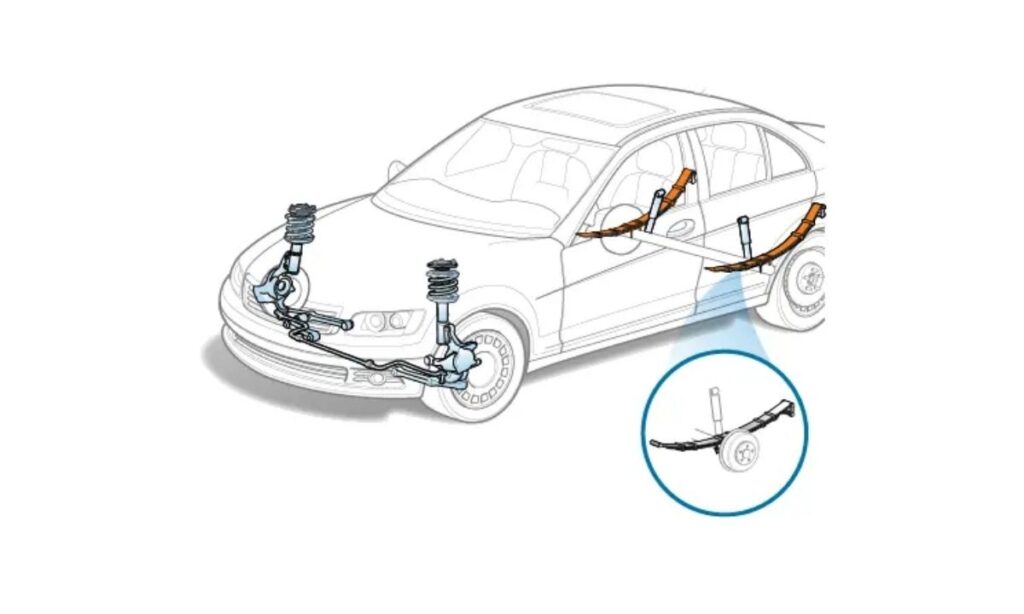

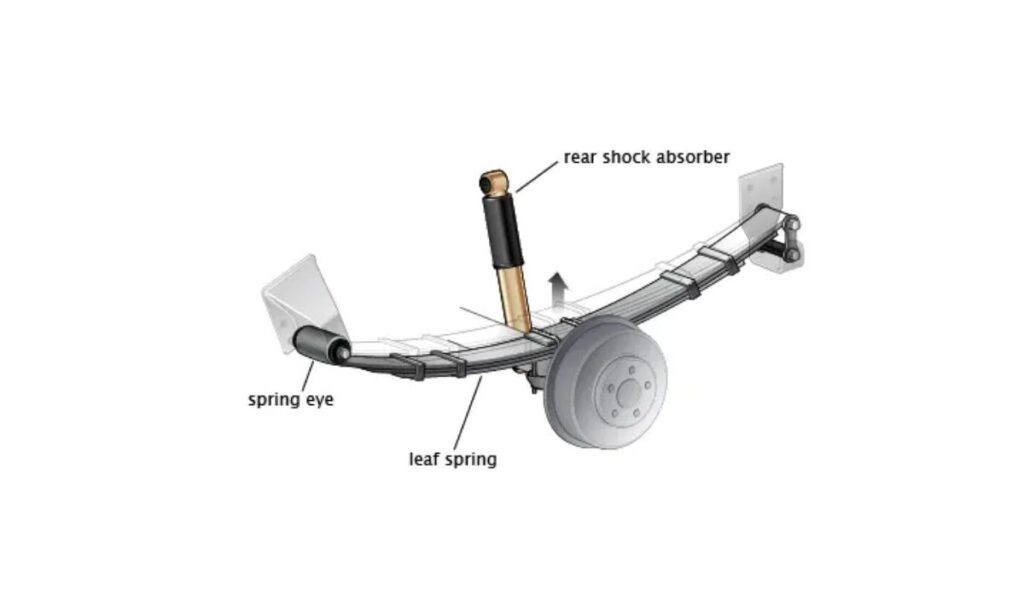

Ever wondered how some trucks and heavy-duty vehicles carry massive loads without their rear ends dragging on the ground? A big part of that capability comes from leaf springs. These robust components are a type of spring used primarily to support the weight of the vehicle and its cargo, and to maintain the correct ride height at the axle where they’re installed.

