Your engine’s coolant is far more than simple antifreeze – it’s a sophisticated chemical system protecting your most expensive automotive investment from catastrophic damage. This complex fluid manages extreme temperatures, prevents corrosion throughout your cooling system, and maintains optimal engine performance in conditions ranging from sub-zero winters to scorching summer heat.

Many drivers treat coolant as a “set and forget” maintenance item, not realizing that this critical fluid degrades over time and loses its protective properties. Unlike oil changes that get regular attention, coolant maintenance often gets overlooked until problems develop. Old or contaminated coolant can cause expensive engine damage, radiator failure, and complete cooling system breakdown.

This comprehensive guide will help you understand how coolant functions, recognize when replacement is needed, and maintain optimal cooling system protection for your vehicle. We’ll explore the different types of coolant available, proper maintenance intervals, and the critical signs that indicate immediate attention is required.

Important Safety Note: Coolant handling requires proper safety precautions due to its toxicity to humans and pets, environmental impact, and potential for causing severe burns when hot. Always follow proper safety procedures and disposal methods when working with cooling systems.

Understanding Coolant: More Than Just Antifreeze

What Coolant Actually Does

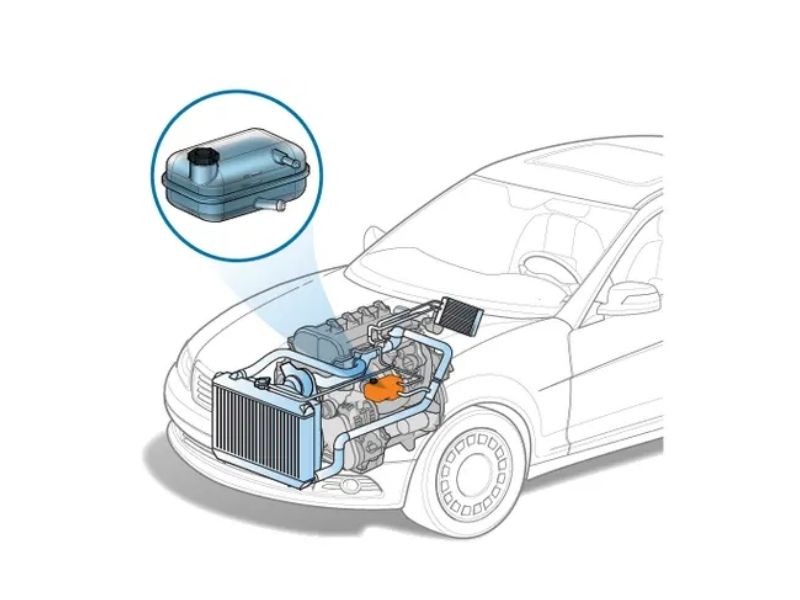

Heat transfer and thermal management represent coolant’s primary function, but the process involves much more than simply moving heat from the engine to the radiator. Modern coolant must efficiently absorb heat from combustion chambers reaching over 2,000°F, transport that heat through the cooling system, and dissipate it through the radiator while maintaining consistent flow characteristics across a wide temperature range.

Freeze protection and boiling point elevation work together to keep your cooling system functional in extreme conditions. Pure water freezes at 32°F and boils at 212°F, but a proper 50/50 coolant mixture provides freeze protection down to -34°F and elevates the boiling point to approximately 265°F. This expanded operating range is crucial for engine protection in varying climates and operating conditions.

Corrosion inhibition for metal components prevents the destruction of radiators, water pumps, engine blocks, and heater cores made from different metals including aluminum, steel, brass, and copper. Without proper corrosion protection, galvanic corrosion between dissimilar metals can cause component failure within months, while general corrosion can clog passages and reduce cooling efficiency.

Lubrication for water pump and seals ensures proper operation of moving components within the cooling system. The water pump depends on coolant lubrication for seal and bearing life, while thermostats, hoses, and gaskets benefit from the lubrication properties of properly formulated coolant. This lubrication function becomes critical in high-temperature, high-pressure cooling systems.

