A failing clutch pilot bearing typically causes noise when the clutch pedal is pressed, particularly a grinding, squealing, or rattling sound from the transmission bell housing area. This small but critical bearing supports the input shaft when the clutch is disengaged. While diagnosis requires some mechanical experience, replacement involves full clutch removal – a complex job best suited for intermediate to advanced DIYers with proper tools and workspace. Most symptoms appear gradually, giving you time to plan the repair, but ignoring the problem can lead to transmission damage and more expensive repairs.

Critical Safety Note: Clutch pilot bearing replacement requires transmission removal and working under a raised vehicle. This repair is recommended for intermediate DIYers (2-5 years experience) with proper equipment and safety measures. Always prioritize safety and consider professional consultation when in doubt.

Understanding the Clutch Pilot Bearing

What Is a Clutch Pilot Bearing?

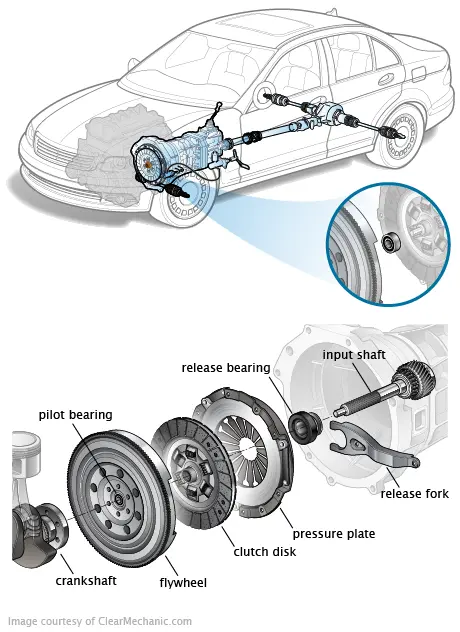

The clutch pilot bearing is a small but essential component located in the center of the crankshaft or flywheel. This bearing supports the front end of the transmission input shaft, but only when the clutch pedal is pressed and the clutch is disengaged. Think of it as a precision support system that keeps everything aligned when your transmission input shaft is spinning freely from the engine.

When you press the clutch pedal, you’re disconnecting the transmission from the engine’s power. During this moment, the pilot bearing becomes the sole support for the input shaft, preventing vibration and maintaining proper alignment. This seemingly simple function is critical for smooth gear shifting and long transmission life.

How the Pilot Bearing Works

Understanding the pilot bearing’s operation helps you diagnose problems more effectively. When the clutch is engaged (pedal released), the clutch disc connects the engine and transmission, and both rotate together as one unit. The pilot bearing isn’t doing much work in this state since everything moves together.

The real action happens when you press the clutch pedal. Now the engine and transmission are disconnected, but the input shaft continues spinning due to momentum from the transmission’s internal components. Without the pilot bearing, this free-spinning shaft would vibrate, wobble, and eventually damage the transmission’s internal synchronizers and bearings.

For intermediate DIYers, this understanding helps explain why pilot bearing problems often manifest as noise only when the clutch is pressed. The bearing is only under load during clutch operation, making diagnosis more predictable than other intermittent mechanical problems.

Common Pilot Bearing Types

Modern vehicles use three main types of pilot bearings, each with distinct characteristics:

Roller Bearings are the most common type, featuring small needle rollers in a metal cage. These provide excellent load capacity and are relatively inexpensive to replace. They’re found in most passenger cars and light trucks.

Ball Bearings use a sealed design with ball bearings instead of rollers. These tend to last longer and handle contamination better, making them popular in newer vehicles and harsh-duty applications.

Bronze Bushings are simpler designs used in older vehicles and heavy-duty applications. While less sophisticated, they’re extremely durable and can handle higher loads than bearing designs.

Skill Level Assessment: Are You Ready for This Diagnosis?

