Ever wonder what connects your wheels and tires to your car’s steering and suspension, letting them turn and absorb bumps? That’s the unsung hero: the ball joint! Without them, you literally wouldn’t get very far. These crucial components are constantly under heavy load, navigating every pothole, speed bump, and uneven road surface you encounter. Because of this relentless stress, they eventually wear out and need replacement.

Here’s the critical part: when a ball joint breaks, it’s not just an inconvenience. It can quickly become a dangerous situation, leaving you stranded or, even worse, causing you to lose control of your car. The good news is that in most cases, a failing ball joint will give you some clear warning signs before it completely gives up.

How to Spot the Warning Signs of a Bad Ball Joint

Pay close attention to these clues – your car might be trying to tell you something!

- Metallic Clunking or Knocking Noise:

- This is one of the most common and noticeable symptoms. If you hear a clunking or knocking sound when your suspension moves up and down – especially when driving over uneven roads, rough terrain, potholes, or speed bumps – a worn ball joint is a prime suspect. The worn parts inside the joint start to rattle in their socket. This noise will typically get louder and more frequent as the joint wears further, a critical warning before it fails completely.

- Squeaking or Creaking Noise:

- Ball joints are constantly moving, so they need grease for smooth, quiet operation. If the protective rubber boot that seals in this grease gets damaged or torn, the grease can leak out and dirt can get in. Without proper lubrication, the ball joint will begin to squeak or creak. You’ll often hear this noise when you turn the steering wheel or go over bumps. It can sound eerily like a noisy door hinge, a rocking chair, or even a creaky spring mattress!

- Vibration:

- A loose or excessively worn ball joint can lead to significant vibration. This can make your car feel unstable, almost like it’s shaking, especially at certain speeds. You might also feel this vibration directly in the steering wheel, which can be quite unsettling.

- Wandering Steering (or Car Pulling):

- When your ball joints are worn, they no longer hold your steering and suspension components tightly in place. This looseness can throw off your front-end alignment, causing your car to pull to one side (right or left) or making the steering feel vague and less precise. You might find yourself constantly compensating with the steering wheel to keep the car going straight. This issue can also lead to uneven tire wear, so keep an eye on your tire treads!

How Ball Joints Work (Your Car’s Shoulder Joint!)

