When your car window moves unevenly, makes grinding noises, or suddenly drops into the door panel, the problem often lies not with the electrical motor, but with the mechanical door window regulator. This crucial component serves as the mechanical interface between your window motor and the glass itself, converting rotational power into smooth linear motion that raises and lowers your windows.

Understanding the distinction between window motor and regulator problems is essential for accurate diagnosis and cost-effective repairs. While the motor provides electrical power, the regulator handles all mechanical aspects of window movement, including guidance, support, and precise positioning of the glass panel.

The door window regulator represents one of the most mechanically complex systems in modern vehicles, incorporating precise engineering to handle repeated stress cycles while maintaining smooth operation. When regulator problems occur, they often manifest as mechanical symptoms such as uneven movement, binding, or complete mechanical failure that prevents proper window operation.

Modern vehicles employ several different regulator designs, each with specific advantages, maintenance requirements, and common failure modes. Understanding these differences helps vehicle owners make informed decisions about maintenance, repair, and replacement strategies that ensure long-term reliability and optimal performance.

This comprehensive guide explores the mechanical aspects of window regulator systems, from basic operation principles to professional replacement procedures. Safety considerations remain paramount throughout this discussion, as mechanical automotive work involves specific hazards and requires proper procedures to prevent injury and component damage.

Whether you’re experiencing regulator problems or seeking to understand your vehicle’s window systems better, this guide provides the technical knowledge needed to make informed decisions about diagnosis, repair, and maintenance of these essential mechanical components.

What is a Door Window Regulator?

