Low air conditioning refrigerant reduces cooling efficiency, increases energy costs, and can damage your system. Common signs include warm air from vents, ice buildup on refrigerant lines, unusual hissing sounds, longer cooling cycles, and higher energy bills. For intermediate DIYers: You can identify these symptoms and understand basic causes, but refrigerant handling requires EPA-certified professionals for safety and legal compliance.

Key safety consideration: Never attempt to add refrigerant yourself—it’s toxic, requires specialized equipment, and improper handling can damage your system or pose health risks.

Professional consultation criteria: Contact an HVAC technician immediately if you notice multiple symptoms, as refrigerant doesn’t “get used up” and low levels always indicate a leak requiring professional repair.

Understanding Air Conditioning Refrigerant Basics

Air conditioning refrigerant is the lifeblood of your cooling system. This specialized chemical compound absorbs heat from indoor air and releases it outside, making your home comfortable during hot weather. Unlike fuel in a car, refrigerant doesn’t get “consumed” during operation—it circulates continuously through a closed-loop system.

How Refrigerant Works in Your AC System

The refrigeration process involves four key stages. First, liquid refrigerant absorbs heat from your indoor air through the evaporator coil, causing it to evaporate into a gas. The compressor then pressurizes this gas, raising its temperature. Next, the hot, pressurized gas releases heat to the outdoor air through the condenser coil, returning to liquid form. Finally, an expansion valve reduces pressure and temperature, allowing the cycle to repeat.

Common Refrigerant Types and Regulations

Modern air conditioning systems use different types of refrigerant depending on their age and design. R-22 (Freon) was widely used until 2010 but has been phased out due to ozone depletion concerns. The EPA banned new R-22 production in 2020, making it expensive and difficult to obtain. R-410A (Puron) became the standard replacement from 2010-2024, offering better efficiency without ozone depletion. However, due to high global warming potential, R-454B and similar low-GWP refrigerants are now required for new systems starting in 2025.

Understanding your system’s refrigerant type is crucial for proper maintenance and repair decisions. Check the equipment nameplate or consult your HVAC manual for specific refrigerant information.

Skill Level Assessment: Are You Ready for Refrigerant Diagnostics?

Beginner (0-2 years experience): Focus on visual symptom recognition and knowing when to contact professionals. You can safely observe ice formation, listen for unusual sounds, and monitor cooling performance without touching any components.

Intermediate (2-5 years experience): You’re ready to perform systematic diagnostics if you can identify basic AC components, understand safety protocols, and recognize the difference between symptoms and root causes. This guide will help you build confidence while respecting safety boundaries.

Professional (5+ years experience): You can leverage advanced diagnostic techniques and efficiency optimization strategies while ensuring proper EPA compliance for refrigerant handling.

Warning Signs of Low Refrigerant: What to Look For

Warm or Insufficient Air From Vents

The most obvious sign of low refrigerant is reduced cooling capacity. When refrigerant levels drop, your system cannot absorb sufficient heat from indoor air. Test this by placing a thermometer near your supply vents—the air temperature should be 15-20 degrees cooler than your thermostat setting when the system is running.

Confidence checkpoint for intermediates: You can easily perform this test, but remember that warm air can also indicate dirty filters, blocked ducts, or electrical issues. Always check these simpler causes first before suspecting refrigerant problems.

Ice Formation on Refrigerant Lines

Low refrigerant causes the evaporator coil to become extremely cold, freezing moisture from the air. This ice can extend to the refrigerant lines connecting your indoor and outdoor units. Safety warning: Never attempt to remove ice yourself or touch frozen components—turn off the system and contact a professional immediately.

Ice formation is particularly common during humid weather or when air filters are dirty, restricting airflow across the evaporator coil. For detailed guidance on filter maintenance, see our guide on how to spot a bad cabin air filter for automotive applications.

Unusual Sounds: Hissing and Bubbling

Refrigerant leaks often produce distinctive sounds. A hissing noise typically indicates gas escaping from a small hole or crack, while bubbling sounds suggest liquid refrigerant leaking or air entering the system. These sounds are most noticeable near the indoor unit, outdoor condenser, or along refrigerant lines.

Important safety note: If you hear these sounds, turn off your system immediately and ventilate the area. Refrigerant exposure can cause health problems, particularly in enclosed spaces.