Beginner Level (0-2 years) – Foundation Building Phase

If you’re new to automotive repair, you can still contribute valuable diagnostic information. Focus on careful observation and documentation of symptoms. Listen for unusual noises during clutch operation and note exactly when they occur. Pay attention to changes in clutch pedal feel or shifting difficulty.

Safe diagnostic activities include monitoring symptoms during normal driving, learning to identify different types of mechanical noises, and understanding basic clutch system operation. However, pilot bearing diagnosis often requires getting under the vehicle and working around the transmission – areas that require more experience for safety.

Important boundary: Stick to observation and learning at this stage. Pilot bearing replacement requires transmission removal, which is beyond beginner scope. Use this time to build your foundation knowledge and observe professional techniques when possible.

Intermediate Level (2-5 years) – Your Prime Opportunity Zone

This repair falls squarely in the intermediate DIYer wheelhouse. You likely have the mechanical understanding and tool collection needed for proper diagnosis and potentially even replacement.

You’re ready for this challenge if you can:

- Safely operate floor jacks and jack stands with confidence

- Distinguish between different types of mechanical noises

- Have experience with manual transmission basics and clutch operation

- Feel comfortable working under vehicles with proper safety protocols

- Handle complex procedures with multiple steps and precise torque specifications

Your confidence-building approach should focus on methodical diagnosis using both auditory and tactile techniques. Document your findings carefully and don’t rush the process. Consider this an opportunity to expand your skills while tackling a genuinely useful repair.

Risk management strategy: Plan the repair during favorable weather with backup transportation available. Have your parts and tools ready before starting, and maintain a realistic timeline that accounts for potential complications.

Professional Level (5+ years) – Efficiency and Advanced Techniques

Experienced technicians can leverage pattern recognition and advanced diagnostic tools for faster, more accurate diagnosis. Consider using automotive stethoscopes for precise noise location and develop systematic approaches for differential diagnosis.

Time-saving professional techniques include quick bearing condition assessment during routine clutch inspections, recognizing early warning signs that prevent major failures, and educating customers about proper clutch operation to extend bearing life.

Cross-training opportunities exist in hydraulic clutch systems, dual-mass flywheel applications, and performance clutch upgrades where pilot bearing selection becomes more critical.

Primary Warning Signs of Pilot Bearing Failure

1. Noise During Clutch Operation – The Primary Indicator

The most reliable sign of pilot bearing failure is noise that occurs specifically when the clutch pedal is pressed. This isn’t just any noise – it has distinct characteristics that help you pinpoint the problem.

Grinding sounds indicate severe bearing failure with metal-on-metal contact. This is an emergency situation requiring immediate attention. The bearing has likely lost its lubrication completely, and continuing to drive risks transmission damage.

Squealing noises suggest the bearing is dry or contaminated but not completely destroyed. This high-pitched sound often starts intermittently and becomes more consistent as the problem worsens. You might notice it’s worse in cold weather when lubrication is thicker.

Rattling sounds point to loose bearing components or excessive wear in the bearing race. This creates a distinctive loose, chattering noise that’s different from engine or transmission sounds. It often has a rhythmic quality that matches input shaft rotation speed.

Chirping or whistling represents early-stage bearing wear. These sounds are subtle but consistent, often masked by engine noise until you specifically listen for them with the engine at idle.

Critical timing factor: The noise occurs primarily when the clutch pedal is pressed with the engine running. It may continue briefly after releasing the pedal as the input shaft winds down, but it shouldn’t persist during normal driving with the clutch engaged.

2. Difficulty Shifting Gears – The Secondary Warning

While not as reliable as noise symptoms, shifting difficulties often accompany pilot bearing problems. The connection lies in input shaft support – a failing bearing allows shaft movement that interferes with smooth synchronizer operation.

Early stage symptoms include slight resistance when shifting into first gear from neutral, especially when the engine is running. You might notice this most when starting from a parking spot or traffic light.

