction, or other electronic accessories to behave erratically.

Power Window Slowness Power windows that operate more slowly than normal, especially when the engine is off, indicate the battery cannot supply adequate current for motor operation. This symptom becomes more pronounced as battery capacity degrades.

Clock and Memory Resets If your vehicle’s clock consistently loses time or radio presets disappear overnight, the battery may not be maintaining proper voltage during extended parking periods. This suggests either battery failure or excessive parasitic electrical drain.

Physical Battery Condition Signs

Corrosion Around Terminals White, blue, or green corrosion around battery terminals indicates electrolyte leakage or excessive gassing during charging. While some corrosion is normal, extensive buildup suggests battery problems or charging system issues that require attention.

Swollen or Cracked Battery Case Physical damage to the battery case, including swelling, cracks, or bulging sides, indicates internal problems such as overcharging, freezing, or age-related deterioration. A damaged case compromises battery safety and requires immediate replacement.

Electrolyte Leakage Visible electrolyte leakage around the battery case or terminals creates safety hazards and indicates case damage or overfilling. Sulfuric acid electrolyte is highly corrosive and requires careful cleanup and battery replacement.

Sulfation on Terminals Heavy white or gray buildup on battery terminals, different from normal corrosion, may indicate sulfation from chronic undercharging or age. This buildup impedes electrical connection and reduces charging efficiency.

Age-Related Deterioration Indicators Batteries typically last 3-5 years under normal conditions. Consider replacement based on age even if the battery still functions, as performance degrades gradually and failure often occurs without warning.

Car Battery Testing and Diagnosis

Proper battery testing helps distinguish between battery problems and other electrical system issues, preventing unnecessary replacement and ensuring accurate diagnosis. For comprehensive electrical system diagnostics, explore our electrical and lights systems guide.

Visual Inspection Procedures

Safety Precautions for Battery Handling Before testing any battery, wear safety glasses and gloves to protect against electrolyte splashes. Ensure adequate ventilation and avoid smoking or creating sparks near the battery. Have baking soda and water available to neutralize any acid spills that may occur during testing.

Terminal Condition Assessment Inspect battery terminals for corrosion, looseness, or damage. Clean terminals provide accurate test results and prevent voltage drops that can mimic battery problems. Look for signs of overheating, such as melted plastic or discolored metal around connections.

Case Integrity Evaluation Examine the battery case for cracks, bulging, or electrolyte leakage. A damaged case compromises safety and indicates battery replacement regardless of electrical test results. Check the hold-down mechanism to ensure the battery is properly secured against vibration.

Electrolyte Level Checking (Serviceable Batteries) For batteries with removable caps, check electrolyte levels in each cell. The electrolyte should cover the plates by approximately 1/2 inch. Low levels may indicate overcharging, age, or case damage that allows electrolyte loss.

Mounting and Hold-Down Inspection Verify that the battery is properly secured in its tray with appropriate hold-down hardware. Loose batteries can suffer internal damage from vibration and may create safety hazards if terminals contact metal components.

Voltage Testing Methods

Resting Voltage Measurement Measure battery voltage with the engine off and electrical systems inactive for at least 30 minutes. A fully charged battery should read 12.6-12.8 volts. Readings below 12.4 volts indicate partial discharge, while readings below 12.0 volts suggest significant discharge or battery problems.

Load Testing Procedures Load testing applies a controlled electrical load while monitoring voltage response. Apply a load equal to half the CCA rating for 15 seconds while monitoring voltage. The battery should maintain at least 9.6 volts at 70°F during load testing.

Cranking Voltage Analysis Monitor battery voltage during actual engine starting to evaluate real-world performance. Voltage should not drop below 9.6 volts during cranking, and should recover quickly to above 12 volts after the engine starts.

Charging System Integration Testing Test battery performance as part of the complete charging system. With the engine running at 2000 RPM, system voltage should measure 13.5-14.5 volts. This confirms both battery condition and alternator performance.

