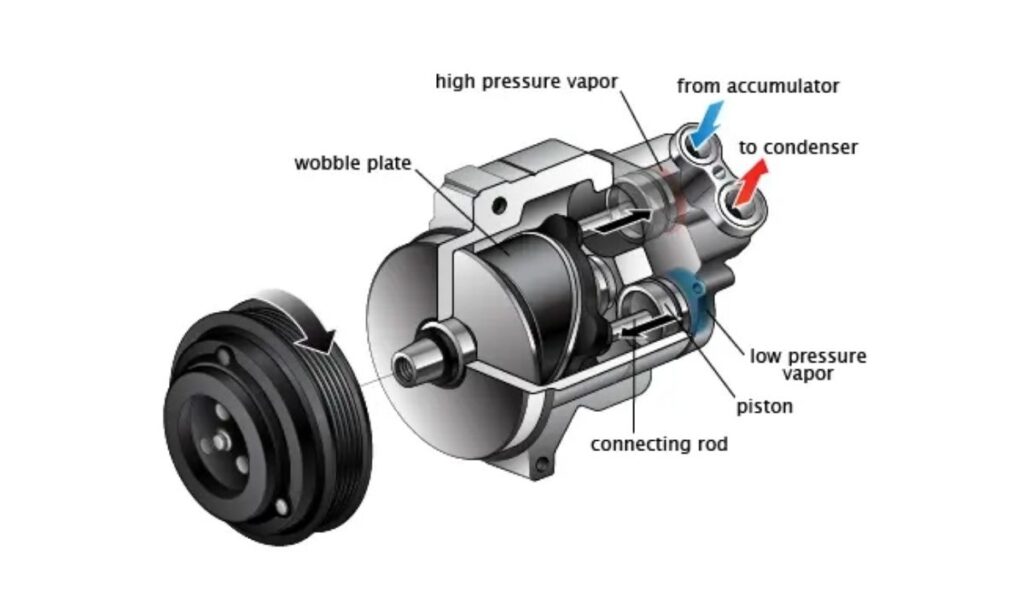

When you crave that delightful blast of cold air in your car, it all starts with one crucial component: the air conditioning (A/C) compressor. This powerful pump is the heart of your A/C system. Its job? To circulate refrigerant throughout the entire system and increase its pressure, which is absolutely essential for the cooling process.

Most A/C compressors are powered by your engine’s drive belt, but they only kick into action when you actually turn on your A/C. A special clutch engages, connecting the compressor to the engine’s power. However, newer vehicles, especially hybrids and electric cars, often use high-voltage electric compressors that run independently of the engine, providing instant cool air.

No matter the type, a healthy compressor is vital for your comfort. But if this “heart” starts to fail, your whole A/C system will feel the pain.

Key Signs Your A/C Compressor Is Giving Up

A faulty A/C compressor can cause a range of frustrating and often audible problems. Here’s what to keep an eye (and ear!) out for:

- A/C Blowing Warm Air (or Just Not Cold Enough):

- This is the most obvious and annoying symptom. If your A/C is on, but you’re getting only warm air, or perhaps air that’s cool but not truly cold, a failing compressor is a prime suspect. It simply can’t generate the necessary pressure to cool the refrigerant.

- Sometimes, you might experience intermittent cooling, where the air goes from cold to warm randomly. This could also point to a problem with the compressor clutch failing to engage consistently. Often, the clutch is an integrated part of the compressor and can’t be serviced separately, meaning a full compressor replacement is needed.

- Strange Noises From Under the Hood:

- Your A/C system should generally run quietly. If you hear rattling, grinding, or clunking noises when you turn on the A/C, it often indicates internal damage to the compressor. The bearings or other components inside might be wearing out.

- Even worse, if you hear a loud squealing sound from the engine drive belt, especially when you engage the A/C, it could mean the compressor is seizing up. A seized compressor puts immense strain on the belt, which can even cause it to break – leaving you stranded!

