Modern engine oil pans serve as far more than simple oil storage containers. These sophisticated components integrate windage tray systems, oil baffles, and advanced sump design features to maintain consistent oil supply under demanding driving conditions while optimizing engine performance through superior windage control.

Safety Note: Oil pan work involves hot engine components and pressurized fluids. Always allow engines to cool completely and follow manufacturer safety procedures. For complex oil pan modifications or installations, professional consultation ensures proper system integration and safety compliance.

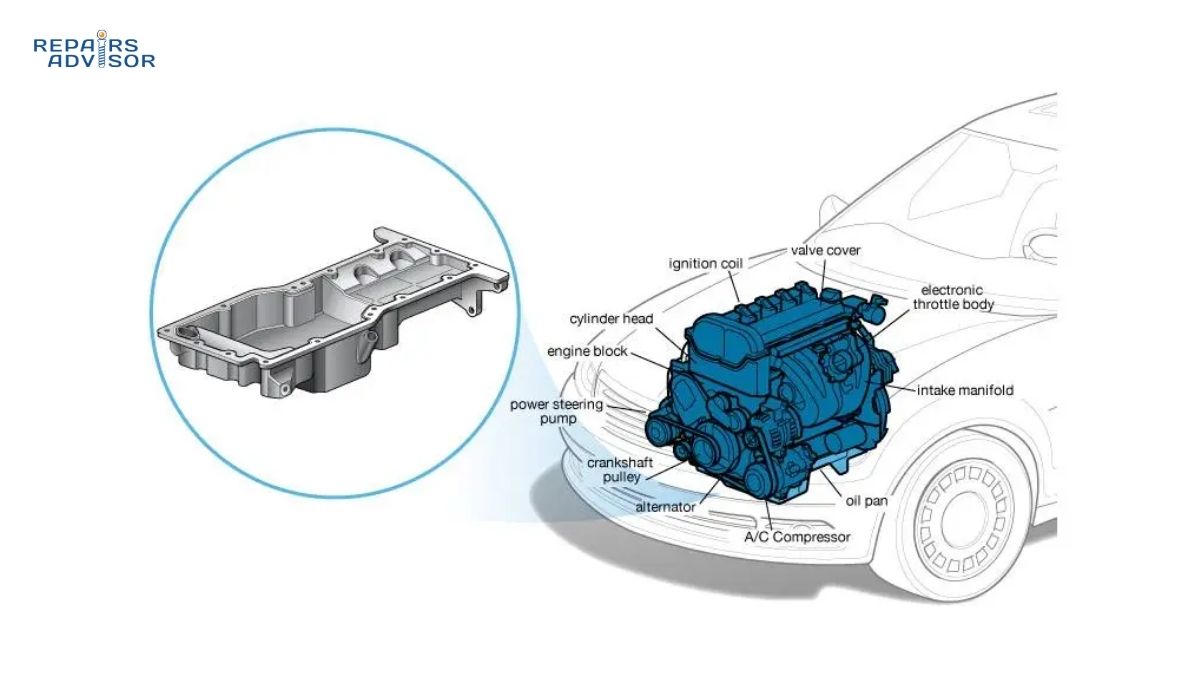

Why Oil Pan Is Critical for Engine Performance

The oil pan functions as the foundation of your engine’s lubrication system, serving multiple critical roles beyond oil storage. Advanced sump design features work together to prevent oil starvation during aggressive driving maneuvers, while windage tray systems minimize parasitic power losses from oil splash interference with the rotating crankshaft assembly.

Modern oil pan designs incorporate sophisticated internal structures including oil baffles that prevent oil movement away from the pickup tube during cornering, acceleration, and braking. The windage tray design creates a barrier between the oil supply and crankshaft rotation, reducing the churning effect that can steal horsepower and create foam in the oil supply.

Professional racing applications demonstrate how critical proper sump design becomes under extreme conditions. High-performance engines rely on anti-slosh design features and carefully positioned baffles to maintain oil pressure even during sustained high G-force maneuvers. Understanding these systems helps DIY enthusiasts appreciate why engine oil pump location and pickup tube positioning require precise engineering.

The pickup tube location within the oil pan directly affects oil supply reliability. Engineers design the sump geometry to ensure the pickup tube remains submerged in oil regardless of vehicle attitude, preventing air ingestion that could damage engine bearings. This integration with engine bearing lubrication systems makes oil pan design a critical component in overall engine reliability.

Oil Pan Parts and Construction Explained

Understanding oil pan construction reveals how each component contributes to effective lubrication system operation. The main pan body forms the oil reservoir, typically manufactured from stamped steel, cast aluminum, or fabricated aluminum for weight reduction and improved heat dissipation characteristics.

