Your vehicle makes thousands of turns every day, and each time, something remarkable happens beneath your wheels. The outer wheel travels farther than the inner wheel, yet both remain powered and under control. This seemingly simple feat requires one of automotive engineering’s most elegant solutions: the differential. Without this crucial component, every turn would cause your tires to skip, scrub, and bind against the pavement, creating dangerous handling problems and rapid tire wear.

Understanding how differentials work reveals why this unassuming gearbox is essential to vehicle operation. Whether you’re navigating a parking lot or cornering on a highway, your differential continuously adjusts power delivery to match the demands of each wheel. This article explains differential operation from basic principles to advanced limited-slip designs, helping you recognize when maintenance is needed and when professional service becomes critical for safety.

What You’ll Learn:

- How differentials enable smooth cornering through variable wheel speeds

- The mechanical operation of ring gears, pinion gears, and spider gears

- Critical differences between open and limited-slip differential designs

- Maintenance intervals and fluid service requirements

- Warning signs of differential failure and when to seek professional help

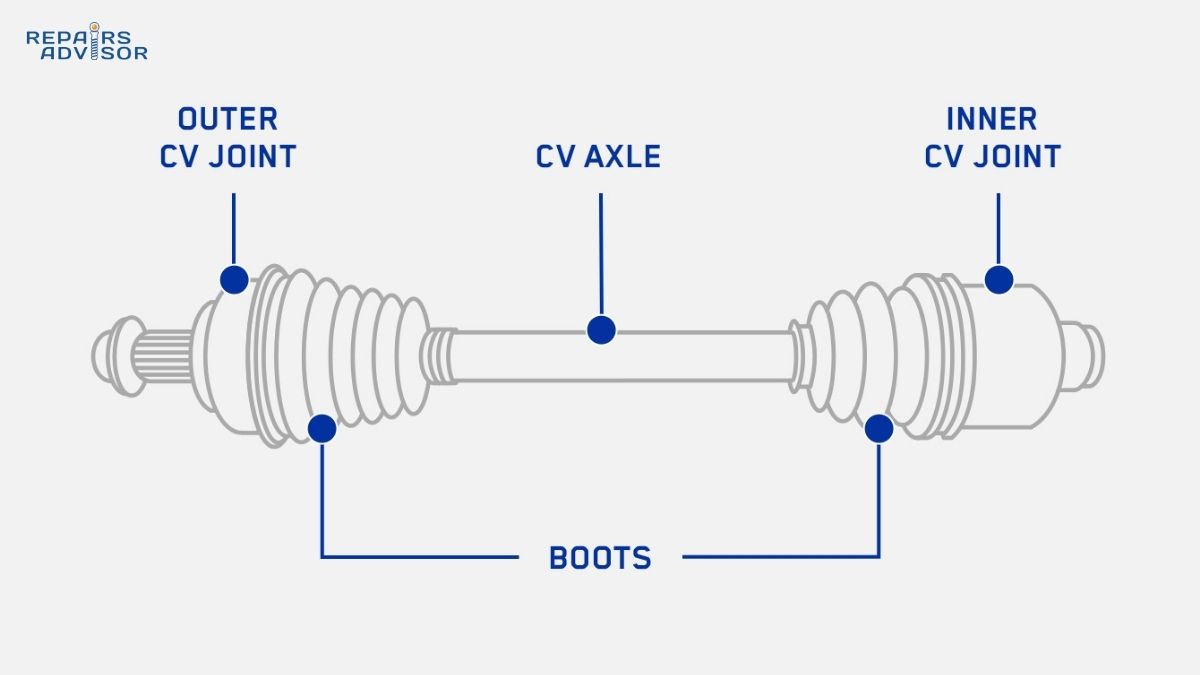

How CV Joints Work delivers power from the differential to your wheels, while How Drive Shafts Work explains the power transmission from your transmission to the differential itself.

Safety Warning: Differential service requires specialized tools, precise measurements, and technical knowledge. Incorrect installation or adjustment can cause catastrophic failure while driving, potentially resulting in loss of vehicle control. If you experience any differential problems—unusual noises, leaks, or handling issues—have your vehicle inspected by a qualified technician immediately.