Basic Function and Mechanical Purpose

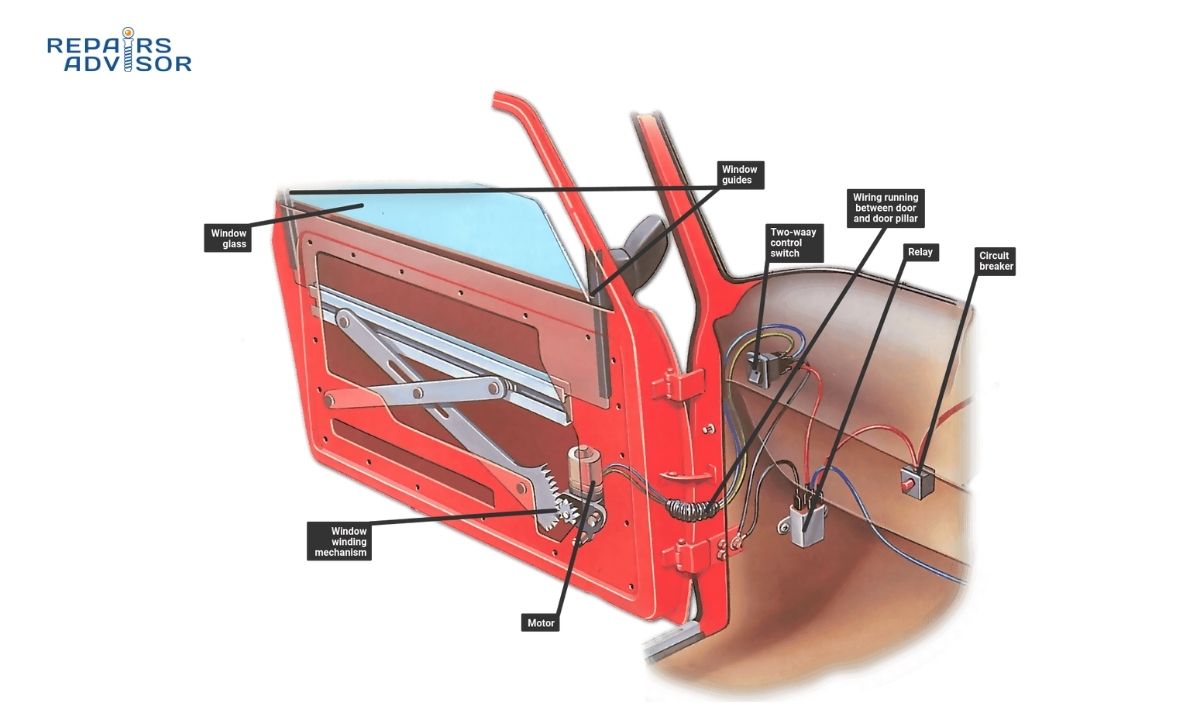

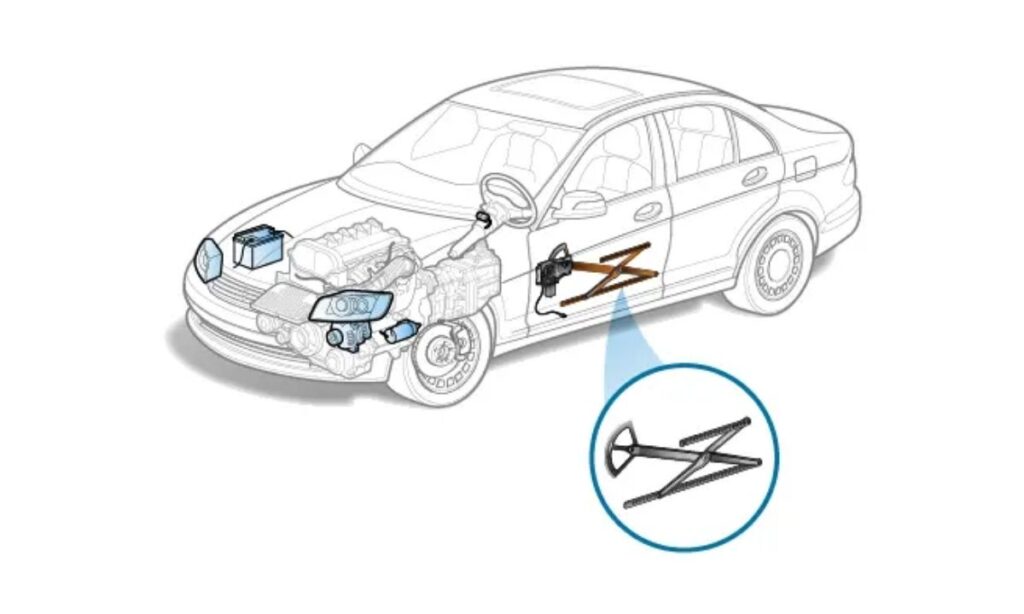

The door window regulator functions as the mechanical heart of your vehicle’s power window system, serving as the critical interface between the electrical motor and the window glass. This precision-engineered mechanism converts the rotational motion from the window motor into controlled linear movement that guides the window glass smoothly along predetermined vertical paths.

Unlike the electrical motor that provides power, the regulator handles all mechanical aspects of window operation, including load distribution, positioning accuracy, and structural support for the glass panel. The regulator must withstand repeated stress cycles while maintaining precise alignment and smooth operation throughout the window’s travel range.

The mechanical design of window regulators incorporates sophisticated engineering to handle the weight of automotive glass while providing the mechanical advantage necessary for smooth operation. Quality regulators distribute loads evenly across multiple contact points, preventing stress concentration that could lead to premature failure or glass damage.

Integration with window tracks, guides, and mounting systems requires precise manufacturing tolerances and proper installation procedures. The regulator must maintain proper alignment with door panel structure while accommodating thermal expansion, vibration, and operational stresses inherent in automotive applications.

Different regulator types employ various mechanical principles to achieve smooth window operation, with each design offering specific advantages in terms of durability, smoothness, and space efficiency. Understanding these mechanical differences helps in selecting appropriate replacement components and maintenance strategies.

Modern window regulators incorporate safety features and fail-safe mechanisms to prevent glass damage and ensure operator safety. These mechanical safeguards work independently of electrical systems to provide protection even during component failures or electrical problems.

Components and Mechanical Assembly

The main regulator frame provides the structural foundation for all mechanical components, incorporating mounting points that secure the assembly within the door panel structure. This frame must withstand operational loads while maintaining precise dimensional stability throughout the regulator’s service life under varying temperature and stress conditions.

Cable and pulley systems in cable-type regulators represent sophisticated mechanical solutions for smooth window operation. High-strength cables route through precision pulleys and attachment points that distribute loads evenly while providing the mechanical advantage necessary for efficient motor operation and smooth glass movement.

Gear mechanisms and drive systems in gear-type regulators employ precision-cut gears and reduction systems to convert motor rotation into appropriate linear motion. These mechanical systems incorporate specific gear ratios designed to balance operational speed with the torque required for reliable window movement under various loading conditions.

Scissor linkages and pivot points in scissor-type regulators utilize sophisticated kinematics to achieve smooth linear motion within compact spaces. The mechanical linkage geometry provides consistent mechanical advantage throughout the window’s travel range while accommodating the space constraints typical in modern vehicle door panels.

Window glass attachment points and clamps represent critical mechanical interfaces that must securely hold the glass while allowing smooth movement along guide tracks. These attachment systems incorporate adjustment mechanisms that enable proper glass positioning and alignment during installation and service procedures.

Track guides and alignment systems ensure precise window movement by constraining lateral motion while allowing smooth vertical travel. These mechanical guides incorporate wear-resistant materials and lubrication provisions that maintain smooth operation throughout the regulator’s service life.

How Window Regulators Work

Mechanical motion transfer from motor to glass involves sophisticated mechanical systems that convert rotational input into precise linear output with appropriate force and speed characteristics. The regulator mechanism must provide smooth motion throughout the entire travel range while handling varying loads from wind resistance, thermal effects, and operational conditions.

Cable and pulley operation principles rely on mechanical advantage and load distribution to achieve smooth window movement with minimal motor effort. Cable routing through precision pulleys reduces friction and wear while providing the mechanical advantage necessary for efficient operation and long component life under repeated stress cycles.

Gear reduction and mechanical advantage in gear-type systems involve carefully calculated ratios that balance operational speed with torque requirements. The gear train provides stepping down of motor speed while increasing available torque, enabling smooth window operation even under adverse conditions such as ice buildup or track contamination.

Scissor mechanism kinematics employ sophisticated linkage geometry to convert rotational input into linear glass movement within confined door panel spaces. The mechanical advantage varies throughout the travel range to provide optimal force distribution and smooth operation regardless of window position or external loading conditions.

Load distribution and stress management throughout the regulator system ensure long-term reliability by preventing stress concentration that could lead to premature component failure. Quality regulators incorporate multiple load paths and stress-relief features that extend service life under normal operating conditions.

Integration with door structure and safety systems requires careful attention to mounting methods, clearances, and operational limits. The regulator must function reliably within the door panel environment while providing safety features that prevent glass damage and ensure operator protection during normal and emergency operations.

For comprehensive understanding of how window regulators integrate with electrical systems, refer to our detailed guide on Signs of a Bad Door Window Motor.

Types of Door Window Regulators

Cable-Type Window Regulators

Cable-type window regulators employ high-strength steel cables routed through precision pulleys to achieve smooth window movement with excellent mechanical efficiency. Design principles focus on load distribution and mechanical advantage to provide smooth operation while minimizing motor effort and extending component life under repeated operational cycles.

The mechanical advantages of cable systems include smooth operation, excellent force distribution, and relatively simple mechanical design that facilitates maintenance and repair procedures. Cable routing through multiple pulleys provides mechanical advantage while distributing loads across several contact points, reducing stress concentration and improving long-term reliability.

