Modern automotive electrical and lighting systems represent some of the most complex and critical components in today’s vehicles, serving as the nerve center that controls everything from basic engine operation to advanced safety features. These interconnected systems have evolved from simple circuits powering headlights and ignition to sophisticated networks managing dozens of computerized modules and hundreds of electrical components.

The electrical system serves as the foundation for virtually every vehicle function, providing power for engine management, safety systems, comfort features, and communication networks. When electrical problems occur, they can affect multiple vehicle systems simultaneously, making accurate diagnosis and proper repair procedures essential for safe and reliable operation.

Understanding the integration between electrical power generation, distribution, and lighting components helps vehicle owners and technicians approach electrical problems systematically rather than randomly replacing components. Modern vehicle electrical networks incorporate multiplexed wiring, computerized control modules, and integrated systems that require specialized knowledge and diagnostic equipment for effective troubleshooting and repair.

The complexity of modern vehicle electrical systems often intimidates DIY enthusiasts and even experienced mechanics, but understanding fundamental electrical principles and systematic diagnostic approaches makes these systems much more manageable. Safety considerations remain paramount, as electrical work involves specific hazards that require proper procedures and precautions.

Common misconceptions about automotive electrical work include the belief that electrical problems are too complex for systematic diagnosis or that electrical components fail randomly without warning signs. In reality, most electrical failures follow predictable patterns and provide diagnostic clues that guide effective troubleshooting procedures.

This comprehensive guide explores automotive electrical and lighting systems from fundamental principles through advanced diagnostic techniques, emphasizing safety procedures and professional consultation guidelines. Whether you’re experiencing electrical problems or seeking to understand your vehicle’s systems better, this guide provides the technical foundation needed for informed decision-making about electrical system maintenance and repair.

Understanding Automotive Electrical System Fundamentals

Basic Electrical Principles in Vehicles

Automotive electrical systems operate on fundamental principles of voltage, current, and resistance relationships defined by Ohm’s Law, which states that voltage equals current multiplied by resistance (V = I × R). Understanding these relationships is essential for diagnosing electrical problems and determining whether issues stem from insufficient voltage supply, excessive current draw, or abnormal circuit resistance.

DC electrical systems in automotive applications use direct current flowing in one direction, unlike household AC systems that alternate current direction. Vehicle electrical systems typically operate at 12 volts nominal voltage, although actual system voltage varies from approximately 11.8 volts with engine off to 13.2-14.4 volts during normal charging system operation.

Ground systems and chassis grounding principles utilize the vehicle’s metal frame and body as the negative conductor for most electrical circuits. Proper grounding is critical for electrical system function, as poor ground connections can cause voltage drops, erratic operation, and component damage that may appear as complex electrical problems.

Circuit types in automotive applications include series circuits where current flows through components sequentially, parallel circuits where current divides among multiple paths, and series-parallel combinations that incorporate both configurations. Understanding circuit types helps predict how component failures affect other circuit elements and guides diagnostic procedures for complex electrical problems.

Electrical load management and capacity planning become increasingly important as vehicles incorporate more electrical accessories and advanced systems. The electrical system must generate sufficient power for all connected loads while maintaining proper voltage regulation and avoiding overload conditions that could damage components or create safety hazards.

Modern vehicles employ sophisticated electrical architecture that balances performance, efficiency, and reliability while accommodating the increasing electrical demands of contemporary automotive technology and consumer expectations for convenience and safety features.

Power Generation and Storage Systems

Battery function centers on chemical energy storage through electrochemical reactions that convert stored chemical energy into electrical energy on demand. Lead-acid batteries remain the standard for automotive applications due to their ability to deliver high current for starting while providing stable voltage for electrical system operation throughout various load conditions.

Alternator operation relies on electromagnetic induction principles, where rotating magnetic fields generate electrical current in stationary windings. The alternator must provide sufficient current for all electrical loads while maintaining proper charging voltage to replenish battery energy and prevent electrical system voltage drop during high-demand conditions.

Voltage regulation and charging control systems monitor electrical system conditions and adjust alternator output to maintain proper charging voltage regardless of engine speed or electrical load variations. Modern voltage regulators incorporate sophisticated control algorithms that optimize charging efficiency while preventing overcharging that could damage the battery or electrical components.

Starting system electrical requirements involve delivering very high current (often 200-400 amperes) for short periods to crank the engine against compression and friction forces. The starting system must function reliably across wide temperature ranges while interfacing with security systems, automatic transmissions, and other vehicle systems that affect starting operation.

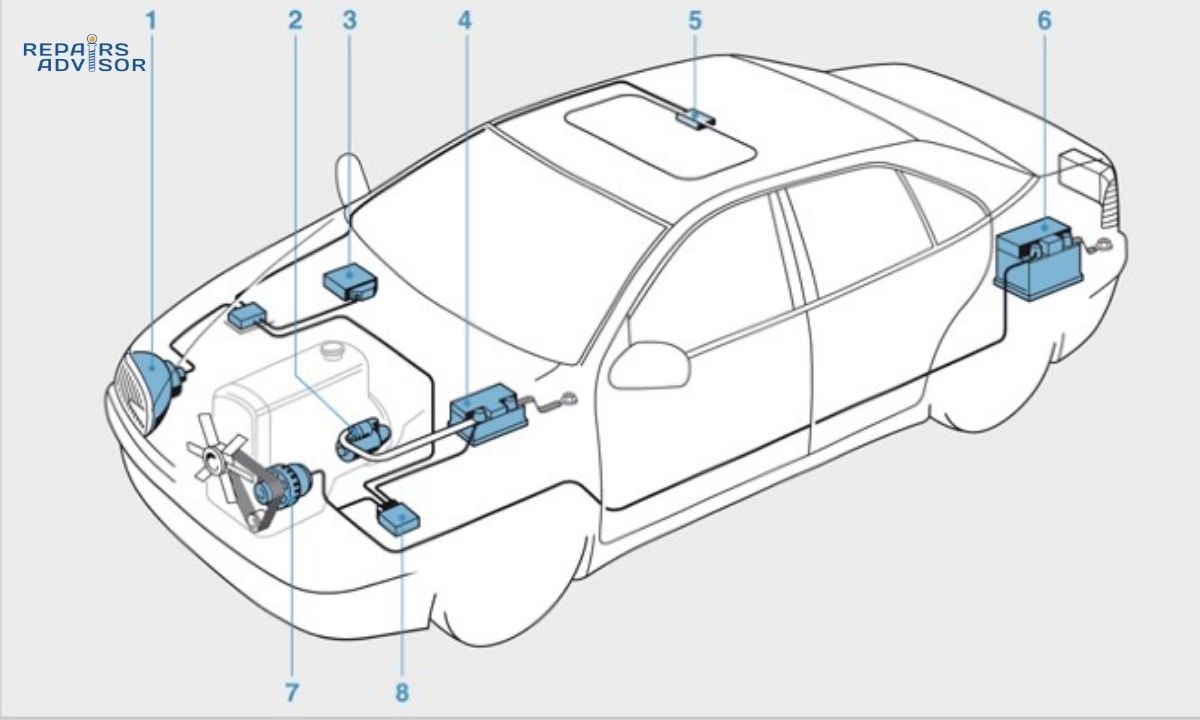

Power distribution from generation to consumption involves complex routing through fuse boxes, relay centers, and control modules that manage electrical flow to various vehicle systems. Understanding power distribution helps diagnose problems that affect multiple circuits and identify root causes of widespread electrical issues.