Progressive symptoms involve harder shifting into any gear from neutral, requiring more force or multiple attempts to engage properly. The resistance feels different from worn synchronizers – it’s more about alignment than grinding.

Advanced stage problems create grinding sensations when attempting to shift, indicating the input shaft is moving enough to prevent proper gear engagement. At this point, you’re risking transmission damage beyond just the pilot bearing.

Important distinction: Pilot bearing problems affect shifting from neutral more than gear-to-gear shifts while moving. If your primary problem is hard shifting between gears while driving, look elsewhere in the transmission or clutch system.

3. Clutch Pedal Behavior Changes – Subtle but Significant

Changes in clutch pedal feel provide supporting evidence for pilot bearing problems, though they’re rarely the primary symptom. A failing bearing can create vibrations and resistance changes that transmit through the clutch system.

Increased pedal effort might be required, though this is more commonly associated with hydraulic or cable problems. When related to pilot bearing failure, it’s usually accompanied by noise symptoms.

Vibration through the pedal during operation can indicate bearing roughness, especially if it correlates with the noise symptoms described earlier. This vibration has a different quality than engine vibration – it’s more mechanical and directly related to clutch operation.

Changes in pedal return feel or unusual resistance patterns during pedal travel sometimes accompany pilot bearing problems, though these symptoms have many possible causes throughout the clutch system.

For intermediate DIYers, use pedal behavior changes as supporting evidence rather than primary diagnostic criteria. Focus on the noise symptoms for reliable pilot bearing diagnosis.

Advanced Diagnostic Techniques

Professional Diagnostic Methods

For experienced DIYers ready to advance their diagnostic skills, several techniques provide definitive pilot bearing assessment. An automotive stethoscope becomes invaluable for isolating bearing noise from other clutch system sounds. Place the probe against the transmission bell housing while an assistant operates the clutch pedal. Compare noise levels and characteristics with the clutch engaged versus disengaged.

The input shaft movement test requires more advanced access but provides definitive diagnosis. With the transmission in neutral and engine off, check for excessive input shaft play. This test typically requires transmission access points that aren’t available on all vehicles, making it more suitable for professional shops or advanced DIYers with lift access.

Transmission fluid analysis can reveal metal particles indicating bearing deterioration. Look for unusual wear patterns in synchronizer rings and changes in fluid color or consistency. While not specific to pilot bearings, this analysis provides valuable supporting evidence.

Differential Diagnosis: Ruling Out Other Problems

Accurate diagnosis requires distinguishing pilot bearing problems from similar symptoms caused by other clutch system components. The throw-out bearing creates noise when the clutch pedal is pressed, but the sound location and characteristics differ from pilot bearing noise.

Clutch disc problems typically cause grabbing, slipping, or chattering symptoms rather than the specific noise patterns associated with pilot bearing failure. These problems are more noticeable during engagement and disengagement rather than while holding the pedal pressed.

Input shaft bearing problems within the transmission create internal noise that’s present regardless of clutch position. This helps distinguish internal transmission problems from clutch-related pilot bearing issues.

Motor mount problems can create vibrations that seem clutch-related but occur during engine operation regardless of clutch position. These symptoms are broader and less specific to clutch operation timing.

Isolation Testing Procedures

Systematic testing helps confirm pilot bearing diagnosis and rule out other problems. The engine running test compares noise levels with the clutch pedal pressed versus released, isolating the bearing’s operational window.

Gear selection testing determines if noise changes with different gear positions. Pilot bearing noise should remain consistent regardless of which gear is selected, since the bearing function doesn’t change with gear position.

RPM variation testing reveals how bearing noise responds to engine speed changes. Since the pilot bearing supports the input shaft during clutch operation, its noise characteristics may change with input shaft speed but shouldn’t directly correlate with engine RPM.

Risk Assessment and Urgency Planning

Immediate Attention Required

Certain symptoms demand immediate professional attention to prevent catastrophic transmission damage. Loud grinding noise with visible metal debris indicates complete bearing failure with metal-to-metal contact. Continuing to drive risks destroying transmission components worth thousands of dollars.

