Every time you drive over a pothole, speed bump, or uneven road surface, your suspension springs are working behind the scenes to keep your ride comfortable and your vehicle stable. These unsung heroes absorb thousands of impacts daily, yet most drivers never think about them until something goes wrong. Understanding how suspension springs work isn’t just about technical knowledge—it directly affects your vehicle’s ride quality, handling characteristics, safety performance, and load-carrying capacity.

Whether you’re considering a suspension upgrade, diagnosing a handling problem, or simply want to understand what’s happening beneath your vehicle, knowing the differences between coil, leaf, and air springs helps you make informed maintenance decisions. Your choice of spring type affects everything from daily comfort to towing capability, and recognizing the early warning signs of spring failure can prevent dangerous driving conditions and costly repairs. Let’s explore how these critical components support your vehicle and keep you connected to the road with your car’s complete suspension system.

What Are Suspension Springs and Why Do Vehicles Need Them?

Suspension springs serve as the primary load-bearing component in your vehicle’s suspension system, performing several critical functions simultaneously. Most fundamentally, they support the entire weight of your vehicle while maintaining proper ride height—the distance between your chassis and the ground. Without springs, your vehicle would sit directly on its suspension stops with no ability to absorb impacts.

Beyond simply holding up your vehicle, springs act as energy storage devices that absorb road impacts from potholes, bumps, speed bumps, and uneven surfaces. When your wheel encounters an obstacle, the spring compresses to absorb that impact energy, then releases it in a controlled manner rather than transmitting the full shock through your chassis and into the passenger compartment. This absorption capability enables your suspension to travel vertically, allowing wheels to move up and down independently while keeping the chassis relatively stable.

Springs work in partnership with shock absorbers and struts to create a complete damping system. While springs store and release energy, shock absorbers control the rate at which that energy dissipates. Without shocks, springs would oscillate freely after hitting a bump, causing your vehicle to bounce uncontrollably. The spring handles the impact absorption while the shock controls the motion, and together they distribute the load efficiently between your chassis and wheels.

Understanding spring rate is fundamental to grasping how springs affect your vehicle’s behavior. Spring rate refers to the amount of force required to compress the spring by one inch—typically measured in pounds per inch. A spring with a 500 lb/in rate requires 500 pounds of force to compress it one inch, 1,000 pounds to compress it two inches, and so on.

Springs come in two basic rate types: linear and progressive. Linear springs maintain the same rate throughout their compression range, providing consistent, predictable behavior. Progressive springs, on the other hand, have a rate that increases as they compress—they start soft for comfortable daily driving but become stiffer under heavy loads or aggressive driving. Automakers carefully tune spring rates for each specific vehicle based on its weight, intended purpose, and desired ride characteristics, balancing comfort with handling performance.