The relationship between power generation, storage, and consumption creates a dynamic system that must balance supply and demand while accommodating varying operating conditions and electrical loads throughout normal vehicle operation.

Electrical Distribution Networks

Main electrical harnesses and routing systems carry power and control signals throughout the vehicle via carefully designed wiring paths that balance protection, accessibility, and space efficiency. Modern vehicles may contain several miles of wiring organized into harnesses that connect various electrical components while protecting wires from environmental damage and mechanical stress.

Fuse boxes and circuit protection systems prevent electrical damage by interrupting current flow when circuits draw excessive current due to short circuits or component failures. Different fuse types and ratings protect specific circuits based on their normal operating current and the components they protect, making proper fuse selection critical for electrical system safety and reliability.

Relay operation and switching systems enable low-current control circuits to switch high-current loads safely and efficiently. Relays isolate control circuits from high-power circuits while providing centralized switching for systems like lighting, cooling fans, and fuel pumps that require high current operation controlled by low-current signals.

Control modules and computerized systems manage complex vehicle functions through integrated circuits that process sensor inputs, execute control algorithms, and operate output devices. Modern vehicles may contain 50 or more control modules that communicate through data networks and coordinate vehicle system operation for optimal performance and efficiency.

Body control modules and integrated circuits centralize control of lighting, comfort, and convenience features while reducing wiring complexity and improving reliability. These modules communicate with other vehicle systems to coordinate operation and provide advanced features that enhance safety and convenience.

Understanding electrical distribution networks helps technicians trace circuits efficiently and identify root causes of electrical problems that may affect multiple vehicle systems simultaneously.

Modern Vehicle Electrical Architecture

Multiplexed wiring systems and data networks reduce wiring complexity by sharing communication lines among multiple control modules rather than providing dedicated wires for each signal. CAN bus and other communication protocols enable modules to share information and coordinate operation while reducing the total amount of wiring required for complex vehicle systems.

CAN bus communication protocols provide standardized methods for control modules to exchange information reliably and efficiently. These digital communication systems enable advanced vehicle features such as integrated diagnostics, coordinated system operation, and sophisticated driver assistance technologies that require real-time information sharing among multiple systems.

Integrated electrical and electronic systems combine traditional electrical functions with advanced electronic control and communication capabilities. This integration enables features like adaptive lighting, intelligent charging systems, and predictive maintenance that enhance vehicle performance, efficiency, and reliability through coordinated system operation.

Hybrid and electric vehicle electrical considerations involve high-voltage systems (typically 200-400 volts) that require specialized safety procedures and diagnostic equipment. These systems operate alongside conventional 12-volt systems and require technicians to understand both high-voltage safety procedures and the interaction between conventional and high-voltage electrical systems.

Advanced driver assistance system electrical requirements include sensors, cameras, radar units, and control modules that demand high reliability and precise operation for safety-critical functions. These systems require understanding of both electrical principles and the specific requirements of safety-critical automotive applications.

For comprehensive understanding of how electrical systems integrate with specific components, refer to our detailed guide on Understanding Your Vehicle’s Electrical and Lights Systems.

Core Electrical System Components

Battery Systems and Energy Storage

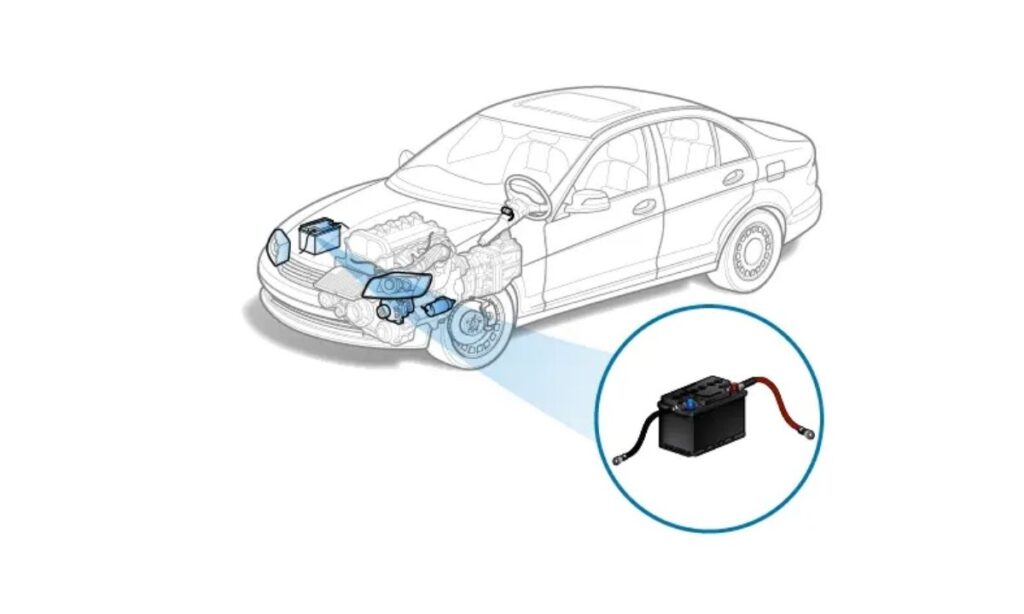

Lead-acid battery construction incorporates positive and negative plates immersed in sulfuric acid electrolyte within a durable case designed to withstand automotive environmental conditions. The electrochemical reactions between lead plates and acid electrolyte create the voltage and current capacity necessary for automotive electrical system operation while providing energy storage for periods when the engine is not running.

Battery types vary in construction and performance characteristics, with conventional flooded batteries providing cost-effective energy storage, while AGM (Absorbed Glass Mat) and gel cell batteries offer enhanced performance in demanding applications. AGM batteries provide superior vibration resistance and deep discharge recovery compared to conventional batteries, making them suitable for vehicles with high electrical demands or frequent deep discharge cycles.

