Why Engine Block Is Critical for Engine Performance

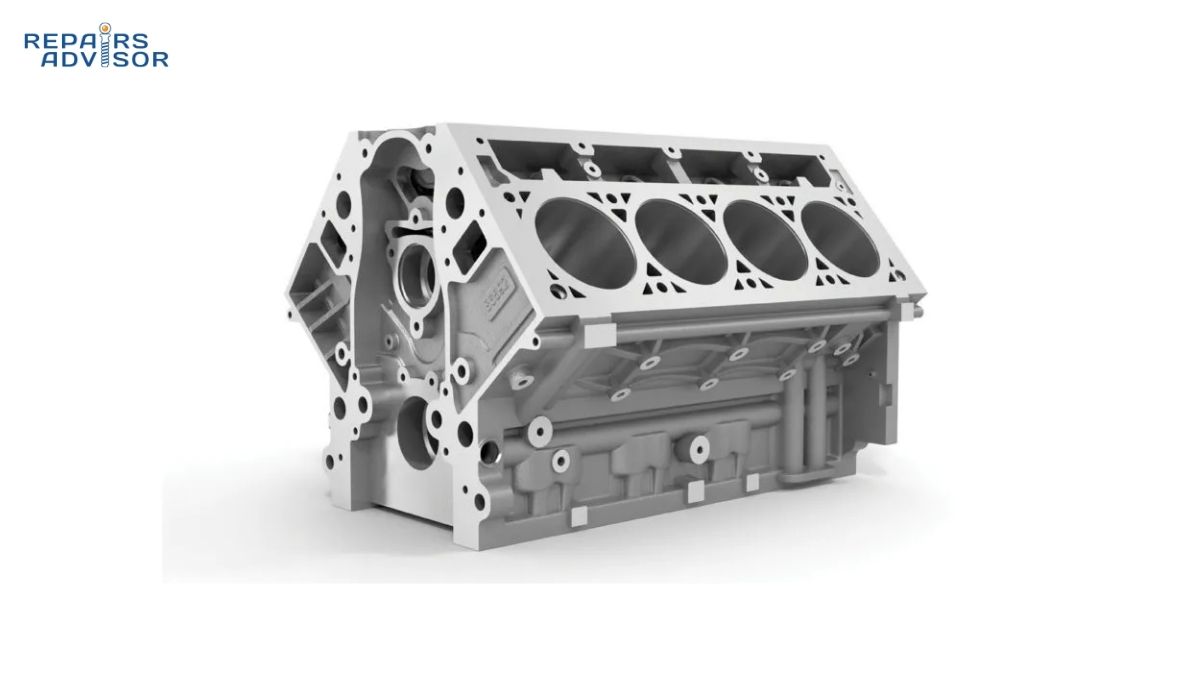

The engine block serves as the engine foundation, housing critical engine block components that enable your vehicle’s power generation. Understanding cylinder block function is essential for anyone working on automotive repairs, as this central assembly determines engine reliability, performance, and longevity.

Quick Facts:

- Function: Houses cylinders, crankshaft, and cooling/lubrication passages

- Category: Core engine structural component

- Maintenance Level: Professional overhaul required for major repairs

- Failure Impact: Complete engine replacement typically necessary

The engine block’s primary responsibility is containing combustion forces while providing mounting points for all major engine components. When engine block components fail, the entire powerplant becomes compromised, often requiring complete engine replacement or extensive machine shop work.

Safety Note: Engine block repairs involve heavy components, high-temperature operations, and precision machining. Always consult qualified automotive professionals for structural engine work, and never attempt engine block repairs without proper equipment and expertise.

Engine Block Parts and Construction Explained

Modern engine blocks integrate sophisticated engine block components designed for durability, thermal management, and performance optimization. The cylinder block function relies on precise engineering of multiple interconnected systems working in harmony.

Primary Assembly Structure: The engine block consists of a cast iron or aluminum housing containing cylinder bores, water jackets, oil passages, and mounting surfaces. Cast iron blocks offer superior durability and heat retention, while aluminum construction provides weight savings and improved heat dissipation for performance applications.

Key Engine Block Components:

- Cylinder Bores: Precisely machined cavities where pistons travel during combustion cycles. Bore dimensions directly impact displacement and compression ratios, with surface finish critical for proper ring sealing and oil control.

- Crankcase: Lower portion housing the crankshaft and providing oil storage. Features main bearing caps, oil drain provisions, and mounting points for oil pumps and filters.

- Coolant Jackets: Advanced coolant passages surrounding cylinders and exhaust ports for thermal management. Strategically designed coolant jackets include steam holes at the highest points preventing air pocket formation that causes hot spots and detonation. This architecture ensures even temperature distribution across all cylinders.

- Oil Galleries: Internal passages distributing pressurized oil to bearings, camshafts, and hydraulic components. Gallery design affects oil pressure and flow characteristics, with oil drain-back provisions ensuring efficient oil return to the crankcase.

Supporting Elements: Deck surfaces provide sealing interfaces for cylinder heads, while mounting bosses secure accessories like starters, alternators, and engine mounts. Bore spacing and deck height specifications define the engine’s fundamental architecture – bore spacing (distance between cylinder centerlines) typically ranges from 95-115mm depending on cylinder diameter and structural requirements, while deck height (crankshaft centerline to head surface) determines overall engine dimensions and performance characteristics. Threaded holes accommodate various sensors, drain plugs, and auxiliary equipment mounting.