The Three Main Types of Suspension Springs

Coil Springs: The Modern Standard

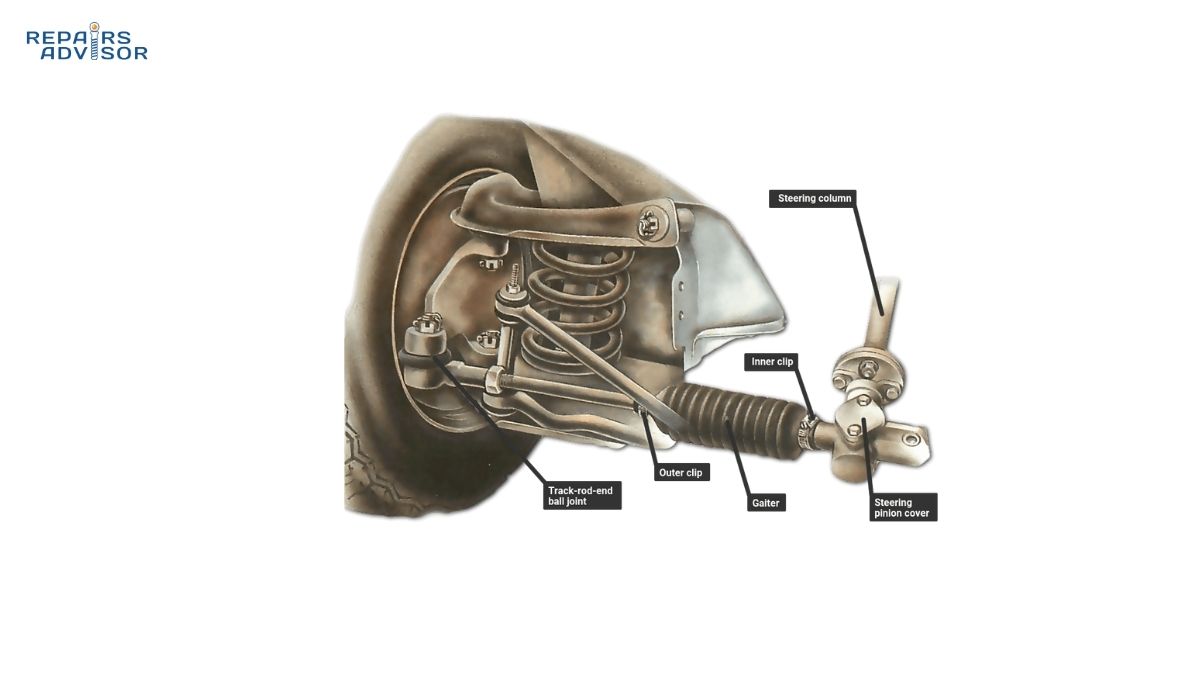

Coil springs have become the dominant choice in modern automotive suspension design, and for good reason. These springs consist of tightly wound steel coils arranged in a helical shape, manufactured from high-grade spring steel designed to withstand millions of compression cycles. The coil spring acts as a buffer between your shock absorbers or struts and the chassis, typically sitting on top of the axle or integrated directly into a strut assembly like a MacPherson strut.

You’ll find coil springs on most modern passenger cars at both the front and rear, as well as on many light trucks and SUVs. They’re especially common in independent suspension systems where each wheel needs to move independently of the others. The coil spring’s cylindrical shape allows it to compress and extend vertically while maintaining its structural integrity, making it ideal for front suspensions that must also accommodate steering movement.

Coil springs deliver superior ride quality and comfort compared to older spring designs. Because each spring operates independently, wheels can respond individually to road irregularities without affecting the opposite side of the vehicle. This independent wheel movement translates directly into better handling characteristics and more predictable vehicle behavior in turns. Coil springs also excel at suspension articulation—the ability to flex and accommodate extreme suspension travel—which is why you’ll find them on many off-road vehicles despite their perceived delicacy.

Weight savings represent another significant advantage. Coil springs typically weigh less than leaf springs capable of supporting similar loads, reducing unsprung weight (the weight not supported by the suspension) which improves ride quality and handling response. Modern coil springs also offer customization options that weren’t possible with older designs: progressive rate springs that start soft but become firmer under load, linear rate springs for consistent behavior, and dual-rate springs that combine characteristics of both.

However, coil springs do have drawbacks. They cost more to manufacture and install than simpler leaf spring designs, and the supporting suspension components add further expense. While excellent for normal loads, coil springs can be less stable than leaf springs when supporting very heavy weights, though modern engineering has largely addressed this limitation. Double wishbone suspension systems that use coil springs require complex geometry with multiple pivot points and mounting locations, making repairs and modifications more involved. Retrofitting coil springs to a vehicle originally designed for leaf springs often requires extensive modification, making the conversion expensive and time-consuming for most applications.