Battery capacity measurements include cold cranking amps (CCA), which indicates starting capability in cold conditions, and reserve capacity, which measures how long the battery can support electrical loads without charging. Understanding these specifications helps select appropriate replacement batteries and diagnose starting and charging system problems that may appear as battery failures.

Battery maintenance procedures for conventional batteries include electrolyte level checking, terminal cleaning, and periodic load testing to assess condition and remaining service life. Maintenance-free batteries require less routine service but still benefit from regular testing and terminal maintenance to ensure optimal performance and prevent premature failure.

Signs of battery deterioration include slow engine cranking, dim lighting, and electrical system irregularities that worsen in cold conditions. Early recognition of battery problems prevents unexpected failures and helps distinguish between battery issues and other electrical system problems that may present similar symptoms.

Our comprehensive guide Why Your Car Battery Dies, and What to Do About It provides detailed information about battery maintenance and troubleshooting procedures.

Charging System Components

Alternator construction utilizes rotating electromagnetic fields to generate AC current that is converted to DC current through internal diodes. The alternator must produce sufficient current to meet all electrical demands while maintaining proper voltage regulation across varying engine speeds and electrical loads that change constantly during normal vehicle operation.

Voltage regulator function involves monitoring electrical system voltage and adjusting alternator field current to maintain proper charging voltage regardless of engine speed or electrical load conditions. Modern voltage regulators incorporate temperature compensation and sophisticated control algorithms that optimize charging efficiency while preventing overcharging that could damage electrical components.

Drive belt systems provide mechanical connection between the engine crankshaft and alternator pulley, requiring proper tension and alignment for reliable operation. Belt tension affects alternator performance and service life, with loose belts causing charging problems and tight belts accelerating bearing wear and creating excessive stress on mounting components.

Charging system output testing involves measuring voltage and current under various load conditions to verify proper alternator and voltage regulator operation. Professional testing equipment enables accurate assessment of charging system capacity and helps identify developing problems before complete failure occurs.

Common charging system failures include alternator diode failures, voltage regulator problems, and drive belt issues that can cause undercharging, overcharging, or intermittent charging problems. Understanding these failure modes helps guide diagnostic procedures and repair strategies.

For detailed alternator diagnostic information, consult our guide on Signs of a Bad or Failing Alternator.

Starting System Electrical Components

Starter motor construction incorporates high-torque electric motors designed to crank engines against compression and friction forces while drawing very high current for short periods. Starter motors must function reliably across wide temperature ranges while providing sufficient torque to start engines under various operating conditions including cold temperatures and high compression ratios.

Solenoid function involves electromagnetically engaging the starter drive gear with the engine flywheel while simultaneously connecting high current to the starter motor. The solenoid must coordinate mechanical engagement with electrical connection to prevent gear damage and ensure reliable starting operation throughout the starter’s service life.

Ignition switch and starting circuit control systems incorporate safety interlocks that prevent starting under unsafe conditions such as automatic transmissions not in park or neutral. Modern starting circuits integrate with security systems, immobilizers, and other vehicle systems that must verify proper authorization before enabling starting operation.

Security system integration with starting circuits requires proper communication between various control modules and may involve encrypted signals or rolling codes that prevent unauthorized starting. Understanding security system integration is essential for diagnosing starting problems that may appear as electrical failures but actually involve security system operation.

Remote start system electrical considerations include additional control modules, extended wiring, and integration with existing vehicle systems that must be carefully coordinated to ensure safe and reliable operation. Professional installation and diagnosis of remote start systems requires understanding of both the aftermarket system and original vehicle electrical architecture.

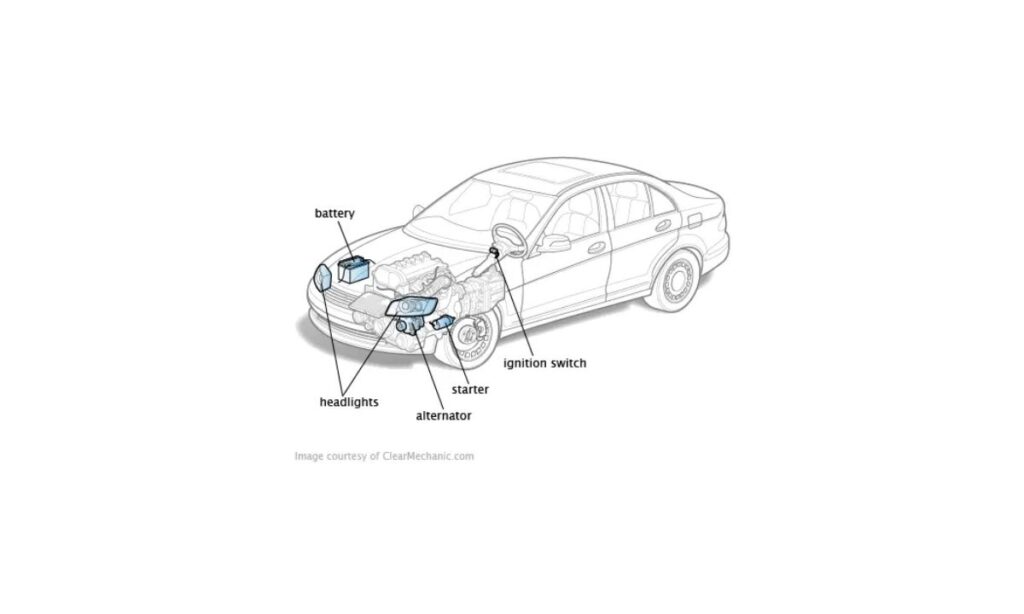

The Alternator: The On-Road Powerhouse

Once your engine is running, the alternator takes over as the primary source of electrical power. Its main job is twofold:

- Recharge the Battery: It replenishes the energy the battery used to start the engine, ensuring it’s ready for the next start.

- Power All Vehicle Electrics: More importantly, it generates all the electricity needed to run every electrical component in your car while the engine is on – from your headlights, radio, and air conditioning to your engine’s computer (ECU) and fuel pump.

Depending on its size and your vehicle’s electrical demands, an alternator can produce 150 amps or more of current. A healthy alternator typically maintains a stable operating voltage between 13.5 and 14.5 volts across your vehicle’s electrical system. If it’s undercharging or overcharging, you’ll start to notice problems.

The Battery: The Initial Energy Bank and Backup

While often thought of as the sole power source, the battery actually has a specific role. Its primary functions are:

- Starting Power: It stores and delivers the massive burst of electrical energy required by the starter motor to initially crank and fire up the engine.

