Connecting rod failure can destroy your engine in minutes, turning a potentially manageable repair into a catastrophic total loss. Unlike many engine problems that develop gradually, connecting rod issues often progress rapidly from minor symptoms to complete engine destruction, leaving drivers stranded with repair bills that can exceed the vehicle’s value.

Many drivers don’t recognize connecting rod problems until they hear the telltale “rod knock” – a rhythmic knocking sound that signals imminent engine failure. By this point, continued operation, even for short distances, can cause irreparable damage to the engine block, crankshaft, and surrounding components. The difference between catching connecting rod problems early and discovering them too late often means thousands of dollars in repair costs.

This comprehensive guide will help you identify connecting rod issues in their earliest stages, understand the critical nature of immediate action, and make informed decisions about repair options. We’ll walk you through the warning signs that precede catastrophic failure, diagnostic procedures you can perform safely, and the crucial steps to take when connecting rod problems are suspected.

Critical Safety Warning: If you suspect connecting rod problems, especially if you hear knocking sounds from the engine, stop driving immediately. Continued operation can cause complete engine destruction within minutes. This is not a problem that allows for “driving to the shop” – professional help must come to you.

Understanding Connecting Rods and Their Critical Role

What is a Connecting Rod and How Does it Work?

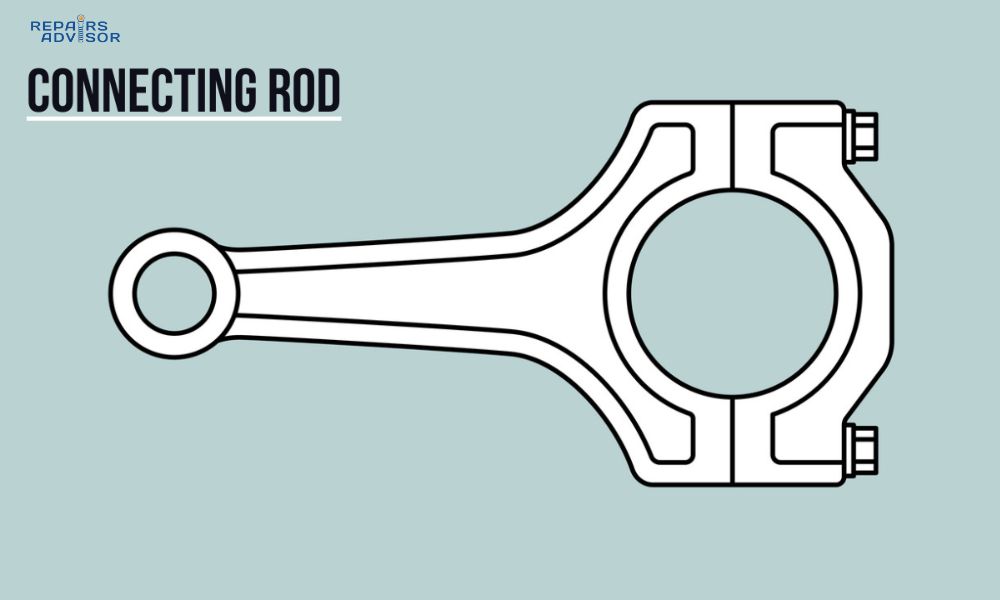

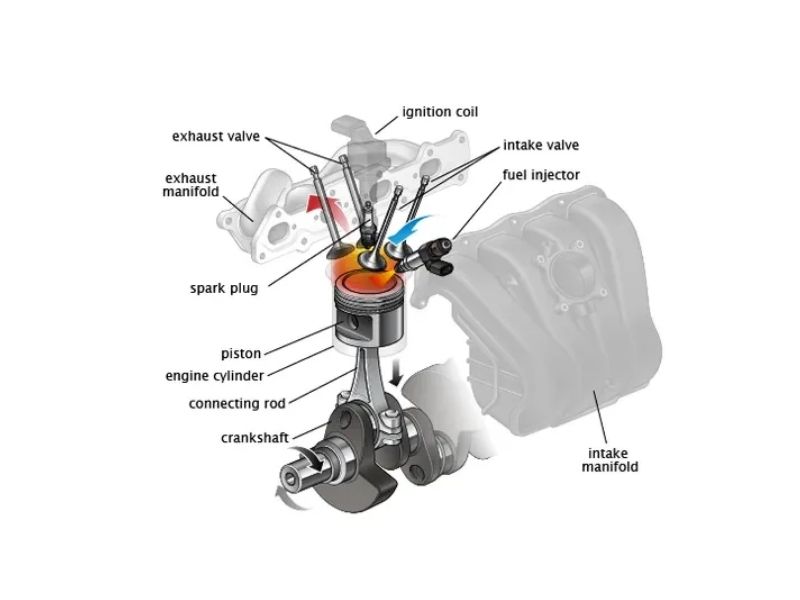

A connecting rod is the crucial link between your engine’s pistons and crankshaft, transferring the explosive force of combustion into the rotational motion that powers your vehicle. This seemingly simple component endures tremendous forces during operation – compression loads during the compression stroke, explosive forces during combustion, and tensile loads during the exhaust stroke.

The connecting rod has two critical ends: the small end connects to the piston via a wrist pin, while the big end connects to the crankshaft through precision bearings. These bearings, typically made of steel backed with softer bearing material, maintain critical oil film clearances measured in thousandths of an inch. When these clearances exceed specifications due to wear or damage, the characteristic “rod knock” develops.