Complete inability to shift gears combined with pilot bearing noise symptoms suggests the bearing failure has progressed to input shaft misalignment. This creates a dangerous driving situation and requires immediate professional intervention.

Burning smell from the clutch area along with pilot bearing symptoms may indicate friction material damage from excessive heat generated by the failing bearing. Stop driving immediately and arrange professional inspection.

Plan Repair Soon (2-Week Timeline)

Consistent noise during clutch operation that doesn’t vary with driving conditions indicates stable bearing wear that will continue progressing. Plan repair within two weeks to prevent advancement to emergency status.

Increasing difficulty shifting that correlates with pilot bearing noise suggests the problem is affecting transmission operation. Address this promptly to maintain safe driving capability.

Progressive symptom worsening over days or weeks indicates accelerating bearing deterioration. Don’t wait for complete failure – plan repair while symptoms are manageable.

Monitor and Plan (2-Month Timeline)

Occasional noise during clutch operation that’s intermittent but identifiable provides time for planned repair. Use this period to gather parts, arrange workspace, and schedule the repair properly.

Slight changes in shifting feel without severe noise allow time for preparation, but don’t ignore these early warning signs indefinitely.

For intermediate DIYers, use monitoring periods to build confidence, gather resources, and plan the repair approach. Don’t let monitoring become procrastination that leads to emergency repairs.

Tools and Equipment Requirements

Essential Diagnostic Tools

Basic diagnostic kit includes a quality flashlight or work light for visual inspection, basic hand tools for accessing inspection points, and safety equipment including jack stands rated for your vehicle’s weight.

Intermediate diagnostic equipment adds an automotive stethoscope for precise noise location, basic measurement tools for assessing input shaft play, and a transmission fluid analysis kit for supporting evidence.

Advanced diagnostic tools include hydraulic lift access for comprehensive inspection, specialized transmission tools for detailed assessment, and precision measurement equipment for professional-level diagnosis.

Safety Equipment Priority

Safety equipment isn’t optional for clutch system work. Vehicle support systems must include jack stands rated above your vehicle’s weight, wheel chocks for additional security, and proper jack placement points to prevent vehicle shifting.

Personal protective equipment requires safety glasses for protection from debris and fluids, work gloves for hand protection, and appropriate clothing for working under vehicles.

Emergency equipment should include a fire extinguisher suitable for automotive fluids, since clutch work involves friction materials and various lubricants.

Remember that pilot bearing replacement requires transmission removal – a complex job requiring proper equipment and workspace. Don’t attempt this repair without adequate tools and safety equipment.

Preventive Maintenance and Early Detection

Regular Inspection Schedule

Establishing a routine inspection schedule helps catch pilot bearing problems early when repair is less complex and expensive. Every six months, listen specifically for clutch operation noises, monitor shifting smoothness, and note any changes in clutch pedal feel.

Annual professional evaluation provides expert assessment of the entire clutch system, including pilot bearing condition. This investment in professional inspection often prevents major failures and provides guidance for repair timing.

Driving pattern assessment during regular inspections helps identify habits that may accelerate pilot bearing wear. Professional evaluation can provide personalized recommendations for your driving style and vehicle usage.

Driving Habits That Protect Pilot Bearings

Proper clutch operation significantly extends pilot bearing life. Complete clutch engagement and disengagement reduces unnecessary wear, while avoiding partial engagement (“riding the clutch”) minimizes heat and stress on all clutch components.

Gentle shifting technique that doesn’t force gears when resistance is felt protects not only the pilot bearing but the entire synchronizer system. If gears won’t engage easily, investigate rather than force them.

Regular driving versus extended parking keeps bearing lubrication distributed and prevents corrosion from moisture accumulation. Vehicles driven regularly typically experience fewer sudden bearing failures.