- Backup Power/Stabilizer: Once the engine is running, the alternator handles most of the power supply. However, the battery still plays a vital role as a voltage stabilizer for the entire electrical system. It acts as a buffer, absorbing voltage spikes and providing supplementary power during moments of high electrical demand (e.g., when you turn on all your lights, wipers, and defrosters simultaneously, especially at low engine RPMs, the battery temporarily helps the alternator meet the load). If the alternator temporarily cannot meet the electrical demands of the vehicle, the battery provides the necessary backup power.

Understanding how these core components work together is essential for recognizing when something might be going wrong with your car’s electrical system.

Circuit Protection and Control Systems

Fuse types and ratings vary according to circuit requirements, with blade fuses, cartridge fuses, and circuit breakers providing different protection characteristics for various automotive applications. Proper fuse selection balances circuit protection with operational reliability, ensuring that fuses protect components without nuisance failures during normal operation.

Circuit breaker applications in automotive systems typically involve high-current circuits such as power windows, cooling fans, and other motor-driven accessories that may experience temporary overloads during normal operation. Circuit breakers automatically reset after overload conditions clear, eliminating the need for fuse replacement while providing reliable circuit protection.

Relay types include conventional electromechanical relays, solid-state relays, and intelligent relays that incorporate diagnostic capabilities and communication with vehicle control systems. Understanding relay operation and testing procedures helps diagnose problems in circuits controlled by relays and prevents unnecessary component replacement.

Control module functions encompass a wide range of vehicle operations from engine management to body control, with each module containing sophisticated microprocessors and software that manage specific vehicle systems. Modern control modules communicate through data networks and may require programming or initialization after replacement to ensure proper operation.

Diagnostic trouble code systems provide standardized methods for identifying electrical and electronic system problems through codes that indicate specific failure modes or operating conditions. Understanding diagnostic code retrieval and interpretation helps guide systematic troubleshooting procedures.

For detailed circuit protection information, refer to our comprehensive guide on Car’s Fuse Box: All Things You Should Know.

Automotive Lighting Systems

Exterior Lighting Components

Headlight systems have evolved from simple tungsten filament bulbs to sophisticated technologies including halogen, HID (High-Intensity Discharge), and LED systems that provide improved illumination while reducing power consumption. Each lighting technology requires different electrical characteristics and control systems, with HID systems requiring ballasts and LED systems requiring driver circuits for proper operation.

Turn signal and hazard warning light circuits incorporate flasher modules that create the characteristic blinking pattern while providing visual and audible feedback to drivers. Modern flasher modules accommodate different bulb types and loads while providing diagnostic capabilities that can detect bulb failures and alert drivers to maintenance needs.

Brake light and tail light systems serve critical safety functions by alerting following drivers to vehicle deceleration and position during low-visibility conditions. These lighting circuits must provide reliable operation with quick response times and sufficient brightness for visibility across varying environmental conditions and distances.

Backup light and license plate illumination systems provide essential visibility for reversing operations and legal identification requirements. Backup lights integrate with transmission range sensors to activate only when the transmission is in reverse, while license plate lights must provide adequate illumination for legal compliance.

Side marker and running light functions enhance vehicle visibility during dawn, dusk, and adverse weather conditions while meeting regulatory requirements for vehicle identification. These lighting systems often integrate with other vehicle systems such as automatic light controls and daylight running light systems.

Understanding different lighting technologies and their electrical requirements helps diagnose lighting problems and select appropriate replacement components that provide optimal performance and reliability.

Interior Lighting Systems

Dome light and courtesy light circuits provide interior illumination for passenger comfort and safety while integrating with door switches, dimmer controls, and delay timers. Interior lighting systems must balance adequate illumination with battery drain prevention through automatic shutoff features and efficient bulb or LED technologies.

Dashboard and instrument illumination systems provide essential visibility for vehicle information displays while incorporating dimmer controls that adjust brightness according to ambient light conditions and driver preferences. Modern instrument lighting often utilizes LED technology for improved reliability, longer service life, and enhanced visibility compared to conventional incandescent bulbs.

Map light and reading light systems provide focused illumination for specific tasks while minimizing interference with driver vision and other passengers. These lighting systems typically incorporate individual switching and may include different color options or intensity settings for optimal functionality.

Ambient lighting and accent systems enhance interior aesthetics while providing subtle illumination that improves nighttime visibility and vehicle ambiance. Ambient lighting systems often integrate with body control modules and may include programmable colors, intensity levels, and activation patterns that can be customized according to driver preferences.

Door ajar and warning light indicators provide critical safety information by alerting drivers to open doors, low fluid levels, and other conditions that require attention. These warning systems integrate with various vehicle sensors and control modules to provide timely alerts while minimizing false alarms.

Interior lighting integration with vehicle electrical systems requires understanding of control modules, dimmer circuits, and timer systems that coordinate lighting operation with other vehicle functions.

Advanced Lighting Technologies

Adaptive headlight systems incorporate motors and sensors that automatically adjust headlight aim and intensity according to vehicle speed, steering angle, and oncoming traffic conditions. These systems require sophisticated control modules and integration with vehicle dynamics sensors to provide optimal illumination while avoiding glare for oncoming drivers.

Daytime running light (DRL) systems enhance vehicle visibility during daylight hours through dedicated lighting circuits that activate automatically when the engine is running. DRL systems must integrate with regular lighting controls and may utilize reduced-intensity headlights, dedicated LED units, or fog lights depending on the specific vehicle design and regulatory requirements.

Fog light and driving light applications provide supplemental illumination for specific driving conditions, with fog lights designed for low-mounted, wide-beam patterns that reduce glare in foggy conditions. Auxiliary lighting systems require proper electrical integration and switching to prevent interference with normal headlight operation and ensure compliance with lighting regulations.

Emergency lighting and hazard systems provide critical safety functions during vehicle breakdowns or emergency situations through high-visibility flashing patterns and bright illumination. These systems must operate reliably even under adverse electrical conditions and may include battery backup capabilities for continued operation with engine off.

LED technology advantages include longer service life, lower power consumption, and improved reliability compared to conventional bulb technologies, making LED retrofits attractive for both performance and efficiency improvements. However, LED retrofit considerations include proper electrical compatibility and heat management requirements.

Lighting Control Systems

Light switch operation encompasses multiple functions including headlight control, turn signal activation, and hazard warning system control through integrated multi-function switches. Modern lighting controls incorporate automatic features such as headlight delay, automatic on/off operation, and integration with vehicle security and convenience systems.

