You’re stuck. One wheel spins uselessly in the mud while the other sits motionless with perfect traction just inches away. Your vehicle rocks back and forth, digging deeper with each attempt. This frustrating scenario plays out thousands of times daily for drivers with standard open differentials—a problem that limited slip differentials were specifically engineered to solve.

A limited slip differential (LSD) is a specialized gear train that allows wheels to rotate at different speeds during normal driving, but automatically limits the speed difference when one wheel begins to slip. Unlike open differentials that send all power to the wheel with least resistance, LSDs redistribute torque to the wheel with better traction, keeping you moving forward in challenging conditions.

This technology matters whether you’re navigating winter roads, towing heavy loads, driving off-road, or pursuing performance driving. Understanding how limited slip differentials work, the different types available, and proper maintenance requirements helps you make informed decisions about this critical drivetrain component. In this comprehensive guide, we’ll explore the mechanics behind LSDs, compare different technologies, examine real-world advantages and limitations, and provide practical maintenance guidance for intermediate DIY enthusiasts and professional mechanics alike.

Before diving into LSDs specifically, it’s helpful to understand the basics of how differential systems work and their role in torque distribution throughout your vehicle’s drivetrain.

Understanding Limited Slip Differential Fundamentals

What Makes LSDs Different from Open Differentials

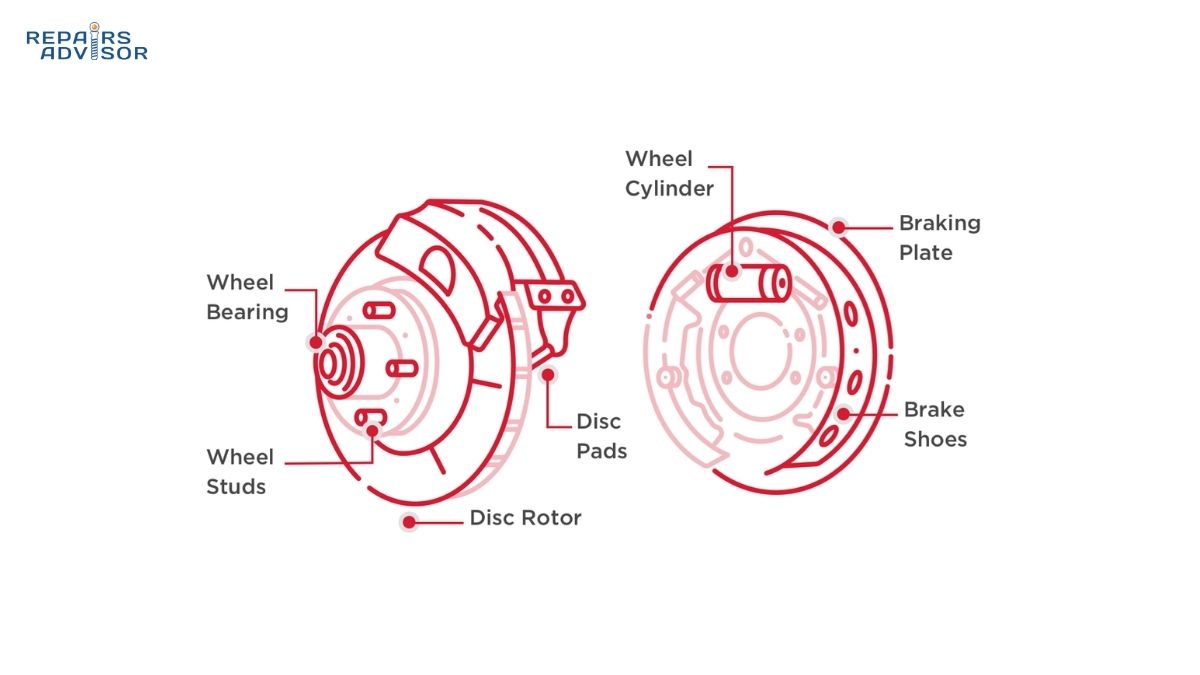

The standard open differential found in most vehicles operates on a simple principle: it splits engine torque equally between the two wheels on an axle while allowing them to rotate at different speeds during turns. This design works perfectly when both wheels have equal traction—the outside wheel turns faster than the inside wheel when cornering, preventing tire scrub and drivetrain binding.

