How Oil Filter Works: Quick Answer

An oil filter works by forcing pressurized oil (15-65 psi) from the engine pump through specialized filter media that captures contaminants via four distinct mechanisms: direct interception, inertial impaction, electrostatic adsorption, and depth entrapment. Clean oil flows through a central tube back to the engine, while bypass valves (opening at 8-17 psi differential) and anti-drainback valves ensure continuous lubrication under all conditions. This complete filtration cycle occurs approximately 12,000 times during a typical 3,000-mile oil change interval, achieving 95-99% efficiency for particles 20 microns and larger.

The oil filter plays a critical role in protecting your engine from contamination that can cause catastrophic damage. This sophisticated filtration system removes harmful particles, metal debris, and combustion byproducts from engine oil, extending both oil life and engine durability. Understanding how oil filters work helps you make informed maintenance decisions and recognize when professional consultation may be needed for complex filtration system issues.

Safety Notice: Oil filter service involves hot oil and pressurized systems. Always allow engines to cool and follow manufacturer safety procedures. This information is for reference only – consult professional mechanics for safety-critical maintenance.

Why Oil Filter Is Critical for Engine Performance

Oil filters serve as the guardian of your engine’s lubrication system, preventing microscopic contaminants from circulating through precision-machined components. Without effective filter media operation, even the highest quality oil becomes a destructive slurry that accelerates wear on bearings, pistons, and other critical engine parts.

The filtration process directly impacts engine performance by maintaining oil viscosity and lubricating properties. Clean oil flows more efficiently through narrow passages, ensuring proper pressure delivery to timing system components and valve mechanisms. When oil filters become saturated or bypass, unfiltered oil creates a cascade of wear that shortens engine life significantly.

Modern engines with tighter tolerances depend even more heavily on oil filtration systems. Particulates that older engines might tolerate can cause immediate damage in today’s high-efficiency powerplants. This makes understanding your specific vehicle’s filtration requirements essential for maintaining engine performance and avoiding expensive repairs.

Professional mechanics recognize oil filter condition as a primary diagnostic indicator. Dark, metallic particles in used filters often reveal internal engine wear patterns before damage becomes severe. For detailed guidance on your specific vehicle’s maintenance requirements, reference manufacturer service manuals for proper specifications and service intervals.

Oil Filter Parts and Construction Explained

Oil filters contain several integrated components that work together to provide effective filter media performance while managing oil flow under varying pressure conditions. The outer housing provides structural integrity and mounting threads, while internal components handle the actual filtration and flow control functions.

The filter media forms the heart of the filtration system, typically constructed from pleated paper, synthetic fibers, or cellulose materials. This media captures particles ranging from large metal flakes down to microscopic combustion byproducts. Higher-quality filters feature denser media with more surface area, providing superior filtration without restricting oil flow excessively.

Critical internal components include the anti-drainback valve, which prevents oil from flowing back into the pan when the engine stops. This valve ensures immediate oil pressure upon startup, protecting engine components during the vulnerable initial moments. The center tube provides structural support for the filter media while directing filtered oil back to the engine block.

The bypass valve represents perhaps the most important safety feature, allowing unfiltered oil to circulate when the filter becomes clogged or when cold oil cannot flow through the media efficiently. While this protects against oil starvation, it also means contaminated oil reaches engine components when filters exceed capacity. Regular filter replacement prevents bypass operation under normal conditions.

End plates seal the filter media assembly and direct oil flow through proper channels. These stamped or molded components must withstand significant pressure differentials while maintaining perfect seals. Quality variations between OEM, performance, and budget filters often become apparent in end plate construction and sealing effectiveness.

For vehicles requiring specific filter specifications, consult Toyota service manuals or Chevrolet documentation to ensure proper media type and flow ratings match engine requirements.

How Oil Filter Works: Step-by-Step Operation

Oil filter operation begins when the engine oil pump creates pressure that forces oil through the complete filtration cycle. Step 1: Oil Entry – Pressurized oil from the pump enters the filter housing through threaded inlet ports, immediately encountering the bypass valve assembly that monitors flow resistance.

Step 2: Media Filtration – Oil passes through the pleated filter media, which traps particles while allowing clean oil to continue toward the center tube. The filtration process occurs as oil molecules navigate the microscopic pathways within the media structure. Larger contaminants get trapped in outer media layers, while smaller particles penetrate deeper before capture.

Step 3: Clean Oil Return – Filtered oil flows through the center tube and exits through the mounting base back to engine galleries. The anti-drainback valve maintains oil within the filter when the engine stops, ensuring immediate filtration upon restart without waiting for the housing to refill.

During high-demand conditions such as cold starts or high RPM operation, oil viscosity changes affect flow characteristics through the filter media. If resistance becomes excessive, the bypass valve opens to maintain oil pressure while allowing some unfiltered oil to circulate. This protective mechanism prevents oil starvation but reduces filtration effectiveness temporarily.