Common failure modes specific to cable systems include cable stretching, pulley wear, and attachment point failures that typically develop gradually and provide warning signs before complete failure occurs. Cable fraying or breakage represents the most serious failure mode, often resulting from inadequate lubrication, overload conditions, or normal wear after extended service.

Maintenance requirements for cable systems include periodic lubrication of pulleys and cable guides, tension adjustment procedures, and inspection of cable condition and routing. Proper lubrication is essential for smooth operation and extended cable life, requiring appropriate automotive lubricants applied at specified intervals.

Repair versus replacement considerations for cable systems often favor complete regulator replacement due to the integrated nature of cable routing and the difficulty of achieving proper cable tension during partial repairs. However, some cable systems allow for cable replacement without complete regulator disassembly.

Gear-Type Window Regulators

Gear-type window regulators utilize precision gear trains to convert motor rotation into linear glass movement, offering excellent durability and precise positioning capabilities. Mechanical gear train configuration typically includes reduction gearing that provides appropriate speed and torque characteristics for smooth window operation under varying load conditions.

Direct drive versus reduction gear systems offer different operational characteristics, with reduction systems providing higher torque output and smoother operation at the expense of slightly reduced speed. Reduction gear systems typically offer superior durability under heavy-use conditions and provide better performance when operating against resistance from ice, debris, or worn tracks.

Durability characteristics of gear-type regulators generally exceed those of cable systems, particularly in heavy-duty applications or severe environmental conditions. Gear systems resist stretching and sudden failure modes that can affect cable systems, providing more predictable wear patterns and longer service life under normal operating conditions.

Noise considerations in gear-type systems require attention to gear quality, lubrication, and mounting methods to ensure quiet operation throughout the regulator’s service life. Quality gear systems incorporate precision-cut gears and appropriate lubrication to minimize operational noise while providing smooth, reliable window movement.

Professional installation requirements for gear-type regulators often include precise alignment procedures and torque specifications that ensure proper gear engagement and long-term reliability. Improper installation can lead to premature gear wear and operational problems that compromise system performance.

Scissor-Type Window Regulators

Scissor-type window regulators employ sophisticated linkage geometry to achieve smooth linear motion within the compact spaces typical of modern vehicle door panels. Linkage geometry provides consistent mechanical advantage throughout the window’s travel range while accommodating space constraints that would prevent installation of other regulator types.

The compact design advantages of scissor systems make them particularly suitable for modern vehicles with limited door panel space and complex internal structures. Scissor mechanisms can operate efficiently in confined spaces while providing smooth window movement and reliable positioning capabilities that meet modern automotive standards.

Adjustment and alignment procedures for scissor-type regulators require careful attention to linkage geometry and pivot point condition to ensure smooth operation and proper glass positioning. Proper adjustment is critical for smooth operation and long-term reliability, requiring specific procedures and measurements during installation and service.

Common binding and wear issues in scissor systems typically involve pivot points, linkage arms, and mounting hardware that experience wear from repeated operational cycles. Lubrication of pivot points is essential for smooth operation and extended service life, requiring appropriate automotive lubricants applied at specified intervals.

Space constraints and access considerations for scissor-type regulators often complicate service procedures, requiring specific tools and techniques for efficient maintenance and replacement. Professional service may be advisable for complex scissor systems due to adjustment requirements and space limitations.

Manual vs Power Window Regulators

Mechanical differences between manual and power window regulators involve gear ratios, operational forces, and control mechanisms designed for different input methods. Manual regulators incorporate higher gear ratios to provide the mechanical advantage necessary for hand operation, while power regulators optimize for motor characteristics and operational speed.

Conversion possibilities between manual and power systems depend on door panel design, available space, and electrical system capacity. Conversion typically requires significant modification to door panels, electrical systems, and mounting hardware, making such conversions complex and potentially expensive undertakings.

Operational force requirements differ significantly between manual and power systems, with manual systems requiring mechanical advantage sufficient for comfortable hand operation. Power systems can employ lower gear ratios and higher operational speeds due to the consistent power availability from electrical motors.

Safety and emergency operation features in both manual and power systems include mechanical stops, overload protection, and fail-safe mechanisms that prevent glass damage and ensure operator safety. Manual systems inherently provide emergency operation capability, while power systems may incorporate backup manual operation features.

Understanding these fundamental differences helps in selecting appropriate replacement components and maintenance strategies. Our comprehensive guide on Signs of a Bad Door Window Regulator provides detailed information about identifying problems in different regulator types.

Common Door Window Regulator Problems

Cable System Failures

Cable stretching and tension loss represent gradual degradation processes that typically develop over thousands of operational cycles, causing progressively slower window movement and eventual positioning problems. Cable material fatigue occurs naturally over time, particularly when subjected to temperature extremes, moisture, and repeated stress cycles that gradually reduce cable strength and dimensional stability.

Cable fraying and breakage often result from inadequate lubrication, excessive operational loads, or contact with sharp edges during normal operation. Frayed cables create safety hazards and operational problems that can damage other regulator components if not addressed promptly through professional inspection and replacement procedures.

Pulley wear and bearing failures in cable systems typically manifest as increased operational noise, rough window movement, and accelerated cable wear. Worn pulleys create irregular cable routing that increases friction and stress, leading to premature cable failure and potentially dangerous sudden window dropping incidents.

Attachment point failures and stress concentration occur when cable mounting hardware experiences fatigue from repeated loading cycles or when improper installation creates stress concentration points. These failures often develop gradually but can result in sudden window dropping that creates safety and security concerns.

Environmental factors such as moisture intrusion, temperature extremes, and road salt exposure accelerate cable system deterioration and require proactive maintenance to prevent premature failure. Proper environmental protection and regular lubrication help extend cable system service life and maintain reliable operation.