Leaf Springs: The Heavy-Duty Workhorse

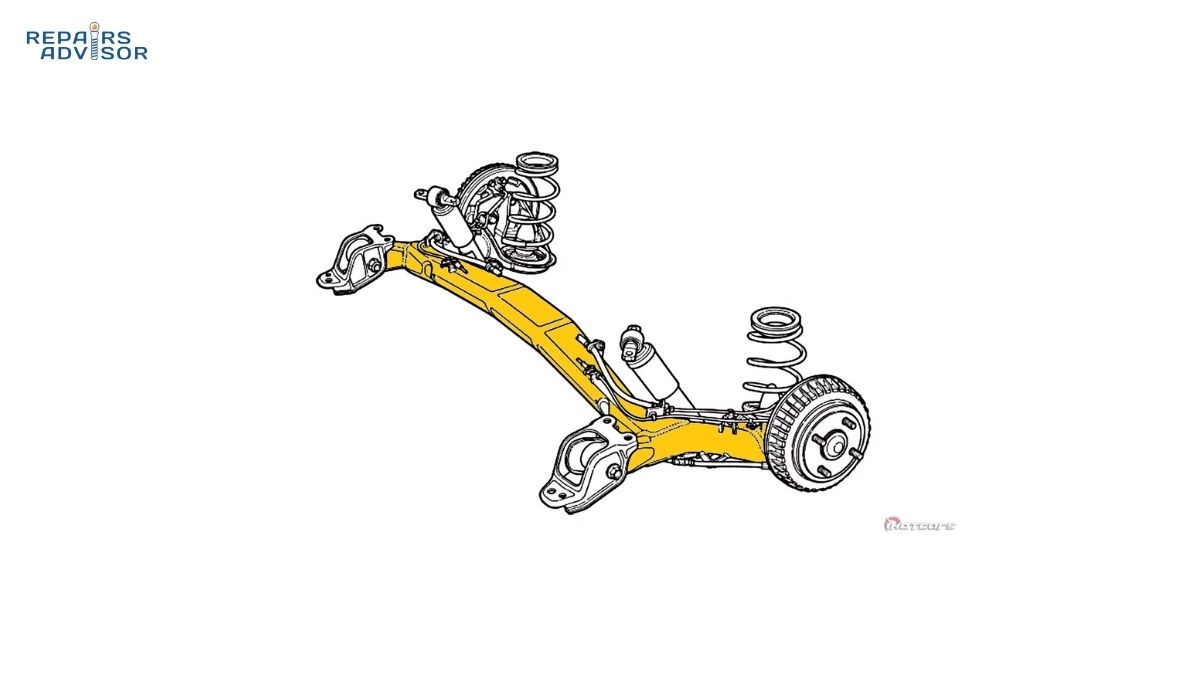

Leaf springs represent one of the oldest suspension technologies still in widespread use, and they remain popular in commercial and heavy-duty applications because of their inherent strengths. These springs consist of multiple layers—called leaves—of spring steel stacked together and formed into an arc or elliptical shape. The spring mounts to the vehicle chassis at both ends while the axle attaches in the middle, creating a simple but effective load-bearing structure.

The arc shape is critical to how leaf springs function. As weight is applied, the arc flattens slightly, and friction between the individual leaves provides inherent damping that helps control spring oscillation. This self-damping characteristic means leaf springs don’t rely as heavily on shock absorbers as coil springs do, though modern leaf spring systems still benefit from quality shocks.

You’ll primarily find leaf springs on heavy-duty trucks and commercial vehicles where load capacity outweighs ride comfort concerns. The rear suspension of rear-wheel drive trucks almost universally used leaf springs for decades, and many still do today. Trailers, agricultural equipment, and off-road vehicles that carry heavy loads or encounter punishing terrain also frequently rely on leaf springs. They work particularly well with solid axle configurations where both wheels on an axle move together rather than independently.

Leaf springs excel at carrying heavy loads. Their wide, flat shape distributes weight over a larger area, and you can increase load capacity simply by adding more leaves to the spring pack. The simple, robust design means fewer components that can fail, and leaf springs typically cost less to manufacture and maintain than more complex coil spring systems. Unlike coil springs which require control arms and multiple mounting points, leaf springs serve a dual function—they support the vehicle’s weight AND locate the axle, eliminating the need for separate control arms in many applications.

Adjusting vehicle ride height is relatively straightforward with leaf springs. Adding blocks between the spring and axle raises the vehicle, while de-arching or removing leaves lowers it. This simplicity makes leaf springs popular for lifted trucks and vehicles used in off-road or commercial settings. Their durability in extreme conditions—whether from overloading, rough terrain, or harsh weather—has been proven over more than a century of use.

The tradeoffs are significant, however. Leaf springs deliver a noticeably rougher, more jarring ride quality compared to coil springs, especially when the vehicle is empty or lightly loaded. The fixed mounting points at both ends limit adjustability and make it difficult to customize suspension geometry for different applications. Leaf springs also allow considerably less suspension articulation and flex than coil springs, which can reduce wheel-to-ground contact in extreme off-road situations.

A phenomenon called “axle wrap” can occur under hard acceleration, where the leaf spring twists into an S-shape as torque tries to rotate the axle. This creates inconsistent suspension behavior and can damage components. While later designs with better control and additional links help manage this issue, it remains an inherent limitation of leaf spring geometry.

Air Springs (Air Bags): The Adjustable Solution

Air springs—also called air bags or air suspension—represent the cutting edge of spring technology, offering adjustability and performance that traditional metal springs simply cannot match. Rather than relying on steel’s physical properties, air springs use compressed air contained within a flexible rubber and plastic bladder to support the vehicle’s weight. The system includes ride height sensors at each wheel, an air compressor, a reservoir tank to store compressed air, and a sophisticated control system that manages everything electronically.