Coolant Chemistry and Composition

Ethylene glycol versus propylene glycol base fluids form the foundation of most automotive coolants, each offering different characteristics. Ethylene glycol provides superior heat transfer properties and lower cost but is highly toxic to humans and animals. Propylene glycol offers reduced toxicity but has slightly inferior heat transfer characteristics and typically costs more.

Corrosion inhibitor packages and their functions determine coolant compatibility and service life. These sophisticated chemical cocktails include silicates for aluminum protection, phosphates for iron protection, nitrites for cavitation control, and organic acids for long-term corrosion prevention. The specific combination and concentration of these additives differentiate coolant types and determine their compatibility with different engines.

Concentration ratios and their importance affect all aspects of coolant performance. Too little coolant reduces freeze protection and corrosion inhibition, while too much coolant actually reduces heat transfer efficiency and can cause overheating. The optimal 50/50 mixture balances all performance requirements, though some extreme climate applications may require different ratios.

Water quality impact on coolant performance cannot be overlooked, as coolant is typically mixed 50/50 with water. Hard water with high mineral content can interfere with corrosion inhibitors and create deposits, while distilled water provides optimal performance by avoiding mineral contamination that can reduce coolant effectiveness over time.

Different Types of Coolant Systems

Conventional green coolant (IAT – Inorganic Acid Technology) uses inorganic additives like silicates and phosphates for corrosion protection. This older technology typically requires replacement every 2-3 years or 30,000 miles due to additive depletion. While less expensive initially, the shorter service intervals can make conventional coolant more expensive over time.

Extended life coolants (OAT – Organic Acid Technology) employ organic acid corrosion inhibitors that last significantly longer than conventional additives. These coolants typically provide 5 years or 150,000 miles of protection but cost more initially. OAT coolants are often orange, red, or other bright colors to distinguish them from conventional green coolant.

Hybrid coolants (HOAT – Hybrid Organic Acid Technology) combine organic acids with some inorganic additives to provide broad compatibility and extended service life. Many vehicle manufacturers specify HOAT coolants as original equipment because they offer good protection for mixed-metal cooling systems while providing extended service intervals.

Manufacturer-specific formulations and requirements have become increasingly common as automakers develop coolants optimized for their specific engine designs and metallurgy. These proprietary formulations may offer superior protection but typically cost more and require exact replacement rather than “universal” alternatives.

Why Coolant Degrades Over Time

Additive depletion and chemical breakdown occur as corrosion inhibitors are consumed protecting system components. Unlike oil additives that primarily wear out from use, coolant additives are chemically consumed preventing corrosion, meaning they gradually disappear even in vehicles that aren’t driven frequently.

Contamination from system components introduces foreign materials that can interfere with coolant chemistry. Rubber hoses contribute sulfur compounds, metal components shed corrosion products, and oil leaks introduce petroleum products that can destabilize coolant chemistry and reduce its protective capabilities.

pH changes and corrosion acceleration develop as coolant additives are depleted and contamination accumulates. Fresh coolant typically maintains a slightly alkaline pH around 8-9, but degraded coolant becomes acidic, accelerating corrosion of all system components and creating a cascade of problems throughout the cooling system.

Thermal cycling effects on chemical stability stress coolant chemistry through repeated heating and cooling cycles. Each cycle can break down some coolant components and create chemical byproducts that interfere with corrosion protection and heat transfer capabilities.

For comprehensive information about engine cooling systems and their maintenance requirements, explore our detailed Engine technical resource library.

Signs Your Coolant Needs Replacement

Visual Inspection Indicators

Color changes and what they indicate provide the first obvious signs of coolant degradation. Fresh coolant maintains its original bright color, whether green, orange, red, or blue. As coolant degrades, colors fade to brown or rust-colored, indicating contamination with corrosion products. Completely brown or black coolant indicates severe degradation requiring immediate replacement.