Temperature Compensation Factors Adjust test results for ambient temperature, as battery capacity decreases in cold weather. Most digital testers automatically compensate for temperature, but manual calculations may be necessary with basic equipment.

Professional Testing Equipment

Digital Battery Analyzers Modern digital analyzers use conductance testing to evaluate battery condition without applying heavy loads. These testers can assess battery condition, starting capability, and remaining life expectancy while the battery remains in the vehicle.

Carbon Pile Load Testers Traditional carbon pile testers apply variable loads to test battery performance under simulated starting conditions. While older technology, these testers provide accurate assessment of battery capability under actual load conditions.

Conductance Testers Conductance testing measures the battery’s ability to conduct current, which correlates with capacity and condition. This non-invasive testing method provides quick results without stressing the battery or requiring removal from the vehicle.

Hydrometer Testing (Flooded Batteries) For serviceable batteries, hydrometers measure electrolyte specific gravity in each cell. Fully charged cells should read 1.265-1.275 specific gravity, with no more than 0.050 difference between cells.

Diagnostic Scan Tool Integration Modern vehicles often monitor battery and charging system performance through the engine management computer. Scan tools can display real-time voltage, current, and system status information for comprehensive diagnosis.

Interpreting Test Results

Voltage Readings and Battery Condition Correlate voltage readings with battery condition: 12.6+ volts indicates full charge, 12.4 volts shows 75% charge, 12.2 volts indicates 50% charge, and 12.0 volts or below suggests 25% charge or less.

Load Test Performance Standards During load testing, batteries should maintain voltage above 9.6 volts at 70°F. Lower readings indicate internal problems, while voltage that continues dropping during the test suggests severe deterioration.

Cold Cranking Amp Verification Compare test results to the battery’s CCA rating. If the battery cannot deliver its rated CCA, replacement is necessary even if other tests show acceptable results.

Internal Resistance Measurements High internal resistance indicates deteriorated plates or connections within the battery. This condition reduces the battery’s ability to deliver current and typically worsens over time.

Replacement Decision Criteria Replace batteries that fail load tests, show significant capacity loss, have damaged cases, or are approaching 4-5 years of age. Consider replacement before complete failure to avoid inconvenient breakdowns.

Car Battery Maintenance and Care

Proper battery maintenance significantly extends service life and prevents unexpected failures. Regular care is especially important for vehicles subjected to extreme temperatures, frequent short trips, or extended parking periods.

Regular Maintenance Schedule

Monthly Visual Inspections Conduct monthly inspections of battery terminals, case condition, and hold-down hardware. Look for corrosion buildup, electrolyte leaks, or physical damage that could affect performance or safety. Address any issues promptly to prevent deterioration.

Quarterly Terminal Cleaning Clean battery terminals every three months or when corrosion becomes visible. Use a mixture of baking soda and water to neutralize acid and remove corrosion, followed by thorough rinsing and drying. Apply terminal protector spray to prevent future corrosion.

Semi-Annual Load Testing Have the battery load tested twice yearly, especially before summer and winter seasons when electrical demands increase. Professional testing identifies developing problems before they cause starting failures.

Annual Replacement Considerations Evaluate battery replacement annually after the third year of service. Consider replacement based on test results, age, and reliability requirements rather than waiting for complete failure.

Climate-Specific Maintenance Adjustments Adjust maintenance frequency based on local climate conditions. Hot climates accelerate battery deterioration and may require more frequent testing, while cold climates demand attention to terminal corrosion and electrolyte condition.

Terminal and Connection Care

Corrosion Prevention Techniques Prevent terminal corrosion by keeping connections tight and dry. Apply dielectric grease or terminal protector spray to prevent moisture intrusion and chemical reactions that cause corrosion buildup.

