The balance shaft belt is a critical but often overlooked engine component that plays a vital role in controlling engine vibration and ensuring smooth operation. This reinforced rubber belt connects the balance shaft to the crankshaft, enabling the sophisticated vibration dampening system that makes modern engines run smoothly and quietly.

Despite its importance, the balance shaft belt remains hidden from view behind the timing cover, making it impossible to inspect without significant engine disassembly. Understanding its function, recognizing failure symptoms, and maintaining proper replacement schedules can prevent catastrophic engine damage and costly repairs.

This comprehensive guide covers everything you need to know about balance shaft belts, from their critical role in engine operation to professional service requirements and cost considerations.

Safety Disclaimer: Balance shaft belt service involves complex engine timing components that require professional expertise, specialized tools, and precise procedures. This information is provided for educational purposes only. Always consult qualified automotive technicians for diagnosis, service, and repairs involving timing components.

Understanding the Balance Shaft Belt System

What Is a Balance Shaft Belt and How Does It Work?

The rubber balance shaft belt connects the balance shaft to the crankshaft, allowing the crankshaft to drive the balance shaft in precise synchronization with engine operation. This seemingly simple component serves a sophisticated engineering purpose: controlling the inherent vibrations that occur in internal combustion engines.

Balance shafts are counter-rotating components designed to cancel out the natural vibrations created by piston movement and combustion forces. As the crankshaft rotates, it drives the balance shaft belt, which in turn rotates the balance shafts at twice the crankshaft speed in opposite directions. This counter-rotation creates forces that oppose and neutralize engine vibrations, resulting in smoother, more refined engine operation.

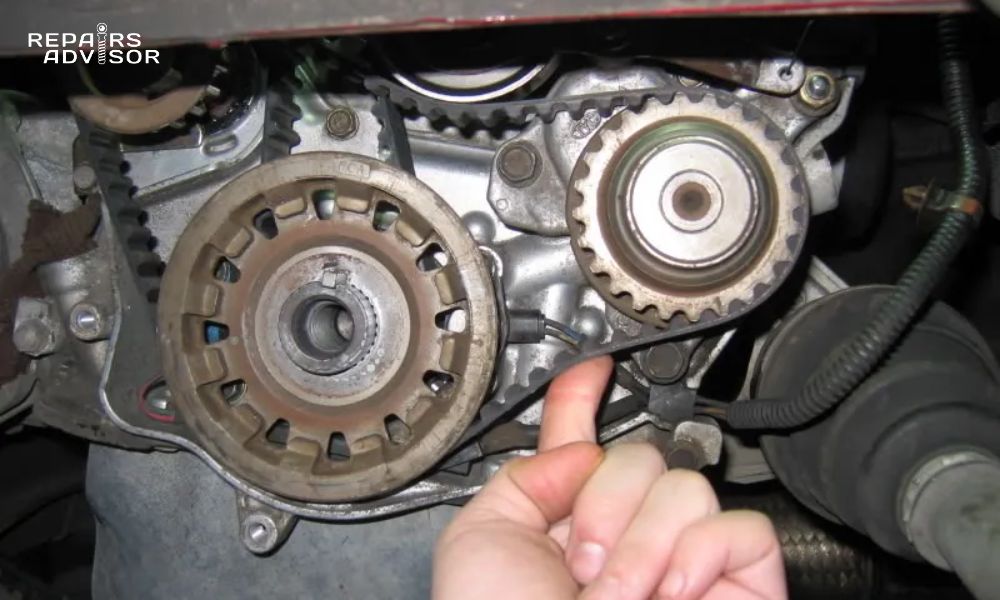

The balance shaft belt system includes several critical components working together. The belt tensioner maintains proper tension and alignment, ensuring consistent power transfer and preventing belt slippage. The pulley system provides the mechanical connection points, with precise timing relationships that must be maintained for proper vibration control.

