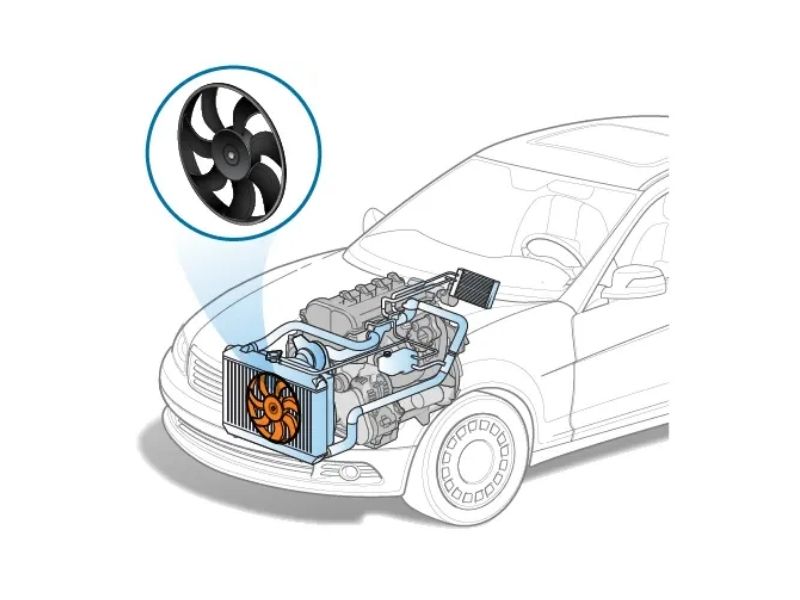

Your vehicle’s cooling system relies on multiple components working in harmony to maintain optimal engine temperature, but there’s one electric component that most drivers never see until it fails: the cooling fan motor. This unsung hero powers the radiator and condenser fans that keep your engine cool when natural airflow isn’t sufficient, particularly during idle, stop-and-go traffic, and air conditioning operation.

When a cooling fan motor fails, the consequences can escalate quickly from inconvenient to catastrophic. Engine overheating at idle, declining air conditioning performance, blown fuses, and complete cooling system failure are just the beginning. Unlike mechanical fan clutches that provide some cooling even when failing, electric fan motors often fail completely, leaving your engine vulnerable to severe overheating damage that can cost thousands of dollars in repairs.

Modern vehicles depend entirely on electric cooling fan motors for thermal management, making their proper operation critical for engine longevity and driving safety. These sophisticated electrical components integrate with your vehicle’s engine management system, responding to temperature sensors, air conditioning demands, and driving conditions to provide precisely the cooling needed while minimizing electrical consumption and noise.

This comprehensive guide provides everything you need to understand, diagnose, and repair cooling fan motor problems safely and effectively. Whether you’re a DIY enthusiast looking to tackle electrical repairs, a professional mechanic seeking advanced diagnostic techniques, or a vehicle owner trying to understand symptoms and costs, you’ll find expert-level guidance with a safety-first approach to automotive electrical work.

Understanding your cooling fan motor isn’t just about fixing problems—it’s about preventing expensive engine damage and ensuring reliable vehicle operation in all conditions. The electrical knowledge you gain here will help you make informed decisions about repairs and maintenance while prioritizing safety in all electrical work. For context on how electric fans compare to mechanical systems, also review our guide on cooling fan clutch operation to understand the complete spectrum of automotive cooling technologies.

What is a Cooling Fan Motor and How Does It Work?

A cooling fan motor is an electric motor that drives the radiator cooling fan and, in many vehicles, the air conditioning condenser fan. Unlike the mechanical fan clutches found in older vehicles, electric cooling fan motors provide precise, computer-controlled cooling based on real-time engine temperature, air conditioning demands, and operating conditions. These motors typically operate on 12-volt DC power, though some high-performance and hybrid applications use higher voltages.

The cooling fan motor receives control signals from the engine control module (ECM) or powertrain control module (PCM), which monitors various sensors throughout the vehicle. When coolant temperature rises above predetermined thresholds, when the air conditioning system operates, or when specific driving conditions are detected, the PCM commands the cooling fan relay to energize the motor. This system provides cooling only when needed, improving fuel economy and reducing noise compared to mechanically-driven fans.

Modern cooling fan motors integrate sophisticated control systems that can vary fan speed based on cooling demands. Rather than simple on-off operation, many systems use pulse-width modulation (PWM) to control motor speed, providing just enough cooling to maintain optimal temperatures while minimizing electrical consumption and noise. This precision control helps engines reach operating temperature quickly in cold weather while preventing overheating under high loads.

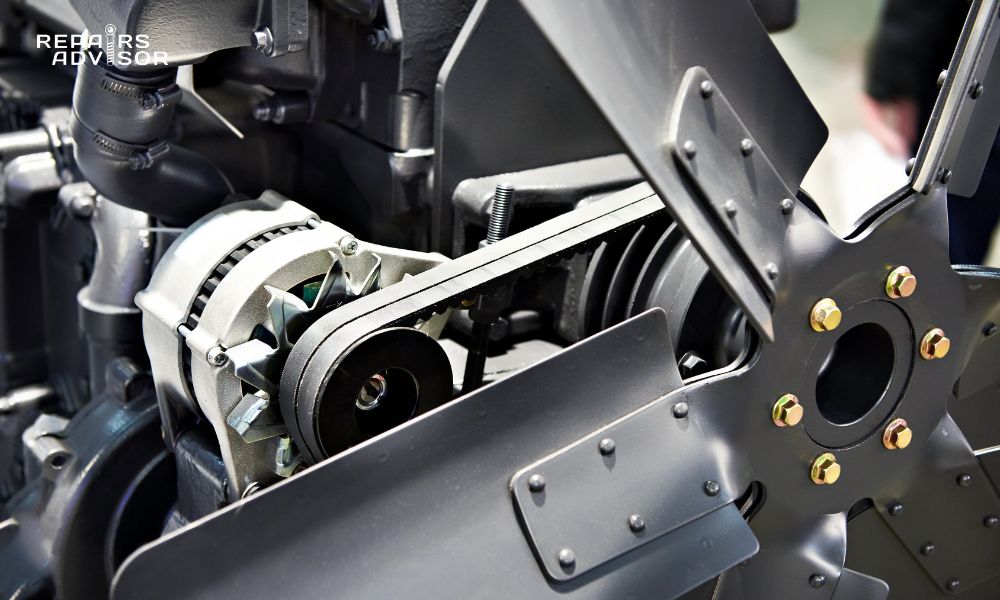

The motor itself consists of standard DC motor components: permanent magnets or electromagnets creating the magnetic field, a rotating armature with windings, carbon brushes for electrical contact, and bearings supporting the rotating assembly. The motor housing mounts directly to the fan shroud, with the fan blades attached to the motor shaft. Most automotive cooling fan motors are designed for continuous operation under high temperature conditions, with thermal protection to prevent damage from overheating.

Understanding the electrical nature of these systems is crucial for safe diagnosis and repair. Unlike mechanical systems that can be tested by hand, electric motors require proper electrical testing procedures and safety protocols. The integration with vehicle electrical systems means problems can affect multiple components, making accurate diagnosis essential for effective repairs. For comprehensive electrical system understanding, review our guide on automotive electrical systems to build the foundation knowledge needed for electrical troubleshooting.