Automatic light sensors and control modules monitor ambient light conditions and activate lighting systems according to preset thresholds and driver preferences. These systems must balance responsiveness with stability to prevent frequent cycling while providing appropriate lighting activation during changing light conditions.

Dimmer controls and brightness adjustment systems enable drivers to optimize instrument and interior lighting for comfort and visibility while preventing excessive battery drain. Dimmer systems often incorporate automatic adjustment based on headlight operation and ambient light sensors to maintain optimal visibility without manual intervention.

Timer circuits and delayed shutoff systems provide convenience features such as headlight delay and interior light timers while preventing excessive battery drain from forgotten lighting systems. These timing functions integrate with body control modules and may include programmable delay periods and activation conditions.

Body control module lighting integration centralizes lighting control functions while enabling advanced features such as welcome lighting, security lighting, and coordinated lighting operation that enhances both functionality and vehicle aesthetics.

Common Electrical and Lighting Problems

Power Generation and Storage Issues

Battery failure modes include gradual capacity loss, internal short circuits, and electrolyte loss that manifest as starting problems, electrical system irregularities, and premature discharge. Understanding battery failure patterns helps distinguish between battery problems and other electrical system issues that may present similar symptoms but require different repair approaches.

Charging system problems encompass alternator failures, voltage regulator malfunctions, and drive belt issues that can cause undercharging conditions leading to battery discharge and electrical system problems. Undercharging conditions often develop gradually and may not become apparent until the battery can no longer compensate for insufficient charging system output.

Electrical load testing and capacity assessment help determine whether electrical problems stem from excessive current draw, insufficient generation capacity, or battery condition issues. Professional load testing equipment enables accurate assessment of electrical system capacity and helps identify developing problems before complete failure occurs.

Parasitic drain problems involve excessive current draw when the vehicle is off, causing battery discharge and starting problems that may be intermittent or occur only after extended parking periods. Parasitic drain diagnosis requires systematic isolation of electrical circuits to identify components or systems that continue drawing current when they should be inactive.

Starting system electrical failures include starter motor problems, solenoid failures, and control circuit issues that prevent engine cranking or cause intermittent starting problems. These failures often interact with battery and charging system condition, making systematic diagnosis essential for effective repair.

Battery connection problems, detailed in our guide on Symptoms of a Bad Battery Cable, can cause symptoms that mimic more serious electrical system failures.

Circuit and Wiring Problems

Open circuits occur when electrical continuity is interrupted by broken wires, failed connections, or component failures that prevent current flow to affected circuits. Open circuit diagnosis requires systematic continuity testing and circuit tracing to locate the interruption point and determine appropriate repair procedures.

Short circuits create unintended electrical paths that can cause excessive current draw, blown fuses, and potential fire hazards if not promptly identified and repaired. Short circuit diagnosis involves isolation testing and careful inspection to locate the fault without creating additional damage or safety hazards.

Ground circuit problems affect electrical system operation by creating voltage drops, erratic operation, and component failures that may appear as complex electrical problems. Poor ground connections are common causes of electrical system irregularities that can be difficult to diagnose without proper testing procedures and understanding of ground circuit operation.

Connector corrosion and connection failures develop over time due to environmental exposure and create resistance that affects electrical system operation. Connector problems often cause intermittent failures that worsen over time and may be affected by temperature, humidity, and vehicle vibration.

Wire harness damage from rodents, wear, or environmental exposure can cause multiple circuit problems that may be difficult to locate without systematic inspection and testing. Understanding wiring routing and protection helps locate damaged areas and prevent recurrence through proper repair procedures.

Lighting System Failures

Bulb failure patterns vary according to bulb type and application, with some failures occurring gradually through reduced brightness while others fail suddenly through filament breakage. Understanding bulb failure modes helps determine whether problems stem from the bulbs themselves or from electrical supply, control, or circuit protection issues.

Ballast failures in HID lighting systems cause lighting irregularities including flickering, color changes, or complete failure that may be intermittent initially but typically progress to complete failure. HID system diagnosis requires understanding of ballast operation and high-voltage safety procedures due to the electrical characteristics of these lighting systems.

LED driver circuit problems affect LED lighting operation through failures in the electronic circuits that regulate voltage and current to LED arrays. LED driver failures often cause complete circuit failure or irregular operation that differs from conventional bulb failure patterns, requiring specific diagnostic approaches.

Switch failures and control system issues affect lighting operation through problems in the switches, relays, or control modules that activate and control lighting circuits. Lighting control problems may affect multiple circuits simultaneously and require understanding of the control system architecture for effective diagnosis.

Wiring problems specific to lighting circuits include issues with dimmer circuits, automatic control systems, and integration with body control modules that may cause complex failure patterns affecting multiple lighting functions simultaneously.

Control System and Module Failures

Body control module malfunctions affect multiple vehicle systems simultaneously and may cause seemingly unrelated problems across lighting, comfort, and convenience systems. Body control module diagnosis requires specialized diagnostic equipment and understanding of module communication protocols and programming requirements.

Communication system failures and data network problems can cause widespread electrical system irregularities as control modules lose the ability to coordinate operation and share information. Network communication problems often cause multiple diagnostic trouble codes and system failures that may appear unrelated without understanding of the communication architecture.

Programming and calibration issues arise when control modules lose their configuration data or when replacement modules require initialization to match vehicle specifications. Module programming typically requires professional diagnostic equipment and access to manufacturer programming procedures and security codes.

Software updates and reflashing procedures may be necessary to correct module operation or incorporate manufacturer updates that address known problems or improve system operation. Software updates typically require professional equipment and procedures to ensure proper installation without damaging module programming.

Integration problems between multiple systems can cause complex failures that affect vehicle operation in ways that may not be obvious without understanding how different control modules coordinate operation and share information throughout the vehicle’s electrical network.

Electrical System Diagnosis and Testing

Basic Electrical Testing Equipment

Digital multimeter functions include voltage, current, and resistance measurement capabilities essential for electrical system diagnosis and testing. Modern digital multimeters provide accuracy and features specifically designed for automotive applications, including auto-ranging, min/max recording, and specialized functions for testing diodes and frequency.

Test light usage provides quick circuit verification and polarity testing but has limitations for diagnostic accuracy compared to digital multimeters. Test lights are useful for basic circuit verification but cannot provide the precise measurements necessary for comprehensive electrical system diagnosis or testing of sensitive electronic circuits.

Battery load tester operation enables assessment of battery condition under simulated starting loads to determine actual capacity and remaining service life. Professional battery load testing provides more accurate assessment than simple voltage measurements and helps distinguish between battery problems and charging system issues.