Unlike external accessory belts that are easily visible and serviceable, the balance shaft belt operates within the engine’s internal timing system, protected by the timing cover but also hidden from routine inspection.

Balance Shaft System Components

Balance shaft construction involves precision-engineered counter-rotating shafts with weighted sections designed to create specific vibrational forces. These shafts must operate in perfect synchronization with the crankshaft to effectively cancel engine vibrations. Any disruption in this timing relationship compromises the system’s effectiveness and can lead to increased engine vibration and stress.

The belt tensioner mechanism provides proper tension throughout the belt’s service life. This tensioner must maintain consistent pressure as the belt stretches and wears over time. Unlike simple spring-loaded tensioners found in accessory belt systems, balance shaft belt tensioners often incorporate more sophisticated mechanisms to handle the precise timing requirements.

The pulley system includes the drive pulley on the crankshaft and driven pulleys on the balance shafts. These pulleys must maintain precise alignment and timing relationships. Any wear, damage, or misalignment in the pulley system can cause premature belt failure or timing disruption.

Understanding these components helps explain why balance shaft belt service is so complex and why professional expertise is essential for proper maintenance and repair.

Why Balance Shafts Are Critical for Engine Operation

Balance shafts serve as the primary vibration control system in many modern engines, particularly inline four-cylinder and V6 configurations that inherently produce significant vibrations. Without proper vibration control, engines would transmit uncomfortable vibrations throughout the vehicle, reducing refinement and potentially causing long-term damage to engine mounts, accessories, and other components.

The vibration control function directly impacts engine smoothness and driver comfort. Properly functioning balance shafts make the difference between a refined, smooth-running engine and one that feels rough and unbalanced. This is particularly noticeable at idle and during acceleration, where vibrations are most apparent.

The relationship between balance shaft operation and overall engine longevity cannot be overstated. When balance shafts function properly, they reduce stress on engine bearings, mounts, and accessories. However, when the balance shaft belt fails, the consequences extend far beyond simple vibration issues.

Without an operational balance shaft, your engine’s harmonics can become destructive, leading to serious damage to many different components. The increased vibration can cause accelerated wear of engine bearings, damage to motor mounts, and stress on the crankshaft itself. Over time, this vibration can damage the clutch, cause the crankshaft to fail, and affect the overall engine lifespan.

For comprehensive understanding of related engine components, review our detailed guide on Balance Shaft: Mitigating Engine Vibration for Smooth Operation for additional technical information about balance shaft systems.

Common Balance Shaft Belt Failure Symptoms

Early Warning Signs of Belt Problems

Increased engine vibration represents the most noticeable early symptom of balance shaft belt problems. This vibration is typically most apparent during idle, when the engine’s natural balance becomes more obvious without the masking effect of road noise and vehicle movement. Drivers may notice the steering wheel, seat, or entire vehicle vibrating more than usual, particularly when stopped at traffic lights or during warm-up periods.

If the balance shaft belt breaks, there may be strange rubbing or grinding noises from the front of the engine. These noises occur because a broken balance shaft belt can interfere with the timing belt operation, creating metal-to-metal contact and potentially causing serious damage to multiple engine components.

Rough engine operation becomes apparent as the balance shaft belt deteriorates or fails completely. The engine may feel less smooth during acceleration, idle roughly, or produce more vibration during normal operation. While the engine will continue to run, the increased vibration and roughness indicate that the balance shaft system is no longer functioning properly.

Dashboard warning indicators, particularly the check engine light, may illuminate when balance shaft belt problems affect engine sensors or timing relationships. Modern engine management systems monitor various parameters that can be affected by balance shaft belt failure, triggering diagnostic codes and warning lights.

Progressive Failure Symptoms

Balance shaft belt failure typically follows a predictable progression, starting with subtle symptoms that gradually worsen over time. In the initial stage, drivers may notice only a slight increase in engine vibration, particularly at idle. This early symptom is often dismissed as normal wear or attributed to other causes, allowing the problem to progress.

