Modern diesel engines produce exceptional fuel efficiency and torque, but they also generate particulate matter that must be controlled for environmental compliance. The diesel particulate filter stands as one of the most critical exhaust aftertreatment components, capturing over 95% of harmful soot particles while maintaining optimal engine performance. Understanding how DPF regeneration cycles work, recognizing soot loading patterns, and managing this sophisticated exhaust aftertreatment system can save thousands in replacement costs while ensuring your diesel vehicle meets emission standards.

Safety Note: Working with exhaust systems involves high temperatures and toxic gases. Always allow complete cooling before inspection and consult professional service documentation for your specific vehicle model. This information is for reference only and does not replace manufacturer specifications.

Why Diesel Particulate Filter Is Critical for Fuel Efficiency

The diesel particulate filter serves a dual purpose in modern diesel engines – environmental protection and fuel efficiency optimization. While capturing microscopic soot particles prevents harmful emissions, the DPF regeneration process actually helps maintain engine efficiency by preventing back-pressure buildup that would otherwise rob power and increase fuel consumption.

During normal operation, the filter substrate accumulates particulate matter from combustion. Without proper filtration, this soot would exit through the tailpipe, but it also indicates incomplete combustion that wastes fuel. The regeneration system burns off accumulated particles at controlled intervals, essentially completing the combustion process that began in the cylinder. This thermal cleaning cycle restores proper exhaust flow, maintaining the precise back-pressure levels diesel engines require for optimal performance.

Professional mechanics recognize that a properly functioning DPF system often correlates with better fuel economy, as the regeneration cycles force the engine to operate at ideal air-fuel ratios. For intermediate DIY enthusiasts, monitoring DPF soot loading levels becomes a valuable diagnostic tool for overall engine health, while beginners should understand that warning lights related to exhaust aftertreatment typically require immediate professional attention to prevent costly system damage.

The SCR system works in conjunction with the DPF to provide comprehensive emission control, while oxygen sensors provide crucial feedback for regeneration timing. Understanding how these systems integrate helps diagnose performance issues across the entire exhaust system.

Diesel Particulate Filter Parts and Construction Explained

The filter substrate forms the heart of the DPF system, typically constructed from silicon carbide or cordierite ceramic materials chosen for their ability to withstand extreme temperatures during regeneration cycles. This honeycomb structure contains thousands of microscopic channels – alternate channels are plugged at opposite ends, forcing exhaust gases through porous ceramic walls where particulate matter becomes trapped.

Soot sensors, positioned both upstream and downstream of the filter substrate, monitor particulate accumulation through differential pressure measurements. As the substrate fills with particles, back-pressure increases, triggering the engine control module to initiate regeneration when predetermined thresholds are reached. These pressure sensors represent critical diagnostic points for professional technicians troubleshooting DPF performance issues.

The regeneration system encompasses multiple components working in precise coordination. Temperature sensors throughout the exhaust stream monitor thermal conditions, while the engine management system controls fuel injection timing and quantity to achieve the 1,100°F+ temperatures required for soot combustion. Some systems incorporate dedicated fuel injectors in the exhaust stream, while others rely on post-combustion fuel injection through the engine’s primary injectors.

Ash cleaning represents the one maintenance aspect that cannot be automated. Unlike soot particles that burn away during regeneration, metallic ash from engine oil and fuel additives accumulates permanently within the substrate. This ash loading eventually requires professional cleaning or filter replacement, typically after 150,000-200,000 miles of normal operation.

The catalytic converter often integrates with DPF systems in modern designs, while exhaust gas temperature sensors provide critical feedback for regeneration control. Professional diagnostics frequently involve analyzing data from the diesel fuel system to ensure proper regeneration fuel delivery.

How Diesel Particulate Filter Works: Step-by-Step Operation

The filtration process begins as exhaust gases enter the DPF substrate at temperatures typically ranging from 400-800°F during normal operation. Particulate matter becomes trapped within the ceramic walls through a combination of mechanical filtration and thermal dynamics. Smaller particles adhere to wall surfaces through electrostatic attraction, while larger particles create a filter cake that enhances collection efficiency over time.

Soot loading accumulates gradually during normal driving, with the engine control module continuously monitoring pressure sensors to calculate filter capacity. Different driving patterns affect accumulation rates dramatically – highway driving with sustained high exhaust temperatures naturally burns off some particles, while stop-and-go city driving allows maximum accumulation. Understanding these patterns helps drivers optimize their driving habits to reduce regeneration frequency.

Passive regeneration occurs naturally when exhaust temperatures exceed 550°F for extended periods, typically during highway cruising or heavy load operations. The high temperatures spontaneously combust accumulated soot particles without any intervention from the engine management system. This represents the ideal operating condition, as it requires no additional fuel consumption and maintains optimal filter capacity.

Active regeneration initiates when soot loading reaches approximately 45-60% of filter capacity and passive conditions haven’t occurred naturally. The engine management system increases exhaust temperatures through modified fuel injection strategies, often accompanied by distinctive operational characteristics like increased idle speed, cooling fan activation, and slightly reduced fuel economy during the 20-40 minute cleaning cycle.

Forced regeneration represents the most intensive cleaning mode, typically requiring professional diagnostic equipment to initiate. This process becomes necessary when active regeneration attempts fail due to incomplete cycles or extremely high soot loading. Professional technicians use specialized scan tools to monitor regeneration parameters and ensure complete cleaning without damaging the substrate.

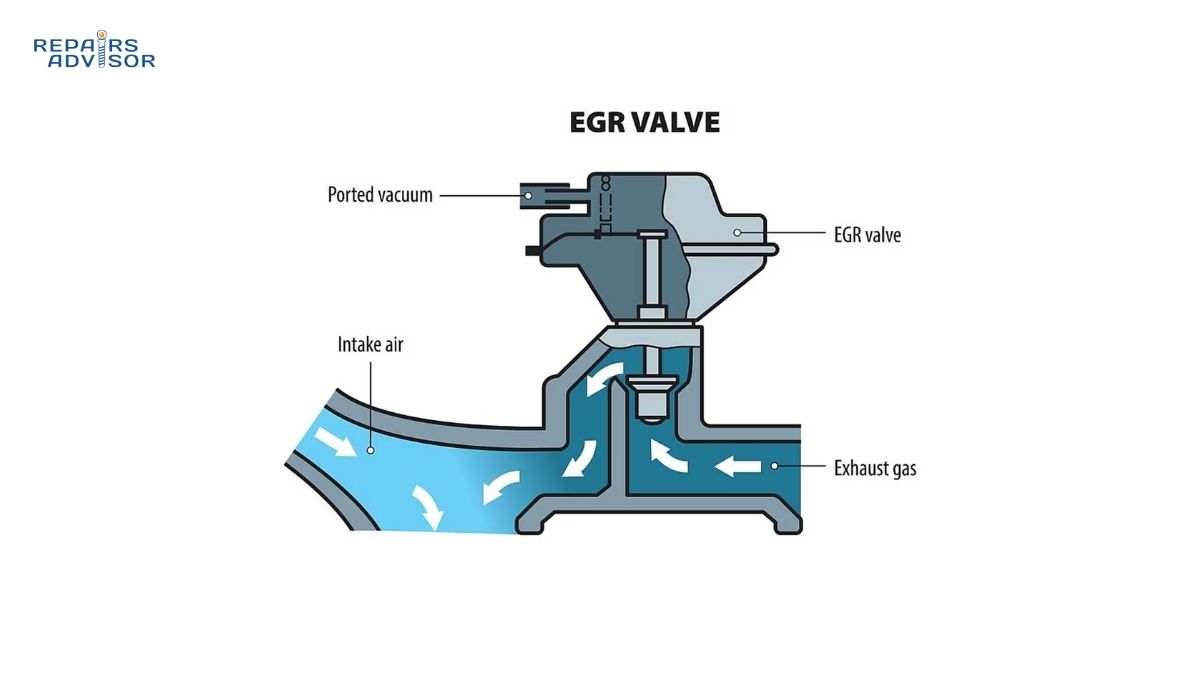

The EGR system affects DPF loading rates by controlling combustion temperatures, while the turbocharger influences exhaust flow dynamics through the filter. Advanced diagnostics often involve analyzing engine management data to optimize regeneration strategies.

Diesel Particulate Filter Location and Access Guide

Most diesel particulate filters mount in the exhaust system between the turbocharger outlet and the muffler assembly, typically underneath the vehicle near the transmission or mid-chassis area. The exact location varies by manufacturer, but visual identification becomes straightforward once you recognize the characteristic cylindrical or rectangular housing with multiple sensor connections and temperature-resistant heat shielding.

Beginner Safety Warning: Never attempt to access DPF components on a hot engine. Exhaust temperatures can exceed 1,200°F during regeneration cycles, causing severe burns even hours after operation. Always verify complete cooling and wear appropriate protective equipment when inspecting these systems.

Access considerations vary significantly between light-duty pickup trucks and heavy commercial vehicles. Light-duty applications often require removing skid plates or accessing from above through the engine compartment, while commercial trucks may provide ground-level access points specifically designed for maintenance. Professional service bays equipped with vehicle lifts provide optimal access for comprehensive inspections.

Pressure sensor locations typically include one measurement point before the DPF substrate and another after, with connecting lines routed to protected areas away from heat and road debris. Temperature sensors may be integrated into the housing or mounted in dedicated bungs throughout the exhaust system. These sensor locations become critical diagnostic access points for professional troubleshooting procedures.

Professional Consultation Recommended: DPF removal requires specialized handling procedures to prevent substrate damage, and installation demands precise torque specifications for exhaust clamps and sensor connections. Additionally, many systems require scan tool procedures to reset soot loading calculations and ensure proper operation after service.

Filter substrate inspection requires complete removal from the housing, a procedure that involves substantial exhaust system disassembly. Professional shops typically remove the entire DPF assembly as a unit, then separate components in controlled environments using appropriate lifting equipment and contamination control procedures.

Heat shielding removal provides access to sensor connections and housing mounting points, but these shields serve critical functions protecting nearby components from extreme temperatures. Proper reinstallation ensures vehicle fire safety and prevents heat damage to fuel lines, brake components, and electrical harnesses located near the exhaust system.

The exhaust manifold connects upstream to the DPF system, while mufflers and resonators handle treated gases downstream. Professional service often involves comprehensive diesel fuel system analysis to ensure optimal regeneration performance and prevent premature filter loading.

Information provided for reference only. Always consult manufacturer service documentation and consider professional assistance for exhaust aftertreatment system repairs. Improper service procedures can result in expensive component damage and emission compliance violations.

Related Resources:

- Complete Guide to SCR Systems and DEF – NOx reduction technology that works with DPF

- EGR System Operation – How exhaust gas recirculation affects particulate formation

- Catalytic Converter Function – Upstream exhaust treatment integration

- Oxygen Sensor Analysis – Fuel mixture control for regeneration

- Professional Diesel Diagnostics – Troubleshooting exhaust aftertreatment systems