Power steering is one of the most crucial safety and comfort systems in modern vehicles, transforming what was once a physically demanding task into an effortless driving experience. Whether you’re navigating tight parking spaces or cruising down the highway, your power steering system works continuously to provide the precise control and reduced effort that today’s drivers expect.

Understanding how your power steering system operates isn’t just about automotive curiosity – it’s about maintaining one of your vehicle’s most important safety features. A failing power steering system can turn routine maneuvers into dangerous situations, making early detection and proper maintenance essential for every vehicle owner. From the traditional hydraulic systems that dominated automotive engineering for decades to the sophisticated electric systems found in today’s vehicles, power steering technology continues to evolve while serving the same fundamental purpose: making your vehicle safer and more comfortable to drive.

This comprehensive guide will walk you through everything you need to know about power steering systems, from basic operation principles to advanced troubleshooting techniques. Whether you’re a DIY enthusiast looking to understand your vehicle better or a professional seeking detailed technical information, you’ll find the knowledge you need to keep your steering system operating at peak performance. For those working with specific vehicle brands, our extensive collection of technical service manuals provides manufacturer-specific guidance for virtually every make and model.

How Power Steering Works: The Complete System Breakdown

Basic Power Steering Principles

Power steering systems operate on a fundamental principle of force multiplication, using either hydraulic pressure or electric motors to amplify the driver’s steering input. When you turn the steering wheel, the system detects this motion and provides additional force to move the wheels, reducing the physical effort required by up to 80% compared to manual steering systems.

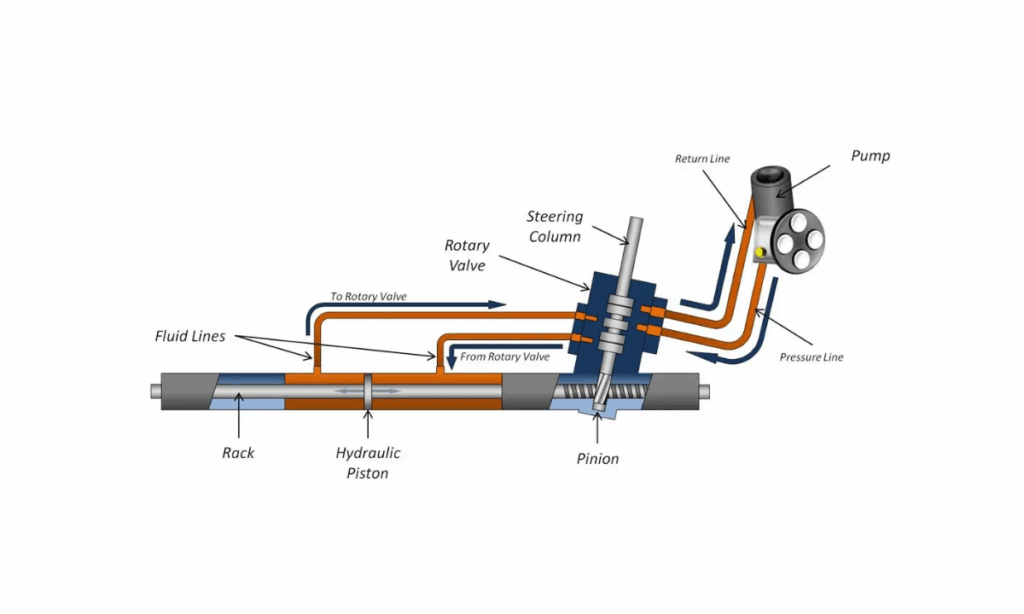

The physics behind power steering involves converting rotational motion from the steering wheel into linear motion at the wheels through a series of mechanical and powered components. In hydraulic systems, pressurized fluid creates the assisting force, while electric systems use precisely controlled motors to provide the same assistance. This force multiplication allows drivers to maintain precise control even when the vehicle is stationary or moving at low speeds, where steering forces are naturally highest.