Oscilloscope applications for electrical diagnosis include waveform analysis for charging systems, ignition systems, and sensor circuits that require precise timing and signal quality assessment. Oscilloscope testing provides insights into electrical system operation that are not available through basic voltage and current measurements.

Scan tool integration for electrical system diagnosis enables access to diagnostic trouble codes, live data streams, and module communication verification that are essential for diagnosing modern vehicle electrical systems with integrated control modules and communication networks.

Professional diagnostic equipment provides capabilities beyond basic testing tools and enables comprehensive electrical system analysis that supports accurate diagnosis and effective repair strategies.

Systematic Diagnosis Procedures

Visual inspection techniques for electrical systems include examining wiring condition, connector integrity, and component mounting to identify obvious problems before beginning electrical testing. Thorough visual inspection often reveals problems that might be missed during electrical testing and helps focus diagnostic efforts on likely problem areas.

Circuit tracing and schematic interpretation require understanding of electrical symbols, circuit operation, and systematic approaches to following electrical paths through complex wiring systems. Effective circuit tracing combines schematic knowledge with practical testing to verify circuit operation and locate problems efficiently.

Voltage drop testing procedures measure electrical resistance in circuits by comparing voltage at different points while the circuit is operating under load. Voltage drop testing identifies resistance problems that may not be apparent through simple continuity testing and helps locate poor connections or damaged wiring.

Current draw measurement and analysis help identify circuits with excessive electrical consumption that could cause battery discharge or overload other electrical system components. Current measurement requires proper equipment and techniques to avoid damage to testing equipment and ensure accurate measurement of circuit consumption.

Resistance testing and continuity verification provide fundamental information about circuit condition and component operation, forming the foundation for more advanced electrical system diagnosis and repair procedures.

Advanced Diagnostic Techniques

Power balance testing for charging systems involves measuring alternator output under various load conditions to verify capacity and identify developing problems before complete failure occurs. Power balance testing requires professional equipment and procedures to safely load the charging system while monitoring electrical parameters.

Parasitic drain isolation procedures systematically identify circuits that continue drawing current when the vehicle is off, requiring methodical disconnection and testing to locate the source of excessive current draw. Parasitic drain isolation can be time-consuming but is essential for resolving battery discharge problems that occur during vehicle storage.

Network communication testing verifies proper data transmission between control modules and identifies communication problems that can cause widespread electrical system failures. Communication testing requires specialized diagnostic equipment and understanding of automotive communication protocols and network architecture.

Module programming and initialization procedures may be necessary after module replacement or when modules lose their programming due to electrical problems or battery disconnection. Module programming typically requires professional diagnostic equipment and access to manufacturer programming procedures and security information.

Intermittent problem diagnosis strategies include techniques for reproducing problems, monitoring electrical parameters over time, and using diagnostic equipment to capture data during fault conditions that may not be present during normal diagnostic procedures.

Safety Procedures for Electrical Work

Safety Warning: Automotive electrical work involves specific hazards including electrical shock, fire risk, and potential damage to sensitive electronic components. Always follow proper safety procedures, use appropriate personal protective equipment, and disconnect electrical power when working on electrical systems. Professional consultation is recommended for complex electrical diagnosis and repair.

Battery disconnection procedures require specific sequences and precautions to prevent electrical system damage and avoid losing module programming or security codes. Proper battery disconnection involves removing the negative cable first and securing it away from the battery terminal to prevent accidental reconnection during electrical work.

High voltage system safety applies to hybrid and electric vehicles that incorporate high-voltage electrical systems requiring specialized training, equipment, and procedures. High voltage electrical systems can be lethal and require qualified technicians with proper training and safety equipment to service safely.

Tool safety and proper grounding techniques prevent electrical shock and protect sensitive electronic components from damage during diagnosis and repair procedures. Proper grounding includes both personal grounding to prevent static discharge and equipment grounding to ensure safe electrical connections.

Fire prevention and emergency procedures are essential when working with electrical systems due to the fire risk from short circuits, overloaded circuits, and improper procedures. Understanding fire prevention and having appropriate emergency response capabilities helps ensure safe electrical work practices.

Professional training and certification in automotive electrical systems become increasingly important as vehicles incorporate more sophisticated electrical and electronic systems that require specialized knowledge and equipment for safe and effective service.

Repair and Maintenance Procedures

Battery Service and Replacement

Battery testing and condition assessment involve multiple procedures including load testing, specific gravity measurement, and visual inspection to determine remaining service life and replacement needs. Comprehensive battery testing provides more accurate assessment than simple voltage measurement and helps distinguish between battery problems and other electrical system issues.

Safe battery removal and installation procedures include proper lifting techniques, environmental protection, and electrical disconnection sequences that prevent system damage and ensure worker safety. Battery replacement requires attention to terminal corrosion, mounting security, and electrical system initialization that may be necessary after battery disconnection.

Terminal cleaning and corrosion prevention help ensure reliable electrical connections and extend battery service life through proper maintenance procedures. Terminal maintenance includes cleaning, protection, and proper torque application to ensure optimal electrical connection without over-tightening that could damage terminals.

Charging system verification after battery replacement ensures that the new battery will receive proper charging and that charging system problems are not present that could cause premature battery failure. Post-replacement testing includes charging rate verification and electrical system load testing to confirm proper operation.

Battery disposal and environmental considerations require proper handling of used batteries due to environmental hazards from lead and acid content. Professional battery recycling ensures environmental protection while recovering valuable materials from used batteries.

Charging System Repair

Alternator testing and replacement procedures involve electrical testing, mechanical inspection, and proper installation techniques that ensure reliable charging system operation. Alternator service may include rebuilding with new components or complete replacement depending on the extent of damage and cost considerations.

Belt tension adjustment and replacement require proper tension specifications and alignment procedures to ensure reliable alternator operation without excessive bearing wear or slippage. Drive belt service includes inspection for wear, proper tension adjustment, and replacement with appropriate belt types for the specific application.

Voltage regulator service and calibration may be necessary when charging voltage is incorrect despite proper alternator operation. Modern voltage regulators are typically integrated with alternators or engine control modules and may require replacement or programming rather than adjustment.

Wiring repair and connector service address problems in charging system wiring that can cause charging irregularities or complete charging system failure. Charging system wiring must handle high current loads and requires proper wire gauge and connection techniques for reliable operation.

System performance verification testing ensures that charging system repairs restore proper operation and that all electrical system parameters are within specification for reliable vehicle operation and battery service life.

Lighting System Repair

Bulb replacement procedures vary according to bulb type and location, with some requiring simple access while others may require partial disassembly of vehicle components. Proper bulb replacement includes verification of bulb type, proper installation orientation, and testing to ensure correct operation after installation.