During the intermediate stage, noticeable noise and roughness become apparent. The engine operates less smoothly, and vibration becomes more pronounced during both idle and acceleration. Unusual noises from the engine compartment may become audible, particularly grinding or rubbing sounds that indicate belt degradation or failure.

Interestingly, when the balance shaft belts break, quite often people don’t notice as the engine doesn’t run really rough or anything, just a bit rougher than normal. This subtle change can lead drivers to continue operating the vehicle without realizing the potential for serious damage. The engine continues to run because balance shaft operation, while important for smoothness, is not essential for basic engine function.

Complete balance shaft belt failure creates the risk of timing belt damage and catastrophic engine failure. When the belt breaks completely, pieces can interfere with timing belt operation, potentially causing the timing belt to jump time or break entirely. This scenario can result in valve damage, piston contact, and complete engine failure requiring major rebuilds or replacement.

Dangerous Consequences of Ignoring Symptoms

The interaction between a failed balance shaft belt and the timing belt creates the most serious risk associated with balance shaft belt failure. This is because the timing belt is likely chewing through the balance shaft drive belt as it is likely resting on the teeth of the timing belt. This contact can cause the timing belt to stretch, skip teeth, or break completely, resulting in catastrophic engine damage.

Cascading damage occurs when balance shaft belt failure affects other engine components. If the belt fails on one balance shaft, it creates excess vibration in the engine, which can cause the bearings to fail in the other balance shaft, effectively damaging the oil pump and potentially leading to catastrophic engine failure. This progression demonstrates how a relatively simple belt failure can escalate to complete engine destruction.

The engine damage potential extends beyond immediate mechanical failure. Over time, increased vibration from balance shaft belt failure can damage the clutch in manual transmission vehicles, cause accelerated wear of the crankshaft and its bearings, and affect the overall engine lifespan through increased stress on all rotating components.

Understanding these consequences emphasizes why professional diagnosis and immediate attention are essential when balance shaft belt problems are suspected. For related engine timing component information, consult our guide on Camshaft: Spotting Camshaft Problems to understand the interconnected nature of engine timing systems.

Balance Shaft Belt Replacement Intervals and Maintenance

Manufacturer Replacement Schedules

Each manufacturer specifies the interval for balance shaft drive belt replacement for each model and year of vehicle produced. These intervals are typically aligned with timing belt service schedules, recognizing that both components operate in the same environment and experience similar wear patterns. Most manufacturers recommend balance shaft belt replacement every 60,000 to 100,000 miles, depending on the specific engine design and operating conditions.

The correlation between timing belt and balance shaft belt service intervals is no coincidence. Both belts operate behind the timing cover, experience similar heat and stress conditions, and require extensive disassembly for access. The best time to replace the balance shaft belt is during your timing belt replacement so you can catch it before it breaks and avoid the extensive labor costs of separate service appointments.

Typical service intervals reflect the engineering reality that rubber belts deteriorate over time regardless of mileage. Heat cycling, ozone exposure, and mechanical stress cause gradual degradation of the belt material. Even vehicles with low annual mileage should have balance shaft belts inspected and potentially replaced based on age rather than mileage alone.

Vehicle-specific variations in service intervals reflect different engine designs, operating environments, and manufacturer engineering philosophies. High-performance engines, diesel applications, and vehicles designed for severe service conditions may require more frequent balance shaft belt service. Always consult the specific service recommendations for your vehicle rather than relying on general guidelines.

Factors Affecting Belt Longevity

Heat exposure represents the primary enemy of balance shaft belt longevity. Balance shaft belts are made from reinforced rubber compounds that gradually deteriorate when exposed to the high temperatures generated by engine operation. The enclosed environment behind the timing cover traps heat and accelerates the aging process, causing the rubber to become brittle and prone to cracking.