Extended Cooling Cycles and Poor Performance

When refrigerant levels are low, your AC must work longer to achieve the desired temperature. You might notice the system running continuously or cycling on and off more frequently than normal. This overwork not only increases energy consumption but can damage the compressor over time.

Monitor your system’s performance by noting how long it takes to cool your home from your normal daytime setting to your desired evening temperature. Significant increases in cooling time often indicate refrigerant issues.

Increased Energy Bills Without Usage Changes

Low refrigerant forces your system to work harder, consuming more electricity while providing less cooling. Compare your current energy bills with the same period from previous years, accounting for weather differences. A sudden 15-30% increase in cooling costs without corresponding usage changes often indicates efficiency problems.

For equipment-specific troubleshooting, consult manuals for your AC brand. Popular manufacturers like Honda, Toyota, and Ford provide detailed diagnostic procedures for their automotive AC systems.

Understanding Refrigerant Leak Causes

Age-Related Wear and Component Deterioration

Most refrigerant leaks develop gradually over time due to normal wear and tear. Copper tubing can develop pinhole leaks from corrosion, particularly in coastal areas with salt air exposure. Rubber seals and gaskets deteriorate, allowing refrigerant to escape at connection points. HVAC systems over 10 years old are particularly susceptible to these issues.

Professional insight: The majority of refrigerant leaks occur at joints and connections rather than in straight sections of tubing. This is why proper installation and maintenance are crucial for system longevity.

Installation and Maintenance Issues

Poor installation practices cause many premature refrigerant leaks. Over-tightened connections can crack fittings, while under-tightened connections allow gradual leakage. Improper brazing techniques during installation create weak points that fail over time. Additionally, inadequate system maintenance allows corrosion and mechanical stress to accumulate.

Physical Damage and Environmental Factors

External damage from lawn equipment, falling branches, or construction activity can puncture refrigerant lines. Vibration from poorly secured equipment or nearby machinery can cause stress fractures. Corrosive chemicals, road salt, or industrial pollutants can accelerate copper tube deterioration.

Prevention tip: Maintain at least two feet of clearance around your outdoor unit and protect refrigerant lines with appropriate covering in high-traffic areas.

Safe Diagnostic Procedures for Intermediate DIYers

Visual Inspection Techniques

Start your diagnosis with a thorough visual inspection, always ensuring the system is turned off first. Look for obvious signs of damage, corrosion, or oil stains around refrigerant connections. Oil residue often indicates slow leaks, as refrigerant and lubricating oil travel together through the system.

Examine the evaporator coil area for ice formation or unusual frost patterns. Check outdoor refrigerant lines for physical damage or signs of repair attempts. Document your findings with photos for reference when consulting with professionals.

Safety reminder: Never touch refrigerant lines or components when ice is present. Refrigerant can cause severe frostbite upon skin contact.

Performance Assessment Methods

Monitor your system’s cooling performance by measuring supply and return air temperatures. The temperature difference should typically range from 15-20 degrees Fahrenheit during normal operation. Consistently lower temperature differences may indicate refrigerant issues or airflow problems.

Time your system’s cooling cycles and note any changes in frequency or duration. A properly charged system should maintain relatively consistent cycle timing under similar weather conditions.