Clarity loss and contamination signs become apparent as particles accumulate in the cooling system. Fresh coolant should be completely clear and transparent, while degraded coolant may appear cloudy, murky, or contain visible particles. Oil contamination creates a milky appearance, while rust particles create a gritty texture and reddish-brown coloration.

Rust particles and metal contamination appear as reddish-brown sediment in the coolant or settled in the radiator neck. These particles indicate active corrosion within the cooling system and loss of corrosion protection. Metal contamination can clog narrow passages and reduce cooling efficiency while indicating expensive component damage.

Oil contamination and foam formation signal serious problems requiring immediate attention. Oil in coolant creates a foamy, milky appearance and indicates head gasket failure, cracked engine components, or transmission cooler leaks. Oil contamination destroys coolant chemistry and requires complete system flushing and component repair.

Performance-Related Symptoms

Overheating patterns and temperature regulation problems often indicate coolant degradation or contamination. Engines that run hotter than normal, overheat in traffic, or show inconsistent temperature readings may have coolant that no longer transfers heat effectively due to degraded chemistry or system deposits.

Heater performance degradation manifests as reduced heat output, slow warm-up, or inconsistent cabin heating. Since heater cores are vulnerable to clogging from coolant contamination, poor heater performance often indicates coolant problems before engine overheating becomes apparent.

Unusual temperature gauge behavior includes erratic readings, sudden temperature spikes, or failure to reach normal operating temperature. These symptoms can indicate coolant circulation problems, thermostat issues, or coolant chemistry problems affecting heat transfer capabilities.

Steam or vapor from cooling system components indicates coolant loss through evaporation or leaks. While small amounts of vapor are normal in cold weather, visible steam from the radiator, overflow tank, or hoses suggests coolant problems requiring investigation.

Chemical and Physical Testing

Test strip usage and interpretation provides quick assessment of coolant condition using inexpensive test strips available at auto parts stores. These strips check pH levels, freeze protection, and corrosion inhibitor levels, providing objective data about whether coolant replacement is needed regardless of appearance.

Hydrometer testing for concentration measures the specific gravity of coolant to determine freeze protection levels and proper mixture ratios. This testing is particularly important in extreme climates where inadequate freeze protection can cause catastrophic engine damage from freezing.

pH testing and significance reveals coolant acidity that accelerates corrosion throughout the cooling system. Fresh coolant maintains alkaline pH levels around 8-9, while degraded coolant becomes acidic with pH below 7, indicating loss of corrosion protection and need for immediate replacement.

Professional coolant analysis options include laboratory testing that can detect contamination, additive levels, and system problems not apparent through visual inspection. Many repair shops offer coolant analysis services that provide detailed reports on coolant condition and remaining service life.

System-Wide Warning Signs

Radiator and component corrosion becomes visible as white, green, or brown deposits on radiator fins, hoses, or cooling system components. External corrosion often indicates internal corrosion that can clog passages and damage expensive components like water pumps and radiators.

Water pump noise or leakage frequently results from coolant chemistry problems that damage pump seals and bearings. Grinding noises, coolant leaks from the water pump weep hole, or excessive pump shaft play all indicate cooling system problems that may be related to degraded coolant.

Thermostat performance issues include stuck-open or stuck-closed operation that can result from coolant contamination or corrosion. Engines that don’t reach normal operating temperature or overheat suddenly may have thermostat problems related to poor coolant condition.

Hose deterioration and soft spots develop when coolant chemistry breaks down rubber compounds in cooling system hoses. Soft, spongy areas in hoses, cracking near clamps, or oil-soaked appearance all indicate coolant problems that can lead to sudden hose failure and overheating.

Coolant Types and Compatibility

Conventional vs Extended Life Coolants

Service interval differences represent the most significant distinction between coolant types. Conventional green coolant (IAT) typically requires replacement every 2-3 years or 30,000-50,000 miles due to additive depletion, while extended life coolants (OAT) can protect for 5 years or 150,000 miles under normal conditions.