The system’s responsiveness is carefully calibrated to provide maximum assistance when needed most during parking and low-speed maneuvers while gradually reducing assistance as vehicle speed increases. This variable assistance ensures that drivers maintain good road feel and control at highway speeds while still benefiting from reduced effort in demanding situations.

Key Components and Their Functions

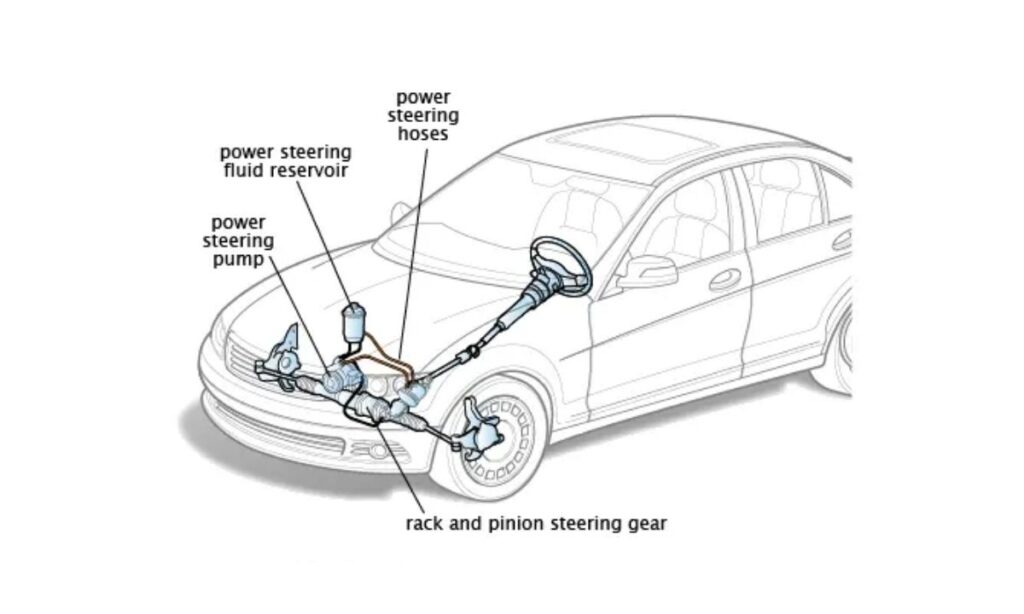

The power steering system consists of several critical components working in harmony to provide seamless steering assistance. The power steering pump serves as the heart of hydraulic systems, creating the pressurized fluid necessary for operation. This engine-driven pump maintains consistent pressure throughout the system, typically operating between 1,000-1,500 PSI during normal conditions.

The steering gear or rack and pinion assembly converts the rotational motion from your steering wheel into the linear motion that turns your wheels. In rack and pinion systems, a toothed rack moves laterally as the pinion gear rotates, directly connecting to the wheel assemblies through tie rods. This design provides precise steering response and takes up less space than traditional steering box configurations.

Power steering fluid acts as the medium for hydraulic force transmission while also lubricating and cooling system components. This specialized fluid must withstand extreme pressures and temperatures while maintaining consistent viscosity throughout its service life. The fluid reservoir stores this fluid and often includes a filter to prevent contamination from entering the system.

The network of pressure hoses and return lines creates a closed-loop system, carrying pressurized fluid from the pump to the steering gear and returning it to the reservoir. These hoses must withstand high pressure while remaining flexible enough to accommodate engine movement and vibration. Understanding these components becomes crucial when diagnosing issues, as problems in any single element can affect the entire system’s performance.

Types of Power Steering Systems

Hydraulic Power Steering (HPS)

Traditional hydraulic power steering systems have been the automotive industry standard for over six decades, providing reliable and effective steering assistance through pressurized fluid dynamics. These systems use an engine-driven pump to pressurize power steering fluid, which then flows through a network of hoses to the steering gear where it provides the force multiplication necessary for easy steering.