What is a Differential? Core Components and Types

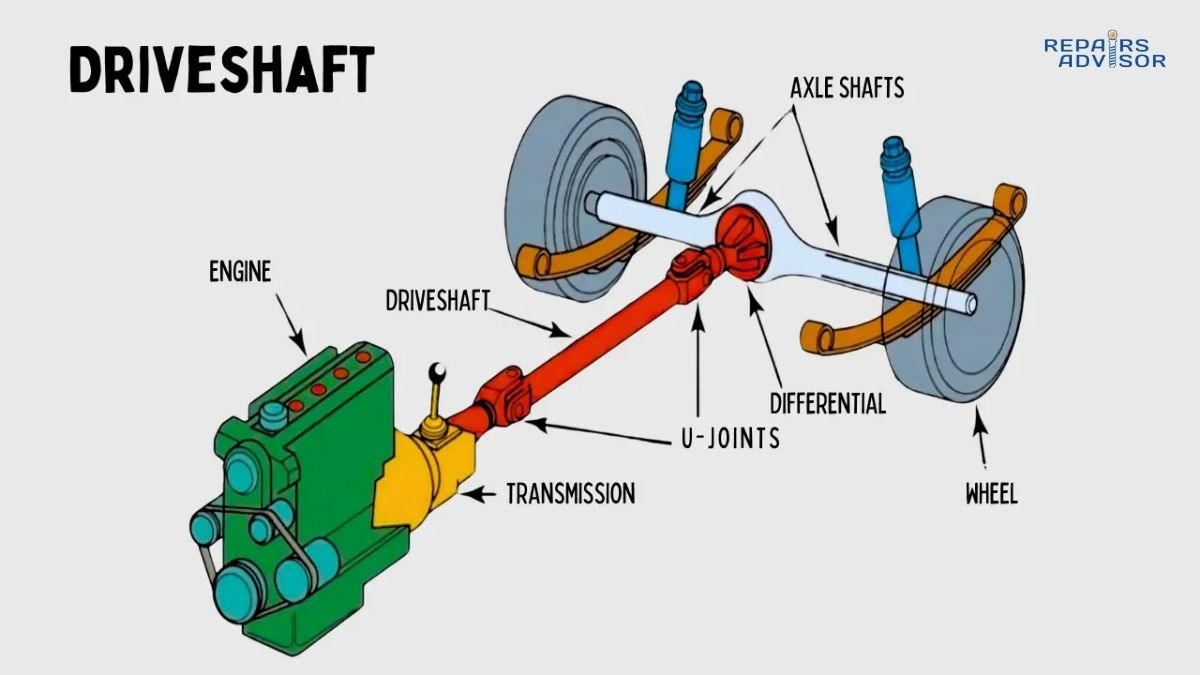

A differential is a mechanical gearbox that serves three critical functions in your vehicle’s drivetrain. First, it transfers rotational power from the engine and transmission to the drive wheels. Second, it allows those wheels to rotate at different speeds when necessary, which happens constantly during turns. Third, it provides the final gear reduction in the drivetrain, slowing the rotation speed from the transmission while multiplying torque to move the vehicle’s weight.

Located in the axle assembly between the drive wheels, the differential contains a precisely engineered system of gears that work together to split engine torque while permitting speed variation. Understanding the components and their interaction reveals how this relatively compact assembly accomplishes such complex tasks.

Core Differential Components

The ring gear (also called the crown wheel) is the largest component in the differential assembly, typically measuring 8 to 12 inches in diameter depending on vehicle size. This massive gear bolts directly to the differential case and serves as the primary input for power entering the differential. The ring gear’s teeth are precisely cut at an angle to mesh smoothly with the pinion gear, and the number of teeth on the ring gear compared to the pinion determines the final drive ratio—a critical specification affecting acceleration, fuel economy, and maximum speed.

The pinion gear is a much smaller gear located at the end of the driveshaft, positioned to mesh with the ring gear at a 90-degree angle. This perpendicular orientation is what allows the differential to change the direction of power flow from longitudinal (along the vehicle’s length) to transverse (across the vehicle’s width). The pinion gear is typically supported by two or three bearings and sealed to prevent lubricant leaks. Common final drive ratios range from 3.08:1 (economy-oriented) to 4.56:1 (performance or towing applications), with the ratio determined by dividing the ring gear teeth by the pinion gear teeth.

