The exhaust system is one of the most critical components for modern vehicle operation, managing everything from engine performance to emissions compliance and cabin comfort. Understanding how these integrated systems work empowers both DIY enthusiasts and professional technicians to diagnose problems, optimize performance, and maintain proper environmental standards.

Safety Note: Working on exhaust systems involves high-temperature components, toxic gases, and potentially sharp edges. Always allow complete cooling before handling components and work in well-ventilated areas. Professional consultation is recommended for complex repairs or when dealing with emissions-related components.

Why Exhaust System Is Critical for Fuel Efficiency

The exhaust system directly impacts fuel efficiency through backpressure management, emissions processing, and engine breathing optimization. When the exhaust manifold collects combustion gases from engine cylinders, the entire downstream system must maintain optimal flow characteristics to prevent restriction that would force the engine to work harder.

Proper backpressure is essential – too much restriction reduces power output and increases fuel consumption, while too little backpressure can actually hurt torque production at lower RPMs. The catalytic converter processes harmful emissions while creating minimal flow restriction, and the muffler reduces noise without significantly impacting exhaust flow.

Modern vehicles rely on precise oxygen sensor feedback from the exhaust stream to maintain optimal air-fuel ratios. When exhaust components fail or become restricted, fuel economy suffers immediately as the engine management system struggles to maintain proper combustion parameters.

For intermediate DIY enthusiasts, understanding these relationships helps identify when poor fuel economy might be exhaust-related rather than engine or fuel system issues. Professional mechanics leverage this knowledge to diagnose complex driveability concerns that may appear unrelated to exhaust function.

Exhaust System Parts and Construction Explained

The complete exhaust system consists of several integrated components working together to manage combustion gases from the engine to the tailpipe exit. The exhaust manifold serves as the collection point, typically constructed from cast iron or stainless steel headers designed to withstand extreme temperatures exceeding 1800°F during normal operation.

The downpipe or front pipe connects the manifold to the first emissions control component, usually incorporating flexible joints to accommodate engine movement and thermal expansion. Heavy-duty gaskets and heat shields protect surrounding components while maintaining proper sealing under thermal cycling conditions.

Catalytic converters represent the most complex internal construction, featuring precious metal catalysts (platinum, palladium, rhodium) applied to ceramic or metallic substrates with thousands of microscopic channels. The housing design balances catalyst protection with minimal flow restriction, while exhaust gas temperature sensors monitor thermal conditions.

Resonators and mufflers use various internal construction methods – from perforated tube designs with sound-absorbing materials to complex baffle systems that cancel specific sound frequencies. Performance-oriented systems may use straight-through designs, while comfort-focused applications employ multiple expansion chambers.

The exhaust pipe sections connecting these components use various joint designs including slip-fit connections, flanged joints, and band clamps. Material selection ranges from aluminized steel for budget applications to full stainless steel for maximum durability and corrosion resistance.

How Exhaust System Works: Step-by-Step Operation

Step 1: Gas Collection and Initial Flow During the exhaust stroke, pistons force combustion gases into the exhaust manifold where runner design creates initial scavenging effects. The manifold’s collector design determines how effectively gases from different cylinders interact – properly tuned systems use pulse energy from one cylinder to help evacuate gases from others. Temperature at this point reaches peak levels, requiring robust construction and proper heat management.