Modern air suspension systems continuously monitor vehicle height and load conditions, automatically adjusting air pressure to maintain optimal ride characteristics. When sensors detect the vehicle sitting too low—perhaps because cargo has been loaded—the control module commands the compressor to pump additional air into the springs. Conversely, when load is removed, the system releases air to maintain the preset ride height.

Luxury vehicles frequently feature air suspension for the superior ride comfort it provides. By varying air pressure, the system can deliver a soft, compliant ride for highway cruising but firm up for spirited cornering. Commercial trucks use air springs for automatic load-leveling, maintaining consistent ride height and handling whether empty or hauling maximum payload. Performance vehicles benefit from adjustable ride height—lowering for improved aerodynamics and handling at speed, then raising for ground clearance over speed bumps or steep driveways.

Many truck owners add air springs as supplemental support to factory leaf or coil springs, using air bags to level the vehicle when towing heavy trailers without replacing the entire suspension system. This bolt-on approach provides the benefits of air suspension at lower cost than a complete system conversion.

The advantages are compelling. Adjustable ride height on demand means you can lower your vehicle for easier loading, improved aerodynamics, or that aggressive stance, then raise it back up for ground clearance when needed. The automatic load-leveling capability maintains consistent handling and headlight aim regardless of cargo weight. Air springs deliver exceptional ride comfort, effectively isolating occupants from road irregularities while maintaining control. The system adapts to varying payload conditions automatically, and many systems reduce body lean in corners by increasing pressure on the appropriate springs.

Cost represents the most significant disadvantage. Air suspension systems typically cost $1,500 or more just for parts when replacement is needed, and that’s often multiplied by four corners. The complexity inherent in having compressors, air lines, sensors, and control modules means more components that can potentially fail. Air leaks anywhere in the system can cause it to fail completely, leaving your vehicle sitting on its bump stops—sometimes suddenly. The system requires a compressor, height sensors, control module, and associated wiring that all need maintenance and eventual replacement, making long-term ownership costs higher than traditional springs.

Common Suspension Spring Failure Symptoms

Visual and Physical Indicators

The most obvious sign of spring failure is uneven ride height. Walk around your vehicle and look at each corner—does one side sit noticeably lower than the other? Is one corner sagging? Grab a tape measure and check the distance from the ground to the center of each wheel arch. Significant differences indicate a problem with the spring at that corner. This sagging happens because springs weaken over time, break, or in the case of air springs, develop leaks that prevent them from maintaining proper pressure. For detailed guidance, check out how to spot a bad front coil spring.

Visible spring damage often telegraphs an impending failure before it becomes critical. Inspect your coil springs for breaks or cracks, especially if you notice rust on the surface. The flexible coating that protects coil springs from corrosion can chip or crack from road debris, allowing moisture to corrode the metal underneath. Corrosion creates stress risers that concentrate force at specific points, eventually causing the spring to fracture at that weak spot.

Leaf springs show their age differently. Look for leaves that have separated from the pack, severe rust on individual leaves, or a spring pack that has lost its arc and appears flattened even without load. The rubber bushings at the mounting points can deteriorate, allowing excessive movement. For leaf spring troubleshooting, reference how to tell if your leaf spring is failing.

Air springs typically fail through leaks in the rubber bladder or cracks in the air lines. You might notice the compressor running more frequently than normal as it tries to compensate for air loss, or find your vehicle sitting low after being parked overnight. Inspect the rubber bladders for cracks, dry rot, or obvious punctures, and check all air line connections for leaks using soapy water—bubbles indicate escaping air.

Driving Performance Issues

Excessive bouncing after hitting bumps signals worn springs that can no longer control vehicle motion properly. When springs weaken, they become easier to compress, giving the suspension more travel than designed. This extra travel manifests as continued bouncing after you hit a bump, drive over a speed bump, or turn into a driveway. A healthy suspension should compress when hitting an obstacle, then quickly settle back to its normal position without oscillating. If your vehicle continues bouncing two or three times after the initial impact, your springs (or shocks) likely need replacement.