Headlight adjustment and aiming procedures ensure proper illumination patterns that provide adequate visibility without creating glare for oncoming drivers. Headlight aiming requires specific equipment and procedures to meet safety and legal requirements for headlight performance and compliance.

Switch replacement and control system repair address problems in lighting control circuits that can affect single circuits or multiple lighting functions. Lighting switch service may require programming or initialization for switches that integrate with body control modules or automatic lighting systems.

Wiring repair specific to lighting circuits includes techniques for splicing, protection, and routing that ensure reliable operation in automotive environments. Lighting circuit wiring must provide adequate current capacity and protection from environmental damage while maintaining proper circuit operation.

LED retrofit considerations and compatibility include electrical compatibility, heat management, and integration with existing lighting controls that may require modification for proper LED operation and optimal performance.

Circuit Repair and Protection

Wire splicing and connection repair techniques ensure reliable electrical connections that can withstand automotive environmental conditions and mechanical stress. Proper splicing techniques include appropriate connector types, environmental protection, and strain relief to prevent connection failure and ensure long-term reliability.

Fuse and relay replacement procedures include proper identification, installation, and testing to ensure correct circuit protection and operation. Circuit protection replacement requires understanding of fuse ratings, relay types, and circuit requirements to prevent problems from incorrect component selection.

Connector repair and pin replacement address connection problems that can cause circuit failures and intermittent operation. Connector repair techniques include proper pin removal, installation, and environmental sealing to ensure reliable electrical connections throughout the connector’s service life.

Heat shrink and environmental protection help ensure reliable electrical connections by protecting splices and connections from moisture, corrosion, and mechanical damage. Environmental protection techniques include proper material selection and installation procedures that provide long-term protection in automotive applications.

Quality assurance and testing after repairs verify that electrical repairs restore proper circuit operation and that no additional problems were created during the repair process. Comprehensive testing helps ensure repair quality and customer satisfaction with electrical system performance.

Preventive Maintenance and System Care

Regular Electrical System Maintenance

Battery maintenance schedules and procedures help extend battery service life and prevent unexpected failures through regular inspection, testing, and care. Regular battery maintenance includes terminal cleaning, electrolyte level checking (where applicable), and load testing to assess condition and remaining service life.

Charging system inspection intervals include belt inspection, connection verification, and output testing to ensure proper charging system operation before problems develop. Charging system maintenance helps identify developing problems early and prevent complete failures that could leave drivers stranded.

Lighting system maintenance and bulb inspection help ensure proper visibility and legal compliance while identifying problems before they affect safety. Regular lighting inspection includes bulb operation verification, lens cleaning, and aim checking to maintain optimal lighting performance.

Connector inspection and cleaning procedures help prevent corrosion and connection problems that can cause electrical system irregularities. Connector maintenance includes visual inspection, cleaning, and protection application to ensure reliable electrical connections throughout the vehicle’s service life.

Environmental protection and corrosion prevention help extend electrical system service life by protecting components from moisture, road salt, and other environmental hazards that can cause premature failure and operational problems.

Seasonal Electrical System Care

Winter electrical system preparation includes battery testing, charging system verification, and protection measures that help ensure reliable operation during cold weather conditions. Cold weather affects battery capacity, charging system operation, and electrical component performance, making seasonal preparation important for reliable winter operation.

Summer heat protection for electrical components includes battery cooling, alternator ventilation, and protection from excessive temperatures that can accelerate component aging and reduce service life. High temperatures affect electrical component performance and longevity, making heat protection important for reliable summer operation and extended component life.

Moisture protection and drainage verification help prevent water intrusion that can cause corrosion, short circuits, and electrical component failures. Proper drainage maintenance includes inspection of door seals, drainage holes, and environmental sealing to prevent moisture accumulation in electrical component areas.

Temperature effects on electrical system performance include reduced battery capacity in cold conditions and increased resistance in hot conditions that can affect system operation. Understanding temperature effects helps anticipate seasonal performance changes and plan appropriate maintenance and preparation procedures.

Storage procedures for seasonal vehicles include battery maintenance, electrical system protection, and preparation measures that help ensure reliable operation after extended storage periods. Proper storage preparation prevents battery discharge and electrical system deterioration during periods of non-use.

Performance Optimization

Electrical load management and efficiency help ensure that electrical system capacity meets vehicle demands while optimizing performance and fuel economy. Load management includes assessment of electrical accessories and their impact on charging system capacity and battery service life.

Upgrade considerations for electrical systems include alternator capacity increases, battery upgrades, and wiring improvements that can support additional electrical accessories or enhanced performance. Electrical system upgrades require careful planning to ensure compatibility and avoid overloading existing components.

Aftermarket electrical accessory installation requires proper integration with existing electrical systems to prevent overloading and ensure reliable operation. Accessory installation considerations include power requirements, control integration, and electrical system capacity to support additional loads.

System capacity planning for additional loads helps ensure that electrical modifications do not exceed system capabilities or compromise reliability. Capacity planning includes assessment of charging system output, battery capacity, and wiring adequacy for proposed electrical modifications.

Professional inspection and maintenance services provide expertise and equipment for comprehensive electrical system assessment and maintenance that may exceed DIY capabilities. Professional services can identify developing problems and provide maintenance that extends electrical system service life.

Professional vs DIY Electrical Work

DIY-Appropriate Electrical Tasks

Basic battery and fuse replacement represent straightforward electrical maintenance tasks that most vehicle owners can perform safely with proper procedures and basic tools. Battery replacement requires attention to safety procedures and proper installation techniques but does not require specialized diagnostic equipment or extensive electrical knowledge.

Simple lighting system repairs including bulb replacement, basic switch testing, and fuse replacement can often be performed by DIY enthusiasts with proper guidance and safety precautions. Basic lighting repairs typically involve straightforward procedures and readily available replacement components.

Basic electrical testing and diagnosis using digital multimeters and test lights enable DIY enthusiasts to verify circuit operation and identify simple electrical problems. Basic testing capabilities include voltage, continuity, and resistance measurement that can identify many common electrical problems.

Connector cleaning and maintenance procedures help prevent electrical problems and can be performed by vehicle owners with basic tools and proper cleaning materials. Connector maintenance involves visual inspection, cleaning, and protection application that requires minimal technical knowledge.

Preventive maintenance procedures including battery terminal cleaning, visual inspection, and basic testing help maintain electrical system reliability and can be performed by most vehicle owners with proper guidance and safety awareness.

