Alright, let’s talk about one of the unsung heroes of your car’s ride, handling, and most importantly, your safety: the control arm. This isn’t just some random metal bar; it’s a vital part of your car’s suspension system that directly connects each wheel to your vehicle’s frame or body structure. Think of it as the “arm” that precisely “controls” how your wheel moves up and down in response to bumps, potholes, and everything else the road throws at you.

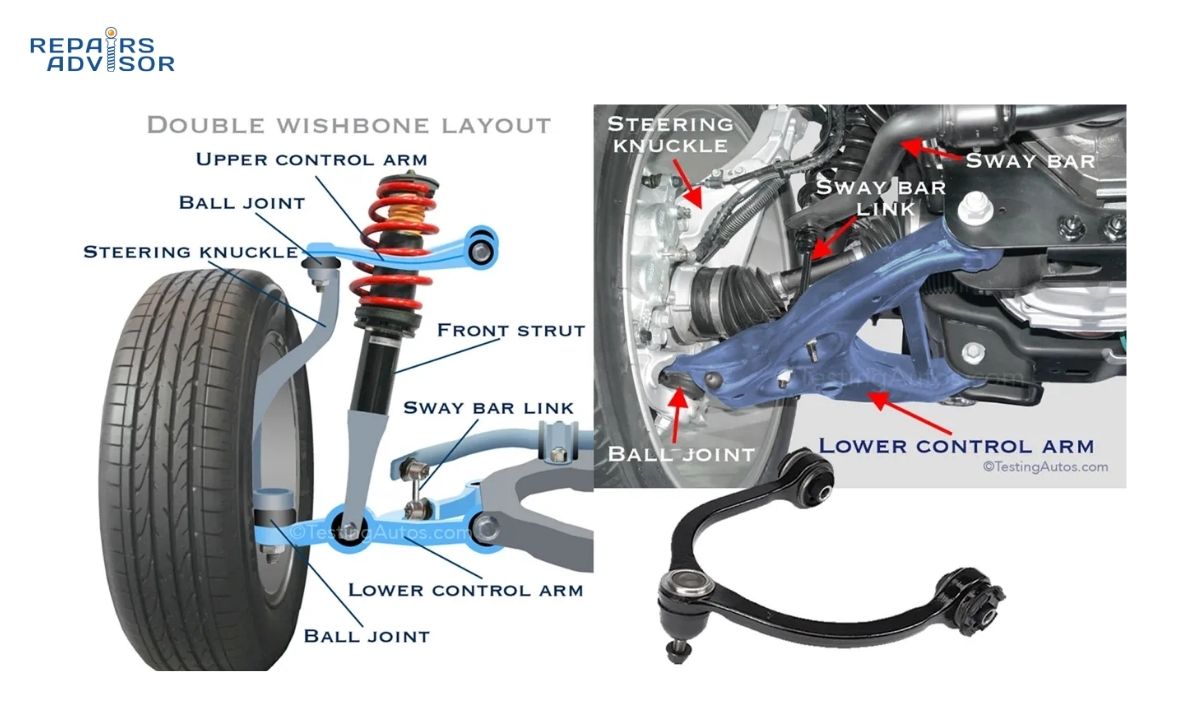

Control arms connect to the frame via flexible bushings (often rubber or polyurethane) that allow them to pivot, and they connect to the wheel assembly (steering knuckle/spindle) using ball joints. This intricate dance allows your wheels to react to road imperfections while keeping everything aligned and stable. They’re also crucial for allowing your shock absorbers and dampers to do their job properly. In the front, they’re intrinsically linked to your steering system, helping guide your wheels precisely.

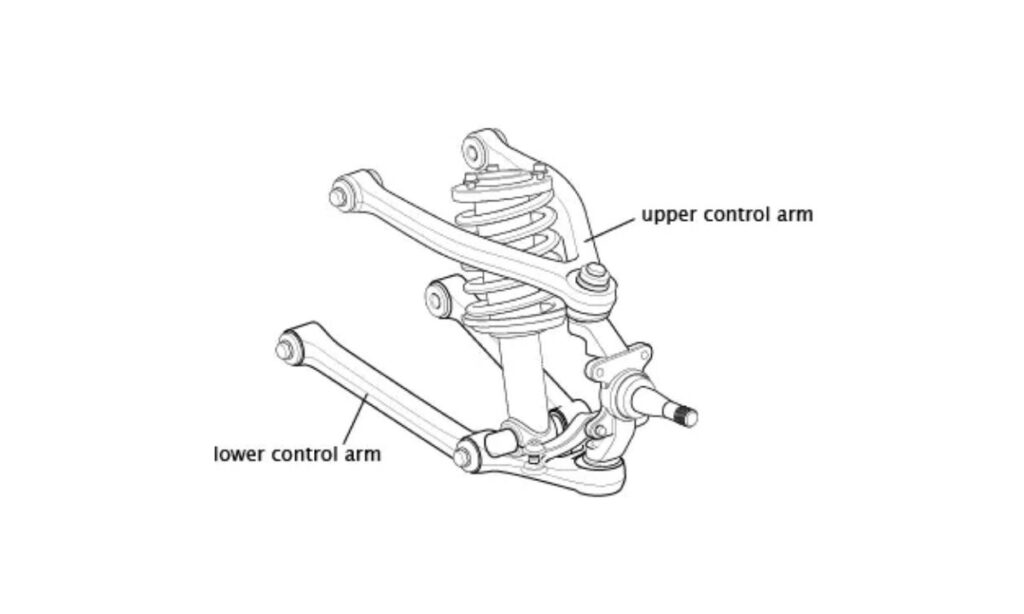

Depending on your vehicle, control arms can be made from iron, steel, or aluminum. Most modern cars with strut-type suspensions will have at least one lower control arm per wheel, front and rear. Some high-performance or heavy-duty vehicles use a “double wishbone” design, featuring both upper and lower control arms for even more precise wheel control. You might also hear them called A-arms, wishbones, track control arms, or rear camber arms – they all do a similar job!