Unlike coil springs, leaf springs consist of several layers (or “leaves”) of spring steel stacked on top of each other and clamped together. As your vehicle drives over bumps, these leaves flex and bend, absorbing impacts and allowing the axle to move up and down. They also play a crucial role in positioning the vertical centerline of your wheels, helping to keep your axle properly aligned. Because of their inherent strength and design, leaf springs are often chosen for vehicles where extra load-carrying capabilities are a must.

However, even these tough components can wear out or break. When that happens, you’ll definitely notice a change in your vehicle’s stance and handling.

How to Spot the Warning Signs of a Bad or Failing Leaf Spring

Catching a problem with your leaf springs early can prevent further issues and ensure your vehicle remains safe to operate, especially when carrying loads. Here are the key symptoms to watch out for:

- Knocking Noise When Going Over Bumps:

- A common audible sign of a failing leaf spring is a distinct knocking, clunking, or rattling noise coming from the rear of your vehicle. This sound is particularly noticeable when you drive over bumps, potholes, or uneven road surfaces. It can indicate that the individual leaves within the spring pack are loose, broken, or that the bushings (which connect the leaf spring to the frame) are worn, allowing metal-on-metal contact.

- Vehicle Ride Height is Low (Sagging Rear End):

- This is often the most visually obvious symptom. If you notice that the rear end of your truck, SUV, or van appears visibly lower than it used to, or if one side (left or right) is noticeably lower than the other, it’s a strong indicator that a leaf spring has weakened, sagged, or is broken. The spring is no longer effectively supporting the vehicle’s weight, causing that side or the entire rear to drop. This can affect ground clearance and the vehicle’s overall level stance.

- Harsh Ride or Poor Handling (Especially with Loads):

- While not explicitly in your original text, this is a critical functional symptom. A weakened or broken leaf spring cannot properly absorb road impacts, leading to a much harsher or stiffer ride, especially in the rear. You might feel every bump more acutely. Additionally, the vehicle’s handling can deteriorate, particularly when carrying a load, as the suspension struggles to maintain stability and control. The vehicle might feel “loose” or “unsettled” over uneven terrain.

Leaf Spring Repair Advice (Important Considerations!)

When a leaf spring fails, replacement is the necessary solution. This isn’t a DIY job for those without proper equipment and experience.

- Always Replace as a Set:

- Leaf springs should ALWAYS be replaced as a set (both left and right side on the same axle). Springs wear out over time, losing their load-carrying capacity and original arch (shape). Replacing only one side will lead to an uneven ride height, unbalanced handling, and could put undue stress on the new spring and other suspension components.

- Wheel Alignment is Essential After Replacement:

- Replacing leaf springs directly affects your vehicle’s rear axle geometry and ride height. Therefore, a four-wheel alignment is strongly recommended (and often mandatory) immediately after the leaf springs are replaced. This ensures your wheels are correctly angled for proper handling, stability, and to prevent rapid, uneven tire wear. Even on solid rear axles, ride height changes can impact thrust angle.

- Professional Installation is Key (Safety First):

- Leaf springs are heavy components that are under significant tension, especially when supporting the vehicle’s weight. Their removal and installation require specialized tools, knowledge, and adherence to strict safety procedures. Improper removal or installation can lead to serious injury or damage to the vehicle. This job should always be left to a qualified professional mechanic.

Your Repair Advisor’s Take:

Your leaf springs are crucial for your truck’s or heavy-duty vehicle’s ability to carry loads, maintain proper stance, and provide a stable ride. Ignoring the signs of a bad leaf spring whether it’s persistent knocking, a noticeable sag, or a harsh ride can severely compromise your vehicle’s safety, especially when you’re hauling cargo. It can also lead to accelerated wear on tires and other suspension components.

Don’t compromise your vehicle’s load-carrying capability or your safety! A failing leaf spring needs immediate attention from a professional.For accurate diagnosis and safe replacement, always consult a qualified automotive mechanic. They have the specialized knowledge, tools, and experience to properly assess your leaf springs and ensure they are replaced correctly, getting your vehicle back to its full capability. Get your ride height and load capacity back – schedule a suspension inspection today!