The entire system depends on pressurized oil circulation to maintain proper lubrication between the bearing surfaces and crankshaft journals. Oil pressure forces lubricant through precisely drilled passages in the crankshaft and connecting rod, creating a thin but critical oil film that prevents metal-to-metal contact. When this lubrication system fails or bearing clearances become excessive, connecting rod failure follows quickly.

Understanding these relationships helps explain why connecting rod problems are so serious: the forces involved are enormous, the tolerances are extremely tight, and failure of this component directly affects the engine’s ability to convert combustion energy into useful work.

Why Connecting Rods Fail: Primary Causes

Lubrication system failures and oil starvation represent the most common cause of connecting rod failure. When oil pressure drops due to pump failure, blocked oil passages, or simply running out of oil, the protective oil film disappears within seconds. Without lubrication, the bearing material begins to overheat and deteriorate, rapidly increasing clearances and creating the conditions for catastrophic failure.

Bearing wear and clearance issues develop gradually through normal operation but accelerate dramatically when lubrication becomes inadequate. As bearing clearances increase, oil pressure to that bearing decreases, creating a vicious cycle where deteriorating bearings receive less lubrication, causing faster deterioration. This process can accelerate from minor symptoms to complete failure in minutes once critical thresholds are exceeded.

Over-revving and mechanical stress can exceed the design limits of connecting rod components, causing immediate failure or creating stress cracks that lead to delayed failure. Modern engines with rev limiters provide some protection, but mechanical over-revving (such as downshifting into too low a gear) can still occur and cause instant connecting rod failure.

Manufacturing defects and material fatigue occasionally cause connecting rod failures in newer engines, though these are relatively rare. More commonly, accumulated stress cycles over hundreds of thousands of miles can create fatigue cracks that eventually lead to failure, particularly in high-mileage engines that have been well-maintained otherwise.

Hydrolock and sudden impact damage occurs when liquid enters the combustion chamber and the piston cannot complete its compression stroke. This can happen due to water ingestion, excessive fuel delivery, or coolant leaks into the cylinder. The connecting rod, being the link between the unstoppable crankshaft and the now-immovable piston, often fails catastrophically in these situations.