Load management appropriate for your vehicle’s design prevents excessive stress on clutch components. Understanding your vehicle’s towing and load limits protects all drivetrain components including the pilot bearing.

Repair Planning and Professional Consultation

DIY Repair Readiness Assessment

Intermediate DIYer qualifications for pilot bearing replacement include access to proper vehicle lifting equipment, experience with transmission removal procedures, and a complete tool set specifically for clutch work.

Understanding of torque specifications and procedures is critical since improper reassembly can cause immediate failure or safety issues. The repair requires following complex sequences with precise specifications.

Workspace requirements include adequate room for transmission removal, proper ventilation for working with clutch materials, and secure vehicle support for extended repair time.

Time commitment planning should account for 6-8 hours for an experienced intermediate DIYer, with additional time for parts procurement and potential complications.

Professional Consultation Criteria

Clear indicators for professional referral include limited experience with clutch systems, lack of proper equipment or workspace, and uncertainty about diagnosis accuracy.

Vehicle considerations such as warranty status, daily transportation needs, and time constraints often make professional repair the practical choice regardless of DIY capability.

Complexity factors like hydraulic clutch systems, dual-mass flywheels, or performance modifications may require specialized knowledge and tools beyond typical DIY scope.

When consulting professionals, ask about complete clutch system condition, flywheel resurfacing needs, upgrade options for your driving style, and preventive maintenance recommendations for extending component life.

Cost Planning and Decision Making

Typical repair scope for pilot bearing replacement always includes clutch removal, creating an opportunity to address other clutch components simultaneously. Consider the cost-effectiveness of replacing the entire clutch assembly versus just the pilot bearing.

Budget considerations should include potential flywheel resurfacing, additional wear items discovered during disassembly, and special tools if purchasing rather than borrowing.

Professional repair costs typically range from $800-1500 depending on vehicle complexity and regional labor rates. Compare this against DIY costs including tools, parts, and time investment.

Value analysis should consider your skill development goals, available time, workspace access, and the satisfaction of completing complex repairs versus professional convenience and warranty protection.

Vehicle-Specific Applications and Considerations

Passenger Car Applications

Most passenger cars use roller-type pilot bearings with relatively straightforward replacement procedures. Import vehicles often have excellent parts availability and detailed service information, while domestic vehicles may offer more aftermarket upgrade options.

Modern vehicles increasingly use sealed pilot bearings with extended service intervals, but they’re often more expensive to replace when they do fail. Older vehicles may use simpler bronze bushing designs that are more durable but require different diagnostic approaches.

Light Truck and SUV Considerations

Heavier duty applications in trucks and SUVs often use bronze bushings instead of roller bearings, requiring different diagnostic techniques and replacement procedures. These applications typically see higher stress levels and may require more frequent service.

Four-wheel drive systems can complicate transmission removal and add complexity to pilot bearing replacement. Consider transfer case involvement and additional sealing requirements.

Performance modifications in trucks used for towing or off-road applications may benefit from upgraded pilot bearing designs capable of handling increased stress levels.

Performance and Modified Vehicle Applications

Performance vehicles with modified clutch systems may require upgraded pilot bearings to match the increased stress levels from performance driving or increased power output.

Upgraded bearing options include sealed designs, premium materials, and heavy-duty constructions designed for racing or high-performance applications.

System compatibility becomes critical when mixing performance clutch components. Ensure pilot bearing specifications match your clutch disc hub and input shaft requirements.

Learning Path and Skill Development

For Beginners: Building Your Foundation

Start with observation and documentation of symptoms while building your understanding of clutch system operation. Study how the clutch system works and practice identifying different types of mechanical noises in various situations.

Recommended learning progression begins with simpler clutch-related repairs like clutch adjustment procedures and brake system work that builds confidence with hydraulic systems and vehicle lifting procedures.