Gear System Deterioration

Gear tooth wear and damage typically develop gradually through normal operation but can be accelerated by inadequate lubrication, contamination, or excessive operational loads. Precision gear systems require proper lubrication to maintain smooth operation and prevent accelerated wear that compromises window movement quality and system reliability.

Lubrication breakdown and contamination represent serious threats to gear system longevity, particularly when moisture or debris enters the gear housing. Contaminated lubricants lose their protective properties and can actually accelerate wear by creating abrasive conditions that damage gear surfaces and bearing components.

Bearing and bushing deterioration in gear systems affects rotational smoothness and can lead to gear misalignment that causes accelerated wear and operational problems. Quality bearings and bushings are essential for long-term gear system reliability and smooth window operation throughout the regulator’s service life.

Drive mechanism misalignment can result from worn mounting hardware, improper installation, or structural changes in the door panel that affect regulator positioning. Misalignment creates uneven gear loading and accelerated wear that compromises system performance and reliability.

Professional diagnosis of gear system problems requires systematic evaluation of gear condition, lubrication quality, and operational smoothness to determine appropriate repair strategies. Early intervention can often prevent complete gear system failure and extend regulator service life through proper maintenance and lubrication procedures.

Mechanical Binding and Alignment Issues

Track contamination and debris accumulation represent common causes of mechanical binding that can overload window motors and cause regulator damage. Foreign material in window tracks creates resistance that forces mechanical components to work beyond design limits, leading to accelerated wear and potential component failure.

Window glass misalignment problems often result from worn regulator components, improper installation, or door panel distortion that affects window positioning. Misaligned glass creates uneven loading on regulator components and can cause binding conditions that prevent smooth window operation and damage mechanical components.

Door panel interference and clearance issues can develop over time due to worn mounting hardware, structural changes, or accumulated debris within the door panel cavity. Adequate clearance is essential for smooth regulator operation and proper window movement throughout the complete travel range.

Structural distortion from impacts or normal wear can affect door panel geometry and create binding conditions that prevent proper window operation. Professional assessment may be necessary to determine whether door panel repairs are required before regulator replacement or adjustment procedures.

Prevention strategies for mechanical binding include regular cleaning of window tracks, periodic lubrication of moving components, and prompt attention to any signs of operational resistance or unusual noise during window operation.

Mounting and Structural Problems

Attachment point fatigue and failure represent serious problems that can affect regulator operation and create safety hazards. Mounting hardware experiences repeated stress cycles during normal window operation and can develop fatigue cracks or loosening that compromises regulator stability and operational reliability.

Door panel distortion affecting regulator operation can result from impacts, normal wear, or manufacturing variations that create misalignment between regulator components and door structure. Proper door panel condition is essential for regulator operation and may require professional assessment and repair before regulator service can be completed.

Corrosion and environmental damage to mounting points and structural components can compromise regulator installation and create safety hazards. Environmental protection and corrosion prevention help maintain structural integrity and ensure reliable regulator mounting throughout the component’s service life.

Assembly tolerance and manufacturing variations can occasionally create installation problems or operational issues that require professional assessment and potential modification during regulator replacement procedures. Quality replacement components and proper installation procedures help minimize these potential problems.

Understanding electrical system interactions helps diagnose problems that may appear mechanical but actually involve electrical components. For comprehensive electrical system information, consult our guide on Understanding Your Vehicle’s Electrical and Lights Systems.

Signs of a Bad Door Window Regulator

Mechanical Performance Indicators

Uneven or jerky window movement represents one of the most common early indicators of regulator deterioration, typically manifesting as inconsistent movement speed or stuttering motion during window operation. This mechanical symptom usually indicates wear in moving components such as gears, cables, or linkages that no longer provide smooth power transmission from motor to glass.

Window falling or dropping unexpectedly constitutes a serious safety concern that often indicates complete mechanical failure of the regulator’s load-bearing components. When windows drop suddenly, immediate professional attention is required to prevent safety hazards and prevent further damage to other window system components that could increase repair costs.

Excessive noise during operation, including grinding, squealing, or clicking sounds, typically indicates mechanical wear, inadequate lubrication, or component misalignment within the regulator assembly. Different noise patterns often point to specific failure modes and can help professional technicians identify the root cause of mechanical problems before complete failure occurs.

Binding or sticking during window travel suggests mechanical interference, contamination, or component wear that prevents smooth operation throughout the window’s normal range of motion. This symptom often worsens over time and can lead to motor overload and electrical system problems if not addressed promptly.

Progressive degradation of mechanical performance typically provides advance warning of impending regulator failure, allowing for planned replacement before emergency situations develop. Attention to subtle changes in window operation enables proactive maintenance and prevents unexpected failures that could compromise vehicle security or safety.

Visual and Physical Symptoms

Visible window misalignment creates obvious visual indicators of regulator problems, typically appearing as uneven gaps between window glass and door frame or weatherstripping. Proper window alignment is essential for weather sealing, operational smoothness, and aesthetic appearance, making misalignment a clear indicator of mechanical problems requiring attention.

Glass tilting or cocking in tracks indicates mechanical support problems that can worsen over time and potentially cause glass damage. Window glass should remain parallel to door frame edges throughout its travel range, with any tilting or rotation indicating worn or damaged regulator components that require professional evaluation.

Abnormal gaps between window and door frame suggest regulator positioning problems that affect weather sealing and may indicate structural or mechanical component failures. Consistent gap dimensions are important for proper weather protection and vehicle security, making gap variations clear indicators of mechanical problems.

Physical interference with door operation can occur when regulator components fail and interfere with normal door function, creating safety hazards and operational problems. Any interference between window and door operation requires immediate professional attention to prevent safety issues.

Visual inspection during window operation can reveal mechanical problems such as cable routing issues, gear engagement problems, or linkage misalignment that may not be obvious during static inspection. Observing window movement patterns helps identify specific mechanical problems and guide appropriate repair strategies.

