Camshaft Seal Explained: Keeping Oil Where It Belongs

You’re under the hood investigating that persistent oil smell, and there it is—a telltale streak of oil running down the back of your engine near the timing cover. Your first thought might be a valve cover gasket, but if the leak is coming from behind that plastic timing cover at the front of your engine, you could be dealing with a failing camshaft seal. This small but critical component might seem insignificant, but when it fails, the consequences can cascade into major engine problems and costly repairs.

The camshaft seal is one of those engine components that most people never think about until something goes wrong. Yet this humble rubber ring plays a vital role in keeping your engine’s lifeblood—oil—exactly where it belongs while preventing contamination from entering your engine’s precision timing system. Understanding how this seal works, recognizing the warning signs of failure, and knowing when to take action can save you from expensive timing belt damage, engine wear, and potentially catastrophic timing system failure.

In this comprehensive guide, we’ll explore everything you need to know about camshaft seals, from their basic function and common failure symptoms to diagnostic procedures, replacement costs, and professional repair considerations. Whether you’re a DIY enthusiast trying to understand that mysterious oil leak or a professional technician looking to explain the importance of timing belt service to customers, this article provides the technical depth and practical guidance you need to make informed decisions about camshaft seal maintenance and repair.

What is a Camshaft Seal?

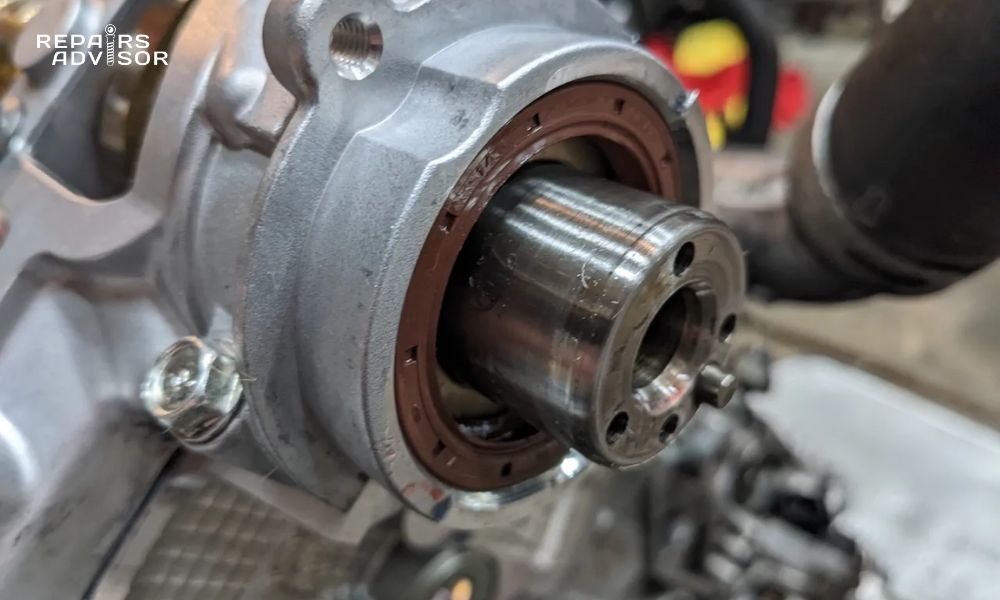

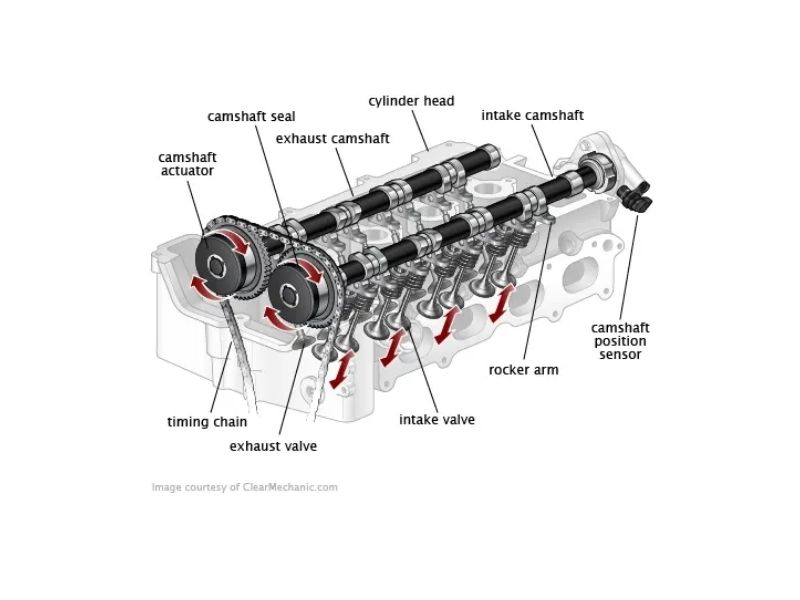

The camshaft seal is a round, precision-engineered oil seal that sits between the rotating camshaft and the stationary cylinder head of your engine. Think of it as a specialized barrier specifically designed to maintain the critical boundary between your engine’s internal oil circulation system and the external environment. This seal prevents engine oil from leaking out while simultaneously blocking dirt, debris, and moisture from entering the engine’s timing system.

Physically, camshaft seals are typically made from durable rubber compounds, though modern applications may use advanced materials like silicone or fluoroelastomer (FPM) for enhanced performance in extreme conditions. The seal features a spring-loaded lip that maintains constant contact with the camshaft surface, creating a dynamic seal that must function effectively while the camshaft rotates at engine speed. Most seals measure between 40-60mm in diameter, with precise internal dimensions matched to specific camshaft specifications.

The camshaft seal is strategically positioned between the cylinder head and valve cover gasket area, typically located behind the timing cover at the front of the engine near the firewall. This location is both its strength and weakness—while it’s protected from external contamination by the timing cover, accessing it for inspection or replacement requires removing timing system components, making it one of the more complex seals to service.