Inside the differential case sit the spider gears (also called planet gears or differential pinions). These smaller gears are mounted on a cross-shaped spider shaft that’s secured to the differential case. Most differentials use either two or four spider gears depending on the design’s torque capacity requirements. The spider gears don’t transmit torque directly to the wheels in normal operation; instead, they act as the mechanism that allows speed differentiation between the left and right wheels. When both wheels need the same speed, the spider gears simply orbit without rotating on their own axis. When wheel speeds must differ, the spider gears rotate to accommodate the speed variation.

The side gears (also called sun gears or output gears) connect directly to the axle shafts through splined connections. These gears mesh with the spider gears and are positioned on opposite sides of the differential case. Each side gear receives torque from the spider gears and transmits it through the axle shaft to its respective wheel. The side gears are what ultimately drive your vehicle forward, with the spider gears acting as intermediaries that allow the side gears to rotate at different speeds when necessary.

The differential case is the housing that contains all these internal gears and rotates as a single unit with the ring gear. Made from cast iron or nodular iron for strength, the case includes machined surfaces for bearings that support the entire assembly within the axle housing. The spider shaft fits through the differential case and is secured with a pin or bolt. When you see the differential rotating during operation, you’re watching the case, ring gear, and spider shaft all turning together while the gears inside adjust to provide the speed differences your wheels need.

Axle shafts extend from the side gears outward to the wheels, transmitting the final torque output from the differential. In semi-floating axle designs (common in passenger cars), these shafts also support the vehicle’s weight. In full-floating axle designs (typical in heavy trucks), the shafts only transmit torque while the axle housing and hub assemblies carry the vehicle’s weight. The splined connection between side gears and axle shafts allows for torque transmission while accommodating slight suspension movement.

Differential Location by Vehicle Type

Differential placement varies significantly based on drivetrain configuration, and understanding these differences helps when locating and servicing your vehicle’s differential. In rear-wheel drive vehicles, the differential sits between the rear wheels, housed in the rear axle assembly. Connected to the transmission through a long driveshaft, this configuration is traditional and offers excellent weight distribution for performance applications. The rear differential in these vehicles tends to be larger and heavier, as it must handle all the vehicle’s driving torque.

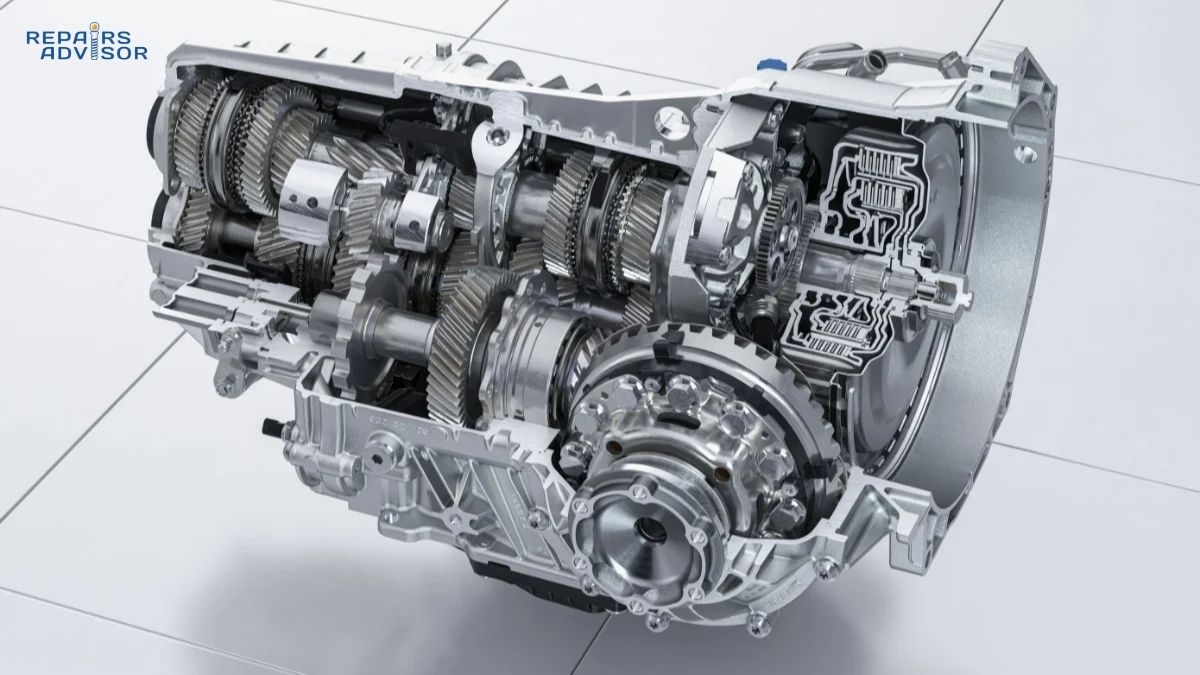

Front-wheel drive vehicles integrate the differential into the transaxle assembly, which combines the transmission and differential into a single compact unit. This packaging efficiency allows the entire powertrain to fit transversely (sideways) under the hood, maximizing passenger and cargo space. The front differential in these applications is typically smaller and operates at higher speeds than rear differentials due to different gear ratios in the transmission section.