Windage Tray Systems represent the most sophisticated internal oil pan component. These perforated metal screens mount between the crankshaft and oil supply, allowing oil to drain back while preventing splash-back from interfering with crankshaft rotation. The windage tray design incorporates drain holes strategically positioned to ensure proper oil return while maintaining separation between moving parts and oil supply.

Oil Baffles and Anti-Slosh Design features include internal walls and doors that control oil movement within the pan. These baffles allow oil to flow toward the pickup tube during normal operation while preventing oil from moving away during vehicle dynamics. Trap door baffles use one-way mechanisms that allow oil in but prevent oil from escaping during cornering forces.

Scrapers and Crank Windage Control components mount close to the crankshaft throws to actively remove oil from the rotating assembly. These scrapers channel oil back to the sump while reducing the amount of oil clinging to moving parts, improving both lubrication efficiency and power output.

The drain plug assembly includes the threaded plug, sealing washer, and magnetic tip in many applications. The magnetic drain plug attracts metallic wear particles, providing an early warning system for internal engine wear. Understanding oil filter contamination control helps explain how the drain plug works as part of the overall filtration strategy.

How Oil Pan Works: Step-by-Step Operation

Oil pan operation integrates multiple systems working together to maintain consistent oil supply under all driving conditions. The process begins with oil return from the engine’s lubrication circuits, including oil that has lubricated bearings, pistons, and valve train components.

Step 1: Oil Collection and Return

Gravity returns used oil from throughout the engine back to the oil pan sump. Oil drains from cylinder heads through return passages, while oil thrown off rotating components falls back through the windage tray. The windage tray allows oil to pass through while preventing splash-back that could interfere with crankshaft rotation.

Step 2: Windage Control and Power Recovery

As the crankshaft rotates, it would normally churn through oil in the sump, creating parasitic drag and oil foaming. The windage tray prevents this churning by maintaining separation between the oil supply and rotating assembly. Scrapers actively remove oil from crankshaft throws, directing it back to the sump while minimizing power losses.

Step 3: Oil Movement Control During Vehicle Dynamics

During cornering, acceleration, and braking, oil baffles control oil movement within the pan. Anti-slosh design features prevent oil from moving away from the pickup tube location, ensuring consistent oil supply even during aggressive driving. Trap door baffles allow oil to flow toward the pickup area while preventing reverse flow during lateral forces.

Step 4: Pickup Tube Supply and Circulation

The oil pump draws oil through the pickup tube, which extends into the deepest part of the sump. Proper sump design ensures the pickup tube remains submerged in oil regardless of vehicle attitude, preventing air ingestion that could cause bearing damage.

This continuous cycle maintains oil pressure and flow throughout the engine while optimizing performance through reduced windage losses and consistent oil supply reliability.

Oil Pan Location and Access Guide

Oil pan access varies significantly between vehicle applications, requiring different approaches for inspection, service, and replacement procedures. Understanding your specific vehicle’s oil pan configuration helps determine the appropriate service approach and tools required.

Front-Wheel Drive Applications typically mount the oil pan on the bottom of the engine block, accessible from underneath the vehicle. These installations often require removing the front subframe or lowering the engine slightly for pan removal. The oil pan gasket replacement may require special timing for engine position and accessibility.

Rear-Wheel Drive Configurations generally provide better oil pan access, though pickup truck applications may require removing skid plates or cross-members. Sports car applications sometimes use multiple oil pan sections or complex baffling systems that require specific removal sequences.

All-Wheel Drive and Performance Applications frequently incorporate more sophisticated oil pan designs with multiple chambers, additional baffling, and sometimes dry sump systems that eliminate the traditional oil pan entirely. These systems require specialized knowledge for proper service and may integrate with cooling system components.

Access Considerations for DIY Enthusiasts:

- Beginner Level: Oil level checking, drain plug service, visual inspection for leaks

- Intermediate Level: Oil pan gasket replacement on accessible applications, pickup tube inspection

- Professional Required: Complex baffled systems, dry sump conversions, engine removal procedures

Safety Requirements for oil pan access include proper vehicle support with jack stands, allowing complete cooling time for hot oil and components, and understanding that oil pan removal may require engine repositioning. The integrated nature of modern oil pan systems with engine mount and structural components means proper support becomes critical during service procedures.

Professional consultation becomes essential when oil pan work involves structural engine components, complex baffling systems, or when oil starvation symptoms suggest internal damage. Understanding the relationship between oil pan design and overall engine lubrication system performance helps determine when professional assistance ensures both safety and proper system function. Windage control benefits and horsepower recovery justify professional installation for performance applications where main cap stud installation requires precision and experience.

Information provided for reference only. No warranty on repair outcomes. Always consult manufacturer specifications and consider professional assistance for complex lubrication system work involving windage tray installation main cap studs or crank scraper clearance modifications.