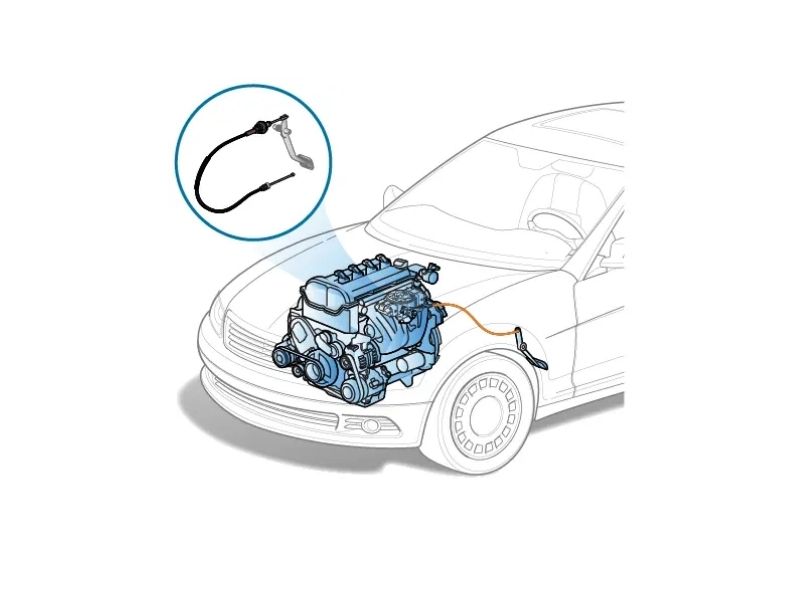

The accelerator cable is one of your vehicle’s most critical safety components, serving as the vital mechanical link between your gas pedal and the engine’s throttle system. This cable-operated mechanism translates your foot’s input directly into engine speed control, making it essential for safe vehicle operation. When functioning properly, the accelerator cable provides smooth, predictable throttle response that allows precise control over your vehicle’s speed and acceleration.

In cable-operated throttle systems, the accelerator cable connects the accelerator pedal assembly to either the throttle body in fuel-injected engines or the carburetor in older vehicles. Unlike modern electronic throttle control systems that use sensors and motors, cable systems rely on direct mechanical linkage to open and close the throttle valve. This mechanical connection means that any damage or deterioration to the cable can immediately affect your ability to control engine power.

The importance of a functional accelerator cable cannot be overstated from a safety perspective. A damaged cable can result in unpredictable throttle response, complete loss of acceleration control, or even a stuck throttle condition. These scenarios create dangerous driving situations that can lead to accidents, making early detection of cable problems crucial for vehicle safety.

This comprehensive guide will help you identify the warning signs of accelerator cable damage before they become safety hazards. You’ll learn to recognize symptoms ranging from subtle changes in pedal feel to obvious mechanical failures. We’ll cover both simple diagnostic techniques you can perform yourself and situations that require immediate professional intervention. Remember that while you can assess many symptoms on your own, any suspected accelerator cable damage should be professionally diagnosed and repaired to ensure your safety and that of other road users.

Understanding the Accelerator Cable System

Accelerator Cable Components

The accelerator cable system consists of several key components working together to provide reliable throttle control. The cable itself is constructed with a flexible inner wire made of multiple steel strands, surrounded by a protective outer housing or sheath. This design allows the cable to transmit pulling force while following the routing path from the pedal to the engine compartment.

The inner cable wire is typically made of high-tensile steel strands braided together for strength and flexibility. The outer housing protects the inner cable from environmental damage while providing a smooth surface for the cable to slide within. Most cables feature plastic or rubber boots at connection points to prevent moisture and debris from entering the cable housing.

Connection points include the pedal assembly attachment, where the cable connects to the accelerator pedal mechanism, and the throttle end, where it attaches to the throttle lever on the throttle body or carburetor. These connections often feature adjustment mechanisms that allow technicians to set proper cable tension and ensure optimal throttle response.

How the System Works

The accelerator cable operates on a simple but effective mechanical principle. When you press the accelerator pedal, the cable pulls the throttle valve open, allowing more air and fuel into the engine. The degree of pedal depression determines how far the throttle opens, directly controlling engine speed and power output.

Cable tension plays a crucial role in smooth operation. Proper tension ensures immediate throttle response without binding or excessive slack. Too much tension can cause binding and premature wear, while insufficient tension creates delays in throttle response and poor pedal feel.