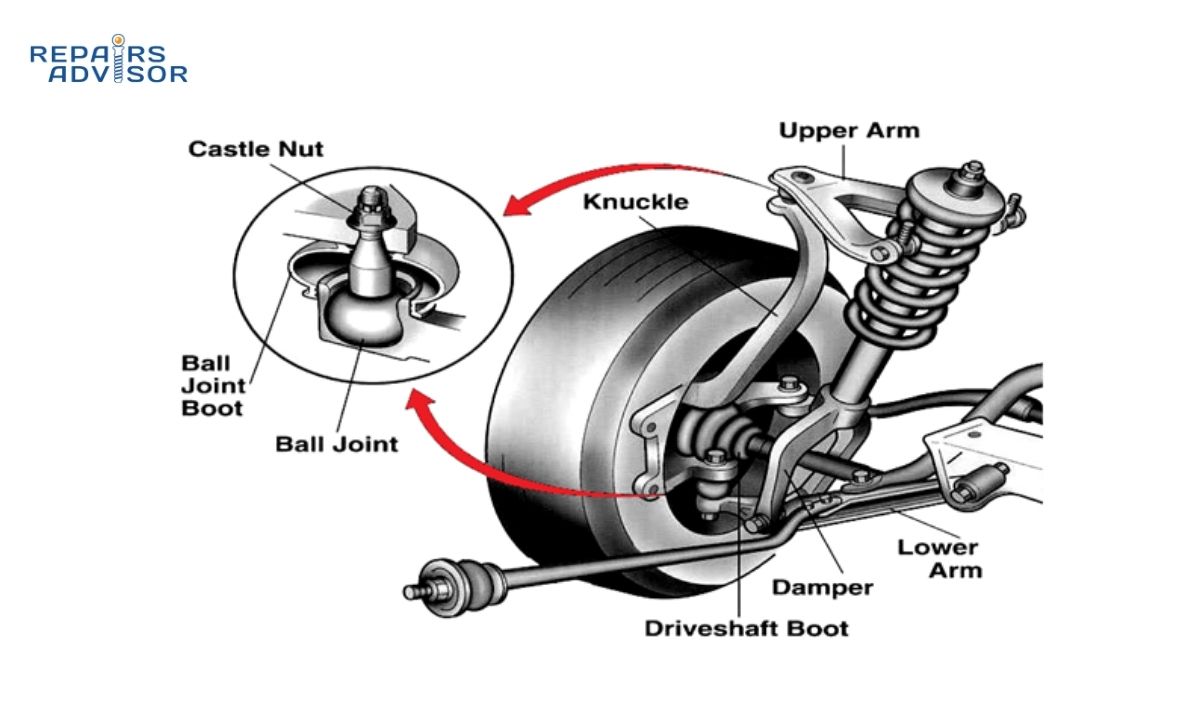

Think of a ball joint as very similar to the ball-and-socket joint in your own shoulder or hip. It’s a hard, spherical component with a threaded, tapered stud sticking out of it. This sphere is housed within a sturdy steel casing, filled with grease for smooth lubrication, and protected from dirt and debris by a flexible rubber boot.

In most cars, you’ll find front lower ball joints. Depending on your vehicle’s specific suspension design, you might also have upper ball joints or even ball joints in the rear suspension. The ball joint effectively connects the steering knuckle (or spindle) to the control arm. It provides a limited range of motion but allows movement in all directions, acting as the crucial pivot point for your steering, allowing your wheels to turn and articulate over bumps.

Ball Joint Repair Advice (When to Call the Pros!)

Most ball joints made in the last few decades are designed as sealed units and aren’t “serviceable” (meaning you can’t typically add grease). However, some older vehicles and heavy-duty trucks might have grease fittings that allow for lubrication. While they aren’t a routine maintenance item like an oil change, they should be inspected periodically for excessive play. Your owner’s manual might suggest specific intervals, but a good rule of thumb is to have them checked during each oil change service.

Ball joints can last for many years, with some even lasting the lifetime of the vehicle. However, factors like rough road conditions, frequent city driving (more bumps and turns!), and aggressive driving can significantly accelerate their wear. A car driven gently on highways might go hundreds of thousands of miles without needing replacement, while a city car could require new ball joints after just 30,000 miles.

If you start experiencing any of the symptoms of a bad ball joint, it is CRITICAL to get your car to a reputable repair facility immediately. A broken ball joint is extremely dangerous – it can cause your car to lose steering control or even lead to the suspension collapsing entirely.

Here’s what your mechanic will do:

- Professional Inspection: They’ll thoroughly check your ball joints for excessive “play” (looseness). They have specific techniques to lift the vehicle and test for movement that indicates wear.

- Pair Replacement Recommendation: Often, if one ball joint is failing, the technician may recommend replacing them in pairs (e.g., both front lower ball joints). This is because if one has worn out, its counterpart on the other side is likely to follow suit soon. It’s also an excellent time to have the entire vehicle’s suspension inspected for any other worn components.

- Cost Considerations: The cost to replace ball joints can vary. On some cars, only the ball joint itself can be replaced. On others, the ball joint is integrated into the entire control arm, meaning the whole control arm needs to be swapped out, which can increase the cost. Labor costs also vary depending on the complexity of your suspension system and whether your car is four-wheel or all-wheel drive.

- Wheel Alignment: Crucially, a wheel alignment will almost always be required after replacing the ball joints. This ensures your steering geometry is correct, preventing uneven tire wear and ensuring safe handling.

Should You Try to Replace a Ball Joint Yourself? (Think Twice!)

This is one job that is definitely best left to professionals. Here’s why you should think twice about tackling it yourself:

- Extreme Caution Required: Your car’s suspension system contains components (like springs) that are under a great deal of tension. If not handled correctly, they can release violently, causing serious injury or even death.

- Specialized Tools & Knowledge: Proper ball joint replacement often requires specific specialized tools (like ball joint presses or separators) and detailed work instructions. The disassembly and reassembly of your suspension components need to be done safely and in a very specific order.

- Safety First: If you do have extensive experience with sophisticated automotive systems and decide to attempt this, ensure you have all the proper tools, use jack stands (never just a jack!), wear safety goggles, and ideally, have a second set of hands and eyes at your disposal.

- Quality Parts & Torque: Always use factory-quality, or OEM, parts and meticulously follow manufacturer torque specifications for all fasteners.

Ultimately, your mechanic has the proper tools, equipment, and expertise to repair your ball joints safely and efficiently, getting your car back on the road with reliable steering and suspension.