Bottoming out represents a more serious symptom. This occurs when your vehicle scrapes its undercarriage on the ground during normal driving—perhaps when entering a driveway at an angle or driving over a dip in the road. When springs can no longer support the vehicle’s weight, the suspension compresses fully until the chassis hits the bump stops or even the ground itself. This can damage your oil pan, drive shaft, transmission, exhaust system, or other undercarriage components. Bottoming out often happens when springs have sagged significantly or broken completely.

Poor handling and stability become noticeable during everyday driving. Excessive body roll when turning corners indicates your springs can no longer resist the lateral forces pushing the vehicle’s weight outward. Your vehicle might lean or sway noticeably during lane changes or feel disconnected from the road. Weak springs also increase stopping distances because the vehicle’s weight shifts forward more dramatically during braking, potentially overwhelming the front suspension and causing instability. When one side sits lower than the other from spring failure, it affects both steering geometry and brake balance, making the vehicle pull to one side or requiring constant steering correction.

Noise and Vibration

Clunking and knocking sounds over bumps or rough pavement often indicate spring problems, though they can stem from other suspension components as well. A broken coil spring fragment can rattle around, striking nearby components. Spring failure throws suspension geometry out of specification, allowing parts that shouldn’t touch to scrape against each other. The metallic knocking or clunking typically worsens over progressively rougher surfaces. For help differentiating spring noise from shock absorber problems, review how to tell if your front shock absorber is failing.

Tire wear patterns provide another diagnostic clue. When springs fail and suspension geometry changes, your tires no longer meet the road at the correct angle. This causes accelerated wear on either the inside or outside edges of the tire tread. Spring-related misalignment typically affects camber (the inward or outward tilt of the tire as viewed from front or rear) or caster (the forward or backward tilt of the steering axis). The uneven tire contact patch can also cause vibrations at higher speeds as the out-of-balance condition becomes more pronounced.

Safety Warning

Driving with broken or severely weakened suspension springs poses serious safety risks that cannot be overstated. A broken spring dramatically reduces your vehicle’s handling capability and stability, especially during emergency maneuvers when you need maximum control. The broken spring fragment can work its way through the spring mount and puncture your tire, potentially causing a sudden blowout at highway speeds. Continuing to drive on failed springs puts excessive stress on shock absorbers, control arms, ball joints, and other suspension components, turning a straightforward spring replacement into a much costlier repair job. Most critically, the unpredictable handling characteristics and increased stopping distances significantly increase your accident risk.

If you discover a broken or severely sagging spring, have your vehicle towed to a repair facility rather than driving it. The cost of a tow truck is minimal compared to the potential consequences of losing control or causing additional damage. This isn’t an issue to defer—address spring failure as soon as you identify it.

Spring Replacement: DIY vs. Professional Service

When to Replace Springs

Always replace suspension springs in pairs—both front or both rear—even if only one has failed. This maintains balanced suspension characteristics and prevents the vehicle from sitting unevenly or handling unpredictably. Installing one new spring alongside an old spring means they’ll have different spring rates, causing uneven ride height and handling issues.

Typical coil spring lifespan ranges from 50,000 to 100,000 miles, though this varies considerably based on driving conditions, vehicle weight, and how the vehicle is used. Constant exposure to salt in winter climates accelerates corrosion and shortens life. Regular overloading or aggressive off-road use can weaken springs prematurely. Leaf springs in commercial applications may need replacement more frequently due to heavier loads and harder use.

Replace springs when you notice sagging that affects ride height, when you discover broken or cracked coils, or when heavy corrosion has weakened the spring structure. Many mechanics recommend replacing springs whenever you replace struts, as labor costs for accessing both components are similar and worn springs can prevent new struts from performing optimally.

Critical note: Any suspension work that changes ride height or suspension geometry requires a front-end alignment afterward. Driving on a misaligned suspension accelerates tire wear and can create handling problems. Factor alignment costs into your budget when planning suspension repairs.

DIY Replacement Considerations

Coil spring replacement demands respect and proper safety procedures. You’ll need a spring compressor—a specialized tool that slowly and safely compresses the spring so it can be removed from the strut or suspension assembly. You’ll also need jack stands rated for your vehicle’s weight, a quality floor jack, basic hand tools, and a torque wrench to properly tighten suspension bolts to manufacturer specifications.

The safety warning cannot be emphasized enough: coil springs store tremendous tension, enough to cause severe injury or death if released improperly. A spring under compression can explode violently if the compressor fails or slips. Many professional mechanics have witnessed or experienced close calls with spring compressors, which is why they treat them with extreme caution. This isn’t a job to attempt without proper training and understanding of the forces involved.