Material Considerations: Cast iron blocks offer excellent wear resistance and thermal stability, making them ideal for high-mileage applications and diesel engines. Precision main bearing saddle machining ensures proper crankshaft alignment and load distribution. Aluminum blocks reduce weight by 30-50% but require cylinder liners or specialized coatings for durability in high-performance applications. Freeze plug installation accommodates thermal expansion management, allowing different materials to expand and contract at varying rates without causing structural damage.

How Engine Block Works: Step-by-Step Operation

Understanding how engine block components function together reveals the sophisticated engineering behind modern powerplants. The cylinder block function encompasses structural support, thermal management, and fluid distribution in an integrated system.

Step 1: Combustion Containment and Force Distribution

During combustion, explosive forces reach thousands of PSI within cylinder bores. The engine block’s thick walls and reinforced webbing distribute these forces throughout the structure, preventing distortion that would compromise sealing surfaces. Cross-bolted main bearing caps and deep-skirt construction enhance structural integrity under extreme loads.

Step 2: Thermal Management and Heat Dissipation

As combustion generates intense heat, coolant circulates through coolant jackets surrounding each cylinder. Steam holes at the highest points prevent air pocket formation that would create dangerous hot spots and engine knock. Strategic coolant flow patterns remove heat from critical areas like exhaust valve seats and cylinder heads. The engine foundation design includes thermal expansion management considerations, with different materials requiring specific clearances and gasket designs to accommodate varying expansion rates.

Step 3: Lubrication Distribution and Pressure Control

Pressurized oil flows through precisely sized galleries, delivering lubrication to main bearings, rod bearings, and valve train components. Oil drain-back provisions include generous return passages and windage control features that prevent oil foaming from crankshaft rotation, ensuring consistent oil supply to critical bearing surfaces while minimizing parasitic power losses. Oil pressure regulation occurs through gallery restrictions and relief valves, ensuring adequate flow at all operating speeds while preventing over-pressurization that damages seals.

Step 4: Component Integration and Mounting

The engine block provides mounting surfaces for cylinder heads, transmission bellhousings, and accessory drives. Precise machining ensures proper alignment of rotating assemblies, while threaded inserts and mounting bosses distribute loads from external components. This integration makes the engine block the central hub for all engine systems.

Step 5: Structural Support During Operation

Under varying loads and temperatures, the engine block maintains dimensional stability critical for proper component operation. Advanced casting techniques and metallurgy prevent distortion that would affect crankshaft alignment, cylinder bore geometry, and sealing surface flatness.

Modern engine blocks incorporate sophisticated engineering solutions like plateau honing for optimal ring sealing, cross-hatch patterns for oil retention, and strategic reinforcement for high-performance applications. Understanding these systems helps diagnose problems and select appropriate repair strategies.

Engine Block Location and Access Guide

The engine block forms the central structural component of your vehicle’s powerplant, typically positioned longitudinally in rear-wheel-drive vehicles or transversely in front-wheel-drive configurations. Engine block components require specific access procedures depending on vehicle design and intended service operations.

Primary Location and Visual Identification: In most vehicles, the engine block occupies the largest portion of the engine bay, distinguished by its substantial casting with visible cylinder head mounting surfaces on top. Look for casting numbers, oil drain plugs, and coolant passages as identifying features. The block extends from the oil pan mounting surface below to the deck surface where cylinder heads attach.

Visual Identification Features:

- Size and Mass: Largest single engine component, typically weighing 150-400 pounds

- Casting Marks: Manufacturer identification, displacement, and casting date codes

- Mounting Points: Engine mount brackets, transmission bellhousing bolt patterns

- Access Ports: Oil drain plugs, freeze plugs, and sensor mounting holes

Access Requirements by Service Type:

Inspection Access: External engine block examination requires basic tools and good lighting. Check for casting cracks, oil leaks around galleries, and coolant seepage from core plugs. Most external inspection possible with engine installed.

Minor Service Access: Oil changes, sensor replacement, and external component service typically require standard hand tools and basic safety equipment. Drain pans, socket sets, and protective eyewear essential for routine maintenance.

Major Service Access: Internal engine block work requires complete engine removal, engine hoist, and specialized machine shop equipment. Engine stand, precision measuring tools, and hydraulic presses necessary for bearing, piston, and cylinder work.

Vehicle Configuration Differences:

- FWD Applications: Transverse mounting complicates access from sides, requires front-end disassembly for major service

- RWD Applications: Longitudinal mounting provides better service access but requires transmission removal for engine extraction

- AWD Systems: Additional complexity from transfer cases and multiple drivelines affects service accessibility

- Hybrid Vehicles: High-voltage components require specialized safety procedures and qualified technician service

Safety Considerations for Engine Block Access: Engine blocks contain residual heat, pressurized fluids, and heavy components requiring proper safety protocols. Always allow cooling time, relieve system pressures, and use appropriate lifting equipment rated for engine weights.

Professional Service Requirements: Major engine block repairs require specialized equipment including cylinder boring machines, pressure testing apparatus, and precision measurement tools. Machine shop capabilities essential for cylinder work, deck surfacing, and bearing line boring. These services exceed typical DIY capabilities and require professional automotive machine shop expertise.

For specific vehicle access procedures and engine block service intervals, consult manufacturer service manuals available through our automotive manual collection. Professional consultation recommended for all internal engine block service work due to precision requirements and safety considerations.

Important Safety Disclaimer: Engine block service involves heavy components, high temperatures, and precision requirements. This information is provided for educational purposes only. Always consult qualified automotive professionals for engine block repairs, and refer to manufacturer service procedures for specific vehicle requirements. Repairs Advisor provides technical manuals and guidance but does not perform direct repair services.

For comprehensive engine repair manuals and technical documentation, explore our complete automotive repair manual library covering all major manufacturers and model years.