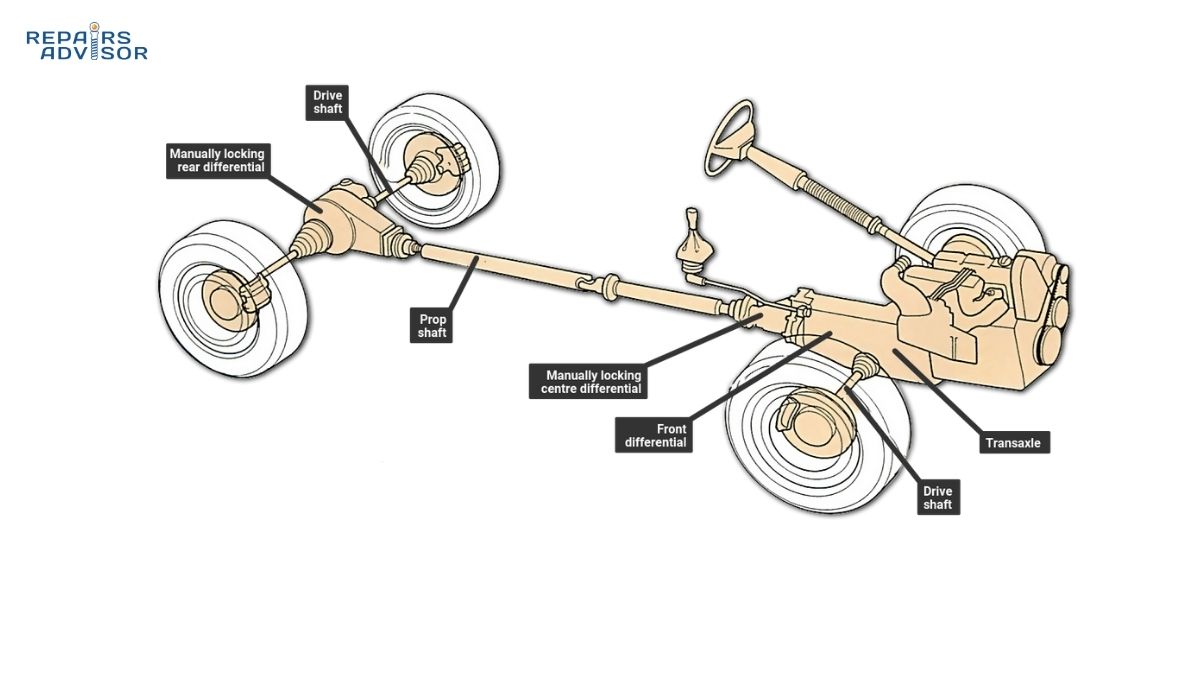

All-wheel drive and four-wheel drive vehicles employ multiple differentials to distribute power among all four wheels. How AWD Systems Work explains how these vehicles use a center differential (or transfer case) to split power between front and rear axles, with each axle having its own differential to distribute power between left and right wheels. This three-differential setup (front, center, rear) provides maximum traction capability but adds complexity and weight. How Transfer Cases Work details the 4WD-specific power distribution systems that allow drivers to select between two-wheel and four-wheel drive modes.

How Differentials Work: Step-by-Step Operation

The brilliance of differential operation becomes clear when you examine what happens during different driving scenarios. The same mechanical system that provides equal power distribution during straight-line driving seamlessly adapts to allow wheel speed variation during turns, all without any electronic controls or driver input.

Step 1: Straight-Line Driving

During normal straight-line driving on level pavement, both drive wheels encounter equal resistance and need to rotate at identical speeds. The driveshaft from the transmission spins the pinion gear, which meshes with and rotates the ring gear. Because the ring gear is bolted to the differential case, the entire case rotates as a single unit at a speed determined by the final drive ratio. For example, if the driveshaft spins at 1,500 RPM and the differential has a 3.50:1 ratio, the differential case rotates at approximately 429 RPM (1,500 ÷ 3.50).