Types of Cooling Fan Motors

Single-Speed Motors

Single-speed cooling fan motors represent the most basic electric fan design, operating in simple on-off mode controlled by a relay. When the PCM determines cooling is needed, it energizes the cooling fan relay, which supplies full battery voltage to the motor. The motor runs at full speed until the PCM opens the relay circuit, stopping the fan completely.

These motors are less expensive to manufacture and simpler to diagnose, making them common in economy vehicles and older applications. The control circuit consists of the temperature sensor, PCM, relay, fuse, and motor, with straightforward troubleshooting procedures. However, the lack of speed control means the motor consumes full electrical power whenever operating, reducing fuel economy and creating more noise than variable-speed alternatives.

Single-speed motors typically draw 15-25 amperes when operating, requiring robust electrical circuits and appropriately rated fuses and relays. The high current draw can stress aging electrical systems, particularly in vehicles with weak alternators or marginal battery condition. This makes electrical system health crucial for reliable single-speed motor operation.

Variable Speed Motors

Variable speed cooling fan motors use electronic control to modulate motor speed based on precise cooling requirements. The PCM sends a pulse-width modulated (PWM) signal to a motor control module, which varies the effective voltage supplied to the motor. By changing the duty cycle of the PWM signal, the system can operate the motor anywhere from minimum speed to maximum output.

This precise control provides several advantages: improved fuel economy through reduced electrical load, quieter operation at lower speeds, faster engine warm-up in cold weather, and more precise temperature control. The motor can operate at just enough speed to maintain desired temperatures rather than cycling on and off at full speed.

Variable speed systems are more complex, requiring additional control modules and more sophisticated diagnostic procedures. The PWM control signals can be analyzed with oscilloscopes or advanced scan tools, but basic multimeter testing may not reveal intermittent problems. Understanding PWM operation is essential for diagnosing these systems effectively.

Dual Fan Systems

Many vehicles employ dual cooling fan systems with separate motors for the radiator and air conditioning condenser. This configuration allows independent control of each fan based on specific cooling requirements. The radiator fan operates based on coolant temperature, while the condenser fan activates with air conditioning operation or when both cooling and A/C demands are high.

Dual fan systems provide redundancy—if one motor fails, the other can provide some cooling capacity. However, they also double the electrical complexity and potential failure points. Each motor has its own relay, fuse, and control circuit, requiring systematic diagnosis to identify which component has failed.

Some dual fan systems use different motor specifications for each application. The radiator fan might be larger and more powerful for engine cooling, while the condenser fan could be smaller and optimized for refrigerant cooling. Understanding these differences is important when ordering replacement parts and diagnosing performance problems.

Hybrid and Electric Vehicle Applications

Hybrid and electric vehicles use specialized cooling fan motors designed for unique thermal management requirements. These systems often operate at higher voltages (typically 200-400 volts) and may include multiple motors for different cooling circuits: traction battery cooling, electric motor cooling, power electronics cooling, and traditional engine cooling in hybrid applications.

Critical Safety Warning: High-voltage cooling systems in hybrid and electric vehicles require specialized training, tools, and safety equipment. Never attempt to service these systems without proper high-voltage safety certification and equipment. Contact with high-voltage components can cause severe injury or death.

These motors often integrate advanced control systems with CAN bus communication, allowing the vehicle’s thermal management system to coordinate cooling across multiple circuits. Battery thermal management is particularly critical, as lithium-ion batteries have narrow temperature operating ranges and can be damaged by overheating or overcooling.

The diagnostic procedures for high-voltage cooling systems require specialized scan tools and safety procedures beyond conventional automotive electrical work. Professional service is strongly recommended for these applications, as improper diagnosis or repair can create serious safety hazards and expensive component damage.

Signs Your Cooling Fan Motor is Failing

Recognizing cooling fan motor failure symptoms early prevents costly engine damage and avoids dangerous overheating situations. Electric motor failures can be sudden and complete, unlike mechanical fan clutches that may provide partial cooling even when worn. Understanding these warning signs helps you address problems before they lead to engine damage or leave you stranded.

Fan Won’t Start or Operate

The most obvious symptom of cooling fan motor failure is a fan that doesn’t operate when it should. With the engine at operating temperature and air conditioning on, both conditions that should activate the cooling fan, a failed motor will show no movement despite receiving electrical power. You might hear a buzzing or humming sound from the motor as electricity flows through the windings, but the fan blades won’t rotate.

This complete failure often results from mechanical problems within the motor: seized bearings, damaged armature windings, or broken internal connections. Unlike intermittent problems that might indicate control circuit issues, a motor that receives power but won’t turn typically requires replacement rather than electrical repair.

Diagnostic Tip: To verify the motor is receiving power, check for battery voltage at the motor connector with the engine hot and A/C on. If voltage is present but the motor doesn’t run, the motor has failed internally. If no voltage is present, the problem lies in the control circuit, relay, or fuse.

Testing for mechanical binding can be done safely with the motor disconnected by attempting to rotate the fan by hand. The fan should turn with minimal resistance. If it won’t turn or requires excessive force, internal motor damage has occurred and replacement is necessary.

Engine Overheating at Idle

Engine overheating during idle or stop-and-go driving while maintaining normal temperatures at highway speeds strongly indicates cooling fan motor problems. At highway speeds, natural airflow through the radiator provides adequate cooling even with a failed fan motor. However, when vehicle speed drops below 35-40 mph, the cooling system depends entirely on the electric fan to pull air through the radiator.

This symptom pattern helps distinguish fan motor problems from other cooling system issues. A clogged radiator, failed thermostat, or low coolant typically cause overheating under various conditions, not just at idle. The speed-dependent nature of fan motor problems makes diagnosis more straightforward once you understand the relationship between vehicle speed and cooling system operation.

Safety Warning: Never ignore engine overheating symptoms. Continued operation with an overheating engine can cause severe damage including cracked cylinder heads, blown head gaskets, and complete engine failure. If your engine overheats, pull over safely, shut off the engine, and allow it to cool completely before diagnosis.

Monitor your temperature gauge closely during stop-and-go driving, particularly in hot weather or while using air conditioning. The temperature should remain stable regardless of vehicle speed. Rising temperatures during idle or slow-speed operation indicate cooling fan problems that require immediate attention.

Intermittent Fan Operation

Intermittent cooling fan operation creates unpredictable overheating problems that can be difficult to diagnose. The fan may work normally during some conditions but fail when most needed, such as during extreme heat or heavy air conditioning use. This symptom often indicates electrical problems rather than complete motor failure.

Common causes of intermittent operation include loose or corroded electrical connections, overheating motor control modules, thermal protection activation within the motor, or marginal relay performance. These problems worsen with heat and electrical load, explaining why failures often occur during hot weather when cooling demands are highest.

Thermal protection within the motor can cause intermittent operation if the motor overheats due to bearing wear, electrical overload, or poor ventilation. As the motor temperature rises, internal thermal switches open the circuit to prevent damage, shutting off the motor until it cools. This creates a cycle of operation and shutdown that provides inadequate cooling.

