How Traction Control Systems Work: Wheel Slip Management

Modern vehicles come equipped with sophisticated electronic safety systems designed to keep you in control during challenging driving conditions. Among these critical systems, traction control stands out as one of the most important innovations in automotive safety technology. Since becoming mandatory on all new vehicles sold in the United States in 2012, traction control has […]

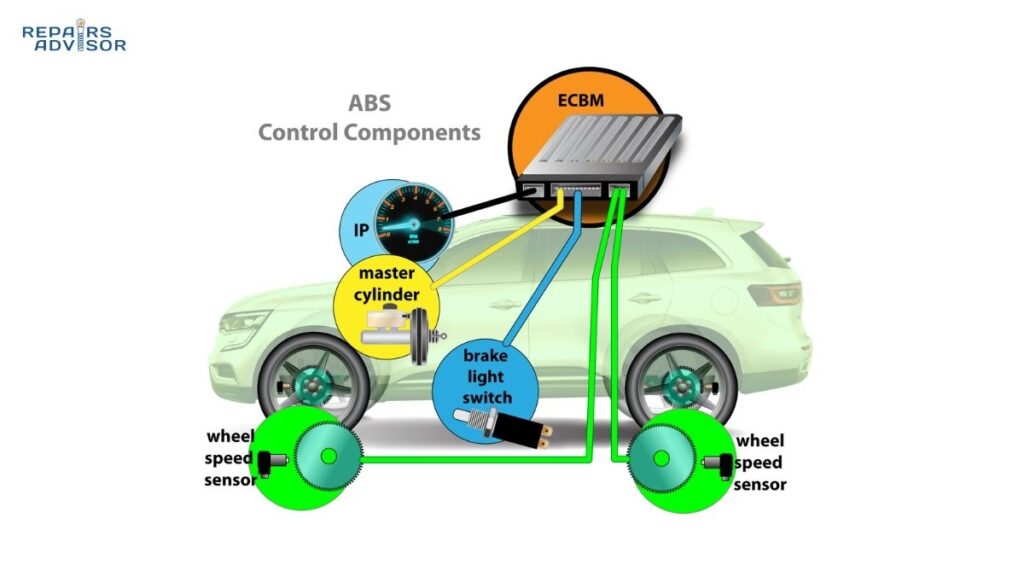

How ABS Systems Work: Anti-Lock Braking Technology

Imagine this scenario: You’re driving down a rain-slicked highway when the car ahead suddenly brakes. You slam on your brakes, but instead of skidding helplessly out of control, your vehicle maintains perfect directional stability as it comes to a controlled stop. You can still steer around the obstacle if needed. That’s the power of Anti-lock […]

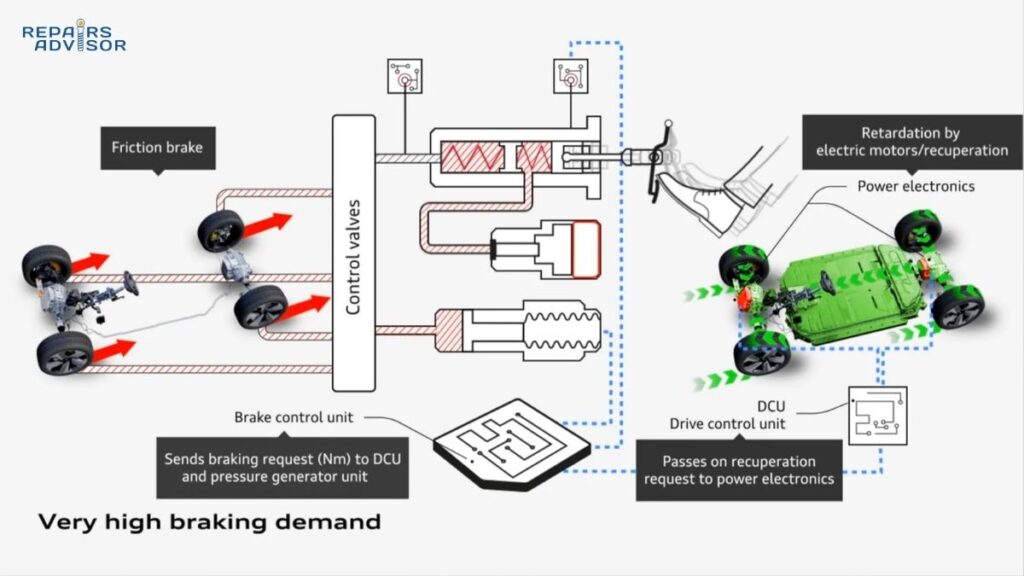

How Brake-by-Wire Systems Work: Electronic Braking

Modern vehicles are experiencing a fundamental transformation in how they stop. If you’ve driven a hybrid, electric vehicle, or recent high-performance car, you’ve likely experienced brake-by-wire technology without realizing it. This electronic braking system represents one of the most significant advances in automotive safety and efficiency since the introduction of anti-lock brakes. Brake-by-wire technology replaces […]