Operational Limitations

Inability to reach full up or down positions typically indicates mechanical stops, component failure, or alignment problems that prevent complete window travel. Windows should operate smoothly throughout their complete range without binding or stopping at intermediate positions, making travel limitations clear indicators of mechanical problems.

Window stopping at specific points during travel often indicates mechanical interference, component binding, or alignment problems at particular positions within the regulator’s operating range. Consistent stopping points usually indicate specific mechanical problems that can be diagnosed and corrected through professional inspection and repair procedures.

Requiring assistance to move windows manually suggests mechanical binding or resistance that exceeds normal operational parameters. Windows should operate smoothly with normal motor power without requiring manual assistance or excessive force that could damage mechanical components or create safety hazards.

Motor running without window movement clearly indicates mechanical problems within the regulator system, typically involving gear engagement, cable attachment, or linkage failures that prevent power transmission from motor to glass. This symptom requires immediate professional attention to prevent motor damage.

Intermittent mechanical function that varies with temperature, humidity, or operational conditions often indicates component wear or environmental sensitivity that will likely worsen over time. Consistent mechanical performance is expected throughout normal environmental conditions, making intermittent problems indicators of developing component failures.

Safety and Security Concerns

Window falling into door panel represents a serious safety and security hazard that requires immediate professional attention to prevent injury and protect vehicle security. Complete mechanical failure can occur suddenly and create dangerous conditions for vehicle occupants and bystanders who may be injured by falling glass or compromised vehicle security.

Inability to secure windows in closed position compromises vehicle security and weather protection, creating potential theft targets and exposing vehicle interiors to environmental damage. Secure window positioning is essential for vehicle security and occupant protection, making positioning problems serious concerns requiring prompt professional attention.

Emergency exit complications can develop when window regulator failures prevent normal window operation during emergency situations. Vehicle occupants may need window access for emergency exit during accidents or other crisis situations, making reliable window operation a safety requirement rather than mere convenience.

Weather sealing compromise from regulator problems affects occupant comfort and can lead to water damage, moisture problems, and interior deterioration that creates additional repair costs and safety concerns. Proper window sealing requires correct mechanical positioning and alignment that depends on regulator function.

Understanding related electrical issues helps distinguish between mechanical regulator problems and electrical motor failures. For detailed electrical troubleshooting information, refer to our comprehensive guide on Car’s Fuse Box: All Things You Should Know.

Professional Diagnosis Procedures

Visual and Mechanical Inspection

Window movement pattern analysis involves systematic observation of glass motion throughout the complete travel range to identify mechanical problems, alignment issues, or operational irregularities. Professional technicians evaluate movement consistency, speed variations, and any deviations from smooth linear motion that indicate specific mechanical component problems requiring targeted repair strategies.

Track alignment and guide condition assessment requires careful inspection of window guide systems, track cleanliness, and structural integrity that affects regulator operation. Proper track condition is essential for smooth window movement and regulator longevity, making thorough track inspection a critical component of comprehensive regulator diagnosis procedures.

Cable tension and routing verification in cable-type systems involves checking proper cable installation, tension adjustment, and routing through pulleys and guides. Correct cable tension and routing are critical for smooth operation and component longevity, requiring specific measurement procedures and adjustment techniques during professional diagnosis.

Gear engagement and backlash evaluation in gear-type systems requires assessment of gear mesh quality, wear patterns, and operational clearances that affect smoothness and reliability. Professional diagnosis includes systematic evaluation of gear condition and proper engagement throughout the operational range.

Component accessibility during inspection may require partial disassembly of door panels or regulator assemblies to enable proper evaluation of internal components and wear patterns. Thorough inspection often requires access to internal components that are not visible during external examination procedures.

Operational Testing Procedures

Load testing and resistance measurement involve systematic evaluation of mechanical resistance throughout the window’s travel range to identify binding, mechanical interference, or component wear that affects operation. Consistent operational loads are expected throughout normal window movement, with variations indicating specific mechanical problems requiring professional attention.

Movement smoothness evaluation includes assessment of operational quality, noise levels, and mechanical consistency during normal window cycles. Professional evaluation identifies subtle mechanical problems that may not be obvious during casual observation but indicate developing component failures requiring proactive maintenance or replacement.

Position accuracy and repeatability testing verifies that window positioning remains consistent and accurate throughout repeated operational cycles. Precise positioning is essential for proper weather sealing and operational reliability, making position accuracy testing an important component of comprehensive regulator evaluation procedures.

Safety mechanism functionality verification ensures that protective features and fail-safe systems operate correctly to prevent component damage and ensure operator safety. Professional testing includes verification of overload protection, position limits, and emergency operation features where applicable.

Integrated testing with electrical systems helps distinguish between mechanical regulator problems and electrical motor or control system issues that may present similar symptoms. Coordinated mechanical and electrical testing provides definitive diagnosis and ensures appropriate repair strategies that address root causes rather than symptoms.

Disassembly and Component Assessment

Systematic component removal procedures follow manufacturer-specified sequences to prevent damage and enable proper inspection of internal regulator components. Professional disassembly techniques preserve component condition and enable accurate assessment of wear patterns, damage, and remaining service life during comprehensive regulator evaluation.

Wear pattern analysis and documentation involves careful examination of component surfaces, contact areas, and stress points to determine failure modes and remaining component life. Professional wear assessment identifies specific failure mechanisms and helps determine whether repair or replacement represents the most cost-effective solution.

Material fatigue and stress point identification requires expertise in mechanical component evaluation and understanding of normal versus abnormal wear patterns. Stress concentration and fatigue failures often occur at predictable locations that can be identified through professional inspection procedures and experience with specific regulator designs.