From an engineering perspective, the camshaft seal must withstand extraordinary demands. It operates in an environment of extreme temperature variations, from sub-zero cold starts to operating temperatures exceeding 200°F, while managing varying oil pressures and maintaining its sealing integrity against a constantly rotating surface. The seal must also accommodate slight camshaft movement and vibration while maintaining its primary function of containing engine oil circulation that’s essential for proper lubrication of timing components.

How Camshaft Seals Work

The camshaft seal operates on a relatively simple but precisely engineered principle. The seal’s inner lip maintains constant contact with the camshaft surface through spring tension, creating a dynamic barrier that moves with the rotating shaft while preventing oil passage. This spring-loaded design ensures consistent sealing pressure regardless of minor variations in camshaft position, thermal expansion, or normal wear patterns that develop over the engine’s lifetime.

The material science behind modern camshaft seals is quite sophisticated. Traditional rubber seals provide excellent flexibility and cost-effectiveness, but they can harden over time when exposed to high temperatures and aggressive oil additives. Advanced fluoroelastomer seals offer superior chemical resistance and maintain flexibility across wider temperature ranges, though they command premium pricing. The choice of material often depends on the specific engine application and expected service life requirements.

A critical aspect of camshaft seal function involves managing the thermal expansion differences between materials. Steel camshaft components and aluminum cylinder heads expand at different rates as the engine reaches operating temperature. This differential expansion can cause traditional seals to loosen slightly in their bores, which is why some manufacturers recommend using gasket sealant on the outer diameter of the seal during installation to prevent movement and ensure long-term sealing integrity.

The camshaft seal also plays a crucial role in protecting the timing belt or chain system from oil contamination. Oil-soaked timing belts lose their grip and can slip or break prematurely, while timing chains can experience accelerated wear when contaminants enter the timing case. By maintaining proper oil containment, the camshaft seal helps preserve the integrity of these critical engine timing components that control valve operation and prevent catastrophic engine damage.

Understanding the relationship between camshaft seals and the broader engine lubrication system helps explain why seal failure can have cascading effects. The seal works in conjunction with the positive crankcase ventilation (PCV) system to manage internal engine pressures that could otherwise force oil past sealing surfaces. When multiple seals begin failing simultaneously, it often indicates broader system issues such as excessive crankcase pressure or oil contamination that require comprehensive diagnosis.

Common Symptoms of Camshaft Seal Failure

The most obvious and common symptom of camshaft seal failure is visible oil leakage behind the timing cover. Unlike valve cover gasket leaks that typically appear on top of the engine, camshaft seal leaks manifest as oil residue on the rear of the engine right below the valve cover area. This oil often flows to the edges or corners of the engine bay, creating distinctive patterns that experienced technicians can recognize immediately.

Engine bay smoke represents a more serious progression of camshaft seal failure. When leaked oil finds its way onto hot exhaust manifolds or pipes, it burns on contact, producing smoke trails and the characteristic odor of burning oil. The intensity of smoke and smell correlates directly with the severity of the leak—small leaks may produce faint wisps barely noticeable except during startup, while major seal failures can generate obvious smoke clouds that persist during driving. This symptom demands immediate attention, as burning oil creates fire hazards and indicates significant oil loss.

Oil contamination of timing system components creates secondary symptoms that often bring camshaft seal problems to light. When oil saturates timing belts, they become slippery and prone to skipping teeth or complete failure. This can manifest as rough engine operation, unusual timing-related noises, or even check engine lights triggered by camshaft position sensor irregularities. Timing chain systems may exhibit increased noise or rattling when oil contamination affects tensioner operation or chain lubrication.

Engine performance changes often accompany advanced camshaft seal failure. As oil loss progresses, insufficient lubrication can affect valve train operation, leading to ticking noises, reduced power output, and irregular idle quality. The engine may consume oil more rapidly than normal, requiring frequent top-offs between regular oil changes. In severe cases, oil starvation can cause actual engine damage, making early detection and repair crucial for preserving engine longevity.

Diagnostic challenges arise when differentiating camshaft seal leaks from valve cover gasket failures, as both can produce oil residue in similar areas. However, camshaft seal leaks typically originate from behind the timing cover and may be accompanied by oil contamination of timing components, while valve cover gasket leaks usually appear higher on the engine and don’t affect timing system components. Professional diagnosis often requires systematic cleaning and monitoring to identify the precise leak source, especially when multiple seals are failing simultaneously.

Modern vehicles may trigger diagnostic trouble codes related to camshaft position sensors when oil contamination affects sensor operation or when timing irregularities develop due to belt slippage. These codes provide valuable diagnostic clues but require correlation with physical inspection findings to determine root causes. Understanding the relationship between diagnostic codes and physical symptoms helps technicians develop comprehensive repair strategies that address underlying problems rather than just symptoms.

Causes of Camshaft Seal Failure

Age and material degradation represent the most common cause of camshaft seal failure. Rubber seals naturally harden over time when exposed to repeated heat cycling, aggressive oil additives, and ozone exposure. As rubber loses its flexibility, the seal can no longer maintain consistent contact with the camshaft surface, allowing oil to escape. This aging process typically accelerates after 60,000-80,000 miles, though severe operating conditions can shorten seal life significantly.

Improper installation during previous repairs creates premature seal failure. Common installation mistakes include using incorrect seal orientations, failing to lubricate seal lips properly, or damaging seals during installation with improper tools. Over-driving seals beyond their proper depth can distort the sealing lip, while under-seating leaves gaps that allow oil passage. Using generic aftermarket seals that don’t match OEM specifications can also lead to early failure due to incorrect materials or dimensions.

Mechanical factors within the engine can accelerate camshaft seal wear beyond normal expectations. Camshaft misalignment or excessive axial play puts additional stress on seals, causing uneven wear patterns and premature failure. Worn camshaft bearings can allow shaft movement that exceeds seal design tolerances, while timing system problems can create vibrations that accelerate seal degradation. These mechanical issues often require correction during seal replacement to prevent repeat failures.

Maintenance-related factors significantly influence camshaft seal longevity. Infrequent oil changes allow contaminants to build up that can damage seal materials and scoring camshaft surfaces. Using incorrect oil viscosity can affect lubrication characteristics and seal performance, while contaminated oil containing metal particles or combustion byproducts accelerates wear on both seals and camshaft surfaces. Poor-quality oil filters that don’t adequately remove contaminants compound these problems over time.

Environmental and operating conditions play crucial roles in seal life expectancy. Extreme temperature cycling, particularly in hot climates or severe-duty applications, accelerates rubber degradation and thermal expansion stress. Stop-and-go driving patterns create more frequent temperature cycles than highway driving, while extended idle periods can cause heat buildup that damages seals. Engines that experience frequent cold starts without adequate warm-up time may develop condensation that affects seal materials and promotes corrosion of camshaft surfaces.

Crankcase pressure problems from malfunctioning PCV systems create additional stress on all engine seals, including camshaft seals. Blocked PCV valves or restricted ventilation systems can cause excessive internal pressure that forces oil past seals designed for normal operating pressures. This explains why multiple seal failures often occur simultaneously and why comprehensive diagnosis should include PCV system evaluation. Understanding the interconnected nature of engine systems helps identify root causes that prevent future problems.

Diagnostic Procedures

Professional camshaft seal diagnosis begins with systematic visual inspection to differentiate seal leaks from other common oil leak sources. The inspection process starts with thorough cleaning of the engine bay to remove existing oil residue, followed by running the engine to operating temperature and monitoring for fresh oil appearance. This controlled approach helps identify active leak sources and eliminates confusion from old oil stains that may obscure current problems.

Accessing the timing cover area for proper inspection requires removing protective covers and air intake components that typically obstruct view of the camshaft seal area. Professional technicians use specialized mirrors and inspection lights to examine the seal area without extensive disassembly. The inspection focuses on identifying oil residue patterns that indicate seal failure versus valve cover gasket leaks, timing cover gasket problems, or other potential sources in the same general area.

Differential diagnosis becomes critical when multiple potential leak sources exist in the same engine area. Camshaft seal leaks typically originate from behind the timing cover and may contaminate timing belt or chain components, while valve cover gasket leaks usually appear higher on the engine without affecting timing system components. Oil pan gasket leaks manifest lower on the engine, and timing cover gasket failures often show oil seepage around the entire cover perimeter rather than concentrated at the camshaft seal location.

Advanced diagnostic techniques include pressure testing the crankcase ventilation system to identify excessive pressure that could cause seal failure. UV-reactive oil additives can help trace leak paths in complex cases where multiple sources are suspected. Some technicians use compressed air to pressurize the crankcase slightly while monitoring seal areas for bubble formation that indicates seal failure, though this technique requires careful pressure control to avoid damage.

Timing system correlation provides valuable diagnostic information about camshaft seal condition. Oil contamination of timing belts or chains often indicates ongoing seal failure even when external leaks aren’t immediately visible. Timing belt tension and condition assessment can reveal oil-related deterioration that suggests camshaft seal problems. Camshaft position sensor diagnostic codes may indicate timing irregularities caused by oil-contaminated timing components, providing additional evidence of seal failure.

Safety considerations during diagnosis include ensuring proper engine cooling before inspection, using appropriate personal protective equipment, and following proper vehicle lifting procedures when under-vehicle access is required. Hot engine components can cause severe burns, while oil-contaminated surfaces create slip hazards. Professional diagnosis often requires specialized tools and equipment that may not be available to DIY mechanics, making professional consultation valuable for accurate problem identification.

Replacement Procedures

Camshaft seal replacement represents a complex procedure that requires advanced mechanical knowledge, specialized tools, and careful attention to timing system integrity. This repair is generally not recommended for DIY mechanics unless they possess significant engine repair experience and access to proper timing tools. The procedure involves removing timing system components that, if improperly handled, can cause catastrophic engine damage requiring complete engine rebuilds.

The replacement process begins with comprehensive preparation including vehicle positioning on level ground, parking brake engagement, and battery disconnection for electrical safety. Complete engine oil drainage is typically required, as timing cover removal often involves oil passages that would otherwise create significant spillage. Engine cooling to ambient temperature ensures safe handling and prevents thermal shock to components during disassembly.

Access to camshaft seals requires timing cover removal and timing system disassembly. This involves removing accessory drive belts, timing belt or chain tensioners, and timing belt/chain assemblies while carefully documenting timing mark positions. Camshaft sprocket removal requires specialized holding tools to prevent camshaft rotation that could disturb valve timing. Each step must be performed with precision to ensure proper reassembly and timing system integrity.

Seal extraction requires careful technique to avoid damaging camshaft surfaces or seal bore areas. Professional seal pullers provide controlled removal force, while improvised tools can score camshaft surfaces and create leak paths for new seals. The seal bore must be thoroughly cleaned and inspected for damage that could affect new seal performance. Surface preparation includes removing all old sealant or gasket material and checking for wear patterns that might indicate camshaft bearing problems.

New seal installation demands precise technique to ensure proper seating and orientation. The seal must be lubricated with appropriate grease or oil to prevent installation damage, while the outer diameter may require gasket sealant application depending on manufacturer specifications. Installation tools must be sized correctly to apply even pressure across the seal face without distorting the sealing lip. Proper installation depth is critical—too shallow allows oil leakage, while too deep can damage the seal or interfere with camshaft operation.

Timing system reassembly requires meticulous attention to timing mark alignment and proper component torque specifications. Timing belt or chain tension must be set according to manufacturer procedures, while camshaft sprocket installation requires specific torque values and sequences. The relationship between timing components means that any assembly errors can result in valve-to-piston contact and severe engine damage. Professional technicians use specialized timing tools and follow precise procedures to ensure proper assembly.

Post-installation testing includes oil system refilling, initial startup procedures, and comprehensive leak monitoring. The engine should be run at idle initially while monitoring for leaks, unusual noises, or timing irregularities. Oil pressure and timing system operation must be verified before returning the vehicle to service. Some seals may show minor initial seepage that stops as the seal lip seats properly, but significant leaks indicate installation problems requiring immediate correction.

Cost Analysis

Camshaft seal replacement costs vary significantly based on vehicle complexity, regional labor rates, and timing system design. Professional replacement typically ranges from $947 to $1,383, with labor representing the majority of the expense due to timing system involvement. The seal itself costs only $22-$50 for most applications, but accessing it requires 6-12 hours of skilled labor depending on engine configuration and timing system complexity.

Vehicle-specific factors dramatically influence repair costs. Four-cylinder engines with simple timing belt systems represent the lower cost range, while V6 and V8 engines with complex timing chain systems or interference engine designs command premium pricing. European luxury vehicles and some Japanese models require specialized tools and procedures that increase labor time and costs. Vehicles requiring engine mount disconnection or other major component removal for timing system access represent the highest cost category.

Timing correlation presents significant cost optimization opportunities. When timing belts are approaching service intervals, combining camshaft seal replacement with timing belt service eliminates duplicate labor charges. Timing belt replacement normally costs $300-$500 as a standalone service, but adds only $100-$200 when performed during camshaft seal replacement. This timing strategy can save $200-$400 in labor costs while ensuring comprehensive timing system maintenance.

Related component replacement often makes economic sense during camshaft seal service. Crankshaft seals, water pumps, and timing system tensioners are commonly replaced during timing belt service since access is already available. While these additions increase immediate costs, they prevent future timing system disassembly for individual component failures. Comprehensive timing system service may cost $1,500-$2,500 but provides long-term reliability and avoids repeat labor charges.

DIY cost considerations include substantial tool investment requirements for specialized timing system tools, seal pullers, and installation drivers. Tool costs can exceed $500 for a complete timing tool set, making DIY replacement economically questionable unless multiple vehicles require service. The risk of timing system damage from improper procedures can result in repair costs exceeding $5,000, making professional service a prudent investment for most vehicle owners.

Regional variations affect pricing significantly, with metropolitan areas typically commanding higher labor rates than rural locations. Dealership service departments usually charge premium rates compared to independent shops, though they offer specialized knowledge and warranty coverage. When evaluating repair options, consider total value including warranty coverage, technician expertise, and facility capabilities rather than focusing solely on initial cost estimates.

Prevention and Maintenance

Regular oil change intervals using high-quality oil represent the most effective camshaft seal preservation strategy. Quality engine oil maintains proper lubrication characteristics while minimizing contamination that can damage seal materials. Oil change intervals should follow manufacturer recommendations or be shortened for severe duty conditions including frequent short trips, extreme temperatures, or stop-and-go driving patterns that accelerate oil degradation and seal wear.

Timing belt service intervals provide optimal opportunities for camshaft seal inspection and preventive replacement. Most timing belts require replacement every 60,000-100,000 miles, coinciding with typical camshaft seal life expectancy. Proactive seal replacement during timing belt service costs significantly less than emergency repair when seals fail and contaminate timing components. This preventive approach also allows comprehensive timing system inspection and component replacement before failures occur.

Operating condition modifications can extend camshaft seal life in severe applications. Allowing proper engine warm-up before driving reduces thermal shock to seals, while avoiding extended high-temperature operation prevents excessive heat damage. Regular highway driving maintains optimal operating temperatures compared to constant stop-and-go conditions that create frequent temperature cycling. These operational considerations are particularly important for vehicles operating in extreme climates or severe duty applications.

PCV system maintenance directly affects camshaft seal longevity by controlling crankcase pressures that stress all engine seals. Clogged PCV valves or restricted ventilation passages can create excessive pressure that forces oil past seals designed for normal operating conditions. Regular PCV system inspection and cleaning, typically performed during major tune-ups, helps maintain proper pressure management and extends seal life across the entire engine.

Professional inspection during routine maintenance provides early detection of seal deterioration before major failures occur. Experienced technicians can identify early signs of seal leakage, timing system contamination, or related component wear that indicates developing problems. Comprehensive maintenance approaches that address multiple systems simultaneously provide better long-term reliability than reactive repair strategies that wait for component failures.

Quality component selection influences long-term seal performance and reliability. OEM or OEM-equivalent seals provide proper materials and dimensional specifications for optimal performance, while generic aftermarket seals may use inferior materials or incorrect dimensions that lead to premature failure. Professional installation using proper tools and techniques ensures optimal seal performance and longevity, making the investment in quality service and components economically justified over the vehicle’s lifetime.

When to Seek Professional Help

Camshaft seal replacement requires specialized knowledge of engine timing systems that extends beyond basic mechanical aptitude. The procedure involves precision timing component handling, specialized tool requirements, and risk of catastrophic engine damage from timing errors. Professional technicians possess the training, tools, and experience necessary to perform this complex repair safely and efficiently while maintaining timing system integrity.

Diagnostic accuracy represents another critical advantage of professional service. Differentiating camshaft seal leaks from valve cover gaskets, timing cover gaskets, or other oil leak sources requires systematic inspection techniques and specialized knowledge. Misdiagnosis can lead to unnecessary repairs that don’t solve the underlying problem, while missed additional problems can result in repeat failures or related component damage.

Tool and equipment requirements for proper camshaft seal replacement often exceed DIY capabilities. Specialized timing tools, seal pullers, installation drivers, and torque measurement equipment represent significant investments that may not be economically justified for single-use applications. Professional shops maintain comprehensive tool inventories and have access to manufacturer-specific equipment that ensures proper repair procedures and optimal results.

Risk assessment favors professional service for most vehicle owners due to potential consequences of timing system errors. Incorrect timing belt or chain installation can cause valve-to-piston contact in interference engines, resulting in complete engine rebuilds costing $5,000-$15,000. This risk far exceeds the cost of professional repair, making expert service a prudent investment for preserving vehicle value and reliability.

Warranty considerations provide additional value through professional service channels. Reputable shops offer warranty coverage on parts and labor, providing protection against premature failure or installation defects. Professional diagnosis and repair also maintain vehicle warranty coverage and service history documentation that supports resale value. Understanding when professional consultation is necessary helps vehicle owners make informed decisions about repair approaches and service providers.

Modern vehicles with complex engine management systems may require specialized diagnostic equipment and software for proper timing system service. Professional shops maintain current diagnostic capabilities and technical information access that enables comprehensive repair and system verification. This technological advantage becomes increasingly important as vehicles incorporate more sophisticated engine control and timing systems.

Conclusion

The camshaft seal may be a small component, but its role in maintaining engine oil containment and protecting timing system integrity makes it critical for long-term engine health and reliability. Early recognition of failure symptoms—particularly oil leaks behind the timing cover and engine bay smoke—enables timely intervention before timing system contamination or severe oil loss occurs. Understanding the relationship between camshaft seals and timing belt service provides opportunities for cost-effective preventive maintenance that avoids emergency repairs.

Professional diagnosis and repair represent the recommended approach for most vehicle owners due to the complexity of timing system involvement and potential consequences of improper procedures. The specialized tools, technical knowledge, and experience required for safe camshaft seal replacement typically exceed DIY capabilities, making professional service a prudent investment in engine protection and reliability. When timing belt service intervals approach, combining seal replacement with comprehensive timing system maintenance provides optimal value and long-term reliability.

Regular maintenance practices including proper oil change intervals, PCV system service, and professional inspections during routine maintenance help maximize camshaft seal life and provide early detection of developing problems. Quality component selection and proper installation techniques ensure optimal performance and longevity, while timing correlation strategies minimize repair costs and maximize system reliability.

For vehicle-specific technical guidance and detailed repair procedures, consult the comprehensive manual resources available through Repairs Advisor, which provide manufacturer-specific information for accurate diagnosis and repair. When in doubt about symptoms, diagnostic procedures, or repair complexity, professional consultation ensures proper problem identification and optimal repair strategies that protect your engine investment and maintain vehicle reliability.

Remember that camshaft seal problems rarely occur in isolation—they often indicate broader timing system maintenance needs or related component wear that requires comprehensive evaluation. Taking a systematic approach to diagnosis and repair, with appropriate professional support when needed, ensures effective problem resolution and helps prevent future issues that could compromise engine performance and longevity.