Proper Cleaning Procedures When cleaning corroded terminals, always disconnect the negative cable first, then the positive cable. Use baking soda solution to neutralize acid, scrub with a wire brush, rinse thoroughly, and dry completely before reconnecting.

Terminal Protection Products Commercial terminal protectors, felt washers, and dielectric grease provide barriers against moisture and chemical corrosion. Apply these products during installation or maintenance to extend connection life.

Connection Tightness Specifications Tighten terminal connections to manufacturer specifications, typically 10-15 ft-lbs for top-post terminals. Overtightening can damage terminals or strip threads, while loose connections cause voltage drops and overheating.

Cable Condition Monitoring Inspect battery cables for corrosion, fraying, or damage that could affect electrical connection. For detailed cable troubleshooting, see our guide on symptoms of a bad battery cable. Replace damaged cables to ensure reliable electrical connections.

Electrolyte and Charging Management

Distilled Water Addition Procedures For serviceable batteries, add only distilled water to maintain electrolyte levels. Tap water contains minerals that can damage battery plates and reduce performance. Fill each cell to cover the plates by 1/2 inch, but avoid overfilling.

Proper Charging Techniques When charging with external chargers, use appropriate charge rates and monitor battery temperature. Slow charging (2-10 amps) is gentler on battery plates than fast charging, which should be reserved for emergency situations.

Overcharging Prevention Avoid overcharging, which causes excessive gassing, electrolyte loss, and plate damage. Monitor charging voltage and disconnect chargers when the battery reaches full charge. Modern smart chargers automatically prevent overcharging.

Deep Discharge Avoidance Prevent deep discharge by avoiding extended periods with electrical accessories running while the engine is off. Deep discharge damages battery plates and reduces capacity, especially in conventional flooded batteries.

Storage and Seasonal Care For vehicles stored long-term, disconnect the battery or use a battery maintainer to prevent discharge. Store batteries in cool, dry locations and recharge periodically to maintain condition during extended storage periods.

Environmental Protection

Temperature Management Strategies Protect batteries from extreme temperatures when possible. In hot climates, consider battery insulation or relocation away from heat sources. In cold climates, battery blankets or engine block heaters can improve starting performance.

Vibration and Shock Protection Ensure proper battery mounting to minimize vibration damage to internal plates and connections. Check hold-down hardware regularly and replace worn or damaged mounting components to prevent battery movement.

Moisture and Contamination Prevention Keep the battery and surrounding area clean and dry. Remove dirt, oil, and debris that can create electrical paths between terminals or trap moisture that accelerates corrosion.

Proper Ventilation Requirements Ensure adequate ventilation around the battery, especially during charging when hydrogen gas emission increases. Never seal battery compartments completely, as gas accumulation creates explosion hazards.

Extreme Weather Considerations Adjust maintenance and testing schedules based on local weather conditions. Extreme heat accelerates chemical reactions and water loss, while extreme cold reduces capacity and increases starting current requirements.

Car Battery Replacement Guide

Knowing when and how to replace your car battery helps maintain vehicle reliability and prevents unexpected failures. Proper replacement procedures ensure safety and optimal performance of the new battery.

When to Replace Your Battery

Age-Based Replacement Guidelines Most car batteries last 3-5 years under normal conditions. Consider replacement after 3 years in hot climates or 4 years in moderate climates, even if the battery still functions. Proactive replacement prevents inconvenient roadside failures.

Performance Degradation Indicators Replace batteries showing reduced cranking performance, slow recovery after starting, or inability to maintain charge during short trips. These symptoms indicate internal deterioration that will progressively worsen.

Seasonal Replacement Timing Plan battery replacement before extreme weather seasons when electrical demands increase. Late fall replacement prevents winter starting problems, while late spring replacement avoids summer heat-related failures.

Preventive Replacement Strategies For critical-use vehicles or those driven in remote areas, consider replacement based on time rather than performance. The cost of premature replacement is often less than the inconvenience and expense of roadside failure.