Contamination and environmental damage evaluation assesses the effects of moisture, debris, and environmental exposure on regulator components and operation. Professional assessment determines whether environmental damage requires specific repair procedures or component replacement to ensure long-term reliability.

Component replacement decisions require consideration of individual component condition, availability, and cost-effectiveness compared to complete regulator replacement. Professional assessment balances repair costs with reliability expectations to recommend appropriate repair strategies that provide optimal value and long-term satisfaction.

Integration Testing with Motor Systems

Motor load analysis during regulator operation involves measurement of electrical current and power consumption to assess mechanical loading and identify developing problems. Excessive motor loading often indicates mechanical problems within the regulator system that can cause motor overheating and premature electrical component failure if not corrected.

Electrical current monitoring during mechanical cycles provides quantitative assessment of regulator condition and can identify developing mechanical problems before complete failure occurs. Current signatures often reveal specific mechanical problems such as binding, misalignment, or component wear that affect motor loading patterns throughout the operational cycle.

Coordinated system performance evaluation assesses the interaction between electrical and mechanical components to ensure optimal system function and identify problems that may not be apparent during isolated component testing. Integrated testing provides comprehensive system assessment that ensures proper function after repair or replacement procedures.

Compatibility verification for replacement components ensures that new regulator assemblies properly integrate with existing motor and electrical systems without creating operational problems or premature component failures. Professional installation includes verification of proper mechanical and electrical compatibility.

Professional diagnostic equipment enables precise measurement and analysis that exceeds the capabilities of basic testing methods, providing definitive assessment of regulator condition and appropriate repair recommendations. Advanced diagnostic techniques identify problems earlier and more accurately than basic inspection methods, enabling proactive maintenance and cost-effective repair strategies.

Door Window Regulator Replacement Process

Preparation and Safety Considerations

Safety Warning: Mechanical window regulator components often operate under spring tension and can cause serious injury if improperly handled. Always follow manufacturer safety procedures and use appropriate tools when working with spring-loaded mechanical systems. Improper procedures can result in component damage, personal injury, or glass breakage.

Required tools and specialized equipment for regulator replacement typically include basic hand tools, trim removal instruments, glass support devices, and specialized hardware for specific vehicle applications. Professional-quality tools ensure safe component removal and proper installation while minimizing risk of damage to door panels, glass, or electrical components during replacement procedures.

Window glass support and protection methods prevent glass damage during regulator removal and installation procedures, requiring specific techniques and equipment to maintain glass position and prevent stress concentration. Proper glass support is essential for preventing expensive glass breakage and ensuring safe working conditions during mechanical component replacement.

Door panel access and preparation procedures involve systematic removal of interior trim, electrical connections, and access panels to enable regulator removal and installation. Professional procedures minimize damage to trim pieces and electrical connections while providing adequate access for efficient component replacement.

Workspace preparation includes adequate lighting, clean work surfaces, and proper ventilation to ensure safe and efficient component replacement procedures. Professional workspace organization reduces replacement time and minimizes risk of component damage or injury during regulator replacement procedures.

Component identification and preparation involves verification of replacement part compatibility and preparation of new components for installation. Proper component preparation ensures efficient installation and optimal performance of replacement regulator assemblies.

Removal and Installation Procedures

Systematic disassembly following manufacturer specifications ensures proper component removal without damage to door panels, electrical systems, or adjacent components. Professional removal procedures follow specific sequences that prevent stress concentration and component damage while enabling efficient access to regulator mounting points and connections.

Component positioning and alignment during installation requires careful attention to manufacturer specifications and proper positioning relative to door structure and window tracks. Precise alignment is critical for smooth operation and long-term reliability, requiring specific procedures and measurements during regulator installation.

Torque specifications and assembly procedures must be followed precisely to ensure proper component clamping and operational reliability without over-stressing mounting hardware or door panel structure. Proper torque application is essential for reliable mounting and long-term operational stability of replacement regulator assemblies.

Cable routing and tension adjustment in cable-type systems requires specific procedures and measurements to ensure proper operation and component longevity. Professional installation includes verification of proper cable routing and tension adjustment according to manufacturer specifications.

Integration with existing electrical and mechanical systems requires careful attention to proper connections and compatibility to ensure optimal performance and prevent premature component failures. Proper system integration ensures reliable operation and maintains manufacturer warranty coverage where applicable.

Adjustment and Calibration

Window travel limit setting and verification ensures that window operation remains within safe parameters and prevents component damage from over-travel or binding conditions. Proper limit adjustment is essential for safe operation and component protection, requiring specific procedures and measurements during regulator installation and adjustment.

Track alignment and guide adjustment may be necessary to ensure proper window positioning and smooth operation throughout the travel range. Correct track alignment prevents binding and ensures optimal regulator performance and longevity under normal operating conditions.

Operational smoothness optimization involves fine adjustment of regulator components and lubrication to ensure smooth window movement and minimize operational noise. Professional adjustment techniques optimize performance and ensure customer satisfaction with replacement regulator operation and reliability.

Integration testing with motor and control systems verifies proper operation and compatibility between replacement regulator and existing electrical components. Professional installation includes comprehensive testing to ensure optimal system performance and identify any remaining problems requiring attention.

Final adjustment and verification procedures ensure that all operational parameters meet manufacturer specifications and customer expectations for performance and reliability. Comprehensive final testing provides confidence in repair quality and long-term satisfaction with replacement regulator performance.

Quality Assurance and Testing

Complete operational cycle verification involves testing window operation throughout the full travel range under various conditions to ensure proper function and identify any remaining problems. Comprehensive operational testing provides confidence in repair quality and ensures customer satisfaction with regulator replacement results.

Load testing and performance validation assess regulator capability under normal and adverse operating conditions to verify proper function and adequate performance margins. Professional load testing ensures that replacement regulators meet performance requirements and provide reliable operation under expected service conditions.