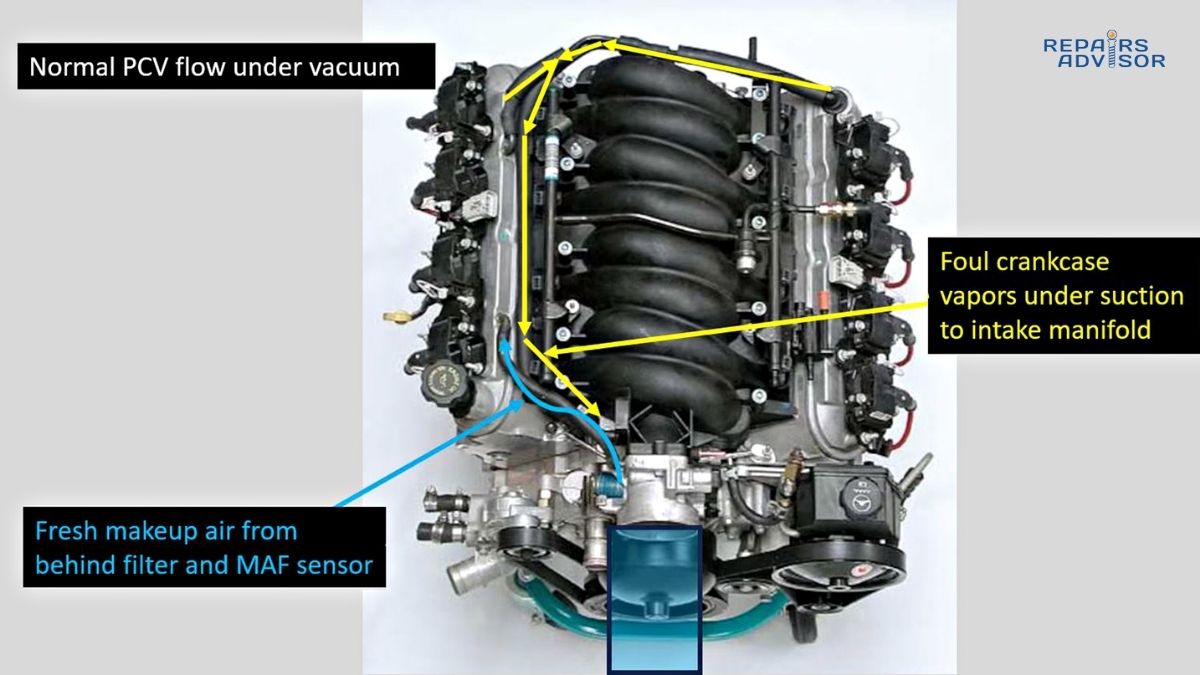

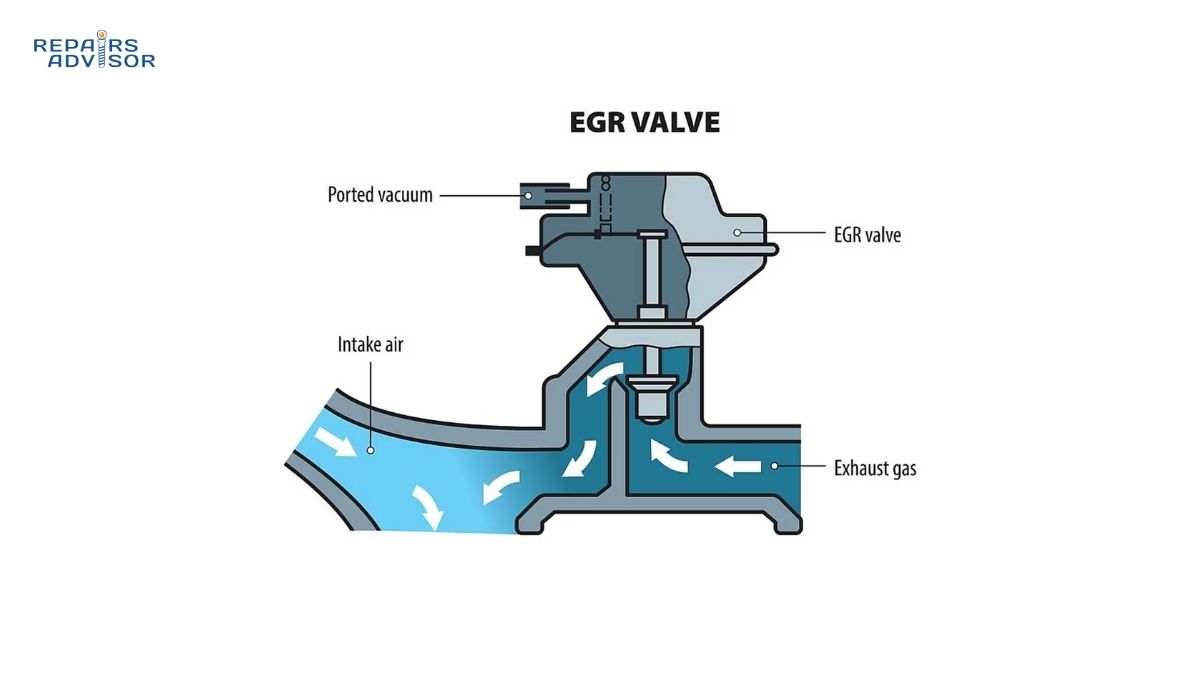

Step 2: Emissions Processing and Flow Control As gases enter the catalytic converter, the honeycomb substrate creates maximum surface area contact with precious metal catalysts. Light-off temperature (typically 400-600°F) activates the chemical reactions that convert hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful compounds. EGR systems may reintroduce measured amounts of exhaust gas back into the intake for NOx control, while oxygen sensors provide continuous feedback to the engine management system.

Step 3: Sound Control and Final Exit The resonator and muffler system uses various acoustic principles to reduce exhaust noise while maintaining acceptable flow characteristics. Sound waves travel through perforated tubes where destructive interference cancels specific frequencies, while expansion chambers reduce pressure pulses. The final tailpipe section directs gases safely away from the vehicle while meeting ground clearance and appearance requirements.

Throughout this process, backpressure characteristics affect engine breathing. Modern systems balance restriction with scavenging effects – optimal designs actually use exhaust pulse energy to help draw intake charges into cylinders. Performance modifications must consider these interactions to avoid losing low-end torque while gaining high-RPM flow.

Advanced Integration: Late-model vehicles incorporate exhaust temperature sensors at multiple points to protect catalysts from overheating, monitor system efficiency, and trigger regeneration cycles in diesel applications with particulate filters.

Exhaust System Location and Access Guide

Engine Bay Access Points The exhaust manifold and initial sections are accessible from above on most vehicles, though turbocharger applications may require removal of heat shields or other components. Always check for engine mount stability before working overhead, as exhaust work often requires significant force for rusty connections.