The primary advantage of hydraulic systems lies in their consistent power delivery and strong assist characteristics, particularly beneficial for larger vehicles and trucks where steering forces are naturally higher. HPS systems provide excellent road feel and feedback, allowing experienced drivers to sense tire grip and road conditions through the steering wheel. This tactile feedback has made hydraulic systems the preferred choice for performance vehicles and heavy-duty applications where precise steering control is paramount.

Hydraulic power steering systems are commonly found in trucks, SUVs, sports cars, and older passenger vehicles. Their robust design handles demanding conditions well, from the extreme cold of northern climates to the heat and dust of construction sites. However, these systems do have drawbacks, including parasitic power loss from the engine-driven pump, potential fluid leaks, and regular maintenance requirements. For detailed maintenance procedures specific to your vehicle, consult the appropriate manufacturer service manuals to ensure proper care of your hydraulic system.

Electric Power Steering (EPS)

Electric Power Steering represents the modern evolution of steering assistance technology, replacing hydraulic pumps and fluid with precision electric motors and electronic control systems. EPS systems use sensors to detect steering wheel input and vehicle conditions, then apply precisely controlled electric motor assistance to reduce steering effort while maintaining optimal road feel.

The benefits of electric power steering extend far beyond simple steering assistance. EPS systems consume power only when assistance is needed, improving fuel economy by 2-3% compared to traditional hydraulic systems. They also enable advanced driver assistance features like lane keeping assist, parking assistance, and autonomous driving capabilities that would be impossible with purely hydraulic systems.

Modern vehicles increasingly feature EPS as standard equipment, particularly in passenger cars and light trucks. The system’s integration with vehicle stability control and other electronic systems allows for sophisticated interventions that can help prevent accidents and improve overall vehicle dynamics. EPS systems also eliminate the need for power steering fluid, reducing maintenance requirements and environmental concerns associated with hydraulic fluid disposal.

Electro-Hydraulic Power Steering (EHPS)

Electro-Hydraulic Power Steering systems represent a transitional technology that combines the best aspects of both hydraulic and electric systems. EHPS uses an electric motor to drive the hydraulic pump instead of connecting it directly to the engine, allowing for more precise control of hydraulic pressure while reducing parasitic power losses.

This hybrid approach provides the strong assist characteristics and familiar feel of hydraulic systems while offering some of the efficiency benefits of electric systems. The electric pump can be operated on-demand, reducing power consumption when steering assistance isn’t needed. EHPS systems are particularly common in luxury vehicles and high-performance cars where the tactile feedback of hydraulic systems is desired but fuel efficiency remains important.

The performance characteristics of EHPS systems make them ideal for vehicles that need strong steering assistance but also benefit from electronic integration. These systems can provide variable assist based on vehicle speed and driving conditions while maintaining the consistent feel that experienced drivers expect from hydraulic systems.

Common Power Steering Problems and Symptoms

Hydraulic System Issues

Hydraulic power steering systems, while generally reliable, can develop several characteristic problems that affect steering performance and safety. Low power steering fluid is among the most common issues, often manifesting as increased steering effort, particularly during parking and low-speed maneuvers. You may notice the steering wheel becomes significantly harder to turn, especially when the vehicle is stationary or moving slowly.

Power steering pump failure typically announces itself through distinctive symptoms that progressively worsen over time. A failing pump often produces a characteristic whining or groaning noise, particularly when turning the steering wheel. This noise may be most noticeable during cold starts or when making sharp turns in parking lots. As pump failure progresses, you may experience intermittent loss of power assistance, where steering effort suddenly increases during turns.

Leak identification requires systematic inspection of the entire hydraulic system. Common leak locations include the pump itself, pressure hose connections, rack and pinion seals, and the fluid reservoir. Power steering fluid typically appears reddish or amber in color when fresh, turning darker as it ages. Look for wet spots under your vehicle, particularly near the front wheels and engine bay. Small leaks may only be visible as fluid residue or staining, while larger leaks create obvious puddles.