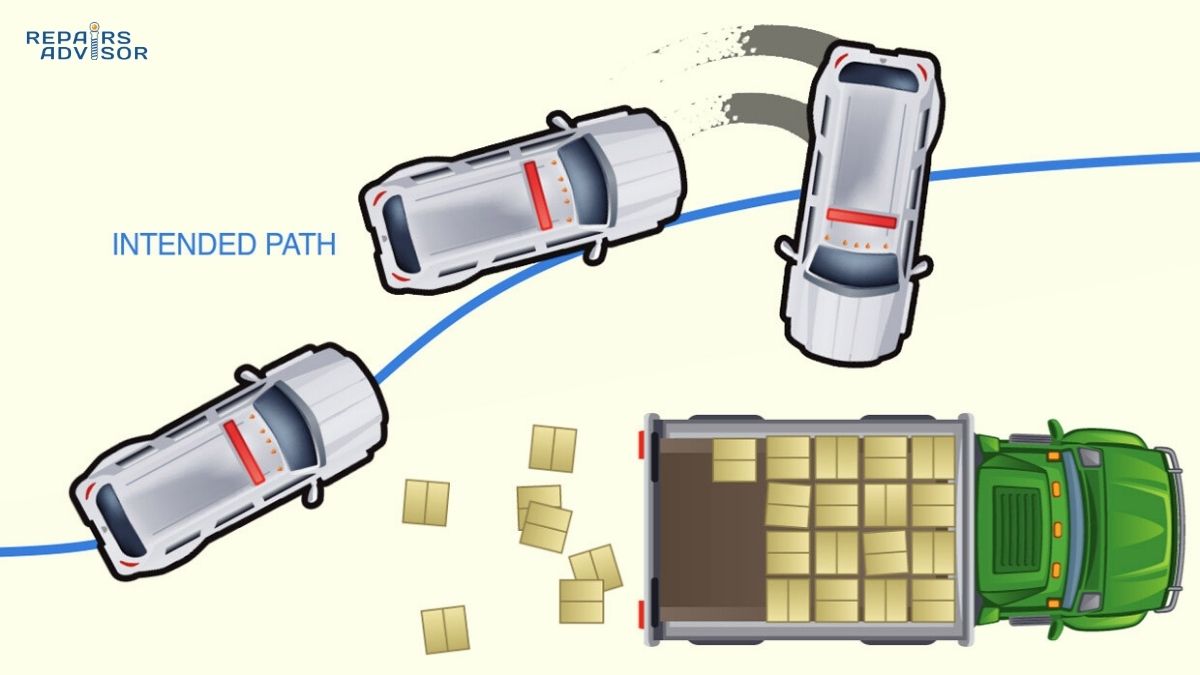

However, open differentials have a critical weakness. They always apply equal torque to both wheels, regardless of traction conditions. When one wheel encounters a low-traction surface like ice, mud, or even just lifts off the ground slightly, that wheel requires very little torque to spin. Since the differential provides equal torque to both sides, the wheel with good traction also receives only that minimal amount of torque—nowhere near enough to move the vehicle. The result? One wheel spins helplessly while the other remains stationary, and your vehicle goes nowhere.

Limited slip differentials solve this problem by adding an internal resistance mechanism that limits the speed difference between the two wheels. When the LSD detects that one wheel is rotating significantly faster than the other—a clear indication of slip—it engages this resistance to transfer more torque to the slower-rotating wheel (the one with better traction). This happens automatically without any driver input.

The key specification that defines an LSD’s capability is its torque bias ratio, typically ranging from 3:1 to 5:1 for most automotive applications. A 4:1 bias ratio means the differential can send up to four times more torque to the wheel with traction compared to the slipping wheel. This doesn’t mean the LSD creates more total torque—it redistributes the available torque based on which wheel can actually use it to propel the vehicle forward.

How Torque Distribution Works

Understanding LSD operation requires grasping a fundamental physics principle. According to Newton’s third law, when a differential applies torque to rotate a wheel, that wheel applies an equal and opposite torque back through the axle. In an open differential, this equal-torque principle means both wheels always receive identical torque, limited by whichever wheel has the least grip.

The limited slip differential adds a twist to this equation—literally. By incorporating friction clutches, meshing gears, or viscous fluid between the differential case and the side gears, the LSD creates internal resistance that opposes the speed difference between wheels. This resistance effectively “costs” the slipping wheel some of its torque allocation, which the differential then redirects to the gripping wheel.

Here’s a real-world example of how this works: Imagine your vehicle’s right wheel sits on glare ice that can only support 70 lb-ft of torque before spinning. In an open differential, this means your left wheel on dry pavement—capable of handling 500+ lb-ft—also receives only 70 lb-ft. Your vehicle barely moves. With a limited slip differential featuring a 4:1 bias ratio, when the right wheel begins slipping at 70 lb-ft, the LSD can transfer up to 280 lb-ft (4 × 70) to the left wheel with traction. That’s enough torque to move most vehicles forward, especially combined with the 70 lb-ft still going to the right wheel, for a total of 350 lb-ft reaching the ground.

It’s called “limited” slip precisely because it can’t provide 100% lockup like a true locking differential. The amount of torque transfer is limited by the bias ratio and the grip available at the slipping wheel. This limitation represents a engineering compromise—the LSD provides better traction than an open differential while maintaining acceptable on-road handling characteristics. For understanding how this torque flows through your drivetrain, see our detailed explanation of how torque converters work and how drive shafts work to transmit that power to the wheels.

Types of Limited Slip Differentials

Limited slip differentials come in four distinct types, each using different mechanisms to limit wheel slip. Understanding these differences helps you choose the right LSD for your application and maintain it properly.

Clutch-Type LSDs: Mechanical Friction Control

Clutch-type limited slip differentials are the most common LSD design in performance and off-road applications. They use stacked friction plates—similar to those in a manual transmission clutch or automatic transmission clutch pack—to mechanically lock the differential when wheel slip occurs.