Age-related deterioration affects all rubber components in the engine, and balance shaft belts are no exception. Like other rubber components such as cooling hoses and seals, balance shaft belts become brittle, crack, and eventually break due to age-related chemical changes in the rubber compounds. Even vehicles with low mileage can experience belt failure if the belt has exceeded its service life in terms of years.

Operating conditions significantly impact belt longevity. Vehicles operated in extreme temperatures, stop-and-go traffic, or high-stress conditions such as towing or mountain driving may experience accelerated belt wear. Frequent cold starts, extended idle periods, and aggressive driving patterns all contribute to increased heat generation and faster belt deterioration.

Quality considerations play a crucial role in belt longevity and performance. Original Equipment Manufacturer (OEM) belts are specifically engineered for each application and typically provide the best combination of durability and performance. Aftermarket belts may offer cost savings but could compromise longevity or performance if not manufactured to the same specifications as OEM components.

Inspection Challenges and Professional Assessment

The balance shaft belt is located behind the timing cover and cannot be inspected unless you remove the cover, which requires significant teardown. This hidden location makes routine inspection impossible and prevents early detection of belt deterioration. Unlike external accessory belts that can be visually inspected during routine maintenance, balance shaft belts remain hidden until major disassembly is undertaken.

Professional diagnosis becomes essential due to the belt’s inaccessible location. Removal of the timing or front cover is necessary for proper inspection, requiring specialized tools, extensive disassembly, and professional expertise. This inspection process is so involved that it’s typically more cost-effective to replace the belt based on service intervals rather than attempting to assess its condition.

The preventive replacement strategy makes economic and practical sense given the inspection challenges. Rather than waiting for symptoms of failure, which may not appear until catastrophic damage occurs, professional technicians recommend scheduled replacement based on mileage and age. This approach prevents the much higher costs associated with timing belt damage and potential engine rebuilds.

For comprehensive timing belt maintenance information, review our detailed guide on engine timing systems to understand the relationship between balance shaft belts and other critical timing components.

Balance Shaft Belt Replacement Process Overview

Professional Service Requirements

Since balance shaft belt replacement necessitates the removal of timing components, it is not recommended for the DIY mechanic to attempt this task. The complexity of this service goes far beyond simple belt replacement, involving precise timing procedures, specialized tools, and extensive knowledge of engine internal components. Any error in timing alignment or installation can result in serious engine damage.

A thorough knowledge of internal engine components, engine timing, accessory systems, and several specialty tools are required to properly perform this repair. Professional technicians must understand timing mark alignment, proper tensioning procedures, and the specific sequence required for component removal and installation. The precision required for this work demands professional training and experience.

Tool requirements extend far beyond basic hand tools to include specialized timing tools, dial indicators, torque measurement devices, and alignment fixtures. Many manufacturers require specific tools for proper timing belt and balance shaft belt installation. These tools are typically available only to professional shops and represent a significant investment that makes DIY attempts impractical.

Safety considerations are paramount when working with timing components. Improper installation can result in valve-to-piston contact, timing chain or belt failure, and complete engine destruction. The critical nature of timing component work means that any uncertainty or lack of proper tools and knowledge can result in catastrophic and expensive engine damage.

Replacement Procedure Overview

Component access represents the most challenging aspect of balance shaft belt replacement. At a minimum, replacement involves removal of the timing cover, balance shaft belt tensioner, balance shaft belt, and the balance shaft belt pulley. However, most vehicles require much more extensive disassembly to access these components properly.

Additional component removal may be necessary for complete access. This can include motor mount removal, engine cooling fans, radiator, and all engine accessories such as the alternator, air conditioning compressor, mounting brackets, coolant or fuel lines, and any other components that interfere with access to the timing cover or front cover. The extent of disassembly varies by vehicle design but is always significant.

Timing alignment procedures require absolute precision and professional expertise. All timing marks must be properly aligned, and the balance shaft timing must be synchronized with crankshaft position. Any error in timing alignment can result in engine damage ranging from poor performance to complete internal destruction. Professional technicians use specific procedures and tools to ensure proper timing throughout the installation process.

Quality control testing follows installation to verify proper operation and timing accuracy. The engine must be tested for proper operation and balance shaft timing before the vehicle is returned to service. This testing requires professional diagnostic equipment and expertise to ensure the repair was completed successfully.

Concurrent Service Recommendations

Since this service requires removal of the balance shaft belt and timing cover, it is recommended to replace the timing belt, water pump and possibly front seals at the same time, unless they have been recently serviced. The extensive labor required to access balance shaft belt components makes concurrent service of related components highly cost-effective.

Cost efficiency drives the recommendation for combined service. It is much more cost effective than returning for the same service after a partial service interval has elapsed. The labor overlap between timing belt service, water pump replacement, and balance shaft belt service makes combined service the most economical approach for vehicle owners.

Water pump service represents a logical concurrent replacement during timing cover removal. Most water pumps are driven by the timing belt and are easily accessible during balance shaft belt service. Since water pump failure can cause timing belt failure and engine damage, replacing both components simultaneously provides optimal reliability and value.

Seal replacement, particularly front crankshaft and camshaft seals, should be considered during balance shaft belt service. These seals are easily accessible during timing cover removal and their failure can contaminate new belts with oil, causing premature failure. Professional technicians typically recommend seal replacement as part of comprehensive timing component service.

Cost Analysis and Service Planning

Professional Service Cost Breakdown

Professional balance shaft belt replacement costs vary significantly based on vehicle complexity, regional labor rates, and concurrent services performed. Recent data shows considerable variation across different vehicle makes and models, reflecting the complexity and time requirements for this service.

Honda Accord balance shaft belt replacement costs average $411-576, reflecting the moderate complexity of Honda’s engine design and accessibility. This cost range includes both parts and labor for basic balance shaft belt replacement without concurrent services.

Mitsubishi Eclipse balance shaft belt replacement costs average $273-328, representing one of the more affordable applications due to relatively straightforward access and less complex timing systems. However, Mitsubishi engines are known for balance shaft problems that may require additional services.

Hyundai Sonata balance shaft belt replacement costs average $270-333, similar to the Mitsubishi application and reflecting modern engine designs that provide reasonable access to timing components. These costs represent baseline replacement without additional concurrent services.

Labor intensity accounts for the majority of balance shaft belt replacement costs due to extensive disassembly required. The actual belt cost represents a small portion of the total service cost, with labor typically accounting for 70-80% of the total expense. This high labor content makes timing the service appropriately crucial for cost control.

Factors Affecting Repair Costs

Vehicle complexity significantly impacts repair costs, with some engines requiring much more extensive disassembly than others. Transverse-mounted engines, tight engine compartments, and complex accessory layouts can substantially increase labor time and costs. European luxury vehicles and some performance applications may require significantly higher labor investment.

Concurrent services can dramatically affect total repair costs, but often provide excellent value when properly planned. Timing belt replacement, water pump service, coolant system maintenance, and seal replacement can be performed efficiently during balance shaft belt service, providing substantial savings compared to separate service appointments.

Regional labor rates create significant geographic variation in service costs. Urban areas with higher labor rates may see costs 25-50% higher than rural locations, while areas with limited qualified technicians may also command premium pricing. Shop reputation and certification levels also influence pricing.

Quality of parts affects both immediate costs and long-term value. Original Equipment Manufacturer (OEM) parts typically cost more than aftermarket alternatives but provide better durability and performance. The hidden nature of balance shaft belts makes quality particularly important, as premature failure requires repeating the expensive disassembly process.

Cost-Benefit Analysis of Preventive Service

Preventive replacement costs pale in comparison to emergency repair expenses when balance shaft belt failure causes timing belt damage or engine destruction. A $300-600 preventive replacement can prevent $3,000-8,000 in engine rebuild costs, making scheduled service an excellent investment in vehicle reliability and value.