Safety mechanism functionality confirmation verifies that protective features and fail-safe systems operate correctly to prevent component damage and ensure operator safety. Safety system verification is essential for preventing accidents and ensuring proper protection during normal and emergency operations.

Long-term reliability assessment procedures evaluate installation quality and component condition to predict service life and identify potential problems that could affect long-term satisfaction. Professional assessment provides confidence in repair durability and long-term performance expectations.

Documentation of replacement procedures and component specifications provides valuable information for future service and warranty support. Proper documentation supports warranty claims and facilitates efficient future service by providing detailed information about replacement components and procedures performed.

Preventive Maintenance and Care

Regular Inspection and Lubrication

Scheduled maintenance intervals and procedures for window regulator systems typically follow manufacturer recommendations but may require adjustment based on environmental conditions and usage patterns. Regular maintenance prevents premature failures and extends regulator service life through proactive care and attention to developing problems before they become serious.

Appropriate lubricants for different regulator types include automotive-grade greases and oils specifically formulated for mechanical components and environmental conditions typical in automotive applications. Quality lubricants provide protection against wear, corrosion, and environmental damage while maintaining smooth operation throughout normal service intervals.

Track cleaning and debris removal techniques help maintain smooth window operation and prevent contamination that can cause binding and accelerated component wear. Regular cleaning prevents problems that could lead to expensive repairs and ensures optimal window performance throughout the regulator’s service life.

Environmental protection and corrosion prevention measures help extend regulator service life by protecting mechanical components from moisture, road salt, and other corrosive substances that accelerate wear and cause premature failures. Proper protection is particularly important in harsh environmental conditions.

Lubrication frequency and procedures depend on environmental conditions, usage patterns, and manufacturer recommendations, with more frequent service required in severe conditions such as dusty environments or extreme temperatures. Proper lubrication schedules prevent premature wear and ensure smooth operation throughout the regulator’s service life.

Operational Best Practices

Proper window operation techniques help prevent unnecessary stress and wear on regulator components while ensuring smooth operation and long service life. Gentle operation and proper timing prevent overloading and extend component life by avoiding sudden loads and excessive operational cycles that accelerate wear.

Avoiding mechanical stress and overload includes recognizing signs of operational problems and avoiding forced operation that can damage regulator components or create safety hazards. Prompt attention to operational problems prevents minor issues from developing into expensive repairs requiring complete regulator replacement.

Seasonal considerations and preparation help maintain optimal regulator performance throughout varying environmental conditions, including winter preparation and summer maintenance that addresses specific seasonal challenges. Seasonal maintenance prevents problems associated with temperature extremes and environmental conditions that affect regulator operation.

Early problem identification and intervention enable proactive maintenance and prevent minor issues from developing into serious problems requiring expensive repairs. Attention to subtle changes in window operation provides opportunities for cost-effective maintenance before complete component failures occur.

Understanding normal operational characteristics helps identify developing problems and distinguish between normal operation and symptoms that require professional attention. Knowledge of proper operation enables early problem detection and appropriate maintenance decisions that extend regulator service life.

Environmental Protection

Weather sealing maintenance and inspection help prevent moisture intrusion that can cause corrosion and accelerated component wear in regulator systems. Proper weather sealing protects mechanical components from environmental damage and extends service life by preventing moisture-related problems and corrosion.

Drainage system functionality verification ensures that door panel drainage systems operate properly to remove moisture and prevent water accumulation that could damage regulator components. Effective drainage prevents moisture problems that cause corrosion and premature component failures in window regulator systems.

Corrosion prevention and treatment measures protect metal components from environmental damage and extend service life through proper protection and maintenance procedures. Corrosion prevention is essential for long-term reliability, particularly in harsh environmental conditions that accelerate metal deterioration.

Impact protection and damage avoidance help prevent physical damage to regulator components and door panels that could affect operation and require expensive repairs. Proper care and attention to potential impact sources help maintain regulator integrity and operational reliability.

Regular environmental assessment helps identify conditions that may require additional protection or more frequent maintenance to ensure optimal regulator performance and longevity. Environmental awareness enables appropriate maintenance strategies that address specific challenges and prevent premature component failures.

Regulator vs Motor: Understanding the Difference

Component Interaction and Dependencies

The relationship between window regulator and motor involves complex mechanical and electrical interactions that require understanding of both systems for effective diagnosis and repair. The motor provides rotational power while the regulator converts that power into precise linear motion, creating a partnership where failure of either component can affect overall window system performance.

Understanding component dependencies helps diagnose problems accurately and avoid unnecessary repairs or component replacement. When motor problems occur, regulator loading increases, potentially causing premature mechanical wear, while regulator problems can overload motors and cause electrical failures if mechanical resistance becomes excessive.

Diagnostic differentiation between motor and regulator failures requires systematic evaluation of both electrical and mechanical symptoms to identify root causes. Motor problems typically manifest as electrical symptoms such as no operation, slow operation, or electrical noise, while regulator problems create mechanical symptoms including binding, uneven movement, or positioning issues.

Integrated system diagnosis considers the interaction between electrical and mechanical components to ensure accurate problem identification and appropriate repair strategies. Professional diagnosis evaluates both systems simultaneously to prevent misdiagnosis and ensure cost-effective repair solutions.

Component isolation testing procedures enable independent evaluation of motor and regulator function to determine which component requires attention. Proper isolation testing prevents unnecessary replacement of functional components and ensures that repair efforts address actual problems rather than symptoms caused by other component failures.

Troubleshooting Decision Trees

Systematic approaches to identifying root causes help distinguish between motor electrical problems and regulator mechanical issues through logical diagnostic procedures. Professional diagnostic trees follow specific sequences that efficiently identify problem sources and guide appropriate repair strategies without unnecessary component replacement or testing.