The Catastrophic Nature of Rod Failure

How rod failure destroys engines involves a cascade of damage that begins with the connecting rod separating from either the piston or crankshaft. When this happens, the loose components are violently thrown around inside the engine, smashing through the engine block, destroying the crankshaft, and damaging surrounding components. The engine block often develops holes, making repair impossible.

Cost implications of continued operation cannot be overstated. A connecting rod bearing that might be repairable with a few hundred dollars in parts and machine work becomes a total engine loss requiring thousands of dollars in replacement costs when the rod actually fails. The difference between stopping immediately when symptoms appear and driving “just a few more miles” often determines whether the engine can be saved.

Why immediate action is critical stems from the rapid progression of connecting rod problems once they begin. Unlike many engine problems that develop gradually over weeks or months, connecting rod bearing failure can progress from barely audible noise to complete engine destruction in less than a mile of driving. The window for salvaging the engine closes very quickly.

The difference between repairable damage and total loss often comes down to whether the connecting rod remains intact and whether the crankshaft journals are damaged. Bearing replacement and machine work can save engines caught early, but once the rod actually separates or the crankshaft is damaged, repair costs typically exceed engine replacement costs.

For comprehensive information about engine systems and their critical interdependencies, explore our detailed Engine technical resources.

Early Warning Signs and Symptoms

Audio Symptoms: The Sound of Trouble

Rod knock characteristics present as a distinct rhythmic knocking sound that directly corresponds to engine RPM. Unlike other engine noises that may be intermittent or speed-related, rod knock maintains a consistent relationship with crankshaft rotation – doubling the RPM doubles the knock frequency. This sound typically becomes more pronounced under load and may initially be barely audible at idle.

The difference between rod knock and other engine noises is critical for proper diagnosis. Rod knock originates deep within the engine and has a hollow, metallic quality that’s distinctly different from valve train noise (which typically occurs at half engine speed) or timing chain noise (which may be more irregular). Piston slap creates a similar rhythm but typically occurs only during cold operation and diminishes as the engine warms up.

How rod knock changes with engine temperature provides important diagnostic information. Early-stage bearing wear often produces noise that’s more noticeable when the engine is cold and thick oil provides less cushioning. As damage progresses, the noise typically becomes constant regardless of temperature. If knocking appears or worsens as the engine warms up, it often indicates severe bearing damage requiring immediate shutdown.

Location and intensity patterns of connecting rod noise help identify which cylinder is affected. Using an automotive stethoscope or even a long screwdriver as a listening device, the noise will be loudest directly over the affected connecting rod bearing area. The intensity typically increases dramatically with throttle application and may temporarily disappear at very low RPMs.

Performance Indicators

Power loss and acceleration problems often accompany connecting rod bearing wear as increased clearances reduce compression and allow combustion gases to leak past worn bearings. The affected cylinder may produce noticeably less power, resulting in rough acceleration and reduced overall engine performance. This power loss is typically most noticeable under load, such as climbing hills or accelerating from stops.

Oil pressure changes and oil consumption become apparent as bearing clearances increase. Lower oil pressure readings, particularly at idle when oil viscosity is thinnest, indicate excessive bearing clearances allowing oil to escape the pressure system. Increased oil consumption may also occur as worn bearings allow more oil to enter the combustion chamber.

Metal particles in oil analysis provide early warning of bearing deterioration before audible symptoms develop. Fresh oil that quickly becomes dark or develops a metallic appearance often indicates bearing wear. Magnetic drain plugs may collect metallic particles, while oil analysis can detect microscopic metal content that indicates bearing material deterioration.

Vibration patterns and engine roughness result from the affected cylinder not contributing full power and the mechanical looseness created by excessive bearing clearances. The engine may develop a noticeable vibration at idle that wasn’t present before, and this vibration typically worsens under load as the loose bearing allows more movement in the rotating assembly.