Cost-Benefit Analysis Considerations Evaluate replacement costs against towing charges, missed work, and inconvenience of unexpected failure. Premium batteries with longer warranties often provide better long-term value despite higher initial costs.

Battery Selection Criteria

Size Group Compatibility Select batteries with the correct group size for your vehicle’s battery tray and hold-down system. Group size determines physical dimensions and terminal configuration, ensuring proper fit and connection.

Cold Cranking Amp Requirements Choose batteries meeting or exceeding your vehicle’s CCA requirements. Higher CCA ratings provide better starting performance in cold weather, but significantly oversized batteries may not fit properly or receive adequate charging.

Reserve Capacity Specifications Reserve capacity indicates how long the battery can power essential systems if the alternator fails. Higher reserve capacity provides additional safety margin for emergency situations or vehicles with high electrical demands.

Terminal Configuration Matching Ensure terminal type and orientation match your vehicle’s cable configuration. Top-post, side-post, and dual-post terminals require specific cable connections that cannot be easily modified.

Quality and Warranty Considerations Balance initial cost against warranty coverage and expected service life. Premium batteries often include longer warranties and better performance, providing superior value for critical applications.

DIY Battery Replacement Process

Safety Preparation and Tool Requirements Gather necessary tools including wrenches for terminal removal, safety glasses, gloves, and terminal cleaning supplies. Have baking soda available for acid neutralization and ensure adequate workspace ventilation.

Memory Preservation for Electronics Modern vehicles may lose radio presets, seat positions, and other electronic memories when the battery is disconnected. Consider using a memory saver device or consult the owner’s manual for procedures to minimize memory loss.

Old Battery Removal Procedures

- Turn off all electrical accessories and remove the key

- Disconnect the negative cable first, then the positive cable

- Remove hold-down hardware and carefully lift the battery from the tray

- Clean the battery tray and cable terminals before installation

New Battery Installation Steps

- Place the new battery in the tray, ensuring proper orientation

- Install hold-down hardware to secure the battery against movement

- Connect the positive cable first, then the negative cable

- Apply terminal protector and verify all connections are tight

System Testing and Verification After installation, start the engine and verify proper operation of all electrical systems. Check charging system voltage and ensure all warning lights function normally. Test electronic accessories to confirm proper operation.

Professional Installation Benefits

Complex Electrical System Considerations Modern vehicles with advanced electronics may require specific procedures during battery replacement. Professional installation ensures proper handling of complex electrical systems and prevents damage to sensitive components.

Warranty Protection Advantages Professional installation often includes warranty coverage for both parts and labor. This protection provides peace of mind and financial protection against defective batteries or installation problems.

Proper Disposal of Old Battery Professional service includes proper disposal of the old battery according to environmental regulations. Battery recycling is crucial for environmental protection and resource conservation.

System Integration and Programming Some vehicles require computer programming or adaptation procedures after battery replacement. Professional technicians have the tools and knowledge to perform these procedures correctly.

Quality Assurance and Testing Professional installation includes comprehensive testing of the charging system, electrical connections, and battery performance to ensure optimal operation and prevent future problems.

Battery Problems and Troubleshooting

Understanding common battery problems helps you diagnose issues accurately and choose appropriate solutions. Many apparent battery failures actually stem from other electrical system problems that proper diagnosis can identify.

Common Battery Failure Modes

Sulfation and Plate Damage Sulfation occurs when lead sulfate crystals form on battery plates during discharge but don’t convert back during charging. This condition reduces capacity and eventually causes permanent damage. Chronic undercharging or extended discharge periods accelerate sulfation.

Internal Short Circuits Short circuits between positive and negative plates within a cell cause rapid discharge and heating. This condition typically results from physical damage, manufacturing defects, or severe overcharging that warps internal components.

Electrolyte Stratification In flooded batteries, electrolyte can separate into layers of different acid concentrations, reducing efficiency and causing uneven plate wear. This problem often results from insufficient charging or extended periods without electrical load.

Grid Corrosion and Breakdown The lead grids supporting active material can corrode over time, especially at high temperatures or with repeated deep cycling. Grid deterioration reduces the battery’s ability to conduct current and eventually causes mechanical failure.

Active Material Shedding Battery plates gradually lose active material through normal use, but excessive shedding indicates overcharging, vibration damage, or manufacturing defects. Lost active material reduces capacity and can cause internal shorts.

Parasitic Drain Issues

Identifying Excessive Electrical Draw Parasitic drain occurs when electrical components continue drawing current after the vehicle is turned off. Normal drain should be less than 50 milliamps; higher readings indicate problems that will discharge the battery during parking.

Common Sources of Battery Drain Typical drain sources include interior lights that don’t turn off, radio memory circuits, alarm systems, computer modules, and aftermarket accessories. Modern vehicles have numerous electronic systems that can malfunction and create excessive drain.

Testing Procedures for Parasitic Loads Use a digital ammeter to measure current draw with the vehicle off and all systems inactive. Allow 30 minutes for electronic modules to enter sleep mode before taking measurements. Isolate circuits systematically to identify the source of excessive drain.

Isolation and Repair Strategies Remove fuses individually while monitoring current draw to isolate the affected circuit. Once identified, inspect components on that circuit for malfunctions, damaged wiring, or improper installations that could cause excessive current draw.

Prevention of Future Drain Problems Regular inspection of electrical accessories, proper installation of aftermarket equipment, and prompt repair of malfunctioning systems prevent parasitic drain problems. Avoid leaving accessories plugged into power outlets when parking for extended periods.

Charging System Interactions

Alternator-Related Battery Problems A failing alternator cannot maintain battery charge, leading to progressive discharge and apparent battery failure. Similarly, an overcharging alternator can damage the battery through excessive heat and electrolyte loss.

Voltage Regulator Malfunctions Defective voltage regulators cause either undercharging or overcharging conditions that damage batteries. Modern integrated regulators are generally reliable but can fail due to heat or electrical surges.

Undercharging and Overcharging Effects Chronic undercharging causes sulfation and capacity loss, while overcharging leads to excessive gassing, electrolyte loss, and plate damage. Both conditions significantly reduce battery life and performance.

System Integration Troubleshooting Diagnose charging system problems by monitoring voltage and current under various load conditions. The alternator should maintain 13.5-14.5 volts at idle and provide adequate current for electrical demands plus battery charging.

Coordinated Repair Approaches Address charging system and battery problems together, as they often interact. A new battery may not perform well with a marginal alternator, while a good alternator cannot overcome a severely deteriorated battery.

Environmental and Usage Factors

Extreme Temperature Effects Hot weather accelerates chemical reactions and water loss, while cold weather reduces capacity and increases starting current requirements. Both extremes shorten battery life and affect performance predictably.

Short Trip and City Driving Impacts Frequent short trips prevent full battery recharging, leading to progressive discharge and sulfation. City driving with frequent stops and heavy electrical loads also stresses the battery and charging system.

Extended Storage Considerations Batteries naturally self-discharge during storage, typically losing 5-10% capacity per month. Extended storage without charging leads to deep discharge and permanent damage, especially in conventional flooded batteries.

High Electrical Load Scenarios Vehicles with extensive electrical accessories, powerful audio systems, or commercial equipment may exceed alternator capacity, causing the battery to supplement electrical demands and potentially leading to chronic undercharging.

Age and Deterioration Patterns Battery capacity naturally decreases with age due to plate deterioration, electrolyte changes, and internal resistance increases. Understanding normal aging helps distinguish between age-related decline and actual failures.

Battery Safety and Handling

Car batteries contain hazardous materials and can produce dangerous gases, making proper safety procedures essential for anyone working with automotive electrical systems.