Component isolation testing procedures involve systematic evaluation of individual components to determine their condition and contribution to overall system problems. Proper isolation techniques prevent misdiagnosis and ensure that repair efforts address actual component failures rather than symptoms caused by other system problems.

Professional diagnostic recommendations include guidelines for determining when professional assistance is needed and when DIY diagnosis may be appropriate. Complex window systems often require professional expertise for accurate diagnosis and proper repair procedures that ensure safe and reliable operation.

Cost-effective diagnosis strategies balance diagnostic time and expense with repair costs to ensure optimal value for diagnostic and repair services. Professional facilities can often provide efficient diagnosis that saves money compared to trial-and-error component replacement approaches.

Understanding diagnostic limitations helps vehicle owners make informed decisions about professional assistance and recognize when additional expertise is needed for complex problems. Accurate diagnosis requires understanding of both electrical and mechanical systems that may exceed typical DIY capabilities.

Professional Diagnostic Recommendations

When to replace individual components versus complete assemblies depends on component condition, cost factors, and reliability expectations that vary with vehicle age and usage requirements. Individual component replacement may be cost-effective when other components remain in good condition and replacement parts are readily available at reasonable cost.

Complete assembly replacement often provides better long-term value when multiple components show wear or when labor costs make individual component replacement uneconomical. Professional assessment helps determine the most cost-effective repair strategy based on specific circumstances and component condition.

Professional service capabilities enable comprehensive diagnosis and repair that may exceed DIY capabilities, particularly for complex systems or when specialized tools and expertise are required. Professional facilities provide warranties and guarantees that protect repair investments and ensure customer satisfaction with repair quality and durability.

Warranty considerations affect repair decisions and may favor specific repair strategies or service providers that maintain warranty coverage. Understanding warranty requirements helps ensure that repairs maintain coverage and provide appropriate protection for repair investments.

Cost Considerations and Repair Planning

Repair vs Replacement Economics

Cost analysis factors for different regulator types include component prices, labor requirements, and expected service life that vary significantly between cable, gear, and scissor-type systems. Cable systems typically cost less initially but may require more frequent replacement, while gear systems offer longer service life at higher initial cost.

Labor complexity and time requirements vary dramatically between different vehicle designs and regulator types, affecting total repair costs and feasibility of DIY repairs. Some regulator replacements require extensive door panel disassembly that increases labor time and cost compared to more accessible installations in other vehicle designs.

Parts availability and quality considerations affect both immediate repair costs and long-term reliability expectations for different replacement options. Original equipment quality parts typically provide superior reliability and longer service life compared to economy alternatives, although initial costs may be higher.

Professional service versus DIY feasibility assessment helps determine appropriate repair strategies based on individual capabilities, available tools, and comfort level with mechanical automotive work. Complex regulator systems often require professional expertise for proper installation and adjustment procedures.

Long-term value analysis considers total cost of ownership including initial repair costs, expected service life, and maintenance requirements for different repair options. Quality repairs with appropriate components typically provide better long-term value despite higher initial costs compared to temporary fixes or economy components.

Long-term Value and Reliability Planning

Expected service life of different regulator types helps plan maintenance and replacement schedules that optimize vehicle reliability and minimize unexpected repair costs. Quality regulator systems typically provide 7-10 years of reliable service under normal operating conditions with appropriate maintenance and care.

Preventive maintenance cost-benefit analysis helps determine appropriate maintenance intervals and procedures that maximize regulator service life while minimizing total maintenance costs. Regular maintenance prevents expensive failures and extends component life through proactive care and attention to developing problems.

Upgrade opportunities during replacement include consideration of improved components or systems that may offer better performance or reliability compared to original equipment. Some replacement regulators incorporate design improvements that address known problems in original equipment and provide enhanced reliability.

Warranty considerations and coverage options affect repair value and may influence selection of repair strategies or service providers that provide appropriate protection for repair investments. Understanding warranty terms helps evaluate repair options and ensure appropriate protection.

Vehicle age and condition influence repair recommendations, as extensive repairs on high-mileage vehicles may not provide adequate return on investment compared to addressing only essential safety and functionality requirements. Professional assessment considers vehicle condition and helps determine appropriate repair strategies that provide optimal value for specific circumstances.

Conclusion

Door window regulator problems require understanding of mechanical systems and their interaction with electrical components to ensure accurate diagnosis and effective repair strategies. Mechanical regulator issues often create symptoms that differ significantly from electrical motor problems, making proper diagnosis essential for cost-effective repairs and long-term satisfaction.

The complexity of modern window regulator systems, including various mechanical designs and integration with electrical components, often requires professional expertise for accurate diagnosis and proper repair procedures. Safety considerations and the potential for component damage make professional consultation advisable for complex mechanical repairs that exceed typical DIY capabilities.

Preventive maintenance and careful attention to early warning signs can significantly extend regulator service life and prevent unexpected failures that compromise vehicle security and weather protection. Regular inspection, appropriate lubrication, and prompt attention to developing problems represent wise investments in both safety and economy.

Understanding the distinction between regulator mechanical problems and motor electrical issues enables vehicle owners to make informed decisions about repair strategies and professional assistance. Proper diagnosis ensures appropriate repair efforts that address root causes rather than symptoms and provide lasting solutions to window operation problems.

When regulator problems occur, prompt professional attention prevents secondary damage and ensures continued vehicle safety and functionality. Quality repairs performed with appropriate components and procedures typically provide years of reliable service and maintain vehicle value and operability.

Remember that window regulator problems affect both convenience and safety, making timely repair a priority for vehicle security and occupant protection. Professional consultation ensures appropriate repair strategies and maintains vehicle safety standards while providing optimal value for repair investments and long-term reliability expectations.