Visual and Physical Signs

Oil contamination and metallic particles become visible as connecting rod bearings deteriorate. Oil may develop a bronze or copper color from bearing material, and metallic flakes may be visible in the oil or on the dipstick. Fresh oil that quickly becomes contaminated with metal particles is a strong indicator of bearing problems requiring immediate attention.

Unusual exhaust smoke patterns can indicate oil entering the combustion chamber through worn bearings. Blue smoke that appears suddenly or worsens rapidly may indicate oil being forced into cylinders through deteriorated bearing seals. This is particularly significant if the smoke appears to come primarily from the tailpipe rather than valve cover leaks.

Engine bay vibration and movement becomes noticeable as bearing clearances increase and the rotating assembly develops more internal movement. The engine may visibly shake more at idle, and vibrations may be felt through the steering wheel, floor, or seat that weren’t present before the bearing problems developed.

Temperature gauge irregularities sometimes accompany severe bearing problems as the affected cylinder may not contribute properly to cooling system circulation or may create hot spots from increased friction. While not always present, sudden changes in operating temperature patterns can indicate internal engine problems requiring investigation.

Progressive Symptom Development

How symptoms typically evolve over time follows a predictable pattern in most cases. Initial symptoms are often subtle – a slight increase in engine noise, minor roughness, or barely perceptible power loss. These early signs may be intermittent or only noticeable under specific conditions like cold starts or heavy acceleration.

Critical threshold indicators requiring immediate shutdown include any rhythmic knocking sound that correlates with engine RPM, sudden oil pressure loss, or dramatic increases in engine noise. These symptoms indicate that bearing failure is imminent or already occurring, and continued operation will likely cause catastrophic damage within minutes.

Symptoms that indicate imminent failure progress rapidly once they appear. A faint knocking sound can become loud and obvious within miles of driving, oil pressure can drop precipitously as bearing clearances suddenly increase, and power loss can become severe as the affected cylinder stops contributing to engine output.

When continued operation becomes impossible is typically marked by loud, constant knocking that cannot be ignored, severe power loss making normal driving difficult, or oil pressure warnings indicating lubrication system failure. At this point, the engine must be shut down immediately to prevent complete destruction.

For vehicle-specific diagnostic guidance, consult our comprehensive collections for cars and trucks covering a wide range of makes and models.

Diagnostic Procedures for Connecting Rod Problems

Audio Diagnosis Techniques

Using an automotive stethoscope for noise location provides the most accurate method for pinpointing connecting rod problems. Place the stethoscope probe directly on the engine block over each connecting rod bearing area while the engine runs at idle. Rod knock will be loudest directly over the affected bearing and will maintain a consistent rhythm that doubles when engine speed doubles.

RPM-based diagnostic procedures help distinguish rod knock from other engine noises. Rev the engine slowly while listening – rod knock maintains a direct relationship with engine speed, unlike valve train noise that occurs at half engine speed or timing chain noise that may be irregular. The knock should be most pronounced during acceleration and may diminish at steady RPM.

Temperature-related diagnostic tests involve comparing noise levels between cold and warm operation. Start the engine cold and note the intensity and character of any knocking sounds. Allow the engine to reach normal operating temperature and repeat the assessment. Bearing wear typically produces noise that changes character with temperature as oil viscosity changes.

Cylinder isolation testing methods can help identify which cylinder has the bearing problem. On engines where individual cylinders can be disabled (by disconnecting spark plugs or fuel injectors), isolating the affected cylinder should significantly reduce or eliminate the knocking sound. This test requires expertise and should only be performed by experienced technicians.

Oil Analysis and Inspection

What to look for in used oil samples includes color changes, metallic particles, and consistency variations. Fresh oil that develops a bronze or copper tint often indicates bearing material contamination. Visible metallic flakes or particles, particularly those that appear bright or reflective, suggest active bearing wear requiring immediate attention.

