Why EVAP System Is Critical for Fuel Efficiency

The EVAP system (Evaporative Emission Control System) captures and prevents fuel vapors from escaping into the atmosphere, making it essential for both environmental protection and optimal fuel efficiency. This sophisticated emission control system reduces hydrocarbon emissions by up to 95% while maintaining proper fuel system operation and preventing fuel waste through vapor recovery.

Modern vehicles rely on the EVAP system to meet stringent emission standards while preserving fuel economy. When functioning correctly, the system captures fuel vapors that would otherwise be lost, essentially recovering fuel that would have evaporated and ensuring your vehicle operates at peak efficiency. A malfunctioning EVAP system can trigger check engine lights, increase emissions, and even cause fuel system pressure problems that affect engine performance.

Quick Facts:

- Function: Captures and stores fuel vapors, then burns them in the engine during combustion

- Category: Fuel efficiency and emissions control system

- Maintenance Level: Intermediate to professional servicing required

- Failure Impact: Increased emissions, check engine light, potential fuel system pressure issues

Safety Note: EVAP system diagnosis involves working with fuel vapors and pressurized components. Always consult manufacturer specifications and consider professional assistance for complex diagnostic procedures.

EVAP System Parts and Construction Explained

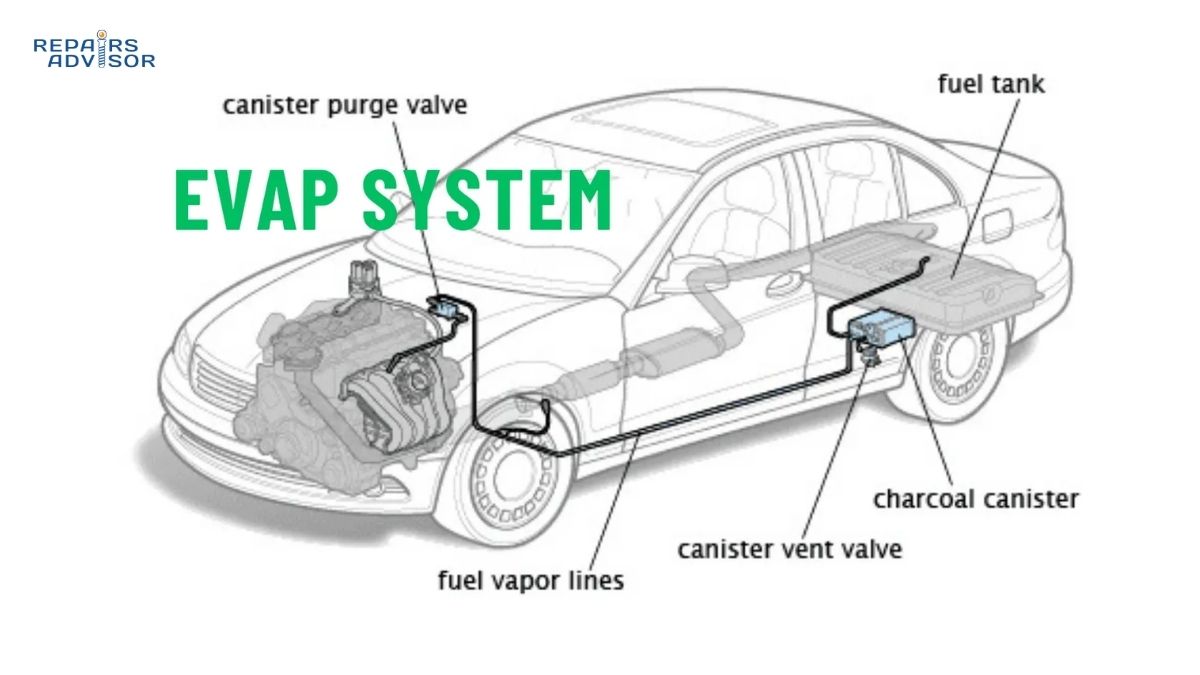

The EVAP system consists of several interconnected components that work together to capture, store, and process fuel vapors. Understanding the construction and location of each component helps diagnose system problems and assess repair complexity.