Chemical Safety Precautions

Sulfuric Acid Handling Procedures Battery electrolyte contains concentrated sulfuric acid that causes severe burns on contact with skin, eyes, or clothing. Always wear safety glasses, acid-resistant gloves, and protective clothing when handling batteries or working with electrolyte.

Personal Protective Equipment Requirements Essential safety equipment includes safety glasses or face shield, chemical-resistant gloves, long sleeves, and closed-toe shoes. Keep a change of clothes available in case of acid contact, and never work on batteries while wearing jewelry that could contact terminals.

Spill Cleanup and Neutralization Clean acid spills immediately with baking soda solution to neutralize the acid, followed by thorough water rinsing. Dispose of contaminated materials according to local environmental regulations. Large spills may require professional hazmat cleanup.

Ventilation and Gas Hazard Awareness Batteries produce hydrogen and oxygen gases during charging, creating explosion hazards in confined spaces. Ensure adequate ventilation when working with batteries, especially during charging. Never smoke or create sparks near batteries.

First Aid Procedures for Accidents For acid contact with skin, flush immediately with large amounts of water for at least 15 minutes. For eye contact, flush with water and seek immediate medical attention. Remove contaminated clothing and continue flushing affected areas.

Electrical Safety Considerations

Short Circuit Prevention Battery terminals can deliver hundreds of amps in short circuit conditions, creating fire and explosion hazards. Remove jewelry, use insulated tools, and avoid allowing metal objects to contact both terminals simultaneously.

Proper Tool Insulation Use tools with insulated handles when working near battery terminals. Cover the positive terminal with a cloth or terminal protector when working with tools near the battery to prevent accidental shorts.

Spark and Arc Avoidance Sparks near batteries can ignite hydrogen gas, causing explosions. Make final connections away from the battery when possible, and ensure all electrical accessories are turned off before connecting or disconnecting cables.

Ground Fault Protection Work on a dry surface and avoid creating ground paths through your body when handling electrical components. Use rubber mats or wooden platforms when working in wet conditions to prevent electrical shock.

Safe Working Procedures Establish safe working procedures including proper tool selection, systematic approach to connections, and emergency response planning. Always disconnect the negative terminal first during removal and connect it last during installation to minimize spark potential.

Physical Handling Guidelines

Proper Lifting Techniques Car batteries typically weigh 40-60 pounds and require careful lifting to prevent injury. Use proper lifting posture with bent knees and straight back, and consider using a battery carrier or getting assistance for heavy batteries. Avoid lifting with extended arms or twisted posture.

Weight Distribution Considerations Distribute battery weight evenly when carrying, using both hands or a proper carrying tool. The weight concentration and awkward shape of batteries make them difficult to handle safely, especially in confined engine compartments.

Secure Transportation Methods When transporting batteries, secure them upright in appropriate containers to prevent tipping and electrolyte spills. Use battery boxes or carriers designed for safe transport, and ensure adequate ventilation during transport in enclosed vehicles.

Storage Requirements Store batteries in cool, dry locations away from heat sources and metal objects. Maintain batteries on wooden shelves or plastic racks rather than concrete floors, which can cause discharge. Keep stored batteries charged and test them periodically.

Disposal and Recycling Protocols Never dispose of batteries in regular trash or landfills. Take old batteries to auto parts stores, service centers, or recycling facilities that accept lead-acid batteries. Most retailers offer core exchange programs that provide credit for old batteries.

Advanced Battery Technologies and Future Trends

Modern vehicles increasingly require advanced battery technologies to meet performance demands, environmental regulations, and consumer expectations for reliability and convenience.

Start-Stop System Integration

Enhanced Battery Requirements Start-stop systems that automatically shut off engines at idle require batteries capable of frequent cycling and rapid recharging. These systems place much higher demands on batteries than conventional applications, requiring specialized technologies.