Metal particle identification and significance requires understanding different types of contamination. Bronze or copper particles typically indicate bearing material loss, while iron or steel particles may suggest more severe mechanical wear. Large metallic flakes or chunks indicate catastrophic failure is imminent or already occurring.

Oil pressure testing procedures provide quantitative assessment of bearing condition. Use a mechanical oil pressure gauge to verify actual pressure readings rather than relying solely on dashboard gauges. Low oil pressure, particularly at idle with warm oil, often indicates excessive bearing clearances even before noise becomes apparent.

Oil consumption monitoring methods involve tracking oil level changes between services and noting any sudden increases in consumption. Worn bearings may allow increased oil flow into combustion chambers, resulting in higher consumption rates. Document oil consumption patterns to identify sudden changes that might indicate bearing problems.

Advanced Diagnostic Methods

Compression and leak-down testing can reveal cylinder sealing problems that sometimes accompany bearing wear. While not directly diagnostic of connecting rod problems, these tests help assess overall engine condition and may reveal related issues that affect repair decisions.

Cylinder balance testing measures each cylinder’s contribution to engine power and can identify cylinders with reduced output due to bearing problems. Professional equipment is required for accurate cylinder balance testing, and results must be interpreted by experienced technicians.

Professional diagnostic equipment usage includes specialized tools like engine analyzers, vibration analyzers, and computerized diagnostic systems that can detect bearing problems before they become audible. These tools are typically found only in professional shops and require training to operate and interpret results correctly.

When diagnostic procedures exceed DIY capabilities includes any testing that requires engine disassembly, specialized professional equipment, or interpretation of complex test results. Rod bearing problems often require professional confirmation before expensive repair decisions are made.

Immediate Actions and Damage Limitation

When to Stop Driving Immediately

Audio cues requiring immediate shutdown include any rhythmic knocking sound that correlates with engine RPM, sudden increases in engine noise intensity, or metallic sounds that seem to originate from deep within the engine. These sounds indicate that bearing failure is occurring or imminent, and continued operation will likely cause catastrophic damage.

Oil pressure warnings and their significance demand immediate attention when they appear. Dashboard oil pressure warning lights, gauges showing abnormally low pressure, or sudden changes in oil pressure readings all indicate lubrication system problems that can cause bearing failure within minutes of occurrence.

Performance degradation indicating critical failure includes sudden power loss, severe engine roughness, or inability to maintain normal operating RPM. When these symptoms appear suddenly, they often indicate that internal engine damage is occurring and continued operation will worsen the damage significantly.

Emergency shutdown procedures should be performed safely even in traffic situations. Turn on hazard lights, signal lane changes carefully, and move to the safest available location before shutting down the engine. Turn off the engine immediately upon reaching a safe location – do not attempt to reach a more convenient location if it requires continued driving.

Damage Assessment Procedures

Safe engine inspection methods begin with allowing the engine to cool completely before attempting any inspection. Check oil level and condition, looking for metallic particles, unusual colors, or consistency changes that indicate bearing material contamination. Visual inspection should be limited to external components until professional assessment is available.

What can be determined without disassembly includes oil condition assessment, external leak identification, and basic audio diagnosis. However, definitive diagnosis of connecting rod bearing condition requires internal engine inspection that should only be performed by qualified technicians with proper equipment and facilities.

Documentation for insurance or warranty claims should include detailed descriptions of symptoms, driving conditions when problems appeared, maintenance history, and any warning signs that preceded the failure. Photos of oil condition, gauge readings, and any visible external evidence can support claims processing.

Professional assessment requirements include evaluation by qualified engine rebuilding specialists who can determine the extent of damage and provide accurate repair cost estimates. This assessment typically requires partial engine disassembly and specialized measuring equipment to determine bearing clearances and component condition.

Towing and Transportation Considerations

Safe vehicle transport methods depend on the suspected severity of engine damage. If the engine seized or made catastrophic failure sounds, the vehicle should not be started again under any circumstances. Flatbed towing is preferred to prevent any possibility of further damage during transport.