The charcoal canister serves as the heart of the system, containing activated carbon that absorbs fuel vapors from the fuel tank. This sealed container typically measures 6-12 inches in length and contains specially treated carbon granules designed to capture hydrocarbon molecules. Modern canisters often include internal baffles and separation chambers to improve vapor absorption efficiency.

The purge valve controls when stored vapors are released from the canister into the engine intake system. This electronically controlled solenoid valve opens and closes based on engine operating conditions, allowing the engine computer to precisely meter vapor flow. Professional-grade purge valves feature PWM (Pulse Width Modulation) control for exact flow regulation.

The vent valve regulates air flow into the canister during fuel vapor purging and prevents vapor escape during refueling. Located between the canister and atmosphere, this normally-open valve closes during fuel system leak testing and certain operating conditions. Quality vent valves include integral filters to prevent contaminant entry.

Additional critical components include vapor lines connecting the fuel tank to the canister, fuel tank pressure sensors that monitor system pressure for leak detection, and various leak detection components that ensure system integrity. These supporting elements work together to create a sealed system capable of capturing virtually all fuel vapors.

How EVAP System Works: Step-by-Step Operation

The EVAP system operates through a continuous cycle of vapor capture, storage, and combustion that adapts to different vehicle operating conditions. Understanding this operational cycle helps diagnose problems and assess system performance.

Step 1: Vapor Generation and Capture During normal operation, fuel in the tank naturally evaporates, especially as temperature increases. These evaporative emissions flow through vapor lines to the charcoal canister, where activated carbon absorbs the hydrocarbon molecules. The system maintains slight negative pressure to ensure all vapors are captured rather than vented to atmosphere.

Step 2: Vapor Storage and Processing The charcoal canister stores absorbed vapors until engine operating conditions are suitable for purging. During this storage phase, the vent valve allows filtered air to enter the system, creating proper pressure balance. The fuel tank pressure sensor continuously monitors system pressure to detect potential leaks or blockages.

Step 3: Vapor Purging and Combustion When the engine computer determines conditions are appropriate (typically during closed-loop operation), the purge valve opens to allow engine vacuum to draw stored vapors from the canister. These vapors mix with incoming air and are burned during normal combustion, effectively eliminating emissions while recovering the fuel energy.

The system includes sophisticated leak detection protocols that can identify problems as small as 0.020 inches in diameter. During these tests, the system seals completely and monitors pressure decay, triggering diagnostic codes like P0442 for small leaks or P0440 for large leaks when problems are detected.

Electronic Control Integration Modern EVAP systems integrate with engine management through real-time monitoring of purge valve operation, vapor flow rates, and system pressures. The engine computer adjusts purge timing based on engine load, temperature, and air-fuel ratio requirements, ensuring optimal emission control without affecting engine performance.

EVAP System Location and Access Guide

EVAP system components are distributed throughout the vehicle, requiring different access procedures and safety considerations for inspection and service. Proper component location knowledge is essential for effective diagnosis and prevents damage during repair procedures.

The charcoal canister is typically located near the fuel tank, often mounted under the vehicle chassis or within the rear fender area. Most canisters can be accessed by removing undercar panels or rear wheel well liners. Professional service requires proper lifting equipment and may involve fuel tank removal for complete access. For beginners, visual inspection is limited to external mounting and vapor line connections.

Purge valve location varies significantly by vehicle design, commonly found in the engine bay mounted on the intake manifold, firewall, or upper engine area. Intermediate DIYers can usually access the purge valve for testing and replacement using basic hand tools. The valve connects to both the intake system and vapor lines running to the canister.