Cost comparison helps illustrate the value calculation. Coil spring parts typically run $70 to $167 per spring, so a pair might cost $140 to $334. Professional installation averages $727 to $1,268 including parts and alignment. Your DIY savings amount to roughly $400 to $800, but you must weigh that against the time required (3 to 6 hours for someone with experience) and the very real safety risks. For first-time attempts, professional service is strongly advised.

Leaf spring replacement is more straightforward than coil springs but still requires proper equipment and care. You’ll need sturdy jack stands, a U-bolt wrench or impact wrench, a complete socket set, torque wrench, and penetrating oil for corroded bolts. DIY parts cost $70 to $150 per leaf spring compared to $450 to $790 for professional installation. The moderate complexity level and lower safety risk than coil springs make leaf spring replacement more DIY-friendly, though proper vehicle support remains critical.

Air spring replacement should almost never be attempted as a DIY project. Professional service averages $1,529 to $1,650, and that high cost reflects the complexity involved. The system must be properly depressurized before work begins, requires electronic diagnostics to identify problems and reset the system after repair, and needs to be purged of air and moisture before recharging. Air spring systems integrate with vehicle computers and sensors that require special tools to access. Unless you have professional training and equipment, leave air suspension work to qualified technicians.

Professional Service Benefits

Professional shops have the proper spring compression equipment, years of experience handling springs safely, warranties on both parts and labor, and usually include alignment in their service packages. Many shops now use Quick-Strut complete strut assemblies that come pre-assembled with new springs, eliminating the dangerous spring compression step entirely while saving labor time.

Suspension work frequently uncovers related problems. When replacing springs, technicians often discover worn ball joints, damaged control arms, or leaking shocks that should be addressed at the same time. Having all these components serviced together saves on labor costs compared to returning multiple times for separate repairs.

How Spring Type Affects Vehicle Performance

Load Capacity and Towing

Leaf springs remain the undisputed champion for heavy loads and frequent towing. Their wide load distribution and ability to add leaves for increased capacity make them ideal for commercial trucks, heavy-duty pickups, and work vehicles. A properly configured leaf spring pack can support thousands of pounds while maintaining structural integrity.

Coil springs work better for lighter, performance-oriented vehicles where load capacity takes a back seat to handling dynamics. They provide adequate support for normal passenger and cargo loads while delivering superior comfort and road feel. Modern coil spring trucks like some Ram 2500 models prove that proper engineering can make coil springs viable even in three-quarter-ton applications, though they remain the exception rather than the rule in heavy-duty segments.

Air springs offer the best of both worlds through adjustability. They can run soft for comfortable unloaded driving, then automatically firm up to support heavy loads. This adaptability makes them increasingly popular on luxury vehicles and heavy trucks. Progressive rate coil springs attempt to bridge the gap, starting soft for comfort but becoming firmer under load to maintain support and control.

Ride Quality Comparison

Coil springs deliver the smoothest ride and best overall comfort. Each wheel responds independently to road irregularities, and the spring’s consistent rate provides predictable behavior that’s easy to tune for specific comfort characteristics. This is why virtually all modern passenger cars use coil springs—occupant comfort ranks as a top priority.

Leaf springs sacrifice comfort for durability and load capacity. The ride is noticeably rougher, particularly when the vehicle is empty or lightly loaded. Each bump transmits more harshly through the chassis. The jarring quality becomes especially pronounced in heavy-duty, dual-rear-wheel applications with stiff spring packs designed for maximum payload.

Air springs provide the most refined ride when properly functioning. The system can actively adjust damping characteristics based on road conditions, vehicle speed, and driving style. You get limousine smoothness for highway cruising but responsive handling for spirited driving. The tradeoff is complexity and cost.

Off-Road and Performance Applications

Coil springs allow substantially greater suspension articulation than leaf springs—critical for serious off-road use where wheels need maximum travel to maintain ground contact on extreme terrain. Rock crawlers and trail vehicles almost universally prefer coil springs for this reason. The independent wheel movement also prevents one side’s motion from affecting the other.

Leaf springs excel in durability for off-road commercial and agricultural use. While they don’t articulate as much, they’re nearly indestructible and simple to repair in the field. Mining operations, logging equipment, and farm trucks rely on leaf springs because complexity is the enemy of reliability in harsh environments.