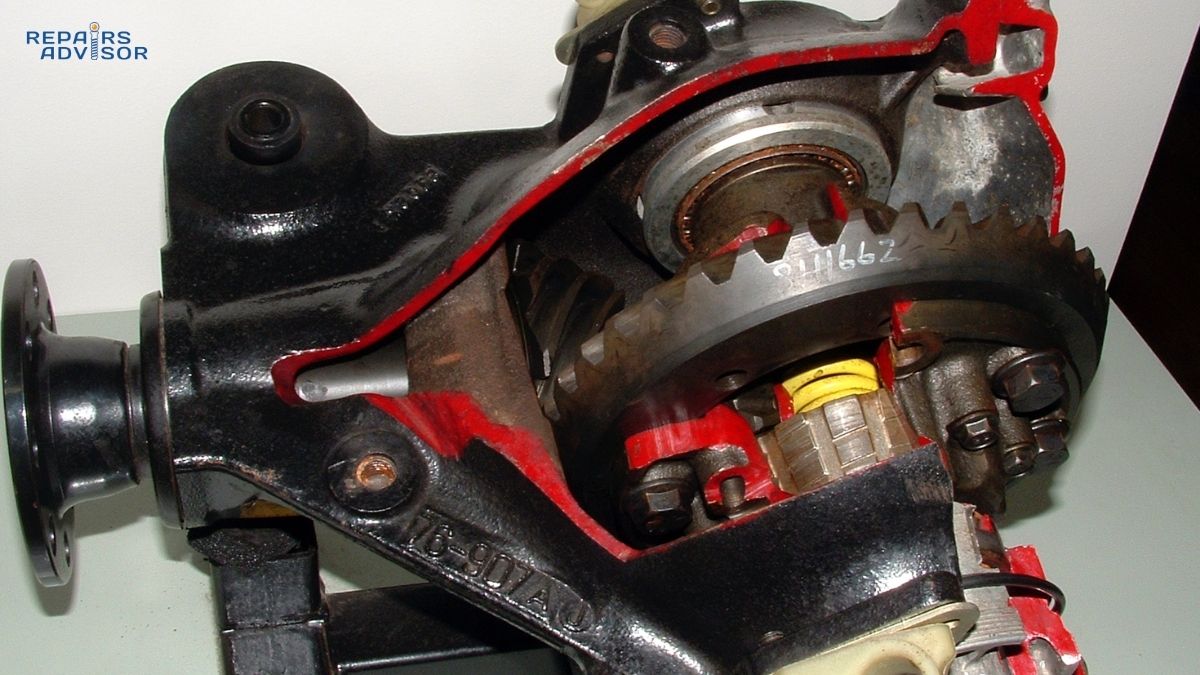

Inside the differential housing, two sets of clutch packs sit behind each side gear. These clutch packs consist of friction plates splined to the side gear alternating with steel plates that lock into the differential case. A central spring assembly or beveled gear design (called ramp-style or cam-style) applies clamping force to these clutch packs. When both wheels rotate at the same speed during normal driving, the spring preload keeps minimal pressure on the clutches, allowing them to slip slightly and the wheels to turn independently during cornering.

The moment one wheel begins to spin faster than the other, the torque imbalance through the differential’s spider gears creates additional clamping force on the clutch packs. In ramp-style designs, the beveled gears try to separate under load, which pushes the clutch packs together harder. This increased clamping friction resists the speed difference between wheels, effectively locking them together and transferring torque to the wheel with grip. The harder you accelerate, the more clamping force develops, providing stronger lockup when you need it most.

Clutch-type LSDs come in three configurations based on when they engage:

1-way LSDs lock only during acceleration (power on), allowing free differentiation during deceleration. These work well for front-wheel-drive vehicles where you want normal steering feel when lifting off the throttle in turns.

1.5-way LSDs provide full lockup on acceleration but reduced (typically 50-70%) lockup during deceleration. This configuration suits rear-wheel-drive performance cars, providing stability under braking while maintaining aggressive power delivery.

2-way LSDs lock equally during both acceleration and deceleration. Professional racing applications and drifting prefer this setup for maximum control and predictability through all phases of cornering.

Advantages of clutch-type LSDs:

- Aggressive torque transfer capabilities exceed other LSD types

- Work effectively even when one wheel is completely off the ground or on ice

- Highly tunable through clutch pack selection, spring rates, and ramp angles

- Provide strong, immediate lockup feel that performance drivers appreciate

- Relatively simple to rebuild when worn

Disadvantages:

- Require periodic maintenance as clutch friction materials wear (typically 50,000-100,000 miles)

- Can exhibit chattering noise during tight, slow-speed turns, especially when cold

- More expensive than open differentials ($800-1,500 for factory installation)

- Must use gear oil with friction modifiers—standard gear oil causes immediate chatter

- Eventual rebuild or replacement needed as clutches wear thin

Helical/Torsen LSDs: Gear-Based Automatic Biasing

The Torsen differential (a portmanteau of “TORque SENsing”) represents an entirely different approach to limited slip operation. Instead of friction clutches, Torsen LSDs use precisely machined helical gears arranged in a complex pattern that automatically responds to torque differences between wheels.

Inside a Torsen differential, pairs of worm gears (helical-cut gears meshing at right angles) connect each side gear to the differential case. When one wheel encounters less resistance and tries to spin faster, the torque imbalance through these helical gears creates axial thrust forces along the gear teeth. These thrust forces push the gears against the differential housing, creating friction that resists the speed difference. The beauty of this design lies in its mechanical elegance—the more torque you apply, the more the gears bind together, automatically increasing the locking effect exactly when needed.

Unlike clutch-type LSDs that have a separate engagement mechanism, Torsen differentials are always “active” but only create resistance proportional to the torque difference between wheels. During gentle cruising with equal traction, the gears mesh smoothly with minimal resistance. The moment wheel slip begins, the helical gears immediately respond by binding tighter. This happens at the speed of mechanical contact—essentially instantaneous—without any perceivable delay.

The Torsen’s bias ratio (typically 3:1 to 6:1 depending on model) is fixed by the gear design and cannot be adjusted after manufacturing. Different Torsen models use varying numbers of gear sets and configurations. The T-1 design uses spur and worm gears, the T-2 employs parallel-axis helical gears for more compact packaging, and the T-3 combines aspects of both for all-wheel-drive center differential applications.

Advantages of helical/Torsen LSDs:

- Completely maintenance-free—no wearing clutches or degrading fluids to service

- Smooth, progressive operation without the chatter associated with clutch types

- Instant mechanical response to torque changes with no perceptible lag

- Long service life often exceeding 150,000 miles without any internal work needed

- Efficient operation with minimal parasitic power loss

- Operates seamlessly without driver awareness during normal driving

Disadvantages:

- Cannot transfer torque effectively if one wheel has zero traction (completely suspended or on glare ice)

- Higher initial purchase cost ($1,200-2,000 for factory installation)

- Generates significant heat in extreme use (racing, rock crawling), requiring differential cooling in competition applications

- Fixed bias ratio not adjustable for different conditions or preferences

- Heavier than some other differential types due to robust gear construction

Professional mechanics appreciate Torsen differentials for their reliability and lack of maintenance requirements, making them excellent choices for performance street cars that see occasional track use. The smooth, transparent operation makes them popular in high-performance sports cars like Corvettes, Mustangs with performance packages, and many Audi Quattro models.

Viscous LSDs: Fluid Resistance Technology

Viscous limited slip differentials use an entirely different principle—fluid dynamics—to limit wheel slip. These LSDs contain a sealed chamber filled with thick silicone-based viscous fluid surrounding a stack of perforated plates. Some plates connect to the differential case while others connect to the side gears.

During normal driving with equal wheel speeds, the plates rotate together through the fluid with minimal resistance. When one wheel begins spinning faster, the plates connected to that wheel shear through the viscous fluid at different speeds relative to the other plates. This shearing action generates heat and internal friction within the fluid, which increases the fluid’s resistance. The greater the speed difference, the more resistance the fluid develops, progressively transferring torque to the slower-rotating (higher traction) wheel.