Chemical composition variations affect both performance and compatibility. Conventional coolants use inorganic corrosion inhibitors like silicates and phosphates that work quickly but deplete rapidly. Extended life coolants use organic acid technology that provides slower initial protection but maintains effectiveness much longer.

Cost comparison and value analysis shows that while extended life coolants cost more initially, their longer service intervals often make them more economical over time. However, this analysis must include the vehicle’s expected service life and whether the owner will maintain the vehicle long enough to realize the extended service benefits.

Performance characteristic differences include heat transfer efficiency, pump lubrication, and compatibility with different metals. Some extended life coolants may not provide optimal protection for older engines designed for conventional coolant, while some conventional coolants may not meet the extended service requirements of newer vehicles.

Color Coding and Manufacturer Specifications

Why color alone doesn’t determine compatibility is crucial to understand, as coolant colors are not standardized across manufacturers. Green doesn’t always mean conventional IAT, orange doesn’t always mean OAT, and some manufacturers use unique colors for their proprietary formulations. Always check chemical composition rather than relying on color identification.

Manufacturer-specific requirements and restrictions have become increasingly common as automakers develop coolants optimized for their engines. BMW, Mercedes-Benz, Volkswagen, and others specify particular coolant formulations that may not be compatible with “universal” alternatives, regardless of color or general chemistry type.

OEM vs aftermarket coolant considerations involve balancing cost, availability, and performance. OEM coolants are specifically formulated for your vehicle but cost more and may be less readily available. Quality aftermarket coolants meeting OEM specifications can provide equivalent protection at lower cost with better availability.

Warranty implications of coolant choice can be significant, particularly for newer vehicles under manufacturer warranty. Using non-specified coolant may void cooling system warranty coverage, while proper coolant documentation may be required for warranty claims on cooling system failures.

Mixing Compatibility Issues

Why different coolant types shouldn’t be mixed involves complex chemical interactions that can reduce protection and create harmful byproducts. Mixing IAT and OAT coolants can cause precipitation of protective additives, while mixing different OAT formulations can create chemical incompatibilities that reduce corrosion protection.

Chemical reactions and precipitate formation occur when incompatible coolants are mixed, potentially creating gel-like substances that can clog radiators, water pumps, and narrow passages. These reactions may not be immediately apparent but can cause expensive damage over time as precipitates accumulate.

Performance degradation from improper mixing affects all aspects of coolant function, including freeze protection, boiling point elevation, corrosion inhibition, and heat transfer. Mixed coolants often provide inferior protection compared to either original coolant type used alone.

Emergency mixing situations and subsequent actions sometimes occur when coolant loss requires immediate attention and only incompatible coolant is available. In emergencies, brief mixing may be acceptable to prevent overheating, but the entire system should be flushed and refilled with proper coolant as soon as possible.

Special Application Coolants

Heavy-duty and commercial vehicle requirements often specify enhanced coolant formulations designed for severe service conditions. These coolants may include supplemental coolant additives (SCAs), enhanced corrosion protection, or specialized chemistry for diesel engines with wet sleeve liners.

Performance and racing applications may require specialized coolants with enhanced heat transfer properties, reduced foaming characteristics, or compatibility with exotic engine materials. Some racing coolants eliminate glycol entirely, using water-based formulations that transfer heat more efficiently but provide no freeze protection.

Aluminum-intensive engine considerations are important for modern engines with aluminum blocks, heads, and radiators. These engines require coolants with enhanced aluminum corrosion protection and may be sensitive to coolants designed primarily for iron engines.

Classic car and older vehicle needs often involve coolants compatible with older seals, gaskets, and metallurgy. Some modern coolants may cause problems in vintage vehicles, while some older coolant formulations may provide better compatibility with period materials and designs.

For vehicle-specific coolant requirements and detailed maintenance procedures, consult our comprehensive resources for cars and trucks covering all major manufacturers.