AGM and EFB Technology Benefits Absorbed Glass Mat (AGM) and Enhanced Flooded Battery (EFB) technologies provide the deep-cycle capability and fast recharge acceptance needed for start-stop systems. These batteries resist the rapid capacity loss that conventional batteries experience under frequent cycling.

Cycling Performance Demands Start-stop systems can cycle batteries hundreds of times more than conventional vehicles. Standard batteries fail quickly under these conditions, while advanced technologies maintain capacity through thousands of start-stop cycles.

System Compatibility Factors Vehicles equipped with start-stop systems require batteries specifically designed for this application. Using conventional batteries in start-stop vehicles typically results in premature failure and system malfunctions.

Maintenance and Replacement Considerations Start-stop batteries require different maintenance and replacement approaches than conventional batteries. These specialized batteries cost more but provide necessary performance for proper system operation.

Hybrid and Electric Vehicle Batteries

High-Voltage Battery Systems Hybrid and electric vehicles use high-voltage battery packs (typically 100-400 volts) separate from the conventional 12-volt system. These systems require specialized training and equipment for safe service and should only be serviced by qualified technicians.

Nickel-Metal Hydride Technology Many hybrid vehicles use nickel-metal hydride (NiMH) batteries for their high-voltage systems. These batteries provide good energy density and reliability but require sophisticated cooling and management systems for optimal performance.

Lithium-Ion Applications Modern electric and hybrid vehicles increasingly use lithium-ion battery technology for its superior energy density and performance characteristics. These systems offer longer range and faster charging but require complex battery management systems.

Safety and Service Requirements High-voltage battery systems present electrocution hazards and require special procedures for safe service. Only technicians with proper training and insulated tools should work on these systems. Emergency responders also require special training for accident response.

Integration with 12-Volt Systems Even electric vehicles maintain conventional 12-volt systems for lights, accessories, and control systems. These 12-volt batteries often require special maintenance due to the unique charging patterns of electric vehicles.

Smart Battery Technology

Battery Monitoring Systems Advanced vehicles include battery monitoring systems that track charge state, health, and performance. These systems provide early warning of battery problems and optimize charging to extend battery life.

Predictive Maintenance Capabilities Smart battery systems can predict failure before it occurs, allowing planned replacement rather than emergency roadside service. This technology reduces maintenance costs and improves vehicle reliability.

Wireless Connectivity Features Some advanced battery systems include wireless connectivity for remote monitoring and diagnostics. Fleet operators can track battery health across multiple vehicles and schedule maintenance proactively.

Diagnostic Integration Modern battery monitoring integrates with vehicle diagnostic systems, providing technicians with detailed battery information during service. This integration improves diagnostic accuracy and reduces service time.

Future Development Trends Battery technology continues evolving toward higher energy density, faster charging, longer life, and improved environmental friendliness. Solid-state batteries and other emerging technologies promise significant improvements in automotive applications.

Cost Considerations and Budgeting

Understanding battery costs and making informed purchasing decisions helps optimize vehicle maintenance budgets while ensuring reliable performance.

Battery Purchase Options

OEM vs. Aftermarket Batteries Original Equipment Manufacturer (OEM) batteries provide exact specifications and fitment but typically cost more than aftermarket alternatives. Quality aftermarket batteries often provide comparable performance at lower cost, while economy batteries sacrifice longevity for affordability.

Quality Tier Comparisons Battery manufacturers typically offer multiple quality tiers ranging from economy to premium. Higher-tier batteries include better materials, longer warranties, and superior performance, often providing better long-term value despite higher initial costs.

Warranty Value Analysis Battery warranties vary from 1-5 years and may include different coverage for replacement versus prorated credit. Longer warranties often indicate manufacturer confidence in product quality and provide financial protection against premature failure.

Performance vs. Cost Optimization Balance battery cost against performance requirements, climate conditions, and vehicle usage patterns. Premium batteries may be cost-effective for harsh environments or critical applications, while economy batteries suffice for mild climates and light usage.