The progressive engagement characteristic of viscous LSDs provides very smooth power delivery without the abrupt engagement feel of clutch-type units or the immediate response of Torsen gears. This makes them pleasant for daily driving applications where subtle operation matters more than aggressive lockup.

Advantages of viscous LSDs:

- Simplest internal design with fewer parts than clutch or gear types

- Smooth, progressive engagement comfortable for daily driving

- Factory sealed unit requires no periodic fluid changes or adjustments

- Lower manufacturing cost than clutch or Torsen types

- Quiet operation without mechanical noise

Disadvantages:

- Performance degrades significantly over time—fluid typically loses effectiveness after 60,000-80,000 miles

- Not serviceable—when performance deteriorates, entire unit must be replaced

- Slower response time than mechanical types due to fluid dynamics

- Heat-sensitive—effectiveness drops when fluid overheats during extended slip conditions

- Weakest torque transfer capability among LSD types

- Declining popularity as better technologies become affordable

Viscous LSDs were common in 1980s-1990s performance cars but have largely been replaced by more effective technologies in modern vehicles. When they were new, viscous differentials provided adequate performance, but their limited lifespan and declining effectiveness with age make them less desirable today.

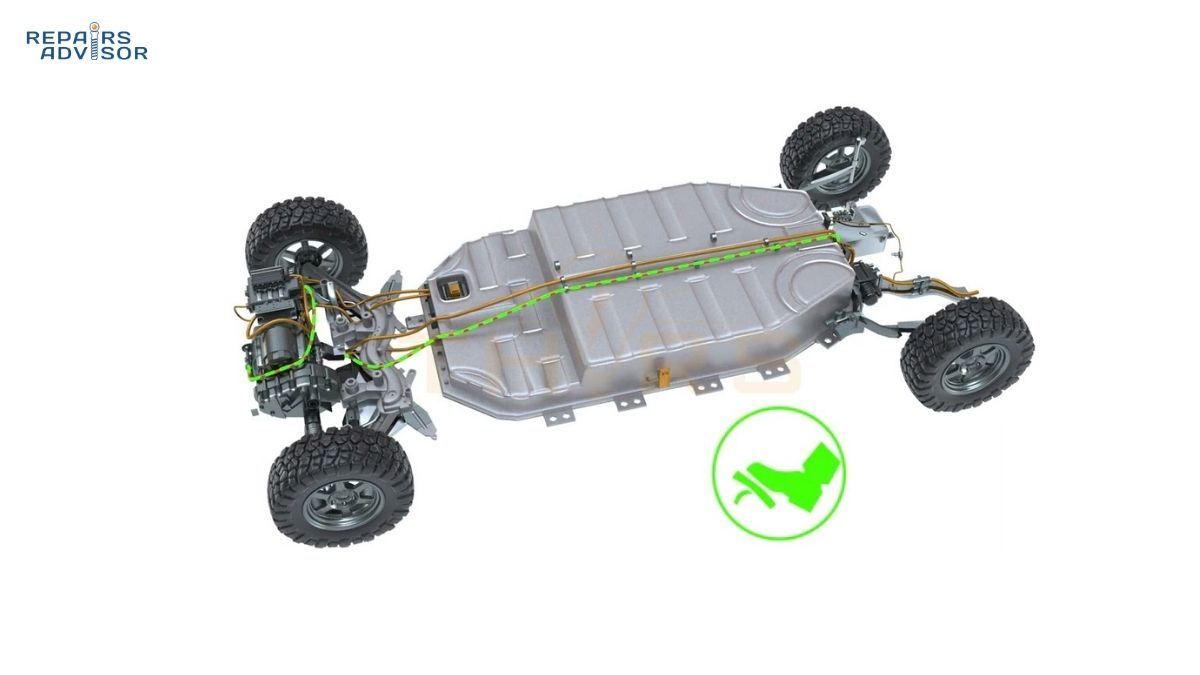

Electronic LSDs: Computer-Controlled Precision

Electronic limited slip differentials represent the latest evolution in traction management technology. These systems use sensors throughout the vehicle to monitor wheel speeds, steering angle, throttle position, and sometimes even yaw rate and lateral acceleration. An electronic control unit (ECU) processes this data in real-time and commands actuators to engage clutch packs or apply individual wheel braking to transfer torque exactly where needed.

Some electronic LSDs use electronically-controlled multi-plate clutches, applying precise clamping force through electric motors or hydraulic actuators. Others employ brake-based torque vectoring, using the ABS system to brake the spinning wheel, which forces the differential to send more torque to the opposite wheel with traction. The most sophisticated systems combine both approaches for maximum effectiveness.

The key advantage of electronic control is adaptability. The system can completely change its characteristics based on selected driving modes—comfort mode for daily driving might allow more wheel slip for efficiency, while sport mode provides aggressive lockup for performance driving. Track mode might maximize cornering grip through aggressive torque vectoring. All this happens automatically as conditions change, without any setup adjustments from the driver.

Integration with other vehicle systems represents another major benefit. Electronic LSDs work seamlessly with traction control, stability control, and adaptive cruise control systems. Some systems can even predict wheel slip before it occurs based on throttle input and steering angle, pre-loading the differential to prevent slip rather than just reacting after it starts.

Advantages of electronic LSDs:

- Most sophisticated traction management available

- Fully adjustable characteristics through software—can optimize for different conditions

- Integrates with vehicle safety systems for comprehensive stability management

- Can provide full 100% torque transfer in some designs

- Proactive rather than purely reactive—can prevent slip before it occurs

- No maintenance required for electronic components (though mechanical clutch packs still wear)

Disadvantages:

- Most expensive differential option ($2,000-4,000 factory installation)

- Complex electronics create more potential failure points

- Requires specialized diagnostic equipment for troubleshooting

- Software-dependent performance—bugs or calibration issues can cause problems

- Heavier than passive mechanical systems due to actuators and control hardware

- Power consumption from electric motors or hydraulic pumps

Electronic LSDs increasingly appear as standard equipment in high-end performance vehicles and luxury SUVs. As costs decrease and reliability improves, expect to see these systems filter down to mainstream performance vehicles over the next decade.