Diagnosing intermittent problems requires monitoring the electrical system during actual failure conditions. This might involve extended test drives in hot weather or using scan tools to monitor cooling fan commands and responses during various operating conditions.

Electrical System Indicators

Cooling fan motor problems often manifest as electrical system symptoms before complete motor failure occurs. Blown fuses are common early warning signs, particularly if they occur repeatedly after replacement. Motors drawing excessive current due to bearing wear or electrical problems can overload the fuse, protecting the wiring harness from damage.

Check engine lights may illuminate when the PCM detects cooling fan circuit problems. Common diagnostic trouble codes include P0480 (Cooling Fan 1 Control Circuit Malfunction), P0481 (Cooling Fan 2 Control Circuit Malfunction), and related codes indicating specific circuit faults. These codes help pinpoint whether the problem involves the motor, control circuit, or PCM output.

Air conditioning performance can decline when cooling fan motors fail or operate intermittently. The A/C system depends on adequate condenser cooling to maintain proper refrigerant pressures and temperatures. A failed condenser fan motor causes high-pressure problems, reduced cooling capacity, and potential compressor damage if operation continues.

Battery drain can occur if cooling fan motors develop internal short circuits that allow current flow even when the motor isn’t commanded to operate. This parasitic draw can discharge the battery overnight or during extended parking, creating starting problems that seem unrelated to the cooling system. For comprehensive battery and charging system information, review our guide on why car batteries die.

Unusual Noises and Vibrations

Abnormal noises from the cooling fan area often indicate impending motor failure and provide early warning before complete breakdown occurs. Grinding or squealing sounds typically indicate bearing wear within the motor, which will eventually cause complete failure if not addressed. These noises often worsen with motor speed and may be more noticeable during initial startup or shutdown.

Rattling or clicking sounds can indicate loose fan blades, damaged motor mounts, or debris caught in the fan assembly. While not always indicating motor failure, these conditions can cause vibration that accelerates bearing wear and leads to premature motor failure. Physical inspection can often identify these problems before they cause motor damage.

Unusual vibration transmitted through the vehicle structure suggests unbalanced fan blades or motor mounting problems. Damaged fan blades create vibration that increases with motor speed, potentially causing additional damage to the motor, shroud, or radiator. Cracked or bent fan blades should be replaced immediately to prevent further damage.

Motor noise that changes frequency or intensity based on temperature or electrical load can indicate internal electrical problems such as worn brushes, damaged commutator segments, or failing windings. These electrical problems typically worsen progressively and eventually cause complete motor failure.

Diagnostic Trouble Codes

Modern vehicles store diagnostic trouble codes when cooling fan circuit problems are detected, providing valuable diagnostic information. Understanding these codes helps focus troubleshooting efforts and prevents unnecessary parts replacement.

P0480 – Cooling Fan 1 Control Circuit Malfunction indicates the PCM has detected a problem with the primary cooling fan circuit. This could involve the motor, relay, wiring, or PCM output circuit. Further testing is required to isolate the specific component causing the code.

P0481 – Cooling Fan 2 Control Circuit Malfunction relates to secondary cooling fan problems in dual-fan systems. The diagnostic approach is similar to P0480, but focuses on the secondary fan circuit components.

P0693 and P0694 indicate high or low voltage conditions in the cooling fan control circuit, suggesting electrical problems such as short circuits, open circuits, or control module failures. These codes often point toward wiring or control module problems rather than motor failure.

Related codes such as P0128 (Coolant Temperature Below Thermostat Regulating Temperature) may be stored when cooling fan problems affect engine temperature regulation. For detailed information about this code and its relationship to cooling system problems, see our guide on Code P0128 diagnosis and repair.

The presence of multiple cooling system codes often indicates systemic problems that require comprehensive diagnosis rather than individual component replacement. Professional diagnostic equipment and expertise may be necessary to properly interpret code relationships and develop effective repair strategies.

How to Diagnose a Failing Cooling Fan Motor

Proper diagnosis of cooling fan motor problems requires systematic electrical testing combined with safety protocols appropriate for automotive electrical systems. Unlike mechanical components that can be evaluated visually, electric motors require electrical measurements and functional testing to determine their condition accurately. Understanding these procedures helps you identify problems correctly and avoid unnecessary parts replacement.

Critical Safety Warning: Automotive electrical diagnosis involves working with live electrical circuits, rotating machinery, and potentially hazardous voltage levels. Always disconnect the battery negative terminal before disconnecting motor connectors or handling electrical components. Never work on electrical systems with wet hands or in wet conditions. High-voltage hybrid and electric vehicle systems require specialized training and equipment—seek professional service for these applications.

Electrical Safety Precautions

Before beginning any cooling fan motor diagnosis, establish proper electrical safety protocols to protect yourself and the vehicle’s electrical system. Disconnect the battery negative terminal and wait at least 5 minutes before working on electrical connections, allowing capacitors in the control modules to discharge. This prevents accidental short circuits and protects sensitive electronic components.

Ensure your multimeter and test equipment are in good condition with intact test leads and proper calibration. Damaged test equipment can provide false readings or create safety hazards during testing. Use only meters rated for automotive use with appropriate input impedance to prevent damage to electronic circuits.

Work in a well-ventilated area with adequate lighting and have a fire extinguisher readily available when working with automotive electrical systems. Though rare, electrical faults can create sparks or heat that could ignite fuel vapors or other combustible materials in the engine compartment.

For hybrid and electric vehicles, verify the high-voltage system is properly shut down according to manufacturer procedures before working on any electrical components. High-voltage cooling systems require specialized safety equipment including insulated tools, voltage detectors, and personal protective equipment rated for high-voltage work.

Initial System Evaluation

Begin diagnosis with a comprehensive visual inspection of the cooling fan motor and associated electrical components. Look for obvious signs of damage such as burnt or corroded connectors, damaged wiring harnesses, cracked motor housings, or debris caught in fan blades. Physical damage often provides clear indication of the problem without extensive electrical testing.

Check the cooling fan fuse and relay in the underhood fuse box, referring to the fuse box diagram for proper identification. A blown fuse indicates overcurrent conditions that could result from motor problems, short circuits, or control system faults. Replace blown fuses only after identifying and correcting the underlying cause to prevent repeated failures.

Inspect electrical connections at the motor for corrosion, looseness, or damage. Corroded connections create resistance that can cause voltage drop, reducing motor performance and creating heat that accelerates corrosion. Clean connections with electrical contact cleaner and apply dielectric grease to prevent future corrosion.

Verify proper cooling system operation by monitoring coolant temperature and observing when the cooling fan should activate. Most systems activate the fan when coolant temperature reaches 200-220°F or when air conditioning is turned on. Understanding normal operation helps identify when motor problems prevent proper cooling system function.

Basic Operational Testing

With the engine at operating temperature, turn on the air conditioning to maximum cold setting, which should immediately activate the cooling fan in most vehicles. If the fan doesn’t operate, the problem could be the motor, control circuit, or related electrical components. If the fan operates normally with A/C but not based on temperature, suspect temperature sensor or PCM control problems rather than motor failure.