Hard steering conditions can result from multiple hydraulic system problems. Air in the system, often introduced through leaks or improper fluid changes, creates inconsistent assistance and may cause the steering to feel spongy or unpredictable. Contaminated fluid, recognizable by its dark color or burnt smell, loses its lubricating properties and can damage internal pump and gear components. For specific troubleshooting procedures, refer to our comprehensive diagnostic and troubleshooting guides that cover these issues in detail.

Electric System Problems

Electric Power Steering systems introduce a different set of potential problems, primarily related to electronic components and sensors rather than hydraulic failures. EPS motor failure often presents as complete loss of power steering assistance, though some systems may provide limited backup assistance in limp-home mode. You might notice the steering suddenly becomes very heavy, similar to driving a vehicle without power steering entirely.

Sensor malfunctions in EPS systems can cause erratic steering behavior that may be dangerous if not addressed promptly. The torque sensor, which detects how much force you’re applying to the steering wheel, can fail partially or completely. A failing torque sensor might cause the system to provide too much or too little assistance, creating an unpredictable steering feel that varies from turn to turn.

Electronic control unit issues represent some of the most complex EPS problems, often requiring professional diagnostic equipment to identify and resolve. The EPS control module continuously monitors system operation and can store diagnostic trouble codes when problems are detected. These codes provide valuable insight into system malfunctions, but proper interpretation requires understanding of the specific vehicle’s diagnostic procedures.

Warning light interpretations vary by manufacturer, but most vehicles display a steering wheel icon or EPS warning message when problems are detected. Some systems may display generic warning lights, making professional diagnosis necessary to determine the exact nature of the problem. Never ignore EPS warning lights, as they often indicate conditions that could lead to sudden loss of steering assistance.

Mechanical Component Failures

Both hydraulic and electric power steering systems rely on mechanical components that can wear or fail over time. Rack and pinion wear typically develops gradually, first appearing as slight play in the steering wheel or minor wandering while driving straight. As wear progresses, you may notice uneven tire wear patterns, particularly on the inner or outer edges of the front tires.

Steering gear problems can affect both hydraulic and electric systems, though the symptoms may vary depending on the type of assistance. Internal gear wear might cause clicking or knocking noises when turning, while seal failures in hydraulic systems can cause internal leakage that reduces steering assistance effectiveness. Electric systems may experience gear reduction unit failures that create grinding noises or erratic assistance levels.

Belt and pulley issues specifically affect hydraulic systems where the power steering pump is driven by the engine’s accessory belt. A worn or loose belt can cause the pump to operate inconsistently, creating intermittent power steering problems that may be more noticeable during certain driving conditions. Belt failure results in immediate loss of power steering assistance in hydraulic systems.

Hose deterioration in hydraulic systems creates both performance and safety concerns. Power steering hoses operate under extreme pressure and temperature conditions, causing rubber components to deteriorate over time. Bulging hoses indicate internal failure and represent a safety hazard, as high-pressure hydraulic fluid can cause serious injury if a hose fails suddenly.

Power Steering Maintenance and Care

Regular Maintenance Schedule

Proper power steering maintenance follows a systematic approach that varies depending on your vehicle’s system type and operating conditions. Hydraulic systems require more frequent attention due to their fluid-based operation, while electric systems need primarily electronic system checks and mechanical component inspection.

For hydraulic power steering systems, establish a monthly routine of checking fluid levels and condition. This simple inspection takes only a few minutes but can prevent expensive repairs by catching problems early. Check the fluid level with the engine warm and idling, ensuring the fluid reaches the appropriate mark on the reservoir or dipstick. The fluid should appear clean and maintain its proper color typically reddish or amber when fresh.

System inspection procedures should include visual examination of all hoses, connections, and components for signs of leakage or wear. Look for fluid stains on the ground beneath your vehicle, particularly after overnight parking. Inspect hose routing to ensure nothing rubs against sharp edges or hot engine components that could cause premature failure.