When and How Often to Replace Coolant

Manufacturer Recommendations vs Real-World Conditions

Standard service intervals by coolant type provide baseline maintenance schedules but may not account for individual operating conditions. Conventional coolants typically require replacement every 30,000-50,000 miles or 2-3 years, while extended life coolants are designed for 100,000-150,000 miles or 5+ years of service.

Severe service condition modifications should reduce coolant replacement intervals significantly. Vehicles used for towing, racing, frequent stop-and-go driving, or operation in extreme temperatures may require coolant replacement at half the normal intervals due to increased thermal stress and contamination.

High-mileage vehicle considerations include cooling system wear that can contaminate coolant more quickly and reduce effective service life. Vehicles with over 100,000 miles may benefit from shorter coolant replacement intervals and more frequent cooling system inspection to prevent expensive failures.

Climate impact on service intervals affects coolant degradation rates and service requirements. Extreme hot or cold climates stress coolant chemistry more than moderate temperatures, while high humidity can introduce moisture contamination that reduces coolant effectiveness over time.

Mileage vs Time-Based Replacement

Why both factors matter for coolant life stems from different degradation mechanisms affecting coolant performance. Mileage-related wear comes from thermal cycling and system contamination, while time-related degradation occurs from chemical breakdown and additive depletion that happens even in stored vehicles.

Low-mileage vehicle special considerations often require time-based rather than mileage-based coolant replacement. Vehicles driven less than 10,000 miles annually may never reach mileage-based replacement intervals but still need coolant service due to additive depletion and contamination from extended storage periods.

Commercial and fleet vehicle scheduling typically emphasizes mileage-based intervals due to high annual mileage accumulation. Fleet managers often coordinate coolant service with other major maintenance items to minimize downtime and service costs while ensuring adequate protection.

Seasonal timing for coolant service can optimize cooling system protection and identify problems before they cause failures. Fall coolant service ensures proper freeze protection for winter, while spring service can address contamination from winter driving and prepare for summer heat stress.

Testing to Determine Replacement Need

When testing can extend service intervals safely applies primarily to extended life coolants that may retain protective properties beyond standard replacement intervals. Professional coolant analysis can confirm whether coolant still provides adequate protection, potentially extending service intervals safely.

Professional vs DIY testing capabilities vary significantly in accuracy and completeness. Basic test strips can check pH and freeze protection but may miss contamination or additive depletion that professional analysis would detect. Professional testing provides more comprehensive assessment but costs more than simple test strips.

Cost-effectiveness of testing vs replacement depends on coolant type, vehicle value, and service costs. Testing may cost $50-100 while coolant replacement costs $100-300, so testing is most valuable for expensive coolants or when replacement intervals are uncertain.

Record keeping for maintenance tracking helps optimize coolant replacement intervals based on actual vehicle operating conditions and coolant performance. Documented testing results and service history provide data for adjusting maintenance intervals to match real-world requirements.

Early Replacement Indicators

System repairs requiring coolant replacement include any work that opens the cooling system, such as radiator repair, water pump replacement, or head gasket service. Fresh coolant should always be installed when major cooling system work is performed to ensure optimal protection and performance.

Contamination events requiring immediate service include oil leaks into coolant, fuel contamination, or introduction of foreign materials. These contamination events destroy coolant chemistry and require complete system flushing and coolant replacement regardless of service intervals.

Performance problems indicating coolant issues such as overheating, poor heater output, or unusual temperature behavior may indicate coolant degradation even within normal service intervals. Performance problems should trigger coolant testing and potential replacement before expensive component damage occurs.

Preventive replacement before problems develop may be cost-effective for high-value vehicles or critical applications where cooling system failure would be extremely expensive or inconvenient. Replacing coolant before problems develop prevents expensive failures and ensures reliable operation.

DIY Coolant Replacement vs Professional Service

DIY Coolant Replacement Considerations

Skill level requirements and tool needs for coolant replacement are moderate but require attention to detail and proper procedures. Basic hand tools, drain pans, funnels, and safety equipment are required, along with knowledge of proper bleeding procedures and system filling techniques.