Listen carefully to motor operation, noting any unusual noises such as grinding, squealing, or rattling that might indicate bearing problems or mechanical damage. Normal electric motor operation should be relatively quiet with consistent speed and smooth operation. Intermittent noises or speed variations suggest internal motor problems.

Observe fan blade rotation to ensure smooth, balanced operation without wobbling or vibration. Unbalanced operation can indicate damaged fan blades, worn motor bearings, or mounting problems that will accelerate motor wear if not corrected. Physical inspection of fan blades should reveal cracks, chips, or missing sections that could cause balance problems.

Monitor electrical system behavior during fan operation, watching for dimming lights or voltage fluctuations that might indicate excessive current draw from motor problems. A motor drawing excessive current due to bearing wear or electrical faults can stress the charging system and affect other electrical components.

Multimeter Testing Techniques

Voltage Supply Verification

Proper voltage testing requires accessing the motor electrical connector, which should be done with the battery disconnected for safety. Reconnect the battery and use your multimeter to measure voltage at the motor connector with the cooling fan commanded on. You should see battery voltage (typically 12.6-14.4 volts with the engine running) at the power feed terminal.

If voltage is present but the motor doesn’t operate, the motor has failed internally and requires replacement. If no voltage is present, the problem lies in the control circuit, requiring further testing of the relay, fuse, wiring, and PCM output circuits.

Test voltage while attempting to activate the fan through different methods: engine temperature-based activation and air conditioning system activation. Some vehicles have separate control circuits for these functions, and testing both helps isolate control system problems.

Ground Circuit Testing

Ground circuit integrity is crucial for proper motor operation but often overlooked during diagnosis. Use your multimeter to measure voltage between the motor ground terminal and battery negative with the motor commanded on. Readings above 0.5 volts indicate ground circuit problems that can cause reduced motor performance or complete failure.

Poor ground connections create resistance that reduces effective voltage to the motor while generating heat at the poor connection point. This heat accelerates corrosion and makes the problem progressively worse. Clean and tighten ground connections, applying dielectric grease to prevent future corrosion.

Motor Resistance Testing

With the motor disconnected from the vehicle wiring, measure resistance between the motor terminals using your multimeter’s ohms function. A typical cooling fan motor should show 1-4 ohms resistance, though specifications vary by application. Infinite resistance indicates open windings, while very low resistance suggests short-circuited windings—both conditions require motor replacement.

Compare your measurements with manufacturer specifications when available, as resistance values vary significantly between motor designs. Some variable-speed motors or high-performance applications may have different resistance specifications than standard single-speed motors.

Current Draw Testing

Current draw testing requires an ammeter or multimeter with clamp-on current measurement capability. With the motor operating normally, measure current flow through the power feed wire. Typical cooling fan motors draw 15-25 amperes, though specifications vary by motor size and vehicle application.

Excessive current draw indicates motor problems such as bearing wear, internal short circuits, or mechanical binding. Current draw significantly above specifications will cause premature relay and fuse failure and may indicate impending motor failure even if the motor currently operates.

Current draw testing should be performed under various conditions: initial startup (which may show higher current for the first few seconds), steady-state operation, and during temperature cycling. Intermittent high current draw can indicate thermal problems within the motor that worsen as operating temperature increases.

For comprehensive electrical system testing procedures, including proper use of multimeters and electrical safety, review our guide on automotive fuse box diagnosis which covers essential electrical troubleshooting techniques applicable to cooling fan motor diagnosis.

Advanced Diagnostic Methods

Scan Tool Diagnostics

Modern vehicles provide extensive diagnostic capabilities through the OBD-II system and manufacturer-specific scan tools. Use a quality scan tool to monitor cooling fan operation in real-time, observing PCM commands to the cooling fan relay and motor response. This helps distinguish between motor problems and control system faults.

Monitor relevant data streams including coolant temperature, air conditioning system status, cooling fan commands, and electrical system parameters. Comparing actual motor operation with PCM commands reveals whether problems involve the motor or control circuits. A motor that doesn’t respond to proper PCM commands has likely failed, while a motor that operates without commands suggests control circuit problems.

Use the scan tool’s actuator testing functions to manually command cooling fan operation, bypassing normal temperature and A/C-based activation. This testing helps isolate motor problems from sensor or control logic issues and provides a controlled method for evaluating motor performance.

Advanced scan tools can display cooling fan duty cycle for variable-speed systems, allowing evaluation of PWM control signal integrity and motor response. Comparing commanded duty cycle with actual motor speed helps identify control module problems or motor performance degradation.

Oscilloscope Testing

Oscilloscope testing provides detailed analysis of electrical signals that multimeters cannot reveal, particularly valuable for diagnosing variable-speed motor control systems. Connect the oscilloscope to monitor PWM control signals, observing signal frequency, duty cycle, and signal integrity during various operating conditions.

Normal PWM signals should show clean square waves with consistent frequency (typically 100-1000 Hz) and variable duty cycle based on cooling demands. Distorted signals, incorrect frequency, or missing signals indicate control module problems, while proper signals with poor motor response suggest motor problems.

Current signature analysis using an oscilloscope connected through a current probe can reveal internal motor condition by analyzing current waveform characteristics. Healthy motors show smooth current patterns, while motors with bearing problems, brush wear, or winding damage display characteristic distortions in the current waveform.

Temperature Correlation Testing

Systematic temperature correlation testing verifies that cooling fan activation occurs at proper coolant temperatures and that motor performance matches cooling demands. Use an accurate thermometer to monitor actual coolant temperature while observing fan activation points, comparing with manufacturer specifications.

Test fan operation across the full temperature range from cold startup through normal operating temperature to near-overheating conditions (never allow actual overheating). Document activation and deactivation temperatures, noting any hysteresis (difference between turn-on and turn-off temperatures) that prevents rapid cycling.

Evaluate motor performance under thermal stress by operating the cooling system under maximum load conditions: high ambient temperature, air conditioning on maximum, and extended idle operation. Motors with marginal performance may operate adequately under light loads but fail when maximum cooling is needed.

Cooling Fan Motor Replacement: Professional Procedures

Cooling fan motor replacement requires careful attention to electrical safety, proper procedures, and quality parts selection. While the mechanical aspects aren’t extremely complex, the electrical connections and system integration demand respect for safety protocols and manufacturer specifications. Understanding these procedures helps ensure reliable repairs and prevents damage to expensive electronic components.

Pre-Repair Safety Protocols and Requirements

Electrical Isolation and Battery Disconnection

Always begin cooling fan motor replacement by disconnecting the battery negative terminal and securing it away from the battery post. Wait at least 10 minutes after disconnection to allow capacitors in control modules to discharge, preventing damage to sensitive electronics during connector removal. This waiting period is particularly important for vehicles with complex engine management systems.

Verify electrical isolation by attempting to activate electrical components such as lights or radio after battery disconnection. No components should operate, confirming proper isolation. Document radio and security system codes before battery disconnection, as many systems require code entry after power restoration.