Engine damage prevention represents the primary value of scheduled balance shaft belt service. When balance shaft belt failure causes timing belt problems, the resulting valve damage, piston contact, or complete timing failure can require complete engine rebuilds or replacement. These catastrophic failures often exceed the vehicle’s value, making prevention essential.

Long-term value protection through proper maintenance preserves the vehicle’s reliability, performance, and resale value. Vehicles with documented timing component service command higher resale prices and provide better long-term transportation value than those with deferred maintenance.

Service bundling benefits provide the most cost-effective approach to timing component maintenance. Combining balance shaft belt, timing belt, water pump, and seal service into a single appointment minimizes labor overlap and provides comprehensive timing system maintenance at substantial savings compared to separate services.

For vehicle-specific service information and technical specifications, consult our comprehensive manual collections including MITSUBISHI Manuals for detailed balance shaft belt service procedures.

Vehicle-Specific Applications and Considerations

Common Applications by Manufacturer

Mitsubishi engines, particularly the 4D56 diesel and related gasoline applications, are well-known for balance shaft belt issues and require special attention to service intervals and procedures. These engines have specific problems with balance shaft seizure that can lead to belt shredding and timing belt damage. Professional technicians familiar with Mitsubishi applications often recommend careful inspection of balance shaft operation during service.

Honda applications, including the Accord and other models with balance shaft systems, generally provide better access and more straightforward service procedures. Honda’s engineering typically results in more reliable balance shaft systems, but proper maintenance remains essential. The company’s timing belt service intervals usually coincide with balance shaft belt replacement recommendations.

Hyundai and Kia vehicles with balance shaft belts, including the Sonata and related platforms, represent modern applications with generally good reliability when properly maintained. These vehicles typically follow conventional service intervals and use readily available replacement parts. However, proper professional service remains essential due to the complexity of the timing systems.

Other manufacturers, including some Chrysler, Ford, and import applications, use balance shaft systems with varying levels of complexity and reliability. Each application requires specific knowledge of timing procedures, special tools, and service considerations that make professional expertise essential.

Engine-Specific Considerations

Diesel applications require particular attention to injection pump timing correlation and the relationship between balance shaft operation and fuel system timing. The balance shaft belt failure in diesel engines can affect injection timing, causing performance problems and potential engine damage beyond simple vibration issues. Professional service must address both balance shaft timing and injection pump synchronization.

Gasoline engines experience different stress patterns and service requirements compared to diesel applications. While generally less complex than diesel timing systems, gasoline engines with balance shaft belts still require precise timing procedures and professional expertise. The consequences of timing errors remain severe regardless of fuel type.

Performance applications and turbocharged engines operate in higher-stress environments that may require more frequent balance shaft belt service. Increased heat generation, higher operating speeds, and greater mechanical stress can accelerate belt deterioration and make scheduled service even more critical.

Commercial vehicles and fleet applications need specialized attention to balance shaft belt maintenance due to higher annual mileage and more severe operating conditions. Fleet maintenance programs should include balance shaft belt service as part of comprehensive timing component maintenance to prevent costly roadside failures.

Model-Specific Service Notes

Known problem areas affect certain engines more than others, with some applications prone to balance shaft seizure, timing belt interference, or premature belt failure. Professional technicians maintain databases of common problems and revised service procedures for problematic applications.

Manufacturer service bulletins provide updated procedures, revised service intervals, and solutions to known problems. These bulletins reflect real-world experience and engineering improvements that may differ from original service recommendations. Professional shops stay current with these updates to provide the best service.

Parts availability varies significantly between applications, with some requiring special-order components or having limited aftermarket options. Planning ahead for parts availability prevents service delays and ensures proper quality components are available when needed.

Special tools and procedures may be required for specific applications, making professional service even more essential. Some manufacturers require proprietary tools or specific alignment procedures that are available only through professional service channels.

For detailed model-specific information, consult our technical resources including HONDA Manuals and HYUNDAI Manuals for comprehensive service procedures and specifications.