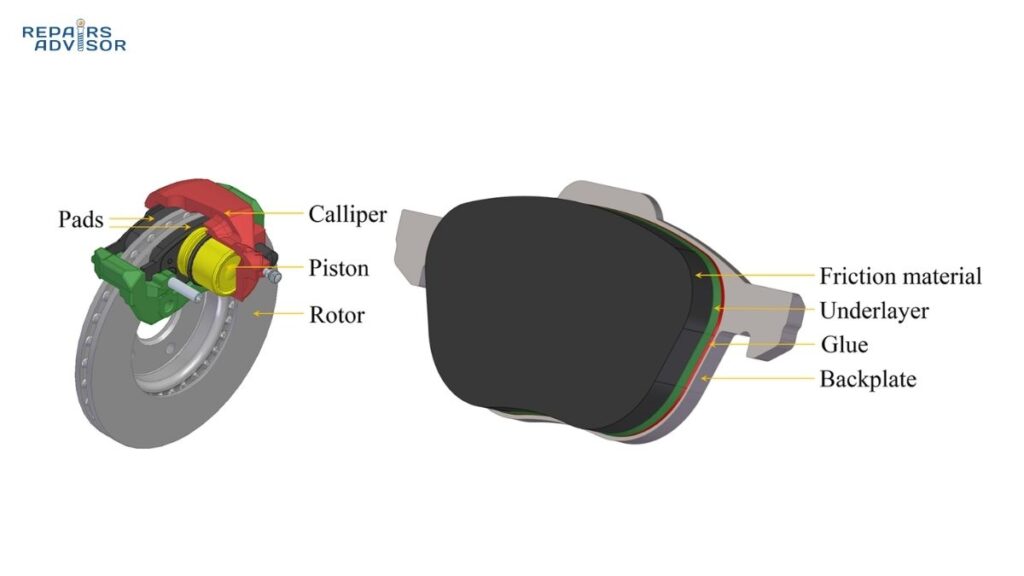

How Brake Pad and Rotor Tribology Works: Friction Science

Every time you press your brake pedal, your vehicle relies on tribology—the science of friction, wear, and lubrication—to safely convert kinetic energy into heat. This seemingly simple act of stopping involves complex interactions between materials operating under extreme conditions: high speeds up to 15 meters per second, contact pressures reaching 4 MPa, and temperatures soaring […]

How Brake Proportioning Valves Work: Force Distribution

Your vehicle’s brake system contains a critical safety component that most drivers never think about—the brake proportioning valve. This unassuming device plays a vital role in preventing dangerous rear wheel lockup during emergency braking, maintaining vehicle stability when you need it most. Understanding how this hydraulic pressure regulator works helps you recognize symptoms of failure […]

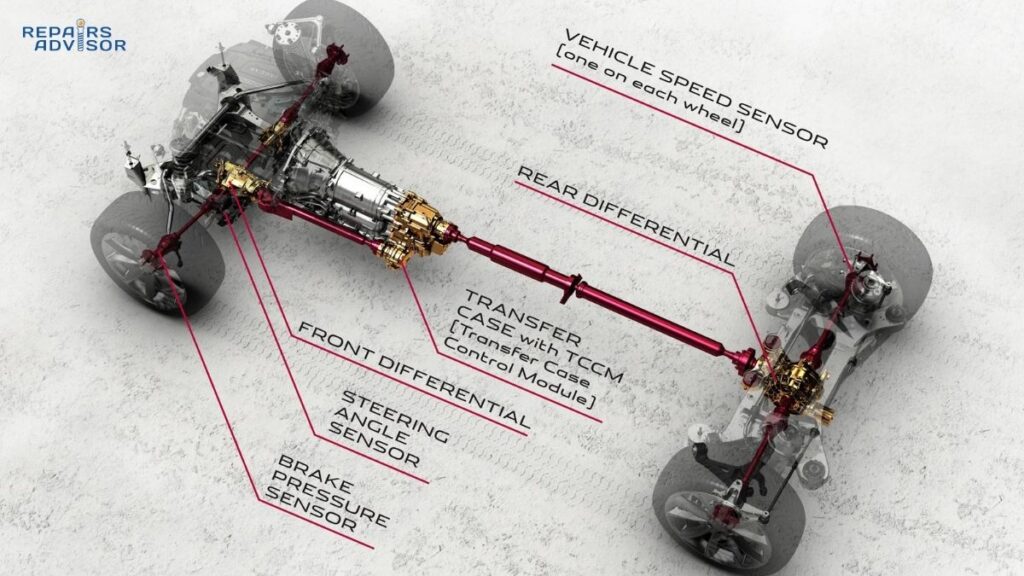

How AWD Systems Work: All-Wheel Drive Coupling

Imagine accelerating from a stoplight on a rain-slicked road. While other vehicles struggle for grip, wheels spinning uselessly, your car surges forward smoothly and confidently. This isn’t magic—it’s the result of an all-wheel drive system working behind the scenes, intelligently distributing power to all four wheels to maximize traction exactly when you need it. All-wheel […]

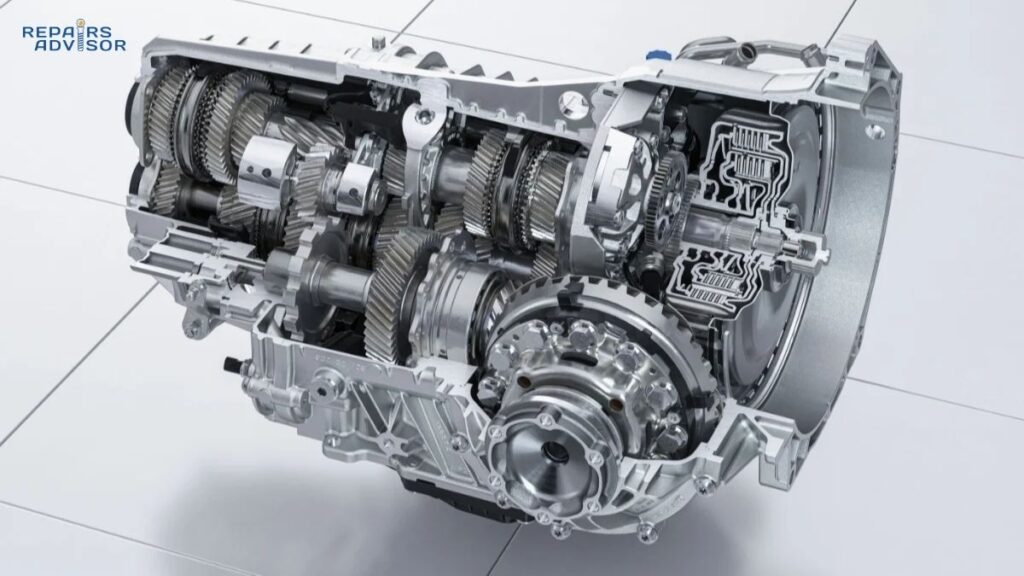

How Dual-Clutch Transmissions Work: Fast Shifting

Imagine shifting gears faster than the blink of an eye—literally. Modern dual-clutch transmissions can change gears in as little as 8 milliseconds, delivering seamless power without the fuel-wasting torque converter of traditional automatics or the skill demands of a manual gearbox. This “best of both worlds” technology has revolutionized both performance cars and everyday vehicles, […]

How Torque Converters Work: Fluid Coupling

If you’ve ever wondered how your automatic transmission vehicle can idle smoothly at a stoplight without stalling the engine, the answer lies in a remarkable component called the torque converter. This fluid coupling device replaces the mechanical clutch found in manual transmissions, using hydraulic pressure instead of friction plates to transfer power from your engine […]

How ATF and Friction Materials Work: Fluid Science

Your automatic transmission contains one of the most engineered fluids in your vehicle—automatic transmission fluid (ATF) is far more than just a lubricant. This specialized hydraulic fluid simultaneously lubricates moving parts, transmits power through the torque converter, cools internal components, and protects against wear—all while enduring temperatures from -40°F to nearly 400°F. Unlike engine oil, […]

How Automatic Transmission Mechatronics Work: Electronic Control

Modern automatic transmissions have evolved far beyond simple hydraulic systems. At the heart of today’s most advanced gearboxes sits a sophisticated component called the mechatronic unit—an integrated electronic-hydraulic control center that manages every aspect of gear shifting. Whether you’re experiencing shifting problems in your VW, diagnosing a dashboard warning in your Audi, or simply want […]

How Automatic Transmissions Work: Hydraulic Control Systems

Picture yourself stuck in rush hour traffic, creeping along at 5 mph, then accelerating to 70 mph on the highway—all without touching a clutch pedal or manually shifting gears. That seamless experience is thanks to one of the most sophisticated mechanical systems in your vehicle: the automatic transmission. This engineering marvel constantly monitors your driving […]

How Manual Transmission Synchronizers Work: Smooth Shifting Technology

If you’ve ever heard that sickening grinding sound when shifting gears, you’ve experienced synchronizer failure firsthand. That metallic crunch isn’t just unpleasant—it’s your transmission telling you something expensive is wearing out. Modern drivers take smooth gear changes for granted, but this seamless operation depends entirely on a set of precisely engineered components called synchronizers. Before […]