Understanding these different LSD types helps when considering related drivetrain components like how AWD systems work with their center differentials, or how transfer cases work in four-wheel-drive vehicles that may incorporate limited slip technology. Modern traction control systems often work in conjunction with LSDs to provide comprehensive wheel slip management.

Advantages and Disadvantages of Limited Slip Differentials

Key Benefits: When LSDs Excel

The primary advantage of limited slip differentials shines brightest in low-traction conditions. Winter driving on snow-covered or icy roads becomes dramatically less stressful when both wheels contribute to forward motion rather than one spinning uselessly. That stuck-in-the-snow scenario that opens this article simply doesn’t happen with a properly functioning LSD—you maintain momentum through the slippery section because power continuously reaches whichever wheel has grip.

Off-road capability improves substantially with an LSD. When traversing uneven terrain where weight constantly shifts between wheels, an open differential would send power to the unweighted wheel spinning in the air. An LSD transfers that power to the loaded wheel maintaining ground contact, allowing you to crawl over obstacles that would stop a vehicle with an open differential. While not as capable as a true locking differential for extreme rock crawling, LSDs provide an excellent balance of off-road capability and on-road manners for recreational off-roading and overland travel.

Wet weather performance receives a noticeable boost from limited slip technology. During hard acceleration from a stop on rain-slicked pavement, an open differential often breaks one tire loose, causing the vehicle to pull sideways and waste power spinning that wheel. An LSD keeps both tires contributing power, delivering stronger acceleration and better stability during wet-weather launches.

Vehicle control improves across multiple driving scenarios. During aggressive cornering, the inside wheel typically carries less weight and can lose traction first. An open differential immediately sends all power to that inside wheel, causing understeer (front-drive) or oversteer (rear-drive) as the car pushes wide or the rear steps out. An LSD continues sending power to the outside wheel with more weight and grip, helping rotate the vehicle through the corner more predictably. This characteristic makes LSDs essential for performance driving, track days, and autocross competition.

Acceleration benefits are straightforward—two wheels putting power to the ground accelerate faster than one. Drag racers have used limited slip and positraction differentials since the 1960s specifically to launch harder and post quicker times. The advantage extends beyond racing; daily drivers appreciate improved acceleration when merging onto highways or passing slower traffic.

Towing performance sees meaningful improvement with an LSD. The added weight on the rear axle when towing a trailer can cause weight transfer that unloads one wheel during acceleration or on uneven terrain. An LSD ensures power reaches the loaded wheel, maintaining forward progress even when one wheel loses traction temporarily. Professional landscapers, contractors, and recreational boaters particularly value this capability.

Tire wear becomes more even with an LSD. An open differential under power often spins one wheel excessively, accelerating wear on that tire while the opposite tire barely contributes. An LSD distributes the workload between both tires, promoting more uniform wear patterns and potentially extending tire life. The reduction in excessive wheel spin also decreases stress on axle components like CV joints—understanding how CV joints work highlights why limiting excessive wheel speed differences benefits these components.

Real-world applications demonstrate LSD value across vehicle segments. Performance cars like the Ford Mustang GT, Chevrolet Camaro SS, and most BMW M models include LSDs as standard equipment because the performance advantages justify the cost. Pickup trucks with towing packages frequently offer LSDs to improve traction when loaded. Off-road focused SUVs and trucks use LSDs to bridge the gap between open differentials and more aggressive locking differential systems.

Important Limitations to Consider

Cost represents the most immediate limitation for many buyers. Factory-installed limited slip differentials typically add $600-1,200 to a vehicle’s purchase price compared to an open differential. Aftermarket LSD installation ranges from $1,000-2,000 including parts and labor, depending on the differential type and vehicle. For clutch-type LSDs, eventual rebuild costs of $800-1,200 every 50,000-100,000 miles add to the total ownership expense. Electronic LSDs command premium pricing of $2,000-4,000 but generally require no periodic rebuilds.

Maintenance requirements exceed those of open differentials. Clutch-type LSDs mandate friction-modified gear oil that costs $15-30 per quart versus $8-15 for standard gear oil. Service intervals run shorter—every 30,000-60,000 miles for normal driving, with more frequent changes (15,000-30,000 miles) recommended for severe duty use including frequent towing, off-roading, or track driving. Neglecting fluid changes accelerates clutch wear and can cause the LSD to eventually function like an open differential. Viscous LSDs don’t require fluid changes but the entire sealed unit needs replacement when performance degrades around 60,000-80,000 miles.

Performance trade-offs accompany LSDs in specific situations. The internal resistance that limits slip also creates slight parasitic drag even during normal driving, theoretically reducing fuel economy by 1-2% compared to an open differential. In practice, this difference is difficult to measure and most drivers never notice. More noticeable is the tendency for LSDs to cause tire scrubbing during tight, slow-speed parking lot maneuvers as the differential tries to maintain speed equality between wheels that need to turn at very different speeds. This manifests as a slight hopping or binding feeling that’s particularly pronounced with clutch-type LSDs featuring high preload.

Steering feel changes with an LSD, especially in front-wheel-drive applications. The differential’s resistance to speed differences creates feedback through the steering wheel that some drivers find unnatural compared to an open differential’s lighter feel. Torque steer—the tendency for front-drive vehicles to pull to one side under hard acceleration—can increase with an LSD as both front wheels fight for traction. Performance-oriented drivers typically appreciate this feedback, but those prioritizing comfort might find it objectionable.

Tire matching becomes critical with an LSD. Running mismatched tires—different sizes, tread patterns, or wear levels—on the same axle causes the differential to constantly fight the diameter difference. This accelerates wear on clutch-type LSDs and generates excessive heat in all LSD types. The problem intensifies with part-time four-wheel-drive systems where front and rear axles must rotate at identical speeds. Always replace tires in pairs on the same axle and maintain similar wear levels across all four tires on AWD vehicles.

Capability limitations exist even with an LSD. Helical/Torsen differentials need at least some traction at both wheels to transfer torque—if one wheel is completely suspended or on glare ice with zero grip, even a Torsen can’t help. In extreme off-road situations with significant articulation, a true locking differential outperforms any LSD. Similarly, deep mud that robs traction from both wheels simultaneously challenges LSD effectiveness since torque transfer requires one wheel to have substantially more grip than the other.

Noise considerations matter for daily drivers. Clutch-type LSDs with aggressive preload can chatter during low-speed turns, creating clicking or grinding sounds that alarm passengers unfamiliar with the phenomenon. While usually harmless (often just indicating the need for fresh fluid with friction modifier), the noise detracts from refinement. Helical LSDs run quieter but generate a subtle gear whine under load that’s audible in some vehicles.

Despite these limitations, LSDs provide net benefits for most performance, off-road, and work truck applications. The key is matching the LSD type to your specific needs and maintaining it properly. Understanding how LSDs interact with other safety systems like electronic stability control helps you appreciate the comprehensive approach modern vehicles take toward traction and stability management. Even suspension components like leaf springs affect LSD performance by controlling how weight transfers between wheels during acceleration and cornering.

Common Problems and Symptoms

Recognizing LSD Failure Signs

Chattering noise during turns ranks as the most common limited slip differential complaint. This manifests as a rhythmic clicking, grinding, or banging sound when making tight turns at low speeds, particularly in parking lots. The chatter results from the clutch packs in clutch-type LSDs rapidly engaging and disengaging—the friction plates “stick-slip” rather than smoothly transferring torque. Several causes can trigger chatter, listed from most to least likely:

Wrong fluid type or missing friction modifier causes immediate chatter in clutch-type LSDs. If someone serviced your differential with standard GL-5 gear oil without adding the required friction modifier additive (typically a 4 oz bottle), chatter will occur immediately. The friction modifier chemicals alter the clutch plates’ coefficient of friction to provide smooth engagement rather than grabbing. Solution: Drain the differential and refill with proper friction-modified gear oil, or try adding a bottle of friction modifier additive to the existing fluid first—this often solves the problem for $10-15 rather than a complete fluid change.

Worn clutch packs produce chatter that persists even with correct fluid. As the friction material wears thin over 50,000-100,000 miles of use, the clutch plates no longer maintain adequate clamping force. The differential effectively becomes a chattery, inconsistent mix between an LSD and an open differential. Solution: Differential rebuild or clutch pack replacement ($800-1,200 at a shop). Some mechanically-inclined intermediate enthusiasts tackle this job themselves with proper service manuals, though it requires specific tools and careful attention to shim specifications.

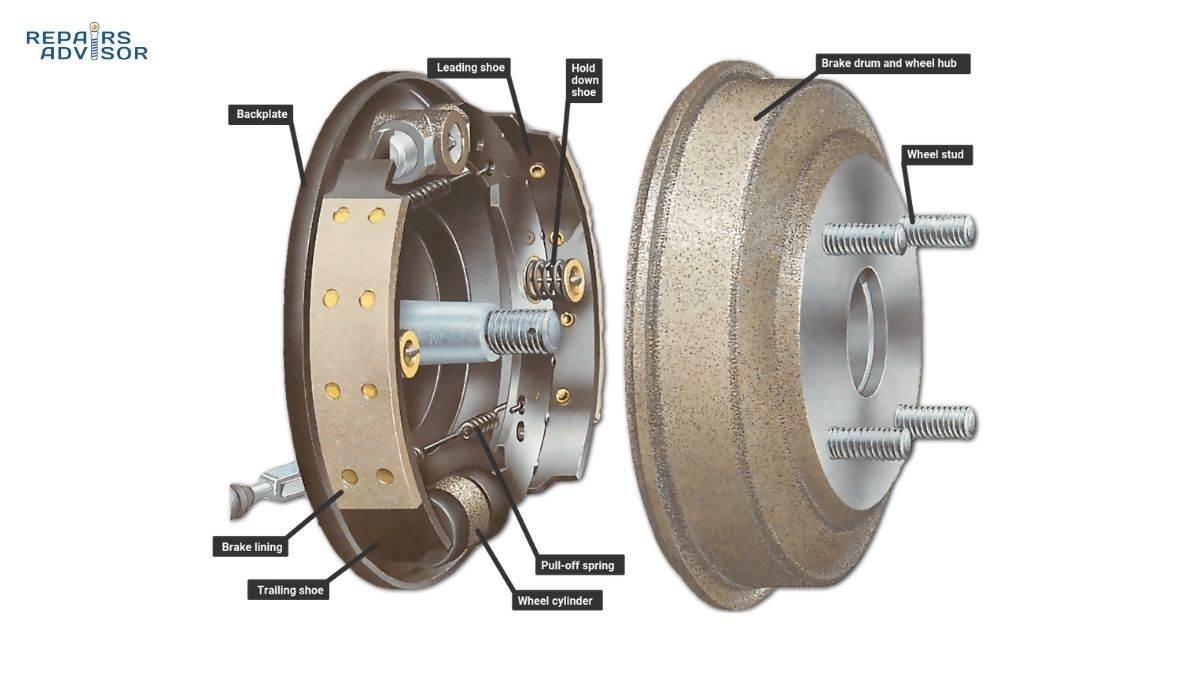

Excessive wheel spin presents the opposite symptom—one wheel spins freely like an open differential would, providing no traction benefit. Jack up the rear of your vehicle and rotate one wheel by hand with the transmission in neutral. In a functioning LSD, both wheels should rotate in the same direction (though not necessarily at exactly the same speed). If the opposite wheel rotates backward (opposite direction), your LSD has failed and is functioning as an open differential.

This problem stems from completely worn clutch packs in clutch-type LSDs, failed internal components in helical/Torsen units, or degraded fluid in viscous LSDs beyond salvaging. Helical gears can wear or crack under extreme loads, though this is rare. More commonly, bearing failures or damaged side gears prevent proper torque transfer. Professional diagnosis requires differential disassembly to inspect internal components.

Unusual noises beyond chatter indicate potentially serious problems. Whining or humming during acceleration, especially a sound that changes pitch with vehicle speed, often indicates worn bearings in the differential carrier. These bearings support the ring and pinion gears under high loads, and failure can cause misalignment leading to accelerated gear wear or catastrophic failure. Clunking sounds when transitioning from acceleration to deceleration or when changing throttle position suggest excessive backlash between the ring and pinion gears, often due to incorrect installation or bearing wear.