Brand Reliability Factors Established battery manufacturers typically provide more consistent quality and better customer support than unknown brands. Research manufacturer reputation and read customer reviews when comparing battery options.

Total Cost of Ownership

Initial Purchase Price Factors Consider not just the battery cost but also installation, disposal fees, and any additional components needed. Professional installation adds labor costs but may include warranties and proper disposal of the old battery.

Installation and Labor Costs DIY installation saves labor costs but requires tools, time, and technical knowledge. Professional installation typically costs $50-100 but ensures proper procedures and may include additional services like system testing.

Maintenance Expense Considerations Factor ongoing maintenance costs into total ownership calculations. Maintenance-free batteries reduce service costs, while conventional batteries require periodic electrolyte checks and terminal cleaning.

Replacement Frequency Impacts Premium batteries lasting 5-6 years may cost less per year than economy batteries requiring replacement every 2-3 years. Calculate annual costs rather than just initial purchase price when comparing options.

Failure-Related Costs Consider the cost of roadside assistance, towing, missed work, and inconvenience when a battery fails unexpectedly. These indirect costs often exceed the price difference between economy and premium batteries.

Fleet and Business Considerations

Volume Purchasing Advantages Businesses operating multiple vehicles can often negotiate volume discounts with battery suppliers or service providers. Group purchasing reduces per-unit costs and simplifies procurement processes.

Preventive Replacement Programs Fleet operators often implement preventive replacement programs that replace batteries based on age rather than failure. This approach reduces roadside failures and associated costs while improving vehicle reliability.

Downtime Cost Analysis For commercial vehicles, battery failure costs include not just replacement expenses but also lost productivity, missed deliveries, and customer dissatisfaction. Premium batteries and preventive maintenance reduce these business impacts.

Service Contract Options Some service providers offer battery maintenance contracts that include regular testing, preventive replacement, and emergency service. These contracts provide predictable costs and reduced administrative burden.

Inventory Management Strategies Large fleets may benefit from maintaining battery inventory for immediate replacement, while smaller operations typically rely on supplier availability. Balance inventory costs against downtime risks when developing procurement strategies.

Understanding your car battery’s function, maintenance requirements, and replacement criteria ensures reliable vehicle operation and prevents unexpected failures. Whether you’re a DIY enthusiast performing basic maintenance or a professional technician diagnosing complex electrical problems, proper battery care is essential for automotive reliability.

For additional electrical system information and repair procedures, explore our comprehensive vehicle systems and parts explained resources. Remember that complex electrical problems or safety concerns should always be referred to qualified automotive technicians with proper training and equipment.

For understanding how batteries integrate with the broader electrical system, review our guides on car fuse boxes and warning lights that may indicate battery or charging system problems. Stay informed about your vehicle’s electrical health through regular maintenance and professional diagnostics when needed.

Safety Disclaimer: Car batteries contain sulfuric acid and produce explosive gases. Always wear appropriate personal protective equipment, ensure adequate ventilation, and avoid sparks or flames near batteries. Follow all safety procedures carefully and consult professionals for complex electrical work. The information provided is for educational purposes only.

Chemical Handling Warning: Battery electrolyte is highly corrosive sulfuric acid that can cause severe burns and eye damage. Always wear safety glasses, gloves, and protective clothing when handling batteries. Have neutralizing agents and first aid supplies readily available. Dispose of batteries according to local environmental regulations.

Professional Consultation Note: While basic battery maintenance can be performed by experienced DIY enthusiasts, complex electrical system problems and high-voltage hybrid systems require professional expertise. When in doubt about safety or procedures, consult qualified automotive technicians.

Information Source Disclaimer: This information is compiled from automotive industry standards and manufacturer guidelines. Always consult your vehicle’s specific service manual for model-specific procedures and specifications. Repairs Advisor provides informational resources only and does not offer direct repair services.