Troubleshooting and Diagnostic Procedures

Professional Diagnostic Methods

Visual inspection requirements present the primary challenge in balance shaft belt diagnosis, as timing cover removal is necessary for belt assessment. Professional technicians must weigh the cost of diagnostic disassembly against preventive replacement based on service intervals. In most cases, the extensive labor required for inspection makes scheduled replacement more cost-effective.

Vibration analysis provides valuable diagnostic information about balance shaft system operation. Professional technicians use specialized equipment to measure engine vibration patterns and identify balance shaft problems. Specific vibration frequencies and patterns can indicate balance shaft belt problems, shaft bearing issues, or complete system failure.

Noise identification helps distinguish balance shaft belt problems from other engine issues. Grinding or rubbing noises from the front of the engine, particularly when combined with increased vibration, strongly suggest balance shaft belt problems. Professional technicians rely on experience and diagnostic techniques to differentiate balance shaft issues from timing belt, water pump, or accessory problems.

System correlation checking involves evaluating timing belt condition, tensioner operation, and related components that may be affected by balance shaft belt problems. Professional diagnosis considers the entire timing system rather than focusing solely on individual components.

Warning Signs Interpretation

Vibration patterns specific to balance shaft problems differ from those caused by engine mounts, accessories, or other sources. Balance shaft vibration typically increases with engine speed and is most noticeable at idle and during acceleration. Professional technicians can distinguish these patterns from other vibration sources through experience and diagnostic procedures.

Noise characteristics help identify the source and urgency of balance shaft belt problems. Grinding or rubbing sounds indicate immediate attention is required, while subtle changes in engine smoothness may suggest developing problems that require monitoring and scheduled service.

Performance changes, including rough idle, reduced smoothness, or increased vibration during specific operating conditions, provide clues about balance shaft system condition. Professional technicians correlate these symptoms with vehicle history and service records to determine appropriate action.

Dashboard indicators, particularly check engine lights triggered by timing-related codes, may indicate balance shaft belt problems affecting engine sensors or timing relationships. Professional diagnostic equipment can identify specific codes and correlate them with balance shaft system problems.

Risk Assessment and Urgency Levels

Immediate attention becomes necessary when grinding noises, severe vibration, or timing-related symptoms suggest balance shaft belt failure or imminent failure. These symptoms indicate high risk of timing belt damage and potential catastrophic engine failure. Professional service should be sought immediately to prevent major damage.

Scheduled replacement based on mileage and age represents the most cost-effective approach to balance shaft belt maintenance. Rather than waiting for symptoms that may not appear until damage occurs, preventive replacement during timing belt service provides optimal protection and value.

Emergency situations requiring immediate professional attention include any symptoms suggesting timing belt interference, complete balance shaft belt failure, or engine damage from balance shaft problems. Continued operation under these conditions can result in complete engine destruction requiring major rebuilds or replacement.

Professional consultation should be sought whenever balance shaft belt problems are suspected, timing component service is due, or unusual engine vibration or noise develops. The complexity and potential consequences of balance shaft belt problems make professional expertise essential for proper diagnosis and service.

For comprehensive engine diagnostic information, review our guide on Camshaft Position Sensor: Is Your Engine’s “Sense of Timing” Off? to understand timing system diagnostics and related sensor problems.

Safety Considerations and Professional Recommendations

Critical Safety Warnings

It is not recommended to drive a vehicle suspected of timing component damage, particularly when balance shaft belt problems are suspected. The risk of timing belt interference and catastrophic engine failure makes continued operation extremely dangerous from both mechanical and financial perspectives. Professional evaluation should be sought immediately when balance shaft belt problems are suspected.

Your engine will run without a balance shaft belt in place, but it is not recommended due to the increased vibration and potential for long-term damage. While the engine will continue to operate, the increased vibration can cause accelerated wear of engine components, damage to motor mounts, and potential clutch problems in manual transmission vehicles.