Here’s where differential operation gets interesting. As the differential case spins, it carries the spider shaft and spider gears around in a circular orbit. However, because both wheels are providing equal resistance, the spider gears don’t rotate on their own axis—they simply orbit around inside the case like planets around the sun. This orbital motion pushes against both side gears equally, causing them to rotate at exactly the same speed as the differential case. Both axle shafts therefore turn at identical speeds, and both wheels rotate together in perfect synchronization.

The power flow follows this path: Engine → Transmission → Driveshaft → Pinion Gear → Ring Gear → Differential Case → Spider Gears (orbiting only) → Side Gears → Axle Shafts → Wheels. The torque splits exactly 50/50 between the two wheels, and because resistance is equal, speed remains equal. This is the differential’s neutral state, where it simply acts as a solid connection between the two wheels.

Step 2: Cornering Operation

When your vehicle enters a turn, the laws of geometry demand that the outer wheels travel a longer distance than the inner wheels. Consider a typical 90-degree turn in a parking lot: if your vehicle has a 60-inch track width (distance between left and right wheels) and turns with a 15-foot radius, the outer wheel must travel approximately 15% farther than the inner wheel to complete the same turn. Without a differential to accommodate this difference, one or both tires would be forced to skip, scrub, or slip across the pavement.

The differential responds automatically to this situation. As you turn the steering wheel and the vehicle begins cornering, the outer wheel encounters more resistance because it must accelerate to cover the longer arc. The inner wheel, traveling a shorter arc, encounters less resistance and tends to slow down. The spider gears, which were previously just orbiting without rotating, now begin to rotate on their own axis in response to these different resistance levels.

This rotation of the spider gears creates the magic of speed differentiation. As the spider gears turn, they effectively “walk around” the slower side gear while pushing harder against the faster side gear. The result: the outer wheel receives slightly more rotational speed while the inner wheel rotates slightly slower, yet both wheels continue to receive equal torque from the engine. The differential case continues rotating at its steady speed, but now the spider gears are spinning to distribute that rotation unevenly between the two side gears.

In practical numbers, imagine your vehicle turning left at 30 mph. The differential case might be rotating at a steady rate equivalent to 30 mph, but the spider gears adjust the output so the right (outside) wheel rotates at approximately 32 mph while the left (inside) wheel rotates at approximately 28 mph. The differential case speed of 30 mph represents the average of these two wheel speeds. The spider gears accommodate the 4 mph difference by rotating on their axis while continuing their orbital path.

This is why we call it a “differential”—it allows a difference in wheel speeds while maintaining equal torque distribution. The greater the turn radius or the wider the track width, the more speed difference the differential must accommodate. Sharp parking lot turns might create 10-15% speed differences, while gentle highway curves might only require 2-3% variation. The differential handles all these scenarios transparently, which is why you never notice it working during normal driving.

Step 3: Traction Loss Scenario

The same characteristic that makes differentials brilliant for cornering becomes a limitation when one wheel loses traction. Because the differential always splits torque equally between both wheels, the maximum torque either wheel can receive is limited by the wheel with the least traction. This fundamental principle of differential operation explains why vehicles with open differentials struggle on slippery or uneven surfaces.

Consider what happens when you’re stuck with one drive wheel on ice and the other on dry pavement. The wheel on ice requires very little torque to spin freely—perhaps only 50 pound-feet of torque overcomes the minimal friction between tire and ice. The differential, designed to always equalize torque, therefore sends 50 lb-ft to both wheels. The wheel on dry pavement, which could potentially use 300 lb-ft or more of available traction, receives only the same 50 lb-ft as the slipping wheel. The result: the wheel on ice spins uselessly while the wheel with traction sits motionless, and your vehicle remains stuck despite having one wheel on a perfectly good surface.

This limitation exists because of how the spider gears function. When one wheel spins freely (encountering almost no resistance), the spider gears rotate rapidly to accommodate the speed difference between the spinning wheel and the stationary wheel. However, the torque output remains equal because the spider gears are simply intermediaries—they don’t create or bias torque, they only allow speed differentiation while the ring gear’s input torque splits equally to both side gears.