The vent valve is generally located near the charcoal canister or integrated into the canister assembly itself. Access often requires working under the vehicle and may involve removing fuel tank shields or protective covers. Professional-level service may be required for complete vent valve replacement due to fuel system proximity.

Vapor lines run throughout the vehicle, connecting components from the fuel tank to the engine bay. These lines are often routed along the frame rails and may be accessed through various undercar panels. Signs that your charcoal canister is failing or signs of a bad canister vent valve can help identify which components require attention.

Safety Requirements:

- Always relieve fuel system pressure before accessing components

- Use proper lifting equipment for undercar access

- Avoid open flames or spark sources near fuel vapors

- Consider professional service for fuel tank-related work

- Follow manufacturer torque specifications for all connections

Professional Consultation Recommended:

- Fuel tank removal or major vapor line replacement

- EVAP system leak testing and diagnostic procedures

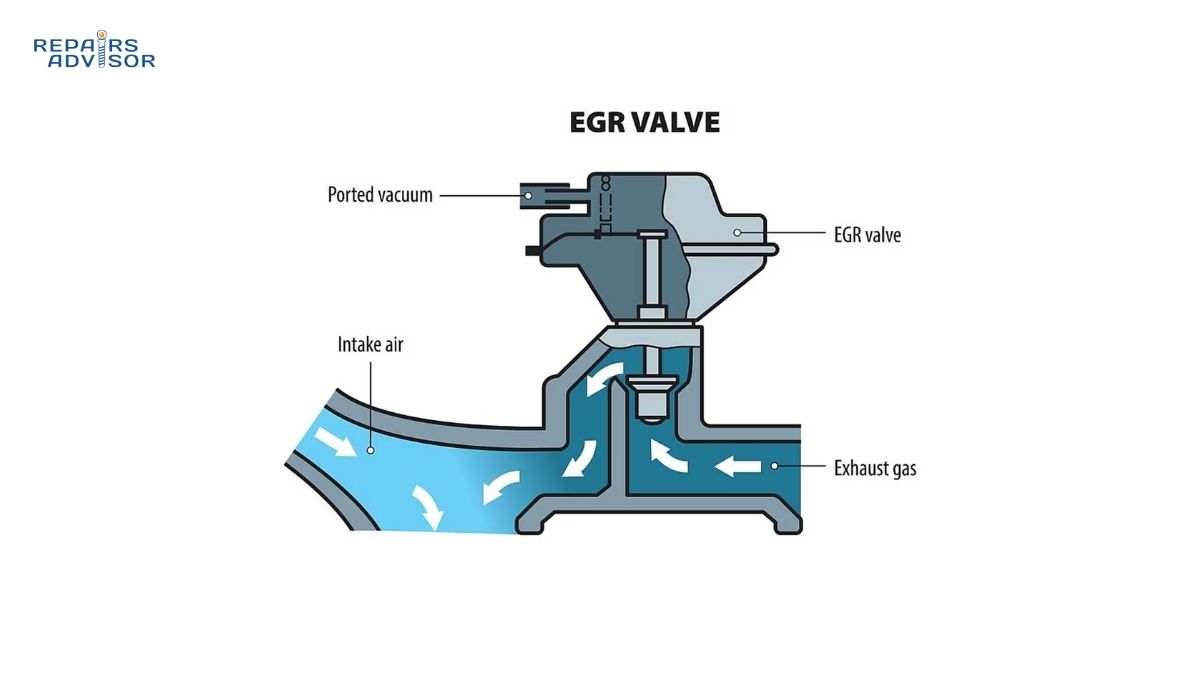

- Integration with other emission control systems like catalytic converters and EGR systems

- Complex diagnostic trouble code resolution

Legal Disclaimer: This information is provided for reference only. Repairs Advisor provides technical manuals and guidance but does not perform direct repair services. Always consult manufacturer specifications and consider professional assistance for safety-critical emission control work. No warranty is provided for repair outcomes following these procedures.