The return spring system is equally important, ensuring the throttle closes completely when you release the accelerator pedal. This spring-loaded mechanism pulls the throttle valve closed and returns the pedal to its rest position. For optimal performance, understanding how your car’s engine works helps you appreciate the critical role of precise throttle control.

Common Cable Types and Configurations

Vehicle manufacturers use different cable configurations depending on the specific application. Single cable systems are most common in passenger cars, using one cable to control throttle opening. The cable pulls the throttle open, while spring pressure closes it when the pedal is released.

Dual cable systems, found in some performance vehicles and motorcycles, use separate cables for opening and closing the throttle. This push-pull arrangement provides more precise control and reduces the likelihood of a stuck throttle condition. One cable pulls the throttle open while the other actively pulls it closed.

Different vehicle types require specific cable configurations. Cars typically use longer cables that must navigate around various engine components, while motorcycles often have shorter, more direct routing. Heavy-duty trucks may use reinforced cables designed to handle increased loads and harsh operating conditions. Understanding your specific system helps you better identify potential problems and communicate effectively with service technicians.

Primary Signs of Accelerator Cable Damage

Pedal Feel and Response Issues

Sticky or Binding Accelerator Pedal

One of the most noticeable signs of accelerator cable problems is a sticky or binding pedal that doesn’t return smoothly to the idle position. When your accelerator pedal hesitates or catches during operation, this typically indicates increased friction within the cable system. You might notice that the pedal requires unusual effort to depress or doesn’t spring back immediately when released.

This binding sensation often starts subtly and progressively worsens over time. Initially, you might experience slight hesitation only during cold weather or after the vehicle has been parked for extended periods. As the condition deteriorates, the binding becomes more frequent and noticeable during all driving conditions.

The increased effort required to operate a binding pedal can lead to driver fatigue, especially during stop-and-go traffic or long drives. More importantly, this condition can delay your ability to reduce speed quickly in emergency situations, creating a significant safety hazard.

Loose or Sloppy Pedal Feel

Excessive play in the accelerator pedal before throttle engagement indicates cable stretch or wear at connection points. This loose pedal feel creates a disconnect between your foot input and engine response, making precise speed control difficult. You might notice that you have to press the pedal further than normal before the engine begins to respond.

This condition often develops gradually as the cable stretches over time or as mounting points wear. The symptom is particularly noticeable when attempting smooth acceleration or maintaining steady speeds. The pedal may feel “mushy” or unresponsive, requiring larger inputs to achieve desired throttle changes.

Inconsistent pedal resistance accompanies this loose feel, where the effort required to move the pedal varies unpredictably. This inconsistency makes it challenging to achieve smooth acceleration and can cause jerky driving behavior that affects passenger comfort and vehicle control.

Hard or Stiff Pedal Operation

When the accelerator pedal becomes unusually hard or stiff to operate, this often indicates cable binding, corrosion, or damaged cable housing. A properly functioning accelerator pedal should move smoothly and require minimal effort throughout its entire range of motion. Stiffness typically develops when the cable can no longer slide freely within its housing.

This condition frequently worsens in cold weather when moisture within the cable housing can freeze, creating additional binding. You might notice that the pedal operates more freely after the engine warms up and heat reaches the cable routing areas. However, any persistent stiffness indicates underlying cable damage that requires attention.

Driver fatigue becomes a significant concern with a stiff accelerator pedal, particularly during extended driving periods. The additional force required can cause leg cramping and reduced driver alertness, indirectly affecting driving safety.

Engine Response Problems

Delayed Throttle Response

Lag between pedal input and engine acceleration is a clear indicator of accelerator cable problems. When you press the accelerator pedal, the engine should respond immediately with increased RPM. Any noticeable delay suggests that the cable is not transmitting your input efficiently to the throttle mechanism.

This delay can manifest as a brief pause before acceleration begins or as gradual, sluggish response to pedal changes. The condition is particularly dangerous during highway merging, passing maneuvers, or emergency acceleration situations where immediate power delivery is crucial for safety.

Inconsistent power delivery often accompanies delayed response, where similar pedal inputs produce varying engine reactions. This unpredictability makes it difficult to anticipate vehicle behavior and can lead to driving errors or dangerous situations.