Safety equipment and procedures required include eye protection, chemical-resistant gloves, proper ventilation, and spill containment materials. Coolant is toxic and can cause burns when hot, while proper disposal requires following environmental regulations that vary by location.

Environmental disposal requirements mandate that used coolant be disposed of at authorized recycling centers or hazardous waste facilities. Coolant cannot be disposed of in regular trash, poured down drains, or dumped on the ground due to environmental toxicity and groundwater contamination concerns.

Cost savings vs risk assessment should consider potential complications and hidden costs. While DIY coolant replacement can save $100-200 in labor costs, improper procedures can cause expensive air lock problems, component damage, or environmental violations that exceed the labor savings.

Step-by-Step DIY Process Overview

System draining procedures and safety begin with ensuring the engine is completely cool and following proper drain procedures to avoid burns from hot coolant. Most vehicles have radiator drain plugs or petcocks, but some require removing the lower radiator hose for complete draining.

Flushing requirements and techniques depend on coolant condition and contamination levels. Mild contamination may require only water flushing, while severe contamination needs chemical flushing compounds. Some cooling systems have reverse-flow flushing capabilities that improve cleaning effectiveness.

Refilling and air bleeding procedures are critical for preventing air locks that can cause overheating and component damage. Proper bleeding may require running the engine with the radiator cap off, using bleeder valves, or following specific manufacturer procedures for complete air removal.

Post-service testing and verification should include checking for leaks, verifying proper temperature operation, confirming adequate heat output, and monitoring coolant levels after initial operation. Test drives should verify normal temperature regulation under various operating conditions.

When Professional Service is Recommended

Complex cooling system designs with multiple zones, electric pumps, or computer-controlled components often require professional service due to specialized bleeding procedures and diagnostic equipment needs. Modern vehicles may have complex air bleeding requirements that exceed DIY capabilities.

Pressure testing and leak detection needs require specialized equipment to identify small leaks or verify system integrity after service. Professional shops have pressure testing equipment that can detect problems not apparent during visual inspection or basic testing.

Environmental disposal and recycling are handled automatically by professional shops that have established waste management systems and recycling partnerships. This eliminates environmental compliance concerns and ensures proper disposal without additional effort or research.

Warranty and liability considerations may favor professional service for newer vehicles or when cooling system problems are suspected. Professional service provides warranty coverage on work performed and liability protection for environmental or component damage issues.

Professional Service Value-Added Benefits

System inspection and component assessment typically accompany professional coolant service, including checks of hoses, belts, radiator condition, and water pump operation. This comprehensive inspection can identify developing problems before they cause failures.

Pressure testing and leak detection using professional equipment can identify small leaks or weak points that might not be apparent during routine service. Early leak detection prevents roadside failures and allows planned repairs at convenient times.

Proper disposal and environmental compliance eliminate concerns about hazardous waste regulations and ensure responsible coolant recycling. Professional shops handle all environmental compliance issues automatically as part of routine service.

Warranty coverage on work performed provides protection against service-related problems and ensures professional resolution of any issues that develop after coolant service. Quality shops stand behind their work with appropriate warranty coverage.

Cooling System Maintenance and Prevention

Regular Inspection Procedures

Visual coolant level and condition checks should be performed monthly when the engine is cool, checking both the radiator (if accessible) and overflow tank levels. Look for proper fluid levels, clean appearance, and absence of contamination or unusual colors that indicate problems developing.

Hose and connection inspection points include radiator hoses, heater hoses, and bypass hoses for signs of swelling, cracking, or soft spots that indicate impending failure. Check hose clamps for tightness and corrosion, and inspect areas where hoses contact other components for wear spots.

Radiator and component examination should include checking radiator fins for damage or blockage, inspecting for external corrosion or leaks, and verifying that cooling fans operate properly. Look for white or green corrosion deposits that indicate coolant leaks or system problems.

Temperature monitoring habits involve becoming familiar with normal operating temperature patterns and watching for changes that might indicate developing problems. Note how quickly the engine warms up, what temperature it maintains under different conditions, and how the heater performs.