Why a Bad Control Arm is a Serious Safety Risk

Let me be clear: a problem with your control arms is very serious. Because these components are integral to both your vehicle’s suspension and steering systems, their failure can directly impact your ability to control and steer your car, especially in an emergency situation. A severely worn or broken control arm could lead to a sudden loss of control, potentially causing a collision.

Control arm problems can stem from various issues:

- Corrosion: Rust can weaken the metal.

- Collisions or Hard Impacts: Hitting a curb, driving through a large pothole, or being in an accident can bend or break them.

- Improper Towing: Incorrect lifting points can damage suspension components.

- Worn-out Ball Joints or Bushings: Often, the control arm itself is fine, but the attached wear items fail, leading to symptoms.

Here are the critical warning signs that your control arms might be failing:

- Strange Noises (Clunking, Squeaking, Popping):

- This is one of the most common and noticeable symptoms. If you hear persistent squeaking, knocking, clunking, banging, popping, or snapping noises, especially when:

- Going over bumps, potholes, or uneven roads.

- Steering (turning the wheel left or right).

- Accelerating hard.

- Decelerating (especially when braking).

- These sounds indicate excessive play in the worn bushings or ball joints attached to the control arm. The metallic components are literally rattling against each other.

- This is one of the most common and noticeable symptoms. If you hear persistent squeaking, knocking, clunking, banging, popping, or snapping noises, especially when:

- Steering Issues (Wandering, Pulling, Instability):

- A worn control arm directly impacts your vehicle’s steering precision. You might notice your car:

- “Wandering” on the road, making it hard to keep a straight line without constant steering corrections.

- Pulling significantly to one side, requiring you to hold the steering wheel off-center.

- Feeling unstable or “loose” when cruising, braking, or driving on uneven surfaces.

- This happens because the front-end alignment relies on all steering and suspension components being tight. A loose control arm throws everything off.

- A worn control arm directly impacts your vehicle’s steering precision. You might notice your car:

- Uneven and/or Accelerated Tire Wear:

- When a control arm is bad, it prevents your wheels from staying at their correct alignment angles. This misalignment forces your tires to drag or scrub unevenly against the road, leading to rapid and uneven tire wear patterns. You might see excessive wear on the inner or outer edge of the tire, or a choppy, feathered appearance. This is a clear sign that your suspension geometry is compromised.

- Vibrations Felt Through the Steering Wheel:

- A loose or worn control arm (specifically its bushings or ball joint) can cause significant vibrations that travel up through the suspension into your steering column. You’ll feel these vibrations directly through the steering wheel while driving, making the car feel unstable and affecting your comfort.

How to Fix a Bad Control Arm: It’s a Pro’s Job

A bad control arm usually fails due to wear and tear or impact damage. While sometimes only the bushings or ball joints are the culprits, the best solution is almost always replacement with a new control arm assembly. Why?

- Cost-Effectiveness: While the metal arm itself might be fine, replacing just the rubber bushings often requires specialized tools (like a shop press) and significant labor time. Many times, your mechanic will find it more cost-effective to replace the entire control arm assembly, which comes with new bushings and a new ball joint already installed.

- System Integrity: This ensures all critical wear components on that control arm are fresh, giving you optimal performance and durability.

Here’s what your mechanic will do:

- Thorough Inspection: They’ll start by putting your vehicle on a lift to get it safely off the ground. A comprehensive inspection of your car’s entire suspension system will be performed to identify the exact source of the problem and check for any other related wear or damage.

- Removal & Replacement: The faulty control arm will be carefully removed. A new control arm will then be installed, usually along with new mounting hardware, bushings, and ball joints.

- Pair Replacement (Recommended): If the control arm problem is due to general wear and tear, it’s highly recommended that both control arms on the affected axle be replaced (e.g., both front lower control arms). This is because if one has failed, the other is likely to be just as worn and will soon follow suit. This approach saves you a trip back to the shop and ensures balanced handling.

- Four-Wheel Alignment: This is absolutely critical! After replacing control arms, your vehicle’s suspension geometry will be out of whack. A four-wheel alignment is mandatory to ensure your wheels are correctly angled, preventing rapid tire wear and restoring proper steering and handling.

Don’t Try to Replace a Control Arm Yourself! (Seriously.)

Unless you have extensive experience working with automotive suspension systems, specialized tools, and access to a professional lift, leave this repair to the professionals! Your control arms are instrumental to your car’s steering and suspension, meaning the job must be done correctly and safely.

- Safety First: Suspension components can be under extreme tension (especially springs and sway bars). Improper handling can lead to severe injury or even death.

- Specialized Tools: Replacing bushings and other related components often requires a shop press and other tools that are custom for specific makes and models. The cost of these tools alone, coupled with the experience and precision required to use them safely, makes this a job for a pro.

- Correct Torque & Procedure: Every bolt in your suspension has a specific torque specification that must be strictly adhered to. Ignoring this can lead to loose components or damaged parts.

Your mechanic has the experience, the proper specialized tools, and the equipment to replace your control arms safely, efficiently, and cost-effectively, getting your car back on the road handling like it should.