Erratic or Hunting Idle

When accelerator cable damage affects the throttle’s ability to return to its proper idle position, you’ll notice unstable engine RPM at idle. The engine may surge, hunt, or fluctuate in speed even when your foot is completely off the accelerator pedal. This condition indicates that the throttle valve is not closing completely or is binding in a partially open position.

Hunting idle creates more than just an annoyance; it can affect transmission behavior in automatic vehicles and make smooth stops difficult. The varying engine speed can cause the vehicle to creep forward inconsistently when stopped, requiring constant brake pressure to maintain position.

This symptom often worsens over time and may be accompanied by higher than normal idle speeds. If you notice your engine running faster at idle than usual, especially combined with other cable symptoms, immediate inspection is warranted.

Limited Throttle Range

Inability to achieve full throttle opening represents a serious accelerator cable problem that limits vehicle performance and can create dangerous situations. When the cable cannot pull the throttle to its fully open position, your engine cannot produce maximum power, affecting acceleration and highway passing ability.

This limitation might start as a slight reduction in top-end power and gradually worsen until you can only achieve partial throttle opening. You might notice that the accelerator pedal reaches its maximum travel before the engine reaches its peak RPM, or that acceleration becomes progressively weaker at higher speeds.

Reduced power capability is particularly dangerous during emergency maneuvers or when attempting to merge into fast-moving traffic. The inability to access full engine power when needed can turn routine driving situations into hazardous scenarios.

Visible Cable Damage

Frayed or Broken Cable Strands

Visible wire breaks or fraying in the accelerator cable represent immediate failure risks that require urgent attention. The inner cable consists of multiple steel strands, and when these strands begin breaking, the remaining wires must carry increased load, accelerating the failure process.

Frayed cable ends often appear fuzzy or split, with individual wire strands visible at connection points. This damage typically occurs due to repeated flexing, corrosion, or excessive tension. Once fraying begins, complete cable failure can happen suddenly and without warning.

Cable separation at connection points is particularly dangerous because it can result in immediate loss of throttle control. Regular visual inspection of cable ends and connection points helps identify this condition before complete failure occurs.

Damaged Cable Housing

Cracked, split, or kinked outer housing compromises cable operation and accelerates inner cable wear. The protective housing keeps moisture and debris away from the inner cable while providing a smooth surface for cable movement. When this housing is damaged, increased friction and corrosion rapidly deteriorate cable function.

Kinked housing often results from improper routing or impact damage and creates tight bends that bind cable movement. These kinks are usually visible as sharp bends or flattened sections in the cable housing and immediately affect throttle response.

Corrosion or rust on cable components, particularly at connection points and housing ends, indicates moisture infiltration that will progressively worsen cable operation. This corrosion often appears as brown or orange discoloration and may be accompanied by white or green corrosion deposits.

⚠️ Critical Safety Note: Any suspected accelerator cable damage requires immediate attention. A broken cable can result in loss of throttle control, creating dangerous driving conditions. If you observe visible cable damage or experience significant symptoms, discontinue driving and seek professional service immediately.

Secondary Symptoms and Related Issues

Intermittent Problems

Intermittent accelerator cable issues often prove more challenging to diagnose than consistent symptoms, but they’re equally important warning signs. Occasional sticking that resolves itself might seem minor, but it indicates progressive cable deterioration that will worsen over time. These intermittent symptoms typically occur during specific conditions such as cold weather startup, after extended parking periods, or during particular driving maneuvers.

Temperature-related symptoms are particularly common with aging accelerator cables. Cold weather can cause moisture within the cable housing to thicken lubricants or even freeze, creating temporary binding that improves as the system warms up. However, the fact that cold weather reveals these symptoms indicates that cable wear has progressed to a point where environmental factors significantly affect operation.

The progressive nature of cable deterioration means that intermittent problems inevitably become constant issues. What starts as occasional morning stiffness develops into persistent binding, and temporary response delays evolve into significant throttle lag. Recognizing these early warning signs allows you to address cable problems before they create safety hazards.

Associated System Effects

Transmission Behavior Changes

Accelerator cable problems significantly impact automatic transmission operation because the transmission relies on throttle position signals for proper shift timing and line pressure control. Delayed or harsh shifting often accompanies accelerator cable issues as the transmission struggles to interpret inconsistent throttle signals. When the cable cannot provide smooth, predictable throttle movement, the transmission’s adaptive systems become confused.

Difficulty achieving smooth acceleration affects more than just driving comfort; it can cause premature transmission wear and reduced fuel economy. The transmission may upshift too early due to inconsistent throttle signals, or it may remain in lower gears longer than necessary, affecting both performance and efficiency.

Modern vehicles with sophisticated transmission control systems are particularly sensitive to throttle inconsistencies. These systems monitor throttle position multiple times per second and adjust shift patterns accordingly. When accelerator cable problems create erratic throttle signals, the transmission may enter “limp mode” or display warning lights. For more information about transmission systems, consult our comprehensive guides on transmission diagnostics and troubleshooting.

Engine Management Reactions

Modern engine management systems continuously monitor throttle position and compare it to accelerator pedal input. When accelerator cable problems create mismatches between expected and actual throttle position, the engine computer may activate the check engine light and store diagnostic trouble codes. These codes often relate to throttle position sensor circuits or idle air control systems.

The engine’s adaptive learning systems attempt to compensate for cable-related throttle inconsistencies by adjusting fuel delivery and ignition timing. While this compensation helps maintain drivability, it often results in reduced performance and fuel economy. The engine computer may also limit power output when it detects throttle system irregularities, creating additional performance symptoms.

Stored trouble codes related to accelerator cable problems typically include throttle position sensor codes, idle air control codes, and sometimes fuel system codes. For specific diagnostic information, refer to our detailed coverage of P-codes for engine and transmission issues.

Environmental and Usage Factors

Weather conditions significantly affect accelerator cable operation, with cold temperatures being particularly problematic for aging cables. Moisture that enters damaged cable housing can freeze, creating temporary binding that may seem to resolve as temperatures rise. However, this freeze-thaw cycle accelerates cable deterioration and indicates that housing integrity has been compromised.

Driving habits also influence cable longevity. Frequent aggressive acceleration puts additional stress on cable components, while consistent highway driving at steady speeds places less demand on the cable system. Vehicles used primarily for stop-and-go city driving experience more cable wear due to constant throttle position changes.

Age-related deterioration follows predictable patterns, with cables typically developing problems after five to ten years of service, depending on environmental conditions and usage patterns. Vehicles operated in harsh climates, such as areas with road salt or high humidity, often experience accelerated cable deterioration due to increased corrosion rates.

Diagnostic Methods and Testing

Visual Inspection Techniques

Under-Hood Inspection

Locating the accelerator cable routing is your first step in visual diagnosis. Follow the cable from the throttle body or carburetor connection point back toward the firewall where it enters the passenger compartment. The cable routing typically follows a path that avoids hot engine components and sharp edges, often secured with clips or brackets along the way.

Check for obvious damage such as kinks, cracks in the housing, or frayed cable ends at connection points. Pay particular attention to areas where the cable bends around corners or passes through mounting points, as these locations experience the highest stress and are most prone to failure.

Inspect connection points and adjustment mechanisms for proper attachment and signs of wear. The cable should be securely attached at both ends without excessive slack or tension. Look for corrosion, loose hardware, or damaged mounting brackets that could affect cable operation.

Pedal Assembly Examination

Remove floor mats and any covers to gain clear access to the pedal assembly area. This inspection allows you to observe the cable connection to the pedal mechanism and check for binding or interference issues that might not be apparent from under the hood.

Check pedal movement by manually operating the accelerator pedal through its full range while observing the cable connection. The cable should move smoothly without binding, and the pedal should return completely to its rest position when released. Any hesitation or incomplete return indicates problems requiring further investigation.

Identify potential binding or interference by looking for obstacles that might impede pedal movement, such as floor mats, aftermarket accessories, or debris that has accumulated around the pedal assembly. Sometimes simple cleaning or repositioning of accessories can resolve minor pedal binding issues.

Functional Testing Methods

Static Pedal Tests

With the engine off, test pedal return action by pressing and releasing the accelerator pedal while observing its movement. The pedal should move smoothly through its entire range and return immediately to the idle position when released. Any sticking, binding, or incomplete return indicates cable problems.

Check for smooth operation by pressing the pedal slowly and feeling for any rough spots, catches, or points of increased resistance. These sensations often indicate internal cable damage or binding within the housing. The pedal effort should remain consistent throughout its travel range.

Assess the pedal-to-cable connection integrity by observing the cable movement as you operate the pedal. There should be no visible slack or delay between pedal movement and cable response. If you can move the pedal without immediate cable movement, this indicates wear or damage at the connection point.

Dynamic Engine Tests

Safe testing with the engine running requires extreme caution and should only be performed in a safe, controlled environment. With the vehicle securely parked and the parking brake engaged, start the engine and observe throttle response as you slowly operate the accelerator pedal. The engine should respond immediately and smoothly to pedal inputs.

Monitor idle stability by allowing the engine to idle with your foot completely off the accelerator pedal. The engine should maintain steady RPM without hunting or fluctuation. Any instability suggests that the cable is not allowing the throttle to close properly.

Test throttle response correlation by making small pedal inputs and observing engine response. There should be no delay or inconsistency between pedal movement and engine speed changes. If you notice any mismatch between pedal input and engine response, discontinue testing and seek professional diagnosis.

Advanced Diagnostic Approaches

Professional diagnosis often involves using OBD scanners to monitor throttle position sensor data while operating the accelerator pedal. This testing can reveal inconsistencies between pedal position and actual throttle opening that indicate cable problems. However, this level of diagnosis typically requires professional equipment and expertise.

Cable tension measurements require specialized tools and knowledge of manufacturer specifications. Professional technicians can measure cable tension and adjust it to proper specifications, ensuring optimal throttle response and cable longevity.

Comparative testing with known good vehicles of the same model can help identify subtle problems that might not be obvious during individual vehicle assessment. However, this approach requires access to similar vehicles and should only be performed by experienced technicians.

Safety Protocols:

- Never perform dynamic testing alone; always have someone nearby who can assist in case of emergency

- Ensure the vehicle is on level ground with the parking brake firmly engaged

- Keep testing sessions brief to avoid overheating or other complications

- Stop testing immediately if you notice any dangerous symptoms such as stuck throttle or loss of engine control

- If symptoms suggest imminent cable failure, discontinue driving and arrange for professional service

Common Causes of Accelerator Cable Damage

Normal Wear and Aging

Accelerator cables typically have a service life of 100,000 to 150,000 miles under normal operating conditions, though this can vary significantly based on environmental factors and usage patterns. The constant flexing and tension cycles that occur during normal driving gradually weaken the cable’s internal wire strands and wear the protective housing.

Several factors accelerate normal wear beyond expected service intervals. Frequent stop-and-go driving creates more throttle position changes than highway driving, increasing the number of cable movement cycles. Aggressive driving habits that involve rapid throttle changes also contribute to accelerated wear by placing higher stress loads on cable components.

Preventive maintenance can significantly extend cable life, though many vehicle owners overlook accelerator cable service. Regular lubrication of cable mechanisms and periodic inspection for early wear signs help identify problems before they become safety hazards. Understanding your vehicle’s maintenance requirements helps ensure reliable cable operation throughout its service life.

Environmental Damage

Corrosion and Rust

Salt exposure from winter road treatments or coastal environments aggressively attacks steel cable components, causing both surface corrosion and internal damage that compromises cable integrity. Road salt creates an electrolytic environment that accelerates corrosion, particularly at cable connection points where moisture can accumulate.

Moisture damage to cable housing often begins as minor cracks or worn areas that allow water infiltration. Once moisture enters the cable housing, it creates an environment where corrosion develops rapidly, especially in areas where the cable flexes during operation. This internal corrosion increases friction and eventually causes cable binding or failure.

Chemical exposure from engine fluids, cleaning products, or industrial environments can deteriorate cable housing materials and contaminate internal lubricants. Modern vehicles route cables away from most chemical hazards, but leaking fluids or improper cleaning procedures can still cause significant damage to cable systems.

Temperature Extremes

Cold weather brittleness affects both cable materials and internal lubricants, making cables more susceptible to binding and breakage during winter months. Low temperatures can cause cable housing to become rigid and internal lubricants to thicken, increasing the force required for cable operation and accelerating wear.

Heat damage typically occurs when cables are routed too close to exhaust components or other high-temperature engine parts. Excessive heat can cause cable housing to soften or crack and may break down internal lubricants, leading to increased friction and premature failure.

Thermal cycling between hot and cold conditions creates expansion and contraction stresses that fatigue cable materials over time. This cycling is particularly problematic in climates with extreme temperature variations, where cables experience wide temperature ranges during daily use.

Mechanical Damage

Improper installation or adjustment during service can immediately create cable problems or accelerate normal wear. Incorrect cable routing that creates tight bends or contact with sharp edges will cause premature failure. Over-tightening cable adjustments places excessive tension on components, while loose adjustments create slack that affects throttle response.

Physical damage from road debris, minor accidents, or contact with other components can compromise cable integrity without creating immediately obvious symptoms. Small nicks in cable housing or bent cable routing can gradually worsen into significant problems that affect vehicle safety.

Interference with other components sometimes develops as vehicles age and components shift or wear. Engine mounts that settle over time can change cable routing, creating new stress points or contact areas that accelerate wear. Aftermarket accessories or modifications can also create interference problems if not properly installed.

Maintenance-Related Issues

Lack of proper lubrication is one of the most common causes of premature accelerator cable failure. The cable mechanism requires periodic lubrication to operate smoothly and prevent corrosion. Many vehicle owners are unaware that accelerator cables need maintenance, leading to binding and premature wear.

Incorrect cable routing during repair or replacement work creates stress concentrations that accelerate failure. Professional installation ensures that cables follow manufacturer-specified routing paths that minimize stress and avoid contact with hot or sharp components.

Aftermarket modifications that affect throttle systems can place unexpected loads on accelerator cables or change their operating characteristics. Performance modifications, in particular, may require upgraded cable systems to handle increased loads or different throttle mechanisms.

For vehicle-specific maintenance requirements and cable service procedures, consult the appropriate service manuals. Our extensive collection includes detailed maintenance information for all major manufacturers: FORD Manuals, CHEVROLET Manuals, TOYOTA Manuals, and many others available through our complete brand directory.

Safety Implications and Risks

Immediate Safety Hazards

Complete throttle control loss represents the most serious safety hazard associated with accelerator cable failure. When a cable breaks completely, you lose all ability to increase engine speed, severely limiting your ability to accelerate, merge with traffic, or respond to emergency situations. This condition requires immediate recognition and appropriate response to maintain vehicle control and safety.

Stuck throttle emergency procedures are critical knowledge for any driver. If your accelerator pedal becomes stuck in a depressed position, immediately shift to neutral (or press the clutch in manual transmissions), apply steady brake pressure, and safely exit traffic. Never turn off the ignition while moving, as this will disable power steering and brake assist systems. Once safely stopped, turn off the engine and seek immediate professional service.

Safe stopping techniques with cable failure involve maintaining calm control while managing reduced vehicle capabilities. Plan your route to avoid situations requiring rapid acceleration, such as highway merging or passing slower traffic. Increase following distances to compensate for reduced acceleration capability and avoid driving situations where full throttle might be necessary for safety.

Progressive Risk Assessment

Minor symptoms often indicate that major failures are approaching, making early intervention crucial for maintaining safety. A slightly sticky pedal that resolves itself may seem insignificant, but it often indicates internal cable damage that will progressively worsen until complete failure occurs.

Warning signs that require immediate action include any sticking or binding that doesn’t resolve quickly, visible cable damage, or significant changes in pedal feel or throttle response. These symptoms indicate that cable integrity has been compromised to a degree where failure could occur without warning.

Risk factors that accelerate cable deterioration include exposure to road salt, extreme temperature variations, high-mileage vehicles, and aggressive driving habits. Vehicles operating under these conditions require more frequent cable inspection and earlier replacement to maintain safety margins.

Emergency Response Procedures

If the accelerator sticks while driving, your immediate response determines the outcome of this dangerous situation. First, attempt to lift the pedal with your foot while maintaining steering control. If this doesn’t resolve the problem, immediately shift to neutral to disconnect engine power from the wheels, then apply steady brake pressure to safely slow the vehicle.

Safe shutdown procedures for cable failure vary depending on the specific problem. For a stuck accelerator, neutralizing the transmission and braking to a stop is the priority. For complete loss of acceleration, maintain control while safely exiting traffic and finding a secure stopping location.

Emergency roadside assessment should focus on determining whether the vehicle is safe to drive to a service facility or requires towing. Never attempt temporary repairs on accelerator cable systems, as improper fixes can create additional safety hazards. If you have any doubt about the safety of continuing to drive, err on the side of caution and call for professional assistance.

Critical Safety Emphasis:

- Never ignore accelerator cable symptoms, regardless of how minor they may seem

- Any visible cable damage or significant change in pedal feel requires immediate professional inspection

- When in doubt about safety, stop driving and seek professional evaluation

- Emergency situations require calm, deliberate responses focused on maintaining vehicle control

When to Replace vs. Repair

Repairable Conditions

Minor adjustment issues often resolve accelerator cable problems without requiring cable replacement. Proper cable tension adjustment can eliminate excessive pedal play or slightly stiff operation, provided the cable itself remains structurally sound. These adjustments require specific knowledge of manufacturer specifications and should typically be performed by qualified technicians.

Lubrication and cleaning solutions can resolve binding problems caused by contaminated or dried lubricants within the cable housing. However, this approach only works when the cable housing remains intact and internal cable strands haven’t been damaged. Professional assessment determines whether lubrication will provide a lasting solution or merely temporary improvement.

Temporary fixes for emergency situations might include cable lubrication or minor adjustments to get you to a service facility safely. However, these measures should never be considered permanent solutions, and professional evaluation should occur as soon as possible after any emergency repair.

Replacement Indicators

Irreversible cable damage includes frayed or broken cable strands, cracked housing, or significant corrosion that affects cable operation. Once internal cable strands begin breaking, the remaining strands carry increased load that accelerates failure of the entire cable. Similarly, damaged housing that allows moisture infiltration will continue to cause problems regardless of other repairs.

Cost-effectiveness analysis often favors replacement over attempted repairs, especially for high-mileage cables or those showing multiple symptoms. The labor cost for cable replacement is typically similar to that for extensive repair attempts, while new cables provide reliable long-term service.

Safety considerations always favor replacement when there’s any doubt about cable integrity. The critical nature of throttle control means that marginal cables pose unacceptable risks. Professional technicians typically recommend replacement rather than repair for any cable showing significant wear or damage.

Professional Assessment Guidelines

Complexity factors requiring expert evaluation include proper cable routing, tension adjustment, and integration with other throttle system components. Modern vehicles often have complex cable routing that requires specific knowledge to ensure proper installation and operation. Improper installation can create new problems or accelerate premature failure.

Warranty considerations for replacement work vary by service provider and parts manufacturer. Quality replacement cables typically include warranties that cover defects and premature failure, providing additional value and peace of mind. Discuss warranty coverage with your service provider before authorizing replacement work.

Integration with other system maintenance presents opportunities to address related issues during cable replacement. Throttle body cleaning, idle air control system service, or transmission service might be appropriate during cable replacement, potentially saving labor costs and ensuring optimal system performance.

Service Recommendations:

- Seek service providers with specific experience in your vehicle make and model

- Ask about warranty coverage for both parts and labor

- Request explanation of the specific cable problem and why replacement is recommended

- Understand the estimated timeline for completion and any driving restrictions during the repair process

- For complex installations, consider dealership service to ensure proper procedures and parts availability

Prevention and Maintenance

Regular Inspection Schedule

Recommended inspection intervals for accelerator cables should align with your vehicle’s regular maintenance schedule, typically every 30,000 to 50,000 miles or during major service intervals. However, vehicles operating under severe conditions such as frequent stop-and-go traffic, extreme temperatures, or corrosive environments may require more frequent inspection.

During routine checks, focus on both visible cable condition and operational feel. Examine cable routing for signs of rubbing, corrosion, or damage to the protective housing. Test pedal operation for smooth movement and immediate return to the idle position. Any changes from previous inspections warrant further investigation.

Documentation and record-keeping help track cable condition over time and identify developing problems before they become serious. Note any changes in pedal feel, visible wear, or environmental damage in your maintenance records. This documentation proves valuable for warranty claims and helps service technicians understand the history of any problems.

Preventive Maintenance Practices

Proper lubrication techniques and schedules vary by vehicle design and environmental conditions. Some cables feature grease fittings that allow periodic lubrication, while others are sealed units that don’t require service. Consult your vehicle’s service manual for specific lubrication requirements and intervals.

Cable adjustment procedures ensure optimal throttle response and prevent premature wear from excessive tension or slack. These adjustments typically involve specific measurements and procedures that require professional knowledge and tools. Improper adjustment can create immediate problems or accelerate cable wear.

Environmental protection measures include keeping cables clean and free from road salt or chemical contamination. Regular undercarriage washing helps remove corrosive materials, while careful routing of aftermarket accessories prevents damage to cable systems. Consider additional protection for vehicles operating in severe environments.

Driving Habits Impact

Smooth, progressive throttle inputs reduce stress on accelerator cable systems and extend service life. Aggressive driving habits that involve rapid throttle changes place higher loads on cable components and accelerate wear. Developing smooth acceleration and deceleration techniques benefits both cable longevity and overall vehicle efficiency.

Environmental considerations for cable care include awareness of conditions that affect cable operation. Cold weather may require gentle throttle inputs until the system warms up, while hot weather driving should avoid extended periods of high throttle positions that increase system stress.

Early intervention strategies focus on addressing minor symptoms before they develop into major problems. Any change in pedal feel or throttle response should prompt inspection, even if the symptoms seem minor. Professional evaluation of these early warning signs can prevent more serious problems and maintain vehicle safety.

For comprehensive vehicle maintenance guidance and specific care recommendations for your equipment type, explore our detailed resources in Agriculture And Equipment, Construction And Equipment, and Home And Garden categories.

Conclusion and Action Steps

Key Takeaways

The most critical symptoms to watch for include any changes in accelerator pedal feel, delayed throttle response, or visible cable damage. These warning signs indicate potential safety hazards that require prompt attention. Remember that accelerator cable problems typically develop gradually, making regular attention to pedal operation your best defense against sudden failures.

A safety-first approach to cable issues means taking any symptoms seriously, regardless of how minor they might seem. The consequences of accelerator cable failure can be severe, making conservative assessment and prompt professional attention the wisest course of action.

Professional help becomes essential when you observe any significant symptoms, visible damage, or have concerns about cable integrity. While basic inspection and symptom recognition can be performed by vehicle owners, diagnosis and repair of accelerator cable problems require specific expertise and tools to ensure safety and proper operation.

Immediate Action Items

Begin with an initial self-assessment by operating your accelerator pedal and noting its feel and response. Pay attention to pedal effort, smoothness of operation, and return action. Perform a visual inspection of accessible cable areas, looking for obvious damage or wear signs.

Seek professional diagnosis immediately if you notice sticking, binding, delayed response, or any visible cable damage. Don’t wait for symptoms to worsen or hope that minor problems will resolve themselves. Early professional assessment can prevent dangerous situations and often reduces repair costs.

Emergency preparation recommendations include knowing how to respond to stuck throttle situations and having contact information for reliable service providers. Consider carrying emergency contact information and understanding your vehicle’s emergency procedures before problems occur.

Long-term Vehicle Care

Integration with your overall maintenance program ensures that accelerator cable condition receives appropriate attention during regular service intervals. Discuss cable inspection with your service provider during routine maintenance and ask them to note cable condition in service records.

Cost-effective prevention strategies focus on addressing environmental factors that accelerate cable wear and maintaining proper operation through appropriate driving techniques. Regular maintenance and early intervention typically cost far less than emergency repairs or accident consequences.

Building mechanical awareness for safety includes understanding how your vehicle’s throttle system works and recognizing early warning signs of problems. This knowledge helps you make informed decisions about vehicle operation and maintenance, contributing to long-term safety and reliability.

Call-to-Action: If you’re experiencing any symptoms described in this guide, schedule a professional inspection immediately. Your safety and that of other road users depends on reliable throttle control. Don’t compromise on this critical safety system – when in doubt, seek expert evaluation and prioritize safety over convenience or cost considerations.

Important Safety Disclaimer: This information is provided for educational purposes only. Any suspected accelerator cable problems should be professionally diagnosed and repaired. Implement these diagnostic techniques at your own risk and responsibility, always prioritizing safety over cost considerations. When in doubt about your vehicle’s condition, consult qualified automotive professionals immediately.

For additional technical resources and vehicle-specific repair information, visit our comprehensive collection of service manuals and diagnostic guides. Whether you’re working on automotive, agricultural, construction, or other equipment, our extensive library provides the detailed technical information you need for safe and effective repairs.

About Repairs Advisor: We provide comprehensive technical repair manuals and diagnostic resources for all types of vehicles and equipment. Our mission is to empower users through reliable technical knowledge while emphasizing safety and professional expertise when needed. For questions or additional support, contact us at [email protected].