Preventive maintenance tasks extend beyond simple fluid checks to include belt inspection in hydraulic systems, ensuring proper tension and condition. Listen for unusual noises during operation, particularly the characteristic whining that indicates pump problems or low fluid levels. Address any changes in steering feel immediately, as early intervention typically prevents more expensive repairs.

Manufacturer maintenance requirements vary significantly between vehicle makes and models, making consultation of official service schedules essential. Some manufacturers recommend power steering fluid changes every 30,000-50,000 miles, while others consider it a lifetime fill. For specific maintenance schedules tailored to your vehicle, reference the appropriate service manual that provides manufacturer-approved procedures and intervals.

Power Steering Fluid Management

Power steering fluid serves multiple critical functions beyond simply transmitting hydraulic pressure. It lubricates internal pump and gear components, helps dissipate heat generated during operation, and contains additives that prevent corrosion and seal deterioration. Understanding proper fluid management ensures system longevity and reliable operation.

Fluid types and specifications vary significantly between vehicle manufacturers, with some requiring specific formulations that aren’t interchangeable. Traditional power steering fluid, ATF (Automatic Transmission Fluid), and specialized synthetic formulations each have distinct properties and applications. Using the wrong fluid type can damage seals, reduce system performance, and void warranties.

Checking and adding fluid properly requires following specific procedures to ensure accurate readings and prevent contamination. Always check fluid levels with the engine warm and running, as cold fluid readings can be misleading. Add fluid slowly to prevent overfilling, which can cause foaming and reduced system performance. Use a clean funnel to prevent contamination, and never mix different fluid types.

Fluid change intervals depend on operating conditions and manufacturer recommendations. Severe service conditions including extreme temperatures, dusty environments, or frequent heavy steering use may require more frequent changes. Signs that indicate fluid replacement needs include dark coloration, burnt odor, or visible contamination. Fresh fluid typically appears clear to light amber, while deteriorated fluid becomes dark and may contain metal particles or other contaminants.

Contamination prevention involves maintaining clean reservoir caps, using clean tools and funnels when servicing, and addressing leaks promptly to prevent air and moisture entry. Water contamination can cause corrosion and reduce fluid effectiveness, while dirt and debris can damage internal components and cause premature wear.

Troubleshooting Power Steering Issues

Diagnostic Procedures

Effective power steering diagnosis follows a systematic approach that begins with basic visual inspection before progressing to more complex testing procedures. Start by examining the entire system for obvious problems like fluid leaks, damaged hoses, or loose belt connections. Many power steering problems have visible indicators that can guide your diagnostic approach.

Visual inspection techniques form the foundation of power steering diagnosis. Check fluid level and condition first, as low or contaminated fluid causes many steering problems. Examine all hoses and connections for leaks, bulging, or cracking. In hydraulic systems, trace the entire fluid path from reservoir to pump to steering gear and back, looking for any signs of leakage or damage.

Fluid analysis methods provide valuable insight into system condition and potential problems. Fresh power steering fluid should be relatively clear and maintain its specified color. Dark, burnt-smelling fluid indicates overheating or contamination, while foamy fluid suggests air in the system or overfilling. Metal particles in the fluid often indicate internal wear in the pump or steering gear.

Pressure testing procedures require specialized equipment but provide definitive diagnosis of hydraulic system problems. A power steering pressure tester connects to the high-pressure line and measures system pressure under various conditions. This testing can isolate problems to specific components and verify proper system operation after repairs.

Electronic system diagnostics for EPS systems require OBD-II scanners capable of reading manufacturer-specific codes. These systems continuously monitor operation and store diagnostic trouble codes when problems are detected. For detailed diagnostic procedures specific to your vehicle’s error codes, consult our DTC code diagnostics resources that explain common steering-related fault codes.

Common Diagnostic Tools

Professional power steering diagnosis requires specific tools, though many basic checks can be performed with standard automotive equipment. Pressure gauges and testing equipment designed for power steering systems can measure system pressure and flow rates, providing definitive diagnosis of pump and system problems.