Professional Service Requirements

Complex electrical system diagnosis involving computerized systems, communication networks, and integrated control modules typically requires professional expertise and specialized diagnostic equipment. Modern vehicle electrical systems incorporate sophisticated technology that exceeds typical DIY diagnostic capabilities and requires professional training and equipment.

Computer programming and calibration procedures for control modules require specialized equipment, manufacturer-specific software, and security codes that are typically available only to professional service facilities. Module programming is essential for proper operation after replacement and may be required after certain electrical repairs.

High voltage system service for hybrid and electric vehicles requires specialized training, safety equipment, and procedures that are beyond typical DIY capabilities. High voltage electrical systems can be lethal and require qualified technicians with appropriate training and certification for safe service.

Warranty-critical electrical repairs may require professional service to maintain warranty coverage and ensure proper repair procedures that meet manufacturer specifications. Warranty considerations often favor professional service for complex electrical repairs and component replacement.

Advanced diagnostic equipment requirements for modern vehicle electrical systems typically exceed DIY tool investments and require professional facilities with appropriate equipment and training for effective electrical system diagnosis and repair.

When to Seek Professional Help

Safety concerns and electrical hazards make professional consultation advisable for electrical work involving high-voltage systems, complex wiring, or unfamiliar procedures. Electrical safety requires proper knowledge, equipment, and procedures that may exceed typical DIY capabilities and safety equipment.

Complex integrated system problems involving multiple control modules, communication networks, or coordinated system operation typically require professional diagnosis and repair capabilities. System integration complexity often exceeds DIY diagnostic capabilities and requires professional expertise for effective problem resolution.

Diagnostic equipment limitations may prevent accurate diagnosis of electrical problems that require specialized testing equipment or procedures. Professional diagnostic equipment provides capabilities that enable accurate diagnosis and effective repair strategies for complex electrical problems.

Time and cost considerations may favor professional service for complex electrical repairs that could require extensive diagnostic time or specialized tools that exceed DIY investment justification. Professional efficiency often provides cost-effective repair solutions for complex electrical problems.

Quality assurance and warranty coverage provided by professional electrical service help ensure repair quality and provide protection for electrical repair investments that may involve expensive components or complex procedures.

For specific electrical component problems, our detailed guide on Signs of a Bad Door Window Motor provides practical examples of electrical system troubleshooting.

Future Trends in Automotive Electrical Systems

Emerging Technologies

Electric vehicle charging systems represent the most significant change in automotive electrical architecture, requiring high-voltage DC charging capabilities and sophisticated battery management systems. EV charging systems incorporate safety features, communication protocols, and thermal management that require new approaches to electrical system design and service.

Advanced driver assistance system electrical requirements include high-reliability power supplies, redundant circuits, and real-time communication capabilities for safety-critical functions. ADAS electrical systems require understanding of safety-critical design principles and specialized diagnostic equipment for proper service and maintenance.

Wireless power transfer and connectivity technologies are emerging for both vehicle charging and data communication applications that reduce wiring complexity while enabling new vehicle capabilities. Wireless technologies require understanding of electromagnetic principles and safety considerations for proper implementation and service.

Smart grid integration and vehicle-to-grid systems enable vehicles to interact with electrical power grids for energy storage and distribution applications. Vehicle-to-grid technologies require sophisticated electrical control systems and communication capabilities that integrate vehicle electrical systems with utility infrastructure.

Autonomous vehicle electrical architecture incorporates redundant systems, high-reliability components, and advanced communication capabilities that support safety-critical autonomous operation. These systems require new approaches to electrical system design, diagnosis, and maintenance.

Maintenance and Repair Evolution

Diagnostic equipment advancement continues to provide more sophisticated capabilities for electrical system diagnosis and repair, enabling faster and more accurate problem identification. Advanced diagnostic equipment incorporates artificial intelligence, pattern recognition, and remote diagnostic capabilities that enhance service efficiency and accuracy.

Mobile electrical service capabilities enable on-site electrical system diagnosis and repair through portable diagnostic equipment and service capabilities. Mobile service technologies provide convenience and efficiency for electrical system maintenance and repair that may not require shop facilities.

Remote diagnosis and programming capabilities enable off-site technical support and module programming that can reduce service time and improve diagnostic accuracy. Remote diagnostic capabilities provide access to manufacturer expertise and specialized knowledge for complex electrical problems.

Predictive maintenance systems use vehicle data and artificial intelligence to identify developing electrical problems before they cause failures. Predictive maintenance helps prevent unexpected electrical system failures and enables proactive maintenance planning that reduces repair costs and vehicle downtime.

Technician training and certification requirements continue to evolve as electrical systems become more sophisticated and require specialized knowledge for safe and effective service. Ongoing education and certification help ensure that service technicians can properly diagnose and repair modern vehicle electrical systems.

Conclusion

Automotive electrical and lighting systems serve as the foundation for virtually all modern vehicle functions, from basic engine operation to advanced safety and convenience features. Understanding these systems requires knowledge of fundamental electrical principles, systematic diagnostic approaches, and proper safety procedures that enable effective troubleshooting and repair of increasingly complex electrical networks.

The integration of electrical power generation, distribution, and lighting components creates sophisticated systems that require systematic diagnosis rather than random component replacement. Modern vehicle electrical architecture incorporates computerized control modules, communication networks, and integrated systems that demand specialized knowledge and diagnostic equipment for effective service and repair.

Safety considerations remain paramount throughout all electrical system work, as electrical hazards, fire risks, and component damage can result from improper procedures or inadequate safety precautions. Professional consultation is strongly recommended for complex electrical diagnosis and repair that exceeds DIY capabilities or involves safety-critical systems.

Preventive maintenance and systematic diagnostic approaches significantly improve electrical system reliability and help prevent unexpected failures that could compromise vehicle safety and leave drivers stranded. Regular inspection, appropriate testing, and prompt attention to developing problems represent wise investments in both safety and economy.

The complexity of modern automotive electrical systems continues to increase with advancing technology and vehicle sophistication, making ongoing education and professional development essential for effective electrical system service. Understanding when to attempt DIY repairs and when to seek professional assistance helps ensure appropriate repair strategies that provide safe and reliable electrical system operation.

When electrical problems occur, systematic diagnosis and proper repair procedures ensure that electrical systems continue to provide the reliable operation essential for vehicle safety, performance, and convenience. Quality electrical system maintenance and repair help preserve vehicle value while ensuring continued safe and reliable operation throughout the vehicle’s service life.

Remember that electrical systems affect virtually every aspect of vehicle operation, making electrical system health a critical component of overall vehicle safety and reliability. Professional consultation and quality repair procedures ensure optimal electrical system performance and maintain the sophisticated capabilities that modern vehicles provide for safety, convenience, and performance.