What information to provide to towing services includes the nature of the suspected engine problem, whether the engine is seized or inoperable, and any special considerations for safe transport. Inform the towing service that engine problems are suspected so they can use appropriate equipment and procedures.

Preventing additional damage during transport involves ensuring the engine remains off, securing any loose components that may have been disturbed during initial assessment, and protecting the vehicle from weather exposure if extensive repair time is expected.

Emergency roadside safety protocols prioritize personal safety over vehicle concerns. If engine failure occurs in traffic, focus first on safely exiting traffic flow before addressing mechanical issues. Use emergency equipment, call for professional help, and avoid attempting roadside repairs on complex internal engine problems.

Repair Options and Cost Considerations

Minor Bearing Replacement Scenarios

When bearing replacement alone is viable requires that the connecting rod itself remains undamaged, crankshaft journals are within specifications, and the engine block shows no signs of damage from loose components. This scenario typically applies only to cases where bearing wear is caught very early, before noise becomes obvious or oil pressure drops significantly.

Required supporting component replacement often includes related bearings (main bearings should be replaced when rod bearings are replaced), gaskets and seals disturbed during disassembly, and oil pump assessment or replacement. The oil system must be thoroughly cleaned to remove any metallic contamination that caused the original bearing failure.

Skill level and tool requirements for bearing work exceed most DIY capabilities due to the precision measurements required, specialized tools needed for proper installation, and critical torque specifications that must be followed exactly. Connecting rod bearing replacement also requires engine disassembly that demands significant mechanical expertise and proper facilities.

Cost comparison with professional service typically favors professional service when all factors are considered. While parts costs may be relatively modest, the specialized tools, machine work often required, and potential for expensive mistakes during DIY attempts usually make professional service more economical for connecting rod bearing work.

Major Engine Rebuild Requirements

Extent of damage requiring complete rebuild includes situations where multiple bearings are affected, crankshaft journals require machining, cylinder walls need attention, or the oil contamination has affected multiple engine systems. Once damage extends beyond simple bearing replacement, complete engine rebuilding often becomes the most cost-effective approach.

Component replacement necessities in major rebuilds typically include all bearings, gaskets, seals, and often pistons, rings, and machined surfaces. The crankshaft may require grinding and polishing, while the engine block may need boring and honing. These extensive requirements quickly escalate costs but ensure long-term reliability.

Machine shop services and requirements include crankshaft grinding, cylinder boring and honing, pressure testing, and precision assembly work that requires specialized equipment and expertise. Quality machine shop work is critical for proper bearing clearances and long-term engine reliability after rebuild.

Total cost implications and timeline for major engine rebuilds often approach or exceed engine replacement costs, particularly when high-quality components and professional machine work are used. Rebuild timelines typically extend several weeks due to machine work requirements and parts availability.

Engine Replacement Considerations

When replacement becomes more economical than rebuilding depends on engine availability, labor costs, and the extent of damage discovered during disassembly. Modern engines with extensive electronic integration often favor replacement over rebuilding due to the complexity and cost of restoring all systems to proper operation.

New versus remanufactured engine options offer different cost and reliability trade-offs. New engines provide maximum reliability and warranty coverage but at the highest cost. Remanufactured engines offer good reliability at moderate cost, while used engines provide the lowest initial cost but with greater risk of future problems.

Installation considerations and additional costs include peripheral component replacement (often required with engine swaps), fluid changes, break-in procedures, and potential modifications needed to integrate the replacement engine with existing vehicle systems. These additional costs can significantly impact the total replacement expense.

Warranty and reliability comparisons vary significantly between repair and replacement options. Quality rebuilds can provide excellent long-term reliability, while replacement engines typically offer warranty coverage that provides peace of mind. Consider both initial costs and long-term reliability when making decisions.