- Refrigerant Leaks (Often Invisible!):

- While refrigerant leaks can occur anywhere in the A/C system, a common spot for a failing compressor is the shaft seal. This seal can degrade over time, allowing refrigerant to escape.

- The tricky part? Refrigerant is colorless, odorless, and evaporates quickly, leaving no visible fluid behind. You won’t spot these leaks with the naked eye! That’s why professionals use special techniques, like introducing a UV-sensitive dye into the A/C system. When exposed to a UV light, the dye will glow brightly, revealing the leak’s exact location.

- Check Engine Light Illuminates:

- While not as common for traditional belt-driven compressors, the Check Engine Light can indeed illuminate due to an A/C compressor issue, particularly with high-voltage, electric compressors found in many hybrid and electric vehicles. If these sophisticated compressors malfunction, the vehicle’s computer system will detect the fault and set a relevant diagnostic trouble code.

How to Fix a Failing Air Conditioning Compressor

A faulty A/C compressor is a serious problem, and its repair is complex and best left to certified professionals. Here’s why:

- Professional Diagnosis is Paramount:

- Before condemning the compressor, always have your mechanic perform a thorough diagnosis of the entire air conditioning system. Symptoms of a bad compressor can sometimes mimic other issues, like low refrigerant, a bad pressure switch, or a faulty relay. A professional will use specialized gauges, leak detectors, and scan tools to accurately pinpoint the problem.

- Addressing the Root Cause (Often Lack of Lubrication):

- Surprisingly, most traditional A/C compressors don’t just fail “out of the blue.” Their failure is often a result of lack of lubrication, which typically happens when there’s a leak in the A/C system that leads to a low refrigerant level. Refrigerant carries the essential lubricating oil throughout the system. So, fixing the leak and ensuring proper lubrication is critical to prevent a new compressor from failing prematurely.

- Compressor Replacement:

- If the compressor is confirmed faulty, it must be replaced. This can be a costly repair due to the component’s price and the specialized labor involved.

- Specialized Equipment and Expertise Required:

- Refrigerant is a hazardous chemical. Improper handling can cause serious injury (like frostbite) and is extremely damaging to the environment. The A/C system operates under high pressure, adding to the danger.

- To replace the compressor, the A/C system must first be professionally evacuated (all old refrigerant safely removed and recovered) using special equipment. After the new compressor is installed, the system needs to be recharged with the correct type and amount of refrigerant and oil, a process that requires precise measurements and specialized tools.

- Contamination Check and Additional Replacements:

- If the old compressor suffered an internal failure (e.g., seized or broke apart), it might have contaminated the entire A/C system with metal shavings. In such cases, several other components, such as the condenser, expansion valve/orifice tube, and accumulator/receiver-drier, may also need to be replaced and the lines flushed to prevent immediate failure of the new compressor. This adds significantly to the repair cost but is vital for long-term reliability.

- High-Voltage Electric Compressors: A Deadly Warning:

- Servicing high-voltage, electric compressors (found in hybrids/EVs) is extremely dangerous. The electrical current from these hybrid systems can be deadly. Only highly trained professionals using proper safety equipment and following strict protocols should ever attempt to diagnose or replace an electric compressor. This is absolutely not a DIY job.

Your Repair Advisor’s Take:

Your A/C compressor is the powerhouse behind your car’s cooling. When it struggles, your comfort quickly disappears, and ignored symptoms can lead to more severe engine issues. Due to the high pressures, hazardous chemicals, and complex nature of the A/C system (especially with electric compressors), this is definitely not a job for the amateur.

Don’t try to fix A/C problems yourself beyond checking basic settings! A bad compressor can be a symptom of a larger issue.

For accurate diagnosis, safe handling of refrigerants, and a lasting repair, always consult a qualified automotive A/C technician. They have the specialized tools, training, and experience to safely get your A/C system running perfectly cold again. Stay cool and drive confidently – schedule a professional A/C system diagnostic today!