Preventive Maintenance Practices

Proper coolant level maintenance requires checking levels regularly and adding coolant when needed, but always use the correct coolant type and avoid overfilling. Low coolant levels reduce cooling efficiency and can cause air pockets, while overfilling can cause overflow and pressure problems.

System pressure cap inspection and replacement should include checking cap condition, proper sealing, and correct pressure rating. Pressure caps typically require replacement every 2-3 years as rubber seals deteriorate and pressure relief valves become unreliable.

Thermostat replacement scheduling should coincide with major cooling system service since thermostats are inexpensive compared to labor costs. Thermostats gradually lose accuracy over time and should be replaced preventively during coolant service to ensure reliable temperature regulation.

Water pump and belt inspection includes checking for coolant leaks from the weep hole, unusual noises, or excessive shaft play that indicate bearing wear. Drive belts should be inspected for proper tension, cracking, or glazing that affects water pump operation.

Seasonal Considerations

Winter freeze protection verification requires testing coolant concentration to ensure adequate freeze protection for local climate conditions. Insufficient freeze protection can cause engine block cracking, radiator damage, and complete cooling system destruction from ice formation.

Summer heat protection preparation involves verifying cooling system capacity for high-temperature operation, checking radiator cleanliness for maximum heat dissipation, and ensuring cooling fans operate properly during hot weather operation.

Coolant concentration adjustment needs may require modification for extreme climate conditions. Very cold climates may benefit from higher coolant concentrations for additional freeze protection, while moderate climates can use standard 50/50 mixtures for optimal performance.

Climate-specific maintenance timing should coordinate cooling system service with seasonal requirements. Fall service ensures winter protection, while spring service addresses any winter damage and prepares for summer heat stress.

Early Problem Detection

Temperature gauge monitoring provides the earliest warning of cooling system problems, but requires understanding normal operating patterns to identify abnormal behavior. Sudden temperature changes, failure to reach normal temperature, or overheating all indicate problems requiring immediate attention.

Coolant loss investigation procedures should begin immediately when coolant levels drop without obvious external leaks. Internal leaks into combustion chambers or transmission coolers can cause expensive damage if not addressed quickly. White exhaust smoke or oil contamination may indicate internal leaks.

Performance change recognition includes noting changes in heater output, engine warm-up time, fuel economy, or overall performance that might indicate cooling system problems. Many cooling system problems initially cause subtle performance changes before obvious overheating occurs.

When to seek professional diagnosis includes any time coolant loss occurs without obvious causes, temperature regulation becomes abnormal, or visual inspection reveals contamination or component problems. Professional diagnosis can identify problems before they cause expensive failures.

For brand-specific cooling system maintenance procedures and specifications, explore our comprehensive collection of technical service manuals covering all major automotive manufacturers.

Environmental and Safety Considerations

Coolant Toxicity and Safety

Human and pet safety considerations are paramount when handling coolant, as ethylene glycol is highly toxic and has a sweet taste that attracts children and animals. Even small amounts can cause serious injury or death, making proper storage and handling procedures critical for household safety.

Proper storage and handling procedures require keeping coolant in original containers with intact labels, storing in locked areas away from children and pets, and using appropriate protective equipment during handling. Never transfer coolant to food or beverage containers that might cause accidental ingestion.

First aid measures for exposure include immediate medical attention for any suspected ingestion, thorough washing with soap and water for skin contact, and eye flushing with clean water for eye exposure. Post emergency contact information and keep first aid supplies readily available when working with coolant.

Workshop safety requirements include adequate ventilation to prevent vapor accumulation, spill containment materials to prevent environmental contamination, and emergency cleanup supplies for accidental releases. Never work with coolant in confined spaces or areas with poor ventilation.

Environmental Impact and Disposal

Proper disposal methods and locations vary by jurisdiction but typically require taking used coolant to authorized recycling centers, auto parts stores with recycling programs, or hazardous waste facilities. Contact local environmental authorities for specific disposal requirements in your area.