OBD scanner usage for EPS systems has become essential as electric power steering becomes more common. Advanced scanners can display live data from steering sensors, show system status, and perform active tests on some systems. Generic OBD-II scanners may read basic fault codes, but manufacturer-specific scan tools provide more detailed information for complex diagnosis.

Basic hand tools for inspection include flashlights for visual inspection, clean rags for checking fluid condition, and basic wrenches for checking connection tightness. A turkey baster or fluid extraction pump helps remove old fluid for analysis or replacement. Keep inspection tools clean to prevent contamination during service.

Safety equipment requirements are crucial when working with power steering systems, particularly hydraulic systems operating under high pressure. Safety glasses protect against fluid spray, while nitrile gloves prevent skin contact with potentially harmful fluids. Never attempt to check for leaks by running your hand along pressurized lines, as high-pressure fluid injection can cause serious injury.

Power Steering Repair Considerations

DIY vs Professional Repair

Power steering repairs range from simple fluid changes that most DIY enthusiasts can handle to complex internal rebuilds requiring specialized tools and expertise. Understanding the complexity and safety implications of different repairs helps you make informed decisions about what to tackle yourself versus when to seek professional help.

Skill level requirements vary dramatically between different power steering repairs. Basic maintenance like fluid checks, hose inspections, and fluid changes require minimal automotive experience and common hand tools. However, pump replacement, rack and pinion service, and electronic system diagnosis demand advanced mechanical skills, specialized tools, and thorough understanding of safety procedures.

Safety considerations and limitations are particularly important with power steering systems due to high-pressure hydraulic components and safety-critical functions. Hydraulic systems operate under pressures exceeding 1,500 PSI, capable of causing serious injury if proper precautions aren’t followed. EPS systems involve high-voltage electrical components in some vehicles, requiring specific safety protocols.

Tools and equipment needed for professional-level repairs include pressure testing equipment, specialized pullers for component removal, and torque wrenches for proper reassembly. Many repairs also require fluid evacuation and refilling equipment to prevent air introduction during service. The investment in specialized tools often exceeds the cost of professional repair for infrequent DIY mechanics.

When to consult professional mechanics includes any repair involving internal system components, high-pressure testing, or electronic system programming. If your initial diagnosis reveals problems beyond basic maintenance or if you’re uncomfortable with any safety aspect of the repair, professional service ensures both proper repair and personal safety.

Component Replacement Guidelines

Determining when power steering components need replacement requires understanding both performance indicators and safety considerations. Pump replacement indicators include consistent noise during operation, inability to maintain proper pressure, or visible leakage from the pump housing. A failing pump often provides warning signs before complete failure, making early replacement more convenient and less expensive than roadside failure.

Rack and pinion service decisions depend on the severity of internal wear and the availability of repair options. Minor seal leaks may be repairable with seal replacement, while internal gear wear typically requires complete unit replacement or professional rebuilding. Consider the vehicle’s age and value when deciding between repair and replacement options.

Hose and fitting replacements should be performed whenever bulging, cracking, or significant leakage is observed. Power steering hoses operate under extreme conditions and can fail suddenly, making proactive replacement advisable when deterioration is evident. Always replace hoses with OEM-equivalent parts designed for the specific pressure and temperature requirements.

Electronic component considerations in EPS systems often require programming or calibration after replacement. Many electronic components are paired to specific vehicles and cannot be simply swapped without proper initialization procedures. This complexity makes professional service advisable for most EPS component replacements.

Safety Considerations and Warnings

Working with power steering systems requires strict adherence to safety protocols due to the high pressures involved in hydraulic systems and the safety-critical nature of steering function. Power steering fluid safety precautions include avoiding skin and eye contact, as many fluids contain additives that can cause irritation or allergic reactions. Always wear nitrile gloves and safety glasses when servicing power steering systems.