For hybrid and electric vehicles, follow manufacturer-specific high-voltage shutdown procedures before beginning any electrical work. These procedures typically involve removing service plugs, waiting for specified discharge times, and verifying system shutdown with appropriate test equipment. Never assume high-voltage systems are safe without proper verification.

Engine Cooling and Pressure Relief

Cooling fan motor replacement often requires working near hot engine components and pressurized cooling system parts. Allow the engine to cool completely before beginning work, preferably after sitting overnight. Hot components can cause severe burns, and pressurized coolant can spray unexpectedly when connections are disturbed.

If work must be performed on a warm engine, relieve cooling system pressure by carefully removing the radiator cap with a thick cloth, allowing pressure to escape slowly. Be prepared for hot coolant spillage and have appropriate cleanup materials available. Never remove the radiator cap from a hot engine, as pressurized coolant can cause severe burns.

Work area preparation includes having fire extinguisher readily available, ensuring adequate ventilation, and removing any combustible materials from the vicinity. While cooling fan motor replacement doesn’t typically involve open flames or high heat, electrical faults can create sparks that could ignite fuel vapors or other combustible materials.

Motor vs. Assembly Replacement Decision

When to Replace Motor Only

Motor-only replacement makes sense when the fan blade, shroud, and mounting hardware are in good condition and the motor can be separated from the assembly easily. This approach typically costs less in parts and may require less labor if the motor mounts externally to the fan assembly.

Consider motor-only replacement for high-mileage vehicles where cost control is important, provided the supporting components are serviceable. Inspect fan blades carefully for cracks, chips, or balance problems that could cause premature failure of the new motor. Any blade damage typically indicates complete assembly replacement is more appropriate.

Motor-only replacement requires careful attention to mounting alignment and electrical connections. The new motor must match the original specifications exactly, including mounting bolt patterns, electrical connections, and performance characteristics. Mismatched motors can cause vibration, inadequate cooling, or electrical problems.

Complete Assembly Replacement Benefits

Complete cooling fan assembly replacement provides several advantages: warranty coverage for the entire system, prevention of subsequent component failures, improved reliability through matched components, and often easier installation with less alignment issues. Modern assemblies integrate motor, fan, and shroud as matched systems optimized for specific cooling requirements.

Assembly replacement eliminates concerns about fan blade balance, motor alignment, and component compatibility. The complete assembly comes pre-balanced and tested, reducing the likelihood of vibration or performance problems. For vehicles under warranty or when long-term reliability is important, assembly replacement often provides better value despite higher initial cost.

Consider assembly replacement when multiple components show wear, when the vehicle is relatively new or low-mileage, or when customer reliability requirements justify the additional cost. Professional shops often prefer assembly replacement due to reduced comebacks and warranty claims.

Removal Procedures

Access and Disassembly

Cooling fan motor access varies significantly between vehicle designs, from simple bolt-on assemblies to complex installations requiring radiator removal. Begin by removing any components blocking access to the cooling fan assembly: air intake ducting, engine covers, or upper radiator supports.

Document the original installation with photographs before disassembly, paying particular attention to electrical connector orientations, mounting hardware locations, and any spacers or brackets that must be reinstalled correctly. These details are easily forgotten during reassembly and can cause problems if incorrect.

Remove the cooling fan electrical connectors by depressing locking tabs and pulling straight out from the motor. Never pull on wires or twist connectors, as this can damage internal connections or push terminals out of the connector body. If connectors are corroded or difficult to remove, clean with electrical contact cleaner before forcing separation.

Motor Extraction from Assembly

If replacing only the motor, carefully separate it from the fan blade and shroud assembly. Most motors mount with three or four bolts through the motor housing into the shroud. Remove these bolts while supporting the motor to prevent it from falling and causing damage.

Mark the relationship between fan blade and motor shaft before removal, as some applications require specific timing or orientation for optimal performance and balance. Fan blades typically attach with a central nut or clip arrangement, requiring appropriate tools for safe removal without damaging blade or motor shaft.

Handle the old motor carefully during removal, as it may contain residual coolant or oil that could spill and create environmental hazards. Dispose of old motors according to local environmental regulations, as they contain materials that require proper recycling or disposal.

Installation Procedures

New Motor Installation

Clean all mounting surfaces and electrical connections before installing the new motor, removing any corrosion, dirt, or coolant residue that could interfere with proper installation. Apply thin layer of anti-seize compound to mounting bolts if specified by manufacturer, but avoid getting compound on electrical connections.

Install the new motor in reverse order of removal, ensuring proper alignment and torque specifications for mounting hardware. Over-tightening can crack plastic shrouds or distort motor housings, while under-tightening allows vibration that accelerates wear. Use a torque wrench when specifications are provided.

Electrical connections must be clean and properly seated to ensure reliable operation. Apply thin layer of dielectric grease to connector terminals if specified, but avoid excess that could interfere with electrical contact. Verify connectors are fully seated and locking tabs engaged properly.

System Integration and Testing

After mechanical installation, perform initial electrical testing before final assembly. Reconnect the battery and use scan tool or manual methods to activate the cooling fan, verifying proper operation before installing access panels or surrounding components.

Monitor current draw during initial operation to verify the new motor operates within specifications. Excessive current draw indicates problems with installation, motor defects, or binding that could cause premature failure. Address any issues before completing installation.

Test cooling fan operation under various conditions: engine temperature-based activation, air conditioning system activation, and manual activation through scan tool commands. All activation methods should produce consistent motor operation without unusual noises or vibrations.

Quality Control and Verification

Post-Installation Testing

Comprehensive post-installation testing ensures the new motor operates correctly and provides adequate cooling under all operating conditions. Perform testing with the engine at operating temperature and air conditioning system operating to simulate maximum cooling demands.

Monitor coolant temperature during extended idle operation to verify the new motor provides adequate cooling when natural airflow is minimal. Temperature should remain stable within normal operating range regardless of ambient conditions or electrical loads.

Evaluate motor noise and vibration levels compared to original equipment operation. New motors should operate quietly and smoothly without excessive noise or vibration that could indicate installation problems or defective components.

Customer Education and Documentation

Provide customers with information about normal cooling fan operation, including when the fan should activate and typical noise levels during operation. Many customers aren’t familiar with electric cooling fan behavior and may be concerned about normal operational sounds.

Document warranty information and recommended maintenance intervals for cooling system components. Electric cooling fan motors typically don’t require regular maintenance, but cooling system service affects motor longevity through contamination and thermal stress reduction.

Explain symptoms that might indicate future cooling system problems and the importance of addressing overheating immediately to prevent engine damage. Customer education helps prevent expensive repairs and builds confidence in the service provided.

For comprehensive cooling system maintenance that supports cooling fan motor longevity, review our guide on understanding coolant replacement to ensure optimal cooling system performance and motor life.

Cooling Fan Motor Replacement Cost and Value Analysis

Understanding the financial aspects of cooling fan motor replacement helps you make informed decisions about repair timing, service provider selection, and cost-effective solutions. Costs vary significantly based on vehicle type, motor specifications, labor requirements, and local market conditions, making it important to understand all factors that affect your investment in reliable cooling system operation.