Grinding sounds during cornering are particularly concerning, potentially indicating damaged gears inside the differential or debris contamination. Metal particles from worn gears act like grinding compound, accelerating wear throughout the entire differential assembly. If you hear grinding, stop driving the vehicle and have it towed to a shop—continued operation can transform a $800 rebuild into a $2,000+ replacement job.

Fluid leaks demand immediate attention. Visible oil puddles under the differential, wet spots on the differential cover, or oil streaks on the axle tubes near the wheels indicate seal failure. Differential gear oil has a distinctive, strong sulfur smell (often described as “rotten eggs”) that makes leaks easy to identify. Common leak points include:

- Pinion seal where the driveshaft enters the differential

- Differential cover gasket on the rear housing cover

- Axle seals where the axle shafts exit the differential housing

Low differential fluid causes rapid damage. The gears generate tremendous heat and require constant oil bath cooling and lubrication. Running even a quart low accelerates wear and can cause bearing failure. Check your differential fluid level if you notice any leaks—on most differentials, the fluid should reach the bottom of the fill plug hole. This relates to broader drivetrain health; problems with CV half-shaft boot kits can also cause issues if contamination reaches the differential.

Maintenance Requirements and Fluid Service

Essential LSD Maintenance Schedule

Proper maintenance dramatically extends limited slip differential service life, while neglect leads to expensive premature failure. The single most important maintenance task is regular fluid changes using the correct lubricant.

Recommended fluid change intervals:

Normal driving conditions (mostly highway, moderate climate, no towing): Every 30,000-60,000 miles. Check your owner’s manual for manufacturer-specific recommendations—some automakers specify even longer intervals with synthetic gear oils.

Severe duty conditions require more frequent service:

- Frequent towing or hauling: Every 15,000-30,000 miles. The added weight increases differential stress and operating temperatures, accelerating fluid breakdown.

- Regular off-road driving: Every 15,000-20,000 miles. Mud, water, and dust contamination plus extended low-speed, high-torque operation degrades fluid faster.

- Track day or performance driving: After every 3-5 track days or annually, whichever comes first. Race pace generates extreme heat that breaks down gear oil quickly.

- Extreme climate operation: Every 20,000-30,000 miles. Consistently hot or cold weather stresses differential components and fluid.

Viscous LSDs present a special case—most are factory-sealed units not intended for service. These differentials typically fail around 60,000-80,000 miles as the silicone fluid degrades. When a viscous LSD stops working effectively, replacement is the only option. Some enthusiasts upgrade to clutch-type or Torsen differentials when their viscous unit fails.

Correct Fluid Selection—CRITICAL

Using wrong fluid in a limited slip differential causes immediate problems. This cannot be overstated—incorrect fluid destroys clutch-type LSDs rapidly.

Clutch-type LSDs require:

- Base oil: GL-5 rated gear oil in viscosity specified by manufacturer (commonly 75W-90 or 75W-140)

- Friction modifier additive: Must add a 4 oz bottle of limited slip friction modifier per manufacturer specification

- Synthetic vs. conventional: Synthetic gear oils provide better protection and last longer but cost more ($25-30/quart vs $10-15/quart for conventional)

The friction modifier is absolutely critical. Standard GL-5 gear oil contains extreme pressure additives that make clutch plates grab too aggressively, causing immediate chatter. Friction modifier chemicals alter the clutch friction coefficient, allowing smooth engagement. Some gear oils come pre-formulated with friction modifier already mixed in—these bottles will state “for limited slip differentials” on the label. Even with pre-treated oil, many manufacturers still recommend adding a 4 oz bottle of friction modifier during service for optimal performance.

Helical/Torsen LSDs are simpler—they use standard GL-5 gear oil without friction modifiers since they contain no clutches. Some manufacturers specify friction-modified oil anyway, which doesn’t hurt the Torsen but isn’t strictly necessary.

Always consult your owner’s manual or service manual for exact specifications. Differential fluid requirements vary by vehicle manufacturer, model year, and LSD type. Ford, for example, specifies particular friction modifier formulations for its limited slip differentials. Using the wrong specification voids warranties and causes problems.

DIY Fluid Change Procedure

Intermediate DIY enthusiasts can successfully change differential fluid with basic tools and proper safety precautions. This job takes 30-60 minutes and saves $150-250 in shop labor costs.

Required tools and supplies:

- Vehicle jack and heavy-duty jack stands rated for your vehicle’s weight

- Socket set or Allen key set (for drain and fill plugs—sizes vary by vehicle)

- Fluid transfer pump or squeeze bottle with extension tube

- Large drain pan (differential holds 2-4 quarts depending on size)

- Torque wrench

- Work gloves and safety glasses

- Gear oil in quantity specified by your vehicle (typically 2-4 quarts)

- Friction modifier additive (4 oz bottle for clutch-type LSDs)

- New differential cover gasket if applicable

- Differential cover bolts if reusing old cover

- Brake cleaner and shop rags for cleanup

Step-by-step procedure:

1. Prepare the vehicle: Park on level ground. Safely lift and support the vehicle on jack stands—never work under a vehicle supported only by a jack. Ensure the differential is accessible from underneath.

2. Remove fill plug FIRST: This critical step prevents a nightmare scenario. Using a breaker bar or large ratchet, remove the fill plug from the side of the differential housing. Some vehicles use Allen/hex plugs, others use square drive plugs. If the fill plug is seized and you’ve already drained the fluid, you’ll have a differential full of air and no way to add oil. Confirm you can remove both plugs before proceeding.

3. Drain the fluid: Position your drain pan under the differential. Remove the drain plug (usually on the bottom of the differential cover) and allow the fluid to drain completely—this takes 10-15 minutes for full drainage. Note the fluid condition: Dark, burnt-smelling fluid indicates overheating. Metal particles visible in the drained oil suggest worn gears requiring professional inspection.

4. Clean and reinstall drain plug: Wipe the drain plug threads clean with a shop rag. Install a new copper or aluminum crush washer if equipped. Thread the drain plug in by hand to prevent cross-threading, then torque to specification (typically 20-30 lb-ft, but check your manual). Over-tightening can strip the threads; under-tightening causes leaks.