High-pressure system dangers cannot be overstated. Hydraulic power steering systems operate under pressures exceeding 1,500 PSI – sufficient to penetrate skin and cause serious injury. Never use your hands to check for leaks on pressurized lines. Instead, use a piece of cardboard or paper to detect pressure leaks safely. Always relieve system pressure before disconnecting any hydraulic components.

Proper lifting and support procedures ensure safe access to power steering components while preventing injury from vehicle movement. Use proper jack stands rated for your vehicle’s weight, and never rely solely on hydraulic jacks for support. Ensure the vehicle is on level ground and engage the parking brake before beginning any work.

Personal protective equipment requirements extend beyond basic gloves and safety glasses to include appropriate clothing and respiratory protection when working with older power steering fluids that may contain harmful additives. Avoid loose clothing that could become entangled in moving components, and ensure adequate ventilation when working with power steering fluids.

Environmental disposal considerations are crucial for responsible power steering service. Used power steering fluid is considered hazardous waste in many jurisdictions and must be disposed of properly. Many auto parts stores and service facilities accept used power steering fluid for recycling. Never dispose of power steering fluid in storm drains, on the ground, or with regular trash.

Modern Power Steering Technology and Trends

The evolution of power steering technology continues to accelerate, driven by demands for improved fuel efficiency, enhanced safety features, and integration with autonomous driving systems. Advanced EPS features now include variable assist algorithms that adjust steering feel based on driving conditions, speed, and even driver preferences. Some systems can completely eliminate steering effort during parking maneuvers while maintaining appropriate road feel at highway speeds.

Integration with driver assistance systems represents perhaps the most significant advancement in steering technology. Modern EPS systems work seamlessly with lane keeping assist, automatic emergency steering, and parking assistance features. These systems can apply corrective steering inputs to help prevent accidents or maintain proper lane position without driver intervention.

Future developments in steering technology point toward fully variable steering ratios, where the relationship between steering wheel input and wheel movement can be continuously adjusted based on driving conditions. Some manufacturers are exploring steer-by-wire systems that eliminate the direct mechanical connection between steering wheel and wheels, relying entirely on electronic control for steering input.

Performance tuning capabilities in modern EPS systems allow customization of steering feel and response characteristics. Some vehicles offer multiple steering modes – comfort, sport, and economythat alter the assist characteristics and feedback levels. This adaptability allows a single vehicle to provide different steering experiences for various driving conditions and preferences..

Conclusion and Next Steps

Understanding your vehicle’s power steering system empowers you to maintain this critical safety component effectively while recognizing when professional service is necessary. Regular maintenance, particularly fluid level checks and system inspection, can prevent most power steering problems and extend component life significantly.

Early problem detection remains the key to avoiding expensive repairs and maintaining vehicle safety. Pay attention to changes in steering feel, unusual noises, or any warning lights related to your steering system. Address minor issues promptly before they develop into major failures that could compromise your safety or require emergency roadside assistance.

Professional consultation becomes essential when dealing with high-pressure hydraulic components, electronic system programming, or any repair that affects vehicle safety systems. Modern power steering systems integrate closely with other vehicle safety features, making proper diagnosis and repair crucial for overall vehicle performance.

For comprehensive repair procedures specific to your vehicle, explore our extensive library of technical service manuals that provide manufacturer-approved procedures and specifications. Whether you’re maintaining a classic vehicle with traditional hydraulic power steering or servicing a modern car with advanced EPS features, having access to proper documentation ensures safe and effective service.

Additional resources for power steering maintenance include our detailed guides on vehicle systems and parts that explain how steering systems integrate with other vehicle components. Understanding these relationships helps you maintain your vehicle more effectively while recognizing how different systems affect each other.

Disclaimer: This information is provided for educational purposes only. Power steering systems operate under high pressure and are critical for vehicle safety. Always follow proper safety procedures and consult qualified professionals when working with pressurized hydraulic systems or safety-critical electronic components. Repairs performed incorrectly can result in loss of steering control and serious accidents.

For detailed service procedures specific to your vehicle, browse our comprehensive collection of service manuals and technical documentation covering all major automotive brands and models.