For detailed repair procedures and specifications for your specific engine, explore our comprehensive brand-specific technical resources covering major automotive and equipment manufacturers.

Prevention and Maintenance Strategies

Lubrication System Maintenance

Oil change intervals and quality requirements represent the most critical factor in preventing connecting rod bearing failure. Follow manufacturer recommendations religiously, but consider shorter intervals for severe service conditions like frequent towing, extreme temperatures, or stop-and-go driving. Use only oil grades specified by the manufacturer, as viscosity affects bearing lubrication critical for rod bearing life.

Oil pressure monitoring importance cannot be overstated for early problem detection. Regularly check oil pressure readings, particularly at idle when pressure is lowest. Install aftermarket oil pressure gauges if the vehicle lacks adequate monitoring equipment, and investigate any pressure changes immediately before they progress to bearing damage.

Warning sign recognition for oil system problems includes unusual engine noises, oil pressure fluctuations, rapid oil consumption increases, or oil contamination changes. Address these symptoms immediately rather than waiting for them to worsen, as oil system problems progress rapidly to expensive internal engine damage.

Proper oil selection for high-stress applications may require synthetic oils or specific additives for engines subject to racing, towing, or other demanding use. Consult manufacturer recommendations and consider upgrading oil specifications for engines operating under severe conditions that exceed normal passenger car use.

Operating Practices That Protect Connecting Rods

Proper warm-up procedures allow oil circulation to reach all bearing surfaces before subjecting the engine to load. Avoid high RPM operation until the engine reaches normal operating temperature, and allow oil pressure to stabilize before driving. Cold oil provides less effective lubrication and requires longer circulation time to reach critical bearing surfaces.

Rev limit respect and over-revving avoidance protects connecting rods from excessive mechanical stress that can cause immediate failure or create stress cracks leading to delayed failure. Understand your engine’s capabilities and avoid mechanical over-revving through improper downshifting or aggressive driving techniques.

Load management and towing considerations should account for increased bearing stress during heavy-load operation. Monitor oil pressure and engine temperature closely during towing, consider shorter oil change intervals for vehicles used for regular towing, and avoid sustained high-load operation without adequate cooling and lubrication system capacity.

Performance modification considerations must account for increased bearing stress from higher power output. Modified engines often require upgraded lubrication systems, shorter maintenance intervals, and higher-quality lubricants to handle increased bearing loads safely.

Regular Monitoring and Inspection

Oil analysis scheduling and interpretation provides early warning of bearing wear before symptoms become apparent. Regular oil analysis can detect bearing material in microscopic quantities, allowing preventive action before expensive damage occurs. Professional interpretation helps distinguish normal wear from problematic trends.

Audio monitoring habits for early detection involve becoming familiar with your engine’s normal sound characteristics so changes become immediately apparent. Regular listening during routine operation helps identify problems in early stages when repair options remain economical.

Performance baseline establishment includes documenting normal oil pressure readings, fuel economy, acceleration characteristics, and operating temperatures. These baselines help identify changes that might indicate developing problems before they become serious.

Professional inspection scheduling should include periodic assessment by qualified technicians familiar with your engine type, particularly for high-mileage engines or those operating under severe conditions. Professional inspection can identify developing problems that owner monitoring might miss.

Professional Resources and Emergency Guidance

Emergency Response Summary

Immediate shutdown criteria and procedures prioritize engine preservation over convenience. Any rhythmic knocking sound, sudden oil pressure loss, or dramatic performance changes require immediate shutdown regardless of location or circumstances. The cost of inconvenience pales compared to complete engine destruction from continued operation.

Safety priorities during roadside emergencies focus on personal safety first, then vehicle security. Use hazard lights, emergency triangles, and safe positioning to protect yourself while awaiting professional assistance. Never attempt complex engine diagnosis or repair in unsafe roadside conditions.