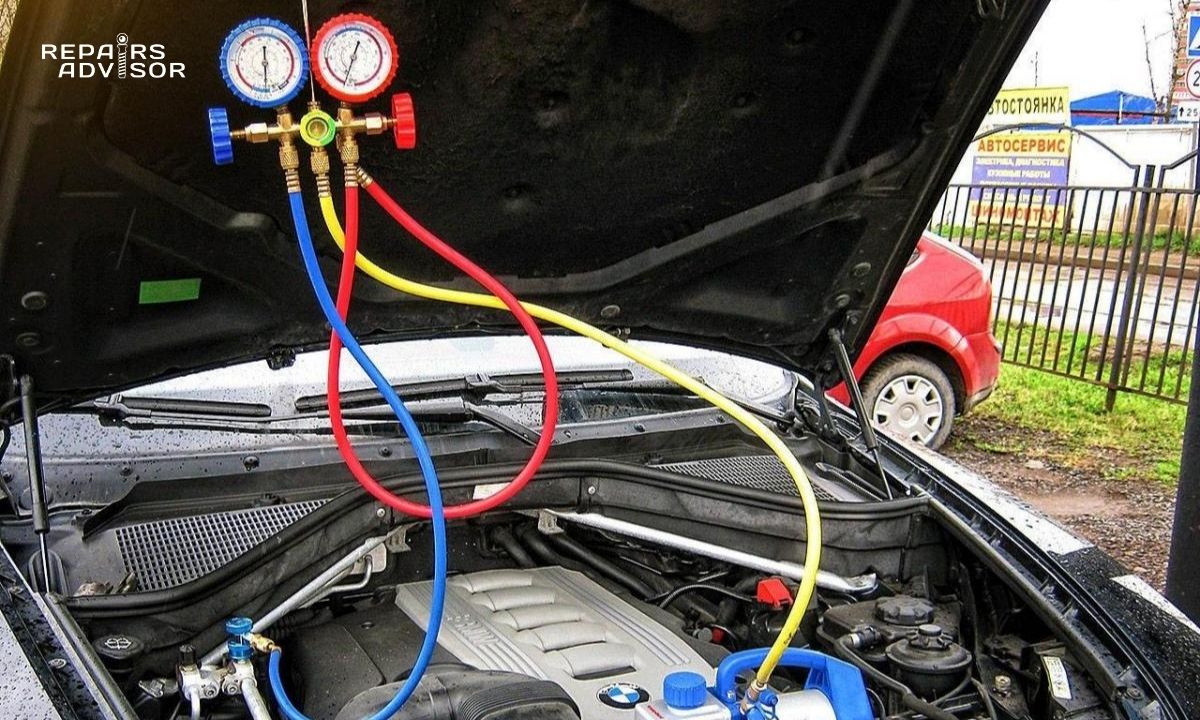

Basic Pressure Understanding (Reference Only)

While intermediate DIYers shouldn’t attempt pressure measurements, understanding normal ranges helps you communicate effectively with technicians. Typical low-side pressures range from 30-40 PSI for most residential systems, though this varies significantly with ambient temperature and specific refrigerant type.

Important note: Pressure testing requires specialized equipment and EPA certification. Attempting to connect gauges without proper training can release refrigerant and violate federal regulations.

Professional Requirements and Safety Protocols

EPA Section 608 Certification Requirements

Federal law requires EPA Section 608 certification for anyone handling refrigerants in stationary air conditioning equipment. This certification ensures proper handling, recovery, and disposal procedures that protect both human health and the environment. Uncertified refrigerant handling can result in fines up to $37,500 per violation.

Professional technicians must use certified recovery equipment to capture refrigerant before making repairs, preventing its release to the atmosphere. They’re also required to document all refrigerant transactions and disposal activities.

Health and Environmental Safety Concerns

Refrigerant exposure can cause various health problems, from mild skin and eye irritation to severe respiratory issues and cardiac sensitization. In confined spaces, leaked refrigerant can displace oxygen, creating asphyxiation risks. Different refrigerant types have varying toxicity levels, but all require careful handling.

Environmental regulations exist because many refrigerants have high global warming potential—some are thousands of times more potent than carbon dioxide. Proper handling and disposal prevent these chemicals from entering the atmosphere and contributing to climate change.

Equipment and Training Requirements

Professional refrigerant work requires specialized equipment including manifold gauge sets, electronic leak detectors, refrigerant recovery machines, and vacuum pumps. Technicians must understand pressure-temperature relationships, proper charging procedures, and leak detection techniques.

For those interested in professional training, many vocational schools and manufacturers offer EPA certification courses. However, for most homeowners, understanding when to call professionals is more valuable than attempting to develop these skills.

When to Contact HVAC Professionals

Immediate Professional Intervention Required

Contact an HVAC technician immediately if you observe ice formation on refrigerant lines, hear hissing or bubbling sounds from your system, or detect any chemical odors near your AC equipment. These symptoms indicate active refrigerant leaks that require immediate attention to prevent system damage and ensure safety.

Complete loss of cooling capacity also warrants emergency service, particularly during extreme weather conditions. Don’t attempt temporary fixes—professional diagnosis is essential for safe and effective repair.

Routine Professional Services

Schedule annual professional maintenance to verify refrigerant levels, check for small leaks, and ensure optimal system performance. Professional technicians can detect minor issues before they become costly problems and optimize your system’s efficiency.

If your system is older than 10 years or uses R-22 refrigerant, consider more frequent inspections. These systems are more prone to leaks, and R-22 replacement costs continue to rise due to phase-out regulations.

For technical documentation and troubleshooting guides specific to your equipment, visit our help center for assistance accessing repair manuals.

