Why Hydraulic Power Steering Is Critical for Vehicle Control

Direct Answer: Hydraulic power steering uses pressurized fluid to amplify your steering input, reducing the physical effort needed to turn the wheels while maintaining precise control and road feel feedback.

Hydraulic power steering systems transform what would otherwise require significant physical strength into effortless steering control through sophisticated fluid pressure management. When you turn the steering wheel, the system instantly responds by directing pressurized hydraulic fluid to assist your input, multiplying your force by 6:1 to 10:1 ratios depending on vehicle speed and steering demand.

The hydraulic assist system proves essential for vehicle control by enabling precise maneuvering of heavy vehicles at low speeds while automatically reducing assistance at highway speeds to maintain road feel and stability. This dynamic response ensures you can easily park in tight spaces while retaining confident control during high-speed driving scenarios.

Quick Facts:

- Function: Force multiplication through pressurized fluid assistance

- System Type: Closed-loop hydraulic circuit with speed-sensitive control

- Maintenance Level: Regular fluid changes and belt inspection required

- Failure Impact: Heavy steering effort, potential loss of control assistance

Understanding hydraulic power steering operation empowers you to recognize early warning signs like fluid leaks, unusual noises, or changes in steering effort, allowing proactive maintenance that prevents costly system failures and maintains optimal vehicle control throughout your ownership experience.

Safety Note: Power steering failure significantly increases steering effort, particularly at low speeds and during parking maneuvers. While mechanical steering control remains functional, the sudden increase in required force can create dangerous situations requiring immediate attention from qualified technicians.

Hydraulic Power Steering Parts and Construction Explained

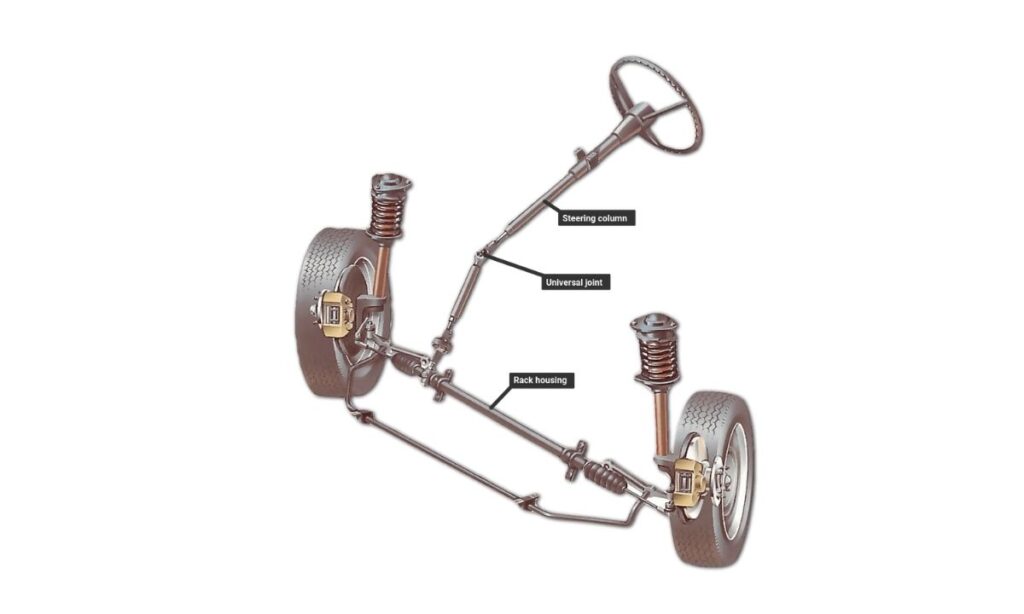

The hydraulic power steering system integrates multiple precision-engineered components working together to provide consistent, speed-sensitive steering assistance through pressurized fluid control and distribution.

Power Steering Pump and Pressure Generation: The engine-driven power steering pump serves as the system’s heart, creating pressurized fluid flow essential for steering assistance. Modern pumps typically generate 1,000-1,500 PSI operating pressure using either vane-type or gear-type designs. Vane pumps offer quieter operation and better pressure consistency, while gear pumps provide durability in heavy-duty applications. The pump incorporates pressure relief valves and flow control mechanisms to maintain optimal pressure across varying engine speeds.

Steering Rack and Hydraulic Cylinders: The rack and pinion steering assembly houses integral hydraulic cylinders that convert fluid pressure into mechanical force assistance. These cylinders feature precision-machined pistons sealed with O-rings and seals, creating chambers that receive pressurized fluid on either side depending on steering direction. The piston design multiplies hydraulic pressure to generate substantial assist forces while maintaining precise control response.

Control Valve and Pressure Distribution: The rotary control valve, integrated within the steering rack or steering gear housing, directs pressurized fluid to appropriate cylinder chambers based on steering input direction and force. This sophisticated valve uses torsion bar technology to sense steering effort, progressively opening flow passages as steering force increases. The valve design ensures proportional assistance – light efforts receive minimal assist while heavy steering loads trigger maximum pressure delivery.

Fluid Reservoir and Cooling System: The power steering fluid reservoir stores hydraulic fluid while incorporating filtration and cooling functions essential for system longevity. The reservoir typically holds 1-2 quarts of specialized power steering fluid with additives for seal protection, corrosion prevention, and foam suppression. Some systems include integrated coolers or remote cooling lines to manage fluid temperatures during extended operation.