The oil filtration system continuously adapts to changing engine conditions through pressure-sensitive valve operation. Understanding these dynamics helps explain why filter service intervals must account for both mileage and operating conditions. Severe service applications require more frequent changes due to accelerated media saturation.

For troubleshooting filtration system issues, reference comprehensive guides in professional service documentation or consult with experienced technicians familiar with your specific engine configuration.

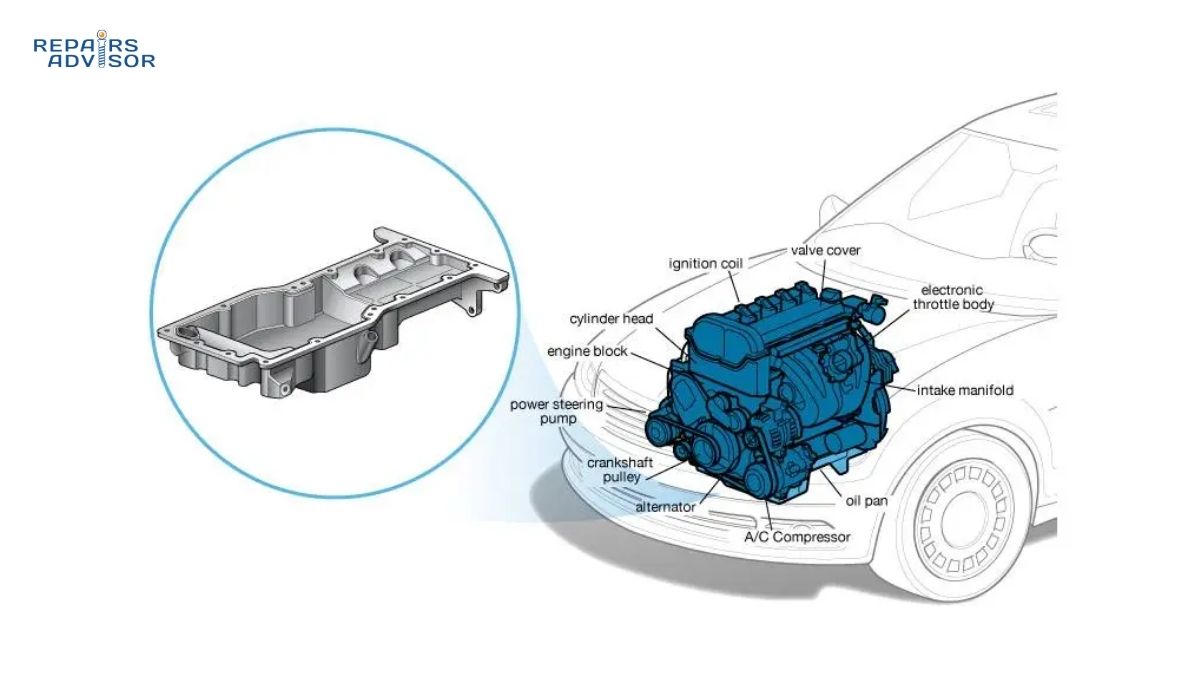

Oil Filter Location and Access Guide

Oil filter accessibility varies significantly between vehicle designs, with some installations requiring specialized tools or extensive disassembly for service. Most automotive applications mount filters on the engine block using threaded connections, though remote mounting systems place filters in more accessible locations using oil lines.

Cartridge-style filters integrate into the engine block or oil pan assembly, requiring removal of housing covers rather than entire filter units. These systems often provide better access but require specific torque specifications and proper gasket replacement during service. Professional mechanics prefer cartridge designs for efficiency, though DIY access may be more challenging.

Spin-on filters thread directly onto engine-mounted bases, providing simpler replacement procedures for intermediate-level technicians. However, tight spaces, hot exhaust components, and awkward angles can complicate access significantly. Always verify adequate clearance for filter removal tools before beginning service procedures.

Safety-critical considerations include proper vehicle support, hot component protection, and environmental containment for used oil and filters. Engine bay components reach extreme temperatures during operation, requiring appropriate cooling time and protective equipment. Used filters contain substantial oil quantities requiring proper disposal through recycling facilities.

Access preparation should include reviewing manufacturer-specific procedures, gathering appropriate tools, and ensuring proper workspace ventilation. Some installations require removal of protective covers, air intake components, or other assemblies to reach filter mounting locations. Professional consultation becomes essential when access requires specialized equipment or safety procedures beyond basic maintenance.

For detailed access procedures and safety requirements specific to your equipment, reference manufacturer service manuals or seek guidance from experienced technicians. Complex installations often benefit from professional service to avoid component damage or safety hazards during filter replacement procedures.

This information is provided for educational reference only. Repairs Advisor provides comprehensive digital manuals and technical documentation but does not offer direct repair services. Always consult manufacturer specifications and professional guidance for safety-critical maintenance procedures. For additional technical support, visit our Help Center or contact [email protected].