Professional service becomes necessary due to the complex timing work required for balance shaft belt replacement. The precision required for timing alignment, the specialized tools needed, and the potential for catastrophic engine damage make professional expertise essential. Attempting DIY replacement of balance shaft belts can result in timing errors that destroy engines.

Emergency procedures when balance shaft belt failure occurs include immediately stopping the vehicle safely, shutting off the engine, and arranging for professional service. Continued operation after balance shaft belt failure can result in timing belt damage and complete engine destruction that may exceed the vehicle’s value.

Professional Service Benefits

Timing accuracy provided by professional service ensures proper synchronization between all timing components. Professional technicians have the tools, knowledge, and experience necessary to maintain precise timing relationships that are critical for engine operation and longevity.

Quality assurance through certified technician expertise provides confidence that the repair will be completed correctly the first time. Professional shops typically offer warranties on both parts and labor, providing protection against premature failure or installation errors.

Complete system inspection during professional service often identifies related problems before they cause failures. Professional technicians evaluate the entire timing system, including timing belts, tensioners, water pumps, and seals, providing comprehensive maintenance that prevents future problems.

Long-term reliability results from professional installation using proper procedures, quality parts, and appropriate tools. Professional service provides optimal performance and durability, protecting the vehicle investment and providing reliable transportation.

Maintenance Planning and Prevention

Service scheduling should coordinate balance shaft belt replacement with timing belt maintenance to minimize costs and maximize value. Planning these services together prevents the need for separate disassembly and provides comprehensive timing system maintenance.

Warning sign monitoring helps identify developing problems before they become serious. Regular attention to engine vibration, noise, and performance changes can provide early warning of balance shaft belt problems that require professional attention.

Professional inspections during routine maintenance can identify potential timing component problems before they cause failures. While balance shaft belts cannot be easily inspected, professional technicians can evaluate related systems and recommend appropriate service timing.

Documentation of service history provides valuable information for future maintenance planning and supports warranty claims when necessary. Proper records demonstrate responsible maintenance and can enhance resale value.

For comprehensive engine system information and maintenance guidance, explore our Vehicle Systems & Parts Explained section for detailed technical resources and expert recommendations.

Conclusion

The balance shaft belt serves as a vital link in your engine’s vibration dampening system, providing the smooth, refined operation that modern drivers expect. Despite its critical importance, this hidden component often receives little attention until failure occurs, potentially causing catastrophic engine damage and expensive repairs.

Key takeaways for balance shaft belt maintenance:

- Professional service is essential due to the complex timing work and specialized tools required

- Preventive replacement during timing belt service provides optimal value and protection

- Ignoring symptoms can lead to catastrophic engine failure through timing belt interference

- Scheduled maintenance prevents expensive emergency repairs and protects your engine investment

The complexity of balance shaft belt replacement, combined with the severe consequences of failure, makes professional service the only safe and practical option. Attempting DIY replacement risks timing errors that can destroy engines, while ignoring maintenance schedules invites expensive failures that often exceed vehicle values.

Professional consultation is essential for proper diagnosis, service timing, and repair procedures. The hidden location behind the timing cover, precision timing requirements, and specialized tools make balance shaft belt service a job for qualified technicians with proper training and equipment.

Regular maintenance planning that coordinates balance shaft belt service with timing belt replacement provides the most cost-effective approach to timing system maintenance. This preventive strategy protects against catastrophic failures while minimizing service costs through efficient labor utilization.

For comprehensive technical information about balance shaft belts and related engine components, Repairs Advisor provides detailed service manuals and expert guidance to support professional technicians and educate vehicle owners about proper maintenance requirements.

Remember: Balance shaft belt service involves critical engine timing components that directly affect engine operation and safety. When symptoms develop or service intervals are reached, immediate professional consultation ensures proper diagnosis and prevents costly engine damage.

Contact Repairs Advisor at [email protected] for technical manual assistance or visit our Help Center for additional automotive maintenance resources and professional service support.