Real-world impacts of this limitation appear in various situations beyond ice. When accelerating hard from a stop, weight transfers to the rear, potentially unloading one drive wheel enough to cause it to spin while the other wheel has traction. In off-road conditions, uneven terrain often lifts one wheel, eliminating its traction entirely. Performance enthusiasts experience this as “one-wheel burnouts” where only one tire leaves a stripe while the other remains stationary. Trucks with open differentials struggle when towing on gravel or in snow, as any traction imbalance immediately shows the differential’s limitation.

How Limited Slip Differentials Work explains the various solutions engineers have developed to overcome this traction limitation while maintaining the differential’s ability to allow speed variation during cornering. These enhanced designs use clutches, Torsen gears, or electronic controls to bias more torque toward the wheel with better traction.

Step 4: Heat Management and Lubrication

Every time the differential’s gears mesh, friction generates heat. During normal operation, gear oil temperatures typically reach 180-220°F, which is warm enough to require specialized lubricants. Under heavy loads—towing trailers, climbing steep grades, or sustained high-speed driving—temperatures can climb to 300°F or higher. Without proper lubrication and heat dissipation, these temperatures would quickly destroy the precisely machined gear surfaces.

Differential fluid serves multiple critical functions beyond simple lubrication. It must maintain adequate viscosity across a wide temperature range, from cold starts at sub-zero temperatures to peak operating temperatures exceeding 300°F. The fluid creates a thin protective film between gear teeth, preventing metal-to-metal contact that would cause rapid wear. It also carries heat away from the gear mesh, transferring it to the differential housing where it dissipates to the surrounding air. Finally, it suspends wear particles and prevents corrosion during storage.

The differential housing itself participates in heat management through its design. Cast iron or aluminum housings conduct heat from the internal components to the exterior surface, where airflow during driving helps cool the assembly. Some high-performance or heavy-duty differentials incorporate external cooling fins on the cover to increase surface area for heat dissipation. Synthetic differential fluids offer improved heat resistance compared to conventional oils, making them popular for towing and performance applications where temperatures regularly exceed normal operating ranges.

Bearing heat adds to the thermal load. The pinion bearings, ring gear carrier bearings, and side bearing all generate friction as they support rotating components under high loads. Proper bearing preload specification ensures these bearings operate efficiently without excessive friction, but they still contribute significantly to the differential’s overall heat generation. When differential bearings begin to fail, one of the first symptoms is often increased operating temperature due to the additional friction from worn bearing surfaces.

Understanding heat management explains why differential fluid condition matters so much to longevity. As the fluid ages, its ability to resist heat degrades. Oxidation from heat exposure breaks down the oil’s molecular structure, reducing its lubricating properties. Moisture contamination (which enters through normal breathing of the differential’s vent) lowers the fluid’s boiling point and promotes corrosion. The combination of degraded fluid and high operating temperatures accelerates gear wear, eventually leading to failure if not addressed through regular fluid service.

Open Differential vs Limited Slip Differential

The differential type installed in your vehicle fundamentally affects its performance characteristics, particularly in challenging traction conditions. While open differentials dominate passenger vehicle applications due to their simplicity and cost-effectiveness, limited-slip differentials offer significant advantages for specific driving needs. Understanding these differences helps you evaluate whether your vehicle’s differential matches your usage patterns.

Open Differential Characteristics

Open differentials represent the original and simplest differential design, using only the basic ring gear, pinion, spider gears, and side gears described earlier. With no additional friction devices, clutch packs, or locking mechanisms, open differentials rely purely on the mechanical interaction of these gears to provide differential action. This simplicity makes them inexpensive to manufacture, typically costing $200-400 for a replacement unit compared to $500-1,200 for limited-slip alternatives.

The advantages of open differentials extend beyond initial cost. Their straightforward design means fewer components to wear out, contributing to exceptional longevity. Many open differentials operate reliably for 150,000 miles or more with nothing more than periodic fluid changes. They provide smooth, predictable operation in normal driving conditions with no unusual noises or behaviors. Maintenance is straightforward—drain and fill the differential fluid every 30,000-60,000 miles depending on driving conditions, and the differential typically needs no other attention until extreme mileage or component failure occurs.

However, the traction limitations discussed earlier represent significant disadvantages in specific situations. Any condition that creates different traction levels between the drive wheels immediately reveals the open differential’s weakness. Single-wheel burnouts occur when one tire breaks traction during aggressive acceleration. Winