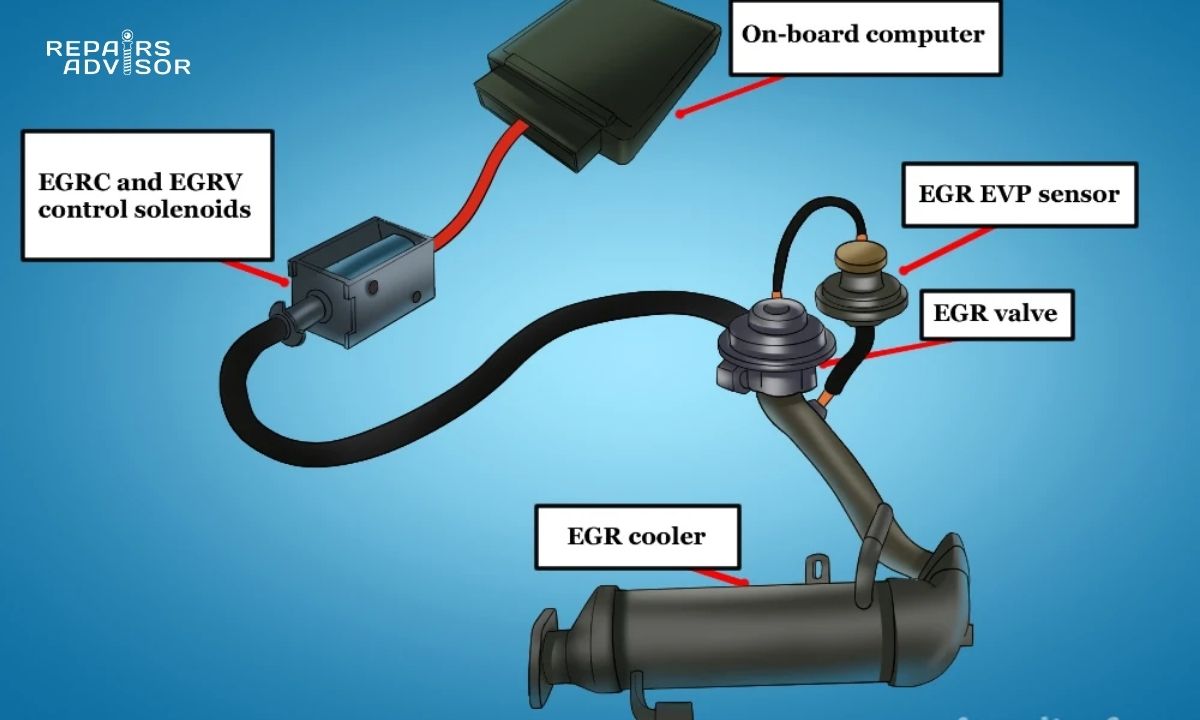

In your vehicle’s Exhaust Gas Recirculation (EGR) system, the EGR position sensor plays a critical role. Think of it as the “eyes and ears” of the engine control module (ECM) for the EGR valve. Its job is to precisely monitor the exact open or closed position of the EGR valve and then send that crucial information as an electrical signal back to the ECM. This feedback loop is essential because the ECM needs to know if the EGR valve is opening to the commanded degree to effectively lower combustion temperatures, reduce nitrogen oxides (NOx), and prevent engine “pinging.”

When this sensor malfunctions, the ECM loses its ability to accurately control the EGR system, leading to various performance and emissions-related headaches.

Key Indicators Your EGR Position Sensor Might Be Failing

When the EGR position sensor acts up, your vehicle often signals a problem with warning lights and noticeable changes in how the engine runs:

- Illuminated Check Engine Light (CEL):

- This is almost always the first and most common sign. If the EGR position sensor sends an implausible signal (e.g., it says the valve is closed when the ECM commanded it open, or vice versa), or if its electrical circuit has an issue, the ECM will detect this discrepancy. This immediately causes the Check Engine Light to illuminate on your dashboard.

- You’ll typically find specific diagnostic trouble codes (DTCs) related to EGR flow, performance, or circuit malfunctions (e.g., P0400 – EGR Flow Malfunction, P0404 – EGR Position Sensor Performance Issue, or codes like P0405/P0406 indicating circuit low/high input).

- Erratic Idle or Lack of Power:

- An inaccurate EGR position sensor can directly impact engine performance. If the ECM receives incorrect information, it might mistakenly believe the EGR valve is in one position when it’s actually in another.

- If the ECM thinks the valve is closed but it’s actually stuck open (or partially open), especially at idle, it can cause rough, erratic idling, stumbling, or even stalling as unwanted exhaust gases enter the engine.

- Conversely, if the ECM thinks the valve is open but it’s actually stuck closed, the engine won’t get the expected EGR flow. This can lead to reduced power, sluggish acceleration, or poor engine response under load, as combustion temperatures aren’t being adequately controlled.

- An inaccurate EGR position sensor can directly impact engine performance. If the ECM receives incorrect information, it might mistakenly believe the EGR valve is in one position when it’s actually in another.

- Emissions Test Failure:

- The EGR system is vital for controlling NOx emissions. If the ECM isn’t receiving accurate data from the EGR position sensor, it can’t properly manage EGR flow. This means the engine might not be reducing NOx effectively, leading to increased levels of nitrogen oxides in the exhaust.

- As a result, your vehicle will likely fail an emissions inspection or smog test in regions with strict environmental regulations.

- Engine “Pinging” or Knocking (Less Common, Indirect):

- While often more directly linked to the EGR valve being stuck closed, an incorrect signal from the position sensor can cause the ECM to mismanage EGR flow, leading to higher combustion temperatures. This can, in turn, result in engine “pinging” or knocking, especially during acceleration.

How to Address a Failing EGR Position Sensor

Fixing a bad EGR position sensor involves careful diagnosis, as the sensor is often integrated with the EGR valve itself.

- Comprehensive Diagnostic is Key:

- Scan for Codes: Start by using an OBD-II scanner to retrieve any stored DTCs related to the EGR system. Specific codes for the EGR position sensor circuit or performance are strong indicators.

- Live Data Monitoring: A professional technician will use a scan tool to monitor “live data” from the EGR position sensor. They’ll observe the sensor’s readings as the EGR valve is commanded to open and close (if possible) and compare these readings to expected values and the commanded position. This helps determine if the sensor is accurately reporting the valve’s movement.

- Wiring and Connector Inspection: The technician will visually inspect the electrical connector and wiring leading to the EGR position sensor for any signs of corrosion, damage, or loose connections. These issues can often mimic a bad sensor.

- EGR Valve Actuation Test: Many advanced scan tools allow mechanics to perform “bidirectional control” tests, where they can command the EGR valve to open and close. The mechanic will then observe if the EGR position sensor’s readings correspond correctly to the commanded movements, and if the valve itself is moving freely and fully.

- Check EGR Passages: It is highly recommended that the EGR system passages are checked to confirm they are clear whenever the EGR valve (which often contains the position sensor) is being replaced. Carbon buildup in these passages can restrict flow, leading to EGR codes even if the valve and sensor are technically working.

- Replacement of the EGR Position Sensor (Often with EGR Valve):

- The EGR valve position sensor is commonly integrated as part of the EGR valve assembly itself. As a result, if the sensor fails, it often requires the replacement of the entire EGR valve assembly. This is important to note, as you typically can’t just replace the sensor component separately.

- Once the EGR valve (with its integrated sensor) is confirmed as the faulty component, the mechanic will carefully remove the old assembly and install a new, OEM-quality replacement. This process can be labor-intensive depending on the valve’s location on the engine.

- Ensure Clear EGR Passages:

- After the new EGR valve assembly is installed, the mechanic will ensure that the EGR system passages are clear of carbon buildup. This might involve cleaning the intake manifold ports or other related passages that the EGR gases flow through. A clear passage is crucial for proper EGR system function and to prevent the new valve from becoming clogged prematurely.

- Clear Codes and Verify Repair:

- Following the replacement and any necessary cleaning, the mechanic will clear the stored diagnostic trouble codes from the vehicle’s computer.

- A final verification step usually involves a test drive, monitoring live data from the EGR system, and ensuring that the Check Engine Light does not return and that the engine performs smoothly without erratic idling or a lack of power. The vehicle should then be able to pass emissions testing.

Your Repair Advisor’s Take:

The EGR position sensor is the ECM’s critical link to understanding the EGR valve’s actions. When this “feedback loop” breaks down, it can cause frustrating driveability issues, trigger that dreaded Check Engine Light, and lead to emissions failures. Since the sensor is often part of the EGR valve itself, replacing it usually means replacing the whole valve assembly.

Don’t overlook symptoms like rough idle or a lack of power, especially if accompanied by a Check Engine Light. While the sensor may seem like a small part, its malfunction can have significant consequences for your engine’s performance and emissions compliance.

For accurate diagnosis and effective repair of your EGR system, always consult a qualified automotive technician. They have the specialized diagnostic tools and expertise to pinpoint whether the position sensor, the EGR valve itself, or carbon buildup in the passages is the true culprit. Ensure your engine runs efficiently and cleanly—schedule a professional EGR system diagnostic today!