Professional Service Cost Breakdown

Labor Cost Factors

Professional cooling fan motor replacement typically requires 1-4 hours of labor, depending on vehicle design and accessibility. Simple, bolt-on assemblies with easy electrical access may require only 1-2 hours, while complex installations requiring radiator removal or extensive disassembly can take 4+ hours. Labor costs vary by region and shop type, with dealership rates typically 20-40% higher than independent shops.

Diagnostic time adds to total labor costs, particularly for intermittent problems or complex electrical issues. Proper diagnosis prevents unnecessary parts replacement and ensures effective repairs, but can add 0.5-2 hours to total labor time. Shops that include diagnostic time in repair estimates provide more accurate cost projections than those quoting parts and installation only.

Regional labor rate variations significantly affect total repair costs. Urban areas with higher cost of living typically see labor rates $20-40 per hour higher than rural markets. Specialty shops focusing on electrical repairs may charge premium rates but often complete diagnosis and repairs more efficiently than general automotive shops.

Emergency or after-hours service commands premium pricing, typically 50-100% above normal rates. Planning cooling fan motor replacement during regular business hours and moderate weather conditions provides maximum cost control and service availability.

Parts Cost Variables

Cooling fan motor costs range from $75-400 for the motor alone, with complete assemblies costing $150-800 depending on vehicle application. Economy vehicles typically use simpler, less expensive motors, while luxury vehicles, trucks, and performance applications require more sophisticated and expensive units.

OEM (Original Equipment Manufacturer) parts typically cost 20-50% more than quality aftermarket alternatives but offer advantages including exact fit, proven reliability, and warranty coverage that may extend original vehicle warranties. Aftermarket parts vary significantly in quality, from economy alternatives that may last 50-75% as long as OEM to premium aftermarket parts that match or exceed OEM specifications.

Variable speed motors and dual-fan systems cost significantly more than single-speed applications. High-performance cooling systems, hybrid applications, and luxury vehicle components often require specialized motors with integrated control modules, increasing parts costs substantially.

Consider total system costs when planning repairs. If the cooling fan motor has failed, other cooling system components may be near end of service life. Combining motor replacement with cooling system service, thermostat replacement, or other maintenance can reduce total labor costs compared to separate service visits.

DIY Cost Considerations

DIY Feasibility Assessment

DIY cooling fan motor replacement is suitable for mechanically inclined individuals with basic electrical knowledge and proper tools. The mechanical aspects aren’t extremely complex, but electrical safety and proper diagnosis require understanding automotive electrical systems and safety protocols.

Required tools include basic hand tools, multimeter for electrical diagnosis, and potentially specialty tools for specific vehicle applications. Tool investment of $50-200 may be required if you don’t own electrical testing equipment, but these tools provide value for future electrical repairs and maintenance.

Time investment varies from 2-6 hours for first-time DIY mechanics, depending on vehicle complexity and diagnostic requirements. Factor in additional time for parts procurement, research, and potential complications that might arise during repair. Rushed electrical work creates safety hazards and increases likelihood of mistakes.

Consider your comfort level with electrical diagnosis and repair. Incorrectly diagnosed problems lead to unnecessary parts replacement and wasted time and money. If you’re uncertain about electrical testing procedures or safety protocols, professional diagnosis followed by DIY installation might provide optimal cost savings with reduced risk.

Risk Assessment for DIY vs. Professional Service

DIY electrical work carries risks including personal injury from electrical shock, damage to expensive electronic components, and fire hazards from incorrect connections or short circuits. These risks increase significantly for hybrid and electric vehicles with high-voltage systems that require specialized training and equipment.

Warranty considerations affect DIY decisions. Many vehicle warranties require professional service for electrical repairs, and incorrect DIY work can void coverage for related components. New vehicles or those with extended warranties may make professional service more cost-effective despite higher upfront costs.

Diagnostic accuracy affects repair success and total costs. Misdiagnosed problems lead to replacing functional components while leaving actual problems unresolved. Professional diagnostic equipment and experience often identify problems that basic DIY testing might miss, preventing unnecessary parts replacement.

Consider the consequences of incomplete or incorrect repairs. Cooling system problems can cause severe engine damage if not properly resolved, potentially costing thousands of dollars more than professional repair. The cost of mistakes often exceeds savings from DIY work, particularly for critical systems like engine cooling.

Value-Based Decision Making

Repair vs. Replacement Analysis

Vehicle age and mileage significantly influence repair vs. replacement decisions. High-mileage vehicles approaching end of useful life may not justify expensive cooling system repairs, particularly if other major components show signs of wear. Consider total anticipated repair costs over the next 2-3 years when making repair decisions.

Cooling fan motor replacement often reveals other cooling system problems that weren’t apparent during normal operation. Radiator condition, coolant contamination, thermostat operation, and water pump condition all affect cooling system reliability and may require attention during motor replacement.

Integration with other needed repairs can provide cost advantages through shared labor and reduced vehicle downtime. Cooling system service, belt replacement, or other maintenance performed simultaneously with motor replacement reduces total labor costs compared to separate service visits.

Consider the value of reliable transportation and the costs of breakdowns or emergency repairs. Proactive cooling fan motor replacement prevents emergency situations and provides better control over repair timing and costs compared to emergency service during hot weather or travel.

Long-Term Ownership Considerations

For vehicles you plan to keep long-term, investing in quality repairs and preventive maintenance provides better value than minimum-cost fixes that may fail prematurely. Quality cooling fan motors and proper installation provide years of reliable service, while economy alternatives may require replacement within 1-2 years.

Document all cooling system repairs and maintenance to track system reliability and identify patterns that might indicate underlying problems. Well-maintained cooling systems typically provide years of trouble-free service, while neglected systems often experience cascading failures that become increasingly expensive.

Consider the relationship between cooling system maintenance and overall vehicle reliability. Proper cooling system operation protects the engine investment and prevents expensive damage that could make the vehicle uneconomical to repair. Regular maintenance and timely repairs preserve vehicle value and reliability.

For commercial vehicles or those used in demanding applications, cooling system reliability becomes even more critical. Downtime costs, towing expenses, and emergency repair premiums often exceed the cost of proactive maintenance and quality repairs. Consider upgrading to heavy-duty cooling components for severe-duty applications found in construction equipment and commercial truck applications.

Extending Cooling Fan Motor Life Through Proper Care

Preventive maintenance significantly extends cooling fan motor service life while improving overall cooling system reliability. Understanding proper maintenance procedures and implementing regular inspection schedules helps avoid unexpected failures and reduces long-term ownership costs through early problem detection and correction.

Regular Inspection and Maintenance

Visual Inspection Protocols

Establish monthly inspection routines that include visual examination of the cooling fan motor and electrical connections. Look for signs of oil leaks, coolant contamination, corrosion at electrical connections, and physical damage to fan blades or motor housing. Early detection of these problems allows correction before they cause motor failure.

Inspect electrical connections for corrosion, looseness, or damage that could affect motor performance. Clean connections showing early signs of corrosion with electrical contact cleaner and apply dielectric grease to prevent future corrosion. Loose connections create resistance and heat that can damage motors and related electrical components.