Undercarriage Service Positions Raising the vehicle provides access to the majority of exhaust system components. Use proper lifting points and safety stands – never rely on jacks alone when working under vehicles. Catalytic converters typically mount directly below the passenger compartment floor, while mufflers usually locate near the rear axle area.

Safety Considerations by Skill Level

- Beginner: Limit work to cold systems and visual inspections. Exhaust gases contain carbon monoxide – never run engines in enclosed spaces.

- Intermediate: Handle basic component replacement with proper tools and safety equipment. Be aware that penetrating oils and heat may be required for seized connections.

- Professional: Complex diagnostic work may require specialized equipment like exhaust gas analyzers or electronic stethoscopes for precise problem identification.

Component-Specific Access Notes Oxygen sensors often require special sockets due to wire harness clearance. Catalytic converter access may be limited by ground clearance, especially on lowered vehicles. Some systems incorporate flexible joints that must be properly aligned during reassembly to prevent stress cracking.

Heat Protection Requirements All exhaust work requires awareness of extreme operating temperatures. Components remain hot long after engine shutdown, and contact with skin causes immediate severe burns. Professional mechanics use infrared thermometers to verify safe handling temperatures before beginning work.

For complex exhaust system diagnosis or when working with emissions-related components, consult qualified professionals who have access to proper diagnostic equipment and understand local emissions compliance requirements. Visit our Help Center for additional technical support resources.