Recycling options and benefits include professional coolant recycling that removes contaminants and restores coolant to like-new condition. Recycled coolant provides environmental benefits while often costing less than new coolant, making recycling both environmentally responsible and economically beneficial.

Groundwater contamination prevention requires preventing coolant from entering storm drains, soil, or water sources where it can contaminate drinking water supplies and harm wildlife. Even small amounts of coolant can contaminate large volumes of groundwater due to its persistence in the environment.

Legal requirements for disposal include federal and state regulations governing hazardous waste disposal, with potential fines and criminal penalties for improper disposal. Businesses handling coolant may have additional reporting and disposal requirements beyond those for individual vehicle owners.

Spill Prevention and Cleanup

Workshop preparation for coolant work should include covering work areas with absorbent materials, having spill cleanup supplies readily available, and ensuring adequate drainage to contain accidental spills. Prepare cleanup materials before beginning work rather than scrambling after spills occur.

Spill containment and cleanup procedures require immediate action to prevent environmental contamination and safety hazards. Use absorbent materials designed for coolant cleanup, dispose of contaminated materials properly, and neutralize residual contamination according to material safety data sheet requirements.

Material selection for absorption should include coolant-specific absorbents rather than general-purpose materials that may not be effective for glycol-based fluids. Some absorbents are specifically designed for coolant cleanup and provide better containment than generic materials.

Environmental reporting requirements may apply to significant spills that threaten groundwater or surface water supplies. Know local reporting requirements and emergency contact information for environmental authorities before beginning coolant work.

Professional Resources and Long-Term Protection

Key Maintenance Takeaways

Most important coolant care practices include following manufacturer replacement intervals, using only specified coolant types, maintaining proper mixture ratios, and addressing problems immediately before they cause expensive damage. Regular inspection and testing can prevent most cooling system failures through early problem detection.

Critical safety considerations prioritize human and environmental safety through proper handling, storage, and disposal procedures. Coolant toxicity requires constant vigilance, while environmental regulations demand responsible disposal practices that protect groundwater and wildlife.

When professional help is essential includes complex cooling system diagnostics, specialized bleeding procedures, environmental compliance issues, and any work requiring pressure testing or component replacement. Professional service provides expertise, equipment, and warranty coverage that justify the additional cost.

Long-term cooling system protection requires consistent maintenance, quality coolant, and prompt attention to developing problems. Preventive maintenance costs significantly less than reactive repairs, while proper coolant maintenance protects expensive engine components throughout the vehicle’s service life.

Professional Consultation Guidance

When to seek professional cooling system service includes any time overheating occurs, coolant contamination is suspected, performance problems develop, or routine testing indicates coolant degradation. Professional diagnosis can identify problems before they cause catastrophic failures and expensive repairs.

Questions to ask service providers should cover their experience with your vehicle type, coolant recommendations, testing procedures used, warranty coverage provided, and disposal methods employed. Quality shops welcome questions and provide detailed explanations of their procedures and recommendations.

How to verify proper coolant service includes checking that correct coolant type was used, proper mixture ratio was achieved, system was adequately bled, and post-service testing confirmed normal operation. Request documentation of coolant type, test results, and any problems discovered during service.

Maintenance record keeping importance helps optimize service intervals, track coolant performance, and provide warranty documentation when problems develop. Detailed records also help identify patterns that might indicate developing problems or validate extended service intervals.

Understanding coolant function, maintenance requirements, and safety considerations protects both your vehicle investment and personal safety. By following proper maintenance intervals, using correct coolant types, and addressing problems promptly, you can ensure reliable cooling system operation while minimizing environmental impact and safety risks.

Disclaimer: This information is provided for educational purposes only. Always follow manufacturer recommendations and safety procedures when working with coolant. Improper handling or disposal can result in serious injury or environmental damage. Consult qualified professionals for complex cooling system problems or when environmental compliance questions arise.