Knowledge building resources include service manuals for your specific vehicle, online educational content about manual transmission operation, and observation of professional diagnostic techniques when possible.

Safety skill development should emphasize proper vehicle lifting, jack stand placement, and working safely under vehicles – skills essential for eventual pilot bearing diagnosis and repair.

For Intermediate DIYers: Expanding Capabilities

Document your diagnostic process to build systematic approaches and create reference materials for future repairs. Photography and detailed notes help cement learning and provide valuable references.

Practice differential diagnosis techniques that distinguish between similar symptoms from different components. This skill proves valuable across many automotive repair situations beyond just pilot bearings.

Build relationships with parts suppliers who can provide technical support and quality components. Professional-grade parts often provide better longevity and performance than economy alternatives.

Consider upgrading your tool collection with diagnostic equipment like automotive stethoscopes and precision measurement tools that support more advanced repair capabilities.

For Professionals: Advanced Techniques and Efficiency

Develop customer education materials that explain pilot bearing function and the importance of addressing symptoms early. Education prevents emergency repairs and builds customer relationships.

Create diagnostic flowcharts that systematically rule out other problems and confirm pilot bearing diagnosis efficiently. Systematic approaches reduce diagnostic time and improve accuracy.

Consider offering pilot bearing inspection as part of routine clutch system maintenance, providing value-added services that prevent major failures and build customer loyalty.

Cross-training opportunities in hydraulic clutch systems, dual-mass flywheel applications, and performance clutch installations expand service capabilities and customer base.

When to Seek Professional Help

Understanding your limitations is as important as understanding your capabilities. Complex vehicle systems with hydraulic clutch actuation, electronic controls, or integrated all-wheel drive systems often require professional expertise and specialized tools.

Time and convenience factors may make professional repair practical even when you have the technical capability. Consider your schedule, backup transportation needs, and the value of your time versus cost savings.

Warranty considerations for newer vehicles may require professional repair to maintain coverage. Check warranty terms before attempting DIY repairs on covered components.

Safety concerns about proper procedures, tool adequacy, or workspace suitability should always err on the side of professional consultation. No repair is worth personal injury or vehicle damage from inadequate preparation.

Professional consultation provides expert diagnosis confirmation, access to specialized tools and equipment, warranty protection on work performed, and often faster completion than DIY approaches.

Questions for professional consultation should cover complete clutch system condition assessment, upgrade recommendations for your driving style, maintenance schedules for preventing future problems, and cost comparisons between repair options.

Conclusion and Action Plan

Pilot bearing problems develop gradually in most cases, providing time for planned response rather than emergency reaction. Early recognition through understanding characteristic noise patterns and operational symptoms allows for proper repair planning and prevents transmission damage.

Skill-appropriate response varies from careful monitoring and professional consultation for beginners to complete DIY repair for experienced intermediate mechanics. Honest assessment of your capabilities, workspace, and available time guides the best approach for your situation.

Safety priorities always come first in clutch system work. Proper vehicle support, adequate workspace, and appropriate tools are non-negotiable requirements for safe completion.

The pilot bearing’s small size belies its critical importance to clutch system operation and transmission longevity. Understanding its function, recognizing failure symptoms, and responding appropriately protects your investment in vehicle reliability and prevents much more expensive transmission repairs.

Professional consultation remains available when diagnosis questions arise, repair complexity exceeds your comfort level, or time constraints demand faster completion than DIY allows. The goal is successful repair completion, whether through your own efforts or professional expertise.

Remember: This diagnostic guide empowers you to identify pilot bearing problems early and make informed decisions about repair strategies. Pilot bearing replacement is a significant undertaking requiring proper preparation, tools, and safety measures. When in doubt, professional consultation ensures safe and effective repair completion.

For additional clutch system information and repair guides, visit our comprehensive brake system articles and explore our automotive troubleshooting resources for related diagnostic techniques. Professional-quality service manuals and technical documentation are available through our manual catalog to support your repair projects.