Contact priorities for professional help should include qualified engine rebuilding specialists, trusted automotive repair facilities with internal engine experience, and towing services equipped for potentially seized engines. Avoid general repair shops that lack specific internal engine expertise for complex connecting rod problems.

Documentation requirements for insurance claims include detailed symptom descriptions, maintenance records, driving conditions when failure occurred, and professional assessment of damage extent. Prompt documentation helps support coverage claims and provides necessary information for professional diagnosis.

Professional Consultation Framework

What information to provide to mechanics includes complete symptom descriptions, recent maintenance history, driving conditions when problems appeared, and any diagnostic steps already taken. Accurate information helps professionals provide better estimates and avoid unnecessary diagnostic time.

Questions to ask about repair options and costs should cover repair versus replacement recommendations, warranty coverage on work performed, timeline expectations, and cost breakdowns for different approaches. Understanding options helps make informed decisions about expensive engine work.

How to verify shop capabilities for internal engine work includes checking certifications, reviewing previous engine work examples, and confirming availability of proper machine shop services. Internal engine work requires specialized expertise that not all repair facilities possess.

Warranty and guarantee expectations for major engine work should include coverage periods, what work is included, and procedures for addressing problems that develop after repair. Quality engine work deserves appropriate warranty coverage that protects your investment.

Cost Planning and Decision Support

Repair versus replacement decision matrix should consider vehicle value, expected remaining service life, repair costs, and reliability requirements. Sometimes engine replacement provides better long-term value than extensive rebuild work, particularly for older or high-mileage vehicles.

Insurance coverage considerations may include mechanical breakdown coverage, extended warranties, or comprehensive policies that cover sudden mechanical failure. Review coverage options before expensive repairs are needed to understand what protection is available.

Transportation alternatives during repair help maintain mobility during extended repair periods. Consider rental vehicles, alternative transportation, or temporary vehicle arrangements when engine work requires significant time to complete properly.

Timeline expectations for different repair approaches vary significantly between bearing replacement, complete rebuilds, and engine replacement. Understanding realistic timelines helps plan for extended vehicle downtime and associated inconvenience or transportation needs.

For manufacturer-specific repair procedures and technical specifications, consult our extensive library of professional service manuals covering automotive, truck, and equipment applications from major manufacturers worldwide.

Critical Takeaways and Final Guidance

Understanding connecting rod problems requires recognizing their critical nature and the narrow window for preventing catastrophic damage. Unlike many engine problems that develop gradually, connecting rod bearing failure progresses rapidly from minor symptoms to complete engine destruction, often within minutes of continued operation after symptoms appear.

The most important warning signs to remember include any rhythmic knocking sound that correlates with engine RPM, sudden oil pressure changes, and unexplained power loss or engine roughness. These symptoms demand immediate shutdown and professional assessment – they are not problems that allow for “driving to the shop” or delayed attention.

Safety and immediate action remain the primary considerations when connecting rod problems are suspected. The potential for complete engine destruction within minutes of continued operation makes this one of the few automotive problems that truly requires immediate shutdown regardless of convenience or location. Professional help must come to you when connecting rod failure is suspected.

Professional consultation becomes essential for any suspected connecting rod problem due to the complexity of internal engine work, specialized tools required, and critical nature of proper diagnosis and repair. This is not an area for DIY experimentation – the stakes are simply too high for anything other than professional assessment and repair.

Remember that connecting rod problems, while serious, are often preventable through proper maintenance, quality lubrication, and attention to early warning signs. By understanding your engine’s normal characteristics and maintaining proper oil change intervals with quality lubricants, you can significantly reduce the risk of connecting rod failure and catch problems early when repair options remain economical.

Disclaimer: This information is provided for educational purposes only. Connecting rod problems require immediate professional attention due to their potential for catastrophic engine damage. Always prioritize safety and seek qualified professional help when internal engine problems are suspected. Improper diagnosis or continued operation can result in complete engine destruction and significant safety hazards.