Aftermarket spring options abound for specialized applications. Off-road enthusiasts can choose softer springs for better articulation, while performance drivers might opt for stiffer progressive springs that reduce body roll. Racing applications frequently use springs with carefully calculated rates for specific track conditions. These suspension components work together with anti-roll bars to fine-tune handling characteristics.

Maintenance and Longevity

Coil springs require periodic inspection for rust, cracks, and sagging. Look for corrosion where the protective coating has chipped away, and measure ride height annually to track any gradual sagging. Catching problems early prevents the dangerous situations that arise from sudden spring failure.

Leaf springs need attention to individual leaves, mounting shackles, and bushings. Inspect for separated leaves, broken center bolts, and wear in the bushings at mounting points. Keep mounting hardware properly torqued and lubricate bushings per manufacturer recommendations.

Air springs demand the most vigilant maintenance. Monitor the system for air leaks in bladders and lines, listen for compressor problems like excessive run time or unusual noises, and have the system’s electronic components checked during regular service intervals. Check air line connections and fittings regularly—a small leak caught early costs much less than a complete system failure.

Regular inspections during oil changes catch most spring problems before they become critical. A few minutes spent looking at your suspension can save hundreds or thousands in repair costs and prevent a dangerous roadside breakdown.

Related Suspension Components Working With Springs

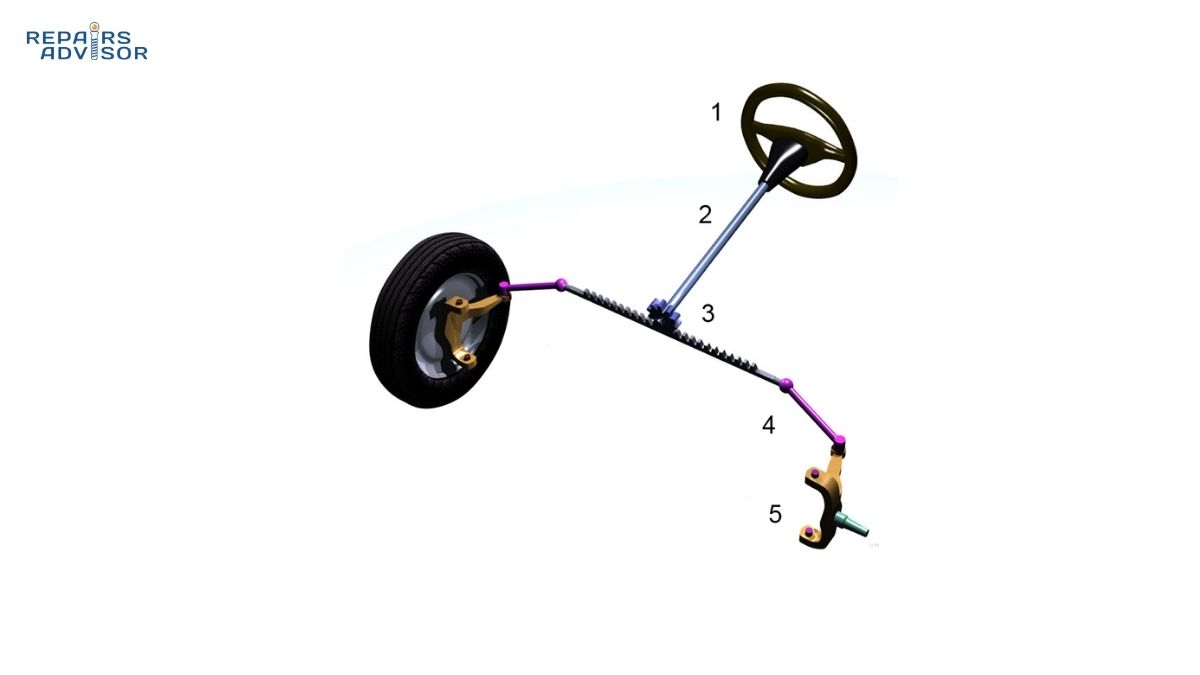

Suspension springs never work in isolation—they’re part of an integrated system where each component depends on the others. Shock absorbers and struts control the oscillation that springs would otherwise continue indefinitely after hitting a bump. Without shocks, springs would bounce freely, making your vehicle nearly undrivable. The shock’s job is damping—converting the spring’s stored kinetic energy into heat and dissipating it, bringing the spring to rest quickly.