Check fan blade condition for cracks, chips, or signs of impact damage that could cause vibration and accelerate motor bearing wear. Damaged blades should be replaced immediately to prevent motor damage. Even minor blade damage can create vibration that causes premature bearing failure and motor replacement.

Monitor cooling system cleanliness around the motor and fan assembly. Debris accumulation restricts airflow and causes motors to work harder, generating excess heat that shortens motor life. Keep the area clean and remove any debris that could interfere with motor operation or cooling airflow.

Electrical System Maintenance

Maintain optimal battery and charging system condition to ensure cooling fan motors receive proper voltage during operation. Low voltage from weak batteries or failing alternators forces motors to draw higher current, generating excess heat and accelerating wear. Regular battery and charging system testing prevents these problems.

Clean electrical connections throughout the cooling system circuit, including fuse box connections, relay sockets, and ground points. Corroded connections create resistance that affects motor performance and can cause control system problems. Annual cleaning and protection of electrical connections significantly improves system reliability.

Verify proper fuse and relay operation during routine maintenance. Marginal relays can cause intermittent motor operation that’s difficult to diagnose, while incorrect fuse ratings can allow damaging overcurrent conditions or cause nuisance failures. Replace fuses and relays according to manufacturer specifications and maintenance schedules.

For comprehensive electrical system maintenance that supports cooling fan motor longevity, review our guide on automotive alternator diagnosis to ensure your charging system provides optimal power for cooling fan operation.

Environmental Protection Strategies

Contamination Prevention

Maintain clean engine air filtration to reduce debris exposure to cooling fan motors. Dirty air filters allow contamination that can clog motor ventilation, causing overheating and premature failure. Replace air filters according to manufacturer recommendations or more frequently in dusty conditions.

Protect cooling system components from road salt and chemical exposure through regular undercarriage washing and application of corrosion inhibitors where appropriate. Salt exposure accelerates corrosion of electrical connections and can damage motor housing, particularly in northern climates where road salt is used extensively.

Keep cooling system fluids clean and at proper concentrations to prevent contamination of motor and electrical components. Contaminated coolant can leak onto electrical connections, causing corrosion and electrical problems. Regular coolant service prevents contamination and maintains optimal cooling system operation.

Monitor for oil leaks or other fluid contamination that could affect cooling fan motor operation. Engine oil or transmission fluid leaking onto electrical connections causes corrosion and insulation breakdown that can damage motors and control circuits. Address leaks promptly to prevent electrical system damage.

Operating Condition Optimization

Maintain proper engine operating temperature through thermostat and cooling system service. Engines that run too hot force cooling fan motors to operate longer and at higher speeds, accelerating motor wear. Engines that run too cool may cause motors to cycle frequently, increasing start-stop wear on electrical components.

Optimize air conditioning system efficiency to reduce cooling fan workload during hot weather operation. Clean condenser coils, maintain proper refrigerant levels, and ensure efficient A/C operation reduces the frequency and duration of cooling fan operation, extending motor life.

Avoid extended idling when possible, particularly in hot weather with air conditioning operating. Extended idle operation places maximum demand on cooling fan motors while providing minimal engine compartment ventilation, creating harsh operating conditions that accelerate motor wear.

Plan driving routes and schedules to minimize stop-and-go traffic during extreme weather conditions when possible. While not always practical, reducing cooling system stress during peak demand periods helps extend component life and reduces the likelihood of failures during demanding conditions.

Professional Service Integration

Maintenance Service Coordination

Coordinate cooling fan motor inspection with routine cooling system service to maximize efficiency and reduce costs. Most cooling system service includes inspection of cooling fan operation, providing professional evaluation of motor condition without additional diagnostic charges.

Include electrical system testing in annual maintenance schedules, particularly for high-mileage vehicles or those operated in severe conditions. Professional electrical system testing can identify marginal components before they fail, allowing planned replacement rather than emergency repair.

Document cooling fan motor performance and maintenance history to track system reliability and identify developing problems. Professional maintenance records help identify patterns that might indicate underlying problems requiring attention before they cause expensive failures.

Schedule cooling system service before hot weather seasons when cooling demands are highest. Spring cooling system service ensures optimal operation during summer months and identifies problems before they cause failures during peak cooling demands.

Early Problem Detection

Professional diagnostic equipment can identify cooling fan motor problems before they cause complete failure. Annual diagnostic testing of cooling system operation can reveal electrical problems, performance degradation, or control system issues that aren’t apparent during normal operation.

Monitor cooling system performance trends through professional service records and customer observations. Gradual changes in fan noise, operation patterns, or cooling effectiveness often indicate developing problems that can be addressed before causing complete failures.

Implement professional inspection schedules based on vehicle age, mileage, and operating conditions. Vehicles operated in severe conditions may benefit from more frequent professional inspection, while normal-duty vehicles may require only annual evaluation.

Consider professional cooling system analysis for vehicles approaching high mileage or showing signs of cooling system aging. Comprehensive evaluation helps prioritize maintenance and repairs for optimal cost-effectiveness and reliability.

For comprehensive vehicle maintenance strategies that support cooling system longevity, explore our vehicle care tips section, which provides guidance on integrated maintenance approaches that optimize overall vehicle reliability and performance.

Professional Service vs. DIY Repair Decisions

Deciding between professional service and DIY repair requires honest assessment of your electrical knowledge, available tools, safety comfort level, and the complexity of modern cooling fan motor systems. While basic motor replacement isn’t the most complex automotive repair, it involves critical electrical systems that demand respect for safety protocols and proper diagnostic procedures.

DIY Capability Assessment

Suitable DIY Scenarios

Cooling fan motor replacement is suitable for DIY mechanics with intermediate electrical skills and proper safety awareness. If you’re comfortable using multimeters, understand basic automotive electrical circuits, and have successfully performed similar electrical repairs, DIY replacement can save significant money while providing valuable learning experience.

Consider DIY repair if you have adequate workspace with good lighting, proper ventilation, and sufficient time to complete the work without rushing. Electrical work requires careful attention to detail and proper safety procedures, making rushed repairs potentially dangerous and ineffective.

DIY repair makes most sense when you can obtain quality replacement parts at reasonable prices and have access to manufacturer service information including wiring diagrams, specifications, and proper procedures. Generic repair information may not account for vehicle-specific requirements or safety considerations.

Evaluate your comfort level with electrical safety procedures and willingness to follow manufacturer specifications exactly. Cooling fan motor circuits carry significant current and integrate with complex engine management systems, making proper procedures essential for safe and effective repair.

Professional Service Requirements

Seek professional service for high-voltage hybrid and electric vehicle cooling systems, which require specialized training, tools, and safety equipment. These systems operate at voltages that can cause serious injury or death, and improper service can create ongoing safety hazards or damage expensive components.

Professional service is recommended when diagnostic requirements exceed basic electrical testing or when multiple cooling system components show signs of problems. Complex diagnostic scenarios often require professional scan tools, experience, and systematic approaches that prevent unnecessary parts replacement.

Consider professional service if your vehicle is under warranty, as improper DIY electrical work could void coverage for related components. Warranty considerations may make professional service more cost-effective despite higher initial costs, particularly for newer vehicles with comprehensive coverage.

Time constraints often make professional service more practical than DIY repair. Most professional shops can complete cooling fan motor replacement within a day, while DIY repairs might require multiple days or weekends, particularly if complications arise or parts aren’t readily available.

Finding Qualified Service Providers

Service Provider Selection Criteria

Look for service providers with ASE (Automotive Service Excellence) certification in electrical systems and engine performance areas. These certifications indicate specialized knowledge and ongoing education in automotive electrical systems, providing confidence in their ability to diagnose and repair cooling fan motor problems accurately.

Evaluate shop equipment and capabilities, particularly diagnostic equipment for modern vehicle electrical systems. Shops with professional scan tools, oscilloscopes, and electrical testing equipment can provide more accurate diagnosis and ensure proper system integration after repairs.

Ask about experience with your specific vehicle make and model, as cooling fan motor systems vary significantly between manufacturers. Shops familiar with your vehicle type can complete repairs more efficiently and are more likely to identify vehicle-specific problems or required procedures.

Check customer reviews and references, paying particular attention to comments about electrical repair quality and customer service. Electrical problems often require follow-up service or warranty work, making shop reputation and customer service important factors in provider selection.

Service Communication and Preparation

Document all symptoms you’ve observed, including when problems occur, environmental conditions, and any patterns you’ve noticed. Detailed symptom information helps technicians diagnose problems more efficiently and reduces diagnostic time and costs.

Provide complete vehicle maintenance history, particularly cooling system service, electrical work, and any modifications that might affect cooling fan operation. This background information helps technicians understand your vehicle’s condition and identify potential related problems.

Request detailed cost estimates that include diagnostic time, parts specifications, labor hours, and warranty information. Understanding what’s included in repair estimates helps you make informed decisions and compare pricing between service providers.

Ask for explanation of diagnostic findings and repair recommendations before authorizing work. Understanding what’s wrong and why helps you make informed decisions about repair options and provides confidence in the work being performed.

Emergency Service Considerations

Cooling fan motor failures can create emergency situations, particularly during hot weather or when traveling. Research emergency service options in your area and keep contact information readily available for unexpected breakdowns.

Understand the risks of continued operation with cooling fan problems. While you might be able to drive short distances at highway speeds, stop-and-go traffic or extended idling can cause severe engine damage within minutes when cooling fans aren’t operating.

Consider roadside assistance coverage that includes cooling system problems and towing services. Many automotive insurance policies and vehicle manufacturers offer roadside assistance that can provide immediate help and safe transportation to qualified repair facilities.

Plan cooling system maintenance before travel or extreme weather seasons to reduce the likelihood of failures during inconvenient times. Proactive maintenance provides better control over repair timing and costs compared to emergency service.

For comprehensive technical support and guidance on cooling system issues, Repairs Advisor offers resources through our contact form and help center, where experienced technicians can provide guidance for your specific situation and help you make informed service decisions.

Cooling Fan Motor Maintenance: Powering Reliable Engine Cooling

The cooling fan motor serves as a critical component in your vehicle’s thermal management system, providing precisely controlled airflow when natural cooling is insufficient. Understanding its operation, recognizing failure symptoms, and performing proper maintenance are essential skills for maintaining reliable engine cooling and preventing expensive overheating damage.

Critical Points Summary

Early symptom recognition provides your first line of defense against costly engine damage and dangerous overheating situations. Complete motor failure, intermittent operation, unusual noises, and electrical system problems all indicate cooling fan motor issues that require prompt attention. Unlike mechanical fan clutches that may provide partial cooling when worn, electric motors often fail completely, leaving your engine vulnerable to rapid overheating.

Professional diagnostic procedures ensure accurate problem identification and prevent unnecessary parts replacement. Systematic electrical testing using multimeters, scan tools, and proper safety protocols provides reliable methods for distinguishing motor problems from control circuit issues, relay failures, or wiring faults.

Electrical safety takes priority over cost savings in all cooling fan motor work. Proper safety procedures, including battery disconnection, electrical isolation, and high-voltage system awareness for hybrid and electric vehicles, protect both technicians and vehicle systems from damage during diagnosis and repair.

Quality parts and professional installation provide optimal reliability and performance. Whether performing DIY repairs or selecting professional service, insist on quality components and adherence to manufacturer specifications for electrical connections, torque values, and system integration procedures.

Action Steps for Vehicle Owners

Establish regular inspection schedules that include monthly visual checks of cooling fan motor condition, electrical connections, and system operation. Early problem detection through systematic inspection allows planned repairs rather than emergency service during extreme weather or travel.

Monitor cooling system performance through temperature gauge observation and symptom awareness. Understanding normal operation helps you recognize problems early and take appropriate action before engine damage occurs.

Address electrical system health through battery and charging system maintenance, as proper voltage is essential for cooling fan motor longevity and performance. Weak batteries and failing alternators create operating conditions that accelerate motor wear and reduce reliability.

Invest in preventive maintenance and quality repairs when service becomes necessary. Proactive cooling system care prevents cascading failures and provides better long-term value than reactive repairs after problems develop.

Safety and Professional Consultation

Never ignore engine overheating symptoms or attempt to operate a vehicle with known cooling fan problems. Engine damage from overheating occurs rapidly and can result in repair costs far exceeding cooling fan motor replacement expenses.

Prioritize electrical safety in all cooling fan motor work, seeking professional service when safety requirements exceed your knowledge or equipment capabilities. High-voltage hybrid and electric vehicle systems require specialized training and equipment that make professional service essential for safety.

Professional consultation provides optimal results for complex diagnostic scenarios or when multiple cooling system components show signs of problems. Experienced technicians have the tools, knowledge, and systematic approaches needed to identify problems accurately and implement effective solutions.

Maintain emergency procedures and contacts for cooling system failures, including understanding safe operation limitations and having reliable towing and repair services available. Proper preparation minimizes damage and inconvenience when problems occur despite preventive maintenance efforts.

Final Safety Reminders

Electrical work on automotive cooling systems involves live circuits, rotating machinery, and potentially hazardous voltages that demand proper safety procedures and equipment. When in doubt about safety requirements or proper procedures, seek professional assistance rather than risking personal injury or expensive system damage.

Modern vehicles integrate cooling fan motors with complex engine management systems that require specialized knowledge for proper diagnosis and repair. Attempting repairs beyond your knowledge level can cause expensive damage to electronic components and create ongoing reliability problems.

Emergency overheating situations require immediate action to prevent engine damage. Understanding proper procedures for safe vehicle shutdown, coolant system inspection, and emergency cooling can prevent minor problems from becoming major repairs.

Whether you’re maintaining a daily driver, managing commercial truck fleets, or caring for specialized material handling equipment, understanding cooling fan motor operation and maintenance ensures reliable thermal management and protects your engine investment.

Your cooling fan motor may operate invisibly behind the scenes, but its role in protecting your engine makes it worthy of attention and care. By following the guidance in this article and maintaining a proactive approach to cooling system maintenance, you’ll ensure your electric cooling system continues providing reliable engine protection for years to come. The investment in understanding and maintaining this critical component pays dividends in reduced repair costs, improved reliability, and the peace of mind that comes from knowing your cooling system will perform when you need it most.