Preventive Maintenance for Refrigerant System Protection

Regular Inspection and Monitoring

Perform monthly visual inspections of your outdoor unit, checking for physical damage, debris accumulation, or signs of refrigerant leaks. Monitor your system’s performance by noting cooling times and energy consumption patterns. Early detection of problems prevents minor issues from becoming major repairs.

Keep vegetation trimmed at least two feet from your outdoor unit to ensure proper airflow and prevent damage from overgrowth. Remove debris like leaves, grass clippings, and dirt that can accumulate around the unit.

Filter Maintenance Impact

Clean air filters are crucial for refrigerant system health. Dirty filters restrict airflow across the evaporator coil, causing it to freeze and potentially damage refrigerant components. Replace or clean filters every 1-3 months during cooling season, more frequently in dusty environments or homes with pets.

Skill building opportunity: Regular filter maintenance is an excellent way for beginners to develop comfort with AC system basics while performing valuable preventive care.

Professional Maintenance Scheduling

Schedule professional maintenance annually, ideally in spring before peak cooling season. Professional service should include refrigerant level verification, leak detection, electrical connection inspection, and system performance optimization.

For systems approaching 15 years of age or those with previous refrigerant issues, consider bi-annual maintenance to catch problems early and extend system life.

Understanding Repair vs. Replacement Decisions

Cost-Benefit Analysis for Older Systems

When facing refrigerant leaks in older systems, particularly those using R-22, repair costs can approach replacement costs. R-22 refrigerant now costs $100-200 per pound, and leak repair labor can add significant expense. For systems over 15 years old requiring major refrigerant work, replacement often provides better long-term value.

Consider factors like overall system condition, expected remaining life, energy efficiency improvements with new equipment, and availability of replacement parts when making repair decisions.

Modern Refrigerant Advantages

New systems using R-454B and similar refrigerants offer improved efficiency, lower environmental impact, and better long-term cost stability. They’re also designed with enhanced leak resistance and easier service access compared to older equipment.

Future planning: Understanding refrigerant transitions helps you make informed decisions about system upgrades and long-term maintenance planning.

Advanced Considerations for Experienced Users

Leak Detection Technology

Professional leak detection has evolved significantly, with electronic sensors capable of detecting refrigerant concentrations as low as a few parts per million. UV dye testing provides visual confirmation of leak locations, while ultrasonic detectors can identify the high-frequency sounds of escaping gas.

Professional tip: Most refrigerant leaks are slow and occur at joints rather than in straight tubing sections. This knowledge helps focus inspection efforts on connection points and fittings.

System Efficiency Optimization

Proper refrigerant charge is just one factor in overall system efficiency. Duct sealing, insulation improvements, and airflow optimization can provide significant efficiency gains even with properly charged systems.

Advanced users should understand the relationship between refrigerant charge, superheat, subcooling, and overall system performance to make informed decisions about service and upgrades.

Regulatory Compliance and Documentation

Stay informed about evolving refrigerant regulations, particularly if you manage multiple properties or commercial systems. Proper documentation of refrigerant transactions, leak repairs, and disposal activities is required and helps demonstrate compliance during inspections.

Conclusion and Next Steps

Low air conditioning refrigerant is a serious issue that requires professional attention for safe and effective resolution. While intermediate DIYers can identify symptoms and understand basic causes, actual refrigerant handling must be left to EPA-certified technicians for safety, legal compliance, and system protection.

Your action plan: Start with visual inspections and performance monitoring to identify potential issues early. Establish relationships with qualified HVAC professionals for routine maintenance and emergency service. Keep detailed records of system performance to help diagnose problems and track improvements over time.

Skill development pathway: Beginners should focus on symptom recognition and safety awareness. Intermediate users can develop diagnostic skills while respecting professional boundaries. Those interested in advanced HVAC knowledge should consider formal training and EPA certification programs.

Remember that proper maintenance prevents most refrigerant issues. Regular filter changes, annual professional service, and prompt attention to performance changes will keep your system running efficiently for years to come.

For additional technical resources and equipment-specific guidance, explore our comprehensive collection of repair manuals and troubleshooting guides covering all major HVAC equipment manufacturers.

Safety Disclaimer: This information is provided for educational purposes only. Refrigerant handling requires EPA Section 608 certification and specialized equipment. Always consult qualified HVAC professionals for system diagnosis, repair, and maintenance. Improper refrigerant handling can result in equipment damage, personal injury, and federal penalties.