5. Add friction modifier (clutch-type LSDs only): Pour the entire 4 oz bottle of friction modifier additive into the differential through the fill hole. This ensures the friction modifier mixes thoroughly with the new gear oil.

6. Fill with gear oil: Using your fluid pump or squeeze bottle, add gear oil through the fill hole until it begins dribbling back out. The correct level is when oil reaches the bottom of the fill hole—you should be able to touch it with your little finger inserted into the fill hole. Fill slowly to avoid air pockets. Most differentials require 2-3 quarts; large truck differentials may need 4+ quarts.

7. Reinstall fill plug: Clean the fill plug threads and install with a new crush washer if equipped. Torque to specification.

8. Check for leaks: Lower the vehicle and let it sit for 10-15 minutes, then check under the differential for leaks at both plugs. Tighten slightly if seepage occurs, but don’t over-torque.

9. Test drive: Drive the vehicle through several turns in both directions to circulate the new fluid through all differential components. Listen for any abnormal noises. Some chatter immediately after service is normal while the friction modifier works in—this should disappear after 10-20 miles of driving.

Safety considerations:

- Differential fluid is hot if you’ve just been driving—wait 30 minutes for cooling to avoid burns

- Gear oil has extremely strong sulfur smell—work in a well-ventilated area

- Wear chemical-resistant gloves—gear oil irritates skin and the smell lingers for days

- Dispose of used gear oil at an approved recycling center—never pour down drains or onto ground

- Support vehicle properly—differential work requires getting underneath

Many intermediate enthusiasts follow similar schedules for other drivetrain fluids; our guide on when to change your oil provides complementary maintenance timing information.

When Professional Service is Required

Certain LSD problems exceed DIY capabilities and demand professional diagnosis and repair. Know your limits—attempting repairs beyond your skill level can transform a minor problem into an expensive disaster.

Differential rebuild indicators:

- Chatter persists after using correct fluid with friction modifier additive

- Excessive one-wheel spin indicates failed clutch packs or internal damage

- Grinding, growling, or howling noises during operation

- Visible metal particles in drained gear oil

- Fluid leaking from pinion seal (requires special tools to replace without damaging housing)

Professional differential rebuilds typically cost $800-1,200 including labor and parts. The mechanic disassembles the differential, inspects all components, replaces worn parts (clutch packs, bearings, seals), and reassembles with proper shim selection and torque specifications. Experienced differential specialists use specialized tools including dial indicators for backlash measurement, gear pattern compound to verify tooth contact, and press equipment for bearing installation.

Upgrade considerations:

Converting from an open differential to a limited slip differential costs $1,000-2,000 depending on vehicle and LSD type selected. This job requires:

- Verification that your axle housing can accept an LSD (not all can)

- Matching gear ratio to your existing ring and pinion

- Proper installation with correct shim specifications

- Driveline rebalancing in some cases

Before committing to an LSD upgrade, research compatibility thoroughly. Some vehicles require different axle housings entirely to accept an LSD, making the upgrade cost-prohibitive. Online forums specific to your vehicle make are invaluable resources for determining upgrade feasibility and parts compatibility.

For professional-grade vehicles, consulting manufacturer specifications becomes critical. Toyota repair manuals and similar resources provide the technical specifications professionals use when servicing limited slip differentials—DIYers benefit from this information when determining whether to attempt service themselves.

Conclusion

Limited slip differentials represent a significant upgrade over open differentials for drivers who regularly encounter challenging traction conditions, pursue performance driving, or tow heavy loads. By automatically redistributing torque to the wheel with better grip, LSDs keep you moving forward in situations that would leave vehicles with open differentials helplessly spinning one wheel.

Choosing the right LSD type depends on your specific needs and priorities. Clutch-type LSDs deliver aggressive, immediate lockup ideal for motorsports, off-roading, and towing applications, but require periodic maintenance and eventual rebuild. Helical/Torsen differentials provide maintenance-free, smooth operation perfect for performance street cars and occasional track use, though they cost more initially and need some traction at both wheels to function. Viscous LSDs offer the smoothest operation and lowest cost but degrade over time and provide the weakest torque transfer. Electronic LSDs represent the cutting edge with infinitely adjustable characteristics and integration with vehicle stability systems, commanding premium pricing justified by their sophisticated capabilities.

Proper maintenance extends LSD service life dramatically. Using correct friction-modified gear oil for clutch-type LSDs prevents premature wear and eliminates the dreaded chatter noise. Following recommended service intervals based on your driving conditions—more frequent changes for towing, off-roading, or track use—keeps the differential functioning optimally. Even basic maintenance like monitoring for leaks and checking fluid level can prevent expensive damage.

For intermediate DIY enthusiasts, differential fluid changes present an achievable maintenance task that saves money while building mechanical skills. The job requires attention to detail, proper tools, and correct fluid selection, but falls well within the capabilities of someone comfortable with basic automotive repairs. More complex work like rebuilds and upgrades should be left to professionals with specialized tools and experience setting critical specifications like pinion depth and gear backlash.

The investment in a limited slip differential—whether factory-equipped or aftermarket installed—pays dividends in improved traction, vehicle control, and confidence when driving in challenging conditions. That initial $600-2,000 cost pales in comparison to being able to navigate winter roads safely, complete that mountain trail without getting stuck, or achieve consistent lap times on track days.

Safety Disclaimer: Working on differential systems involves supporting heavy vehicles, handling hot fluid with strong odors, and precise torque specifications. Improper service can cause differential failure while driving, potentially resulting in loss of vehicle control and serious accidents. If you’re uncomfortable with any maintenance procedure, or if your differential exhibits symptoms beyond simple fluid service needs, consult a professional mechanic with differential experience. Your safety and that of others on the road depends on properly functioning drivetrain components.

Understanding your vehicle’s differential type, maintaining it according to manufacturer specifications, and recognizing problem symptoms early ensures your LSD delivers reliable traction performance for the life of your vehicle. Check your owner’s manual for specific maintenance intervals, fluid specifications, and service procedures tailored to your exact make, model, and differential type.