High-Pressure Lines and Return Circuit: The complete hydraulic circuit features high-pressure supply lines rated for 2,000+ PSI working pressure, connecting the pump to the steering gear through reinforced rubber hoses with steel braiding. The return circuit uses lower-pressure lines to carry fluid back to the reservoir, completing the closed-loop system. All connections use specialized fittings designed to prevent leaks under extreme pressure and temperature variations.

Integration with steering columns and steering geometry ensures optimal steering response and vehicle stability across all driving conditions.

How Hydraulic Power Steering Works: Step-by-Step Operation

Understanding hydraulic power steering operation reveals how pressurized fluid technology creates effortless steering control while maintaining the precision and feedback essential for safe vehicle operation.

Step 1: Pump Pressurization and Flow Generation The engine-driven power steering pump continuously circulates fluid through the system, maintaining 1,000-1,500 PSI pressure in the supply circuit. When the steering wheel remains in neutral position, the pump sends fluid through the control valve and directly back to the reservoir with minimal restriction. This recirculation mode ensures instant pressure availability while minimizing power consumption during straight-line driving.

Step 2: Input Detection and Valve Actuation When you apply steering force, the torsion bar within the control valve deflects proportionally to your input effort. This deflection rotates the inner valve spool relative to the outer sleeve, progressively opening ports that direct pressurized fluid to the appropriate side of the hydraulic assist cylinder. Light steering inputs create small valve openings and minimal assist, while heavy steering loads generate larger openings and maximum pressure delivery.

Step 3: Hydraulic Assist and Force Multiplication Pressurized fluid enters the hydraulic cylinder chamber corresponding to your steering direction, pushing the assist piston to reduce steering effort dramatically. The hydraulic system typically provides 6:1 to 10:1 force multiplication, transforming 10 pounds of steering wheel force into 60-100 pounds of assist at the wheels. Simultaneously, fluid exits the opposite cylinder chamber through the control valve return circuit, allowing smooth piston movement and precise steering control.

Speed-Sensitive Assist Modulation: Modern hydraulic systems incorporate speed-sensitive valves or electronic controls that reduce assist levels at higher speeds. This modulation maintains light steering effort for parking while ensuring stable, controlled steering feel during highway driving. The system automatically adjusts assist levels based on vehicle speed inputs or centrifugal valve mechanisms.

Pressure Relief and System Protection: When steering reaches full lock position, pressure relief valves prevent system damage by redirecting excess flow back to the reservoir. This protection prevents pump damage and maintains consistent system pressure under extreme conditions. The relief valve setting typically opens at 1,800-2,200 PSI to protect system components.

Return Flow and Heat Management: Used hydraulic fluid returns to the reservoir through the low-pressure return circuit, where it releases heat and allows air bubbles to separate before recirculation. The reservoir design and optional cooling systems manage fluid temperature to maintain optimal viscosity and prevent seal degradation during demanding operation.

The hydraulic power steering system integrates seamlessly with vehicle control systems and brake systems to provide comprehensive vehicle dynamics management.

Hydraulic Power Steering Location and Access Guide

Locating and accessing hydraulic power steering components requires understanding their distribution throughout the engine compartment and following the pressurized fluid circuit from pump to steering gear.

Power Steering Pump Location and Identification The power steering pump typically mounts on the engine’s front accessory drive, usually on the passenger side near the alternator and air conditioning compressor. You can identify the pump by following the drive belt routing – it’s typically a cylindrical component with a pulley on one end and high-pressure line connections on the pump body. The pump reservoir may be integral to the pump housing or mounted separately nearby with connecting lines.

Steering Rack and Hydraulic Connections The steering rack assembly mounts across the vehicle’s front subframe, typically visible from both above in the engine compartment and below the vehicle. Look for the rack housing between the front wheels, with tie rods extending to each wheel assembly. The hydraulic connections appear as reinforced rubber lines connecting to fittings on the rack housing – one high-pressure supply line and one lower-pressure return line.

Fluid Reservoir and Fill Point Access The power steering fluid reservoir location varies by vehicle design but typically positions near the power steering pump for easy access during maintenance. The reservoir features a threaded cap or dipstick for fluid level checking and filling. Some vehicles use remote reservoirs mounted on the firewall or fender well, connected to the pump via suction lines.

High-Pressure Line Routing and Inspection Points The high-pressure line routes from the pump outlet to the steering gear input, typically following a path that avoids heat sources and sharp edges. Trace this line to identify potential leak points at fittings, routing clamps, and flex points where the line connects to the moving steering gear. The line construction features steel braiding under rubber covering, making it stiffer and more substantial than typical automotive hoses.

Access Requirements and Service Considerations Power steering service typically requires access from above for pump and reservoir service, with underneath access needed for rack and line inspection. Basic tools include wrenches for line fittings, a funnel for fluid filling, and protective equipment due to high-pressure system risks. Always ensure the engine is cool before service to avoid contact with hot components.

Vehicle Configuration Differences and System Variations Front-wheel-drive vehicles typically use rack-mounted systems with shorter line runs, while rear-wheel-drive applications may use recirculating ball steering gears with longer hydraulic circuits. Electronic power steering systems in newer vehicles eliminate hydraulic components entirely, using electric motors for steering assistance.

For detailed maintenance procedures and troubleshooting guidance, reference our comprehensive power steering repair guides or explore vehicle-specific service information through our automotive manual categories.

Safety Warning: Hydraulic power steering systems operate under extremely high pressure (1,000-2,200 PSI). Never disconnect lines or fittings while the engine is running or immediately after operation. High-pressure fluid injection can cause serious injury, and proper eye protection is essential during any hydraulic system service. Always consult manufacturer specifications for proper fluid types and service procedures to prevent system damage or personal injury.