Control arms provide the mounting points for springs in independent suspension systems while maintaining proper suspension geometry. They allow the spring to compress and extend vertically while keeping the wheel properly positioned relative to the chassis. The control arm’s pivot points and mounting locations are precisely engineered to maintain specific camber, caster, and toe angles throughout the suspension’s travel.

Ball joints connect control arms to the steering knuckle, providing a pivot point that allows steering movement while supporting the vehicle’s weight. These critical components handle enormous forces—supporting the vehicle while allowing the suspension to articulate and the wheels to steer. Ball joint failure can cause catastrophic suspension collapse.

Bump stops limit suspension travel to protect components from damage. These polyurethane or rubber blocks provide progressive resistance as the suspension approaches full compression, preventing metal-to-metal contact between the chassis and suspension. Without functioning bump stops, your suspension can bottom out violently, damaging springs, shocks, control arms, and the chassis itself.

Sway bars (anti-roll bars) work with springs to reduce body roll during cornering. When one side of the vehicle compresses in a turn, the sway bar transfers some of that force to the opposite side, resisting the body roll that would otherwise occur. This improves handling feel and maintains more even tire contact with the road surface.

Multi-link suspension systems use multiple control arms and links along with springs to achieve sophisticated suspension characteristics. These systems can independently control camber, toe, and caster changes throughout the suspension’s travel, delivering excellent handling while maintaining ride comfort. Control arm bushings provide compliance and isolation between metal components, absorbing vibrations and allowing slight movement that improves ride quality while maintaining control.

Conclusion

Suspension springs represent one of the most fundamental components in automotive engineering, simultaneously supporting your vehicle’s weight, absorbing countless road impacts, and enabling the suspension travel that keeps you comfortable and safe. The three main spring types—coil, leaf, and air—each serve specific purposes and excel in different applications. Coil springs have become the modern standard for passenger vehicles because of their superior comfort and handling characteristics. Leaf springs remain essential for heavy-duty applications where load capacity and durability outweigh ride comfort concerns. Air springs offer adjustability and refinement unavailable from metal springs, though at significantly higher cost and complexity.

Understanding how springs work alongside shock absorbers, control arms, and other suspension components helps you appreciate the engineering sophistication beneath your vehicle. Springs don’t just bounce up and down—they’re carefully tuned energy management devices that balance competing demands for comfort, handling, load capacity, and durability.

Common failure symptoms like sagging, excessive bouncing, unusual noises, and uneven ride height provide clear warning signs that spring replacement is needed. Because springs are safety-critical components that directly affect vehicle control, addressing these symptoms promptly prevents dangerous driving conditions and protects other suspension components from accelerated wear. Always replace springs in pairs to maintain balanced suspension characteristics, and remember that professional alignment is mandatory after spring replacement.

When to Consult a Professional

Seek professional service immediately if you discover broken or severely sagging springs—this isn’t a situation to defer or attempt as a first-time DIY project. The safety risks and specialized tools required for coil spring replacement make professional service the wise choice for most vehicle owners. Unusual handling characteristics, persistent noises, or any situation where you’re unsure about diagnosis or repair procedures warrant professional inspection.

Air suspension work absolutely requires professional service given the system’s complexity, specialized diagnostic requirements, and integration with vehicle computers. Even experienced DIY mechanics typically leave air suspension repairs to specialists. Whenever alignment or complex diagnostics are needed, professional shops have the equipment and expertise to properly evaluate and repair your suspension system.

Preventive Maintenance

Incorporate visual suspension inspections into your routine maintenance schedule. During oil changes or tire rotations, take a few minutes to inspect springs for visible damage, check ride height at each corner, and note any changes in ride quality or handling. Early detection of corrosion allows you to treat rust and extend spring life before structural integrity is compromised.

Monitor how your vehicle’s ride height and handling characteristics change over time. Gradual degradation can be difficult to notice day-to-day, but comparing current ride height to measurements from a year ago reveals developing problems. If you regularly tow heavy loads or use your vehicle for commercial purposes, consider upgraded spring options designed for increased load capacity and durability.

Understanding suspension springs empowers you to maintain your vehicle properly, diagnose problems accurately, and make informed decisions about repairs and upgrades. Whether you’re troubleshooting a handling concern, planning a suspension upgrade, or simply want to understand what’s happening beneath your vehicle, this knowledge helps you keep your suspension system functioning safely and effectively for years to come. For more information about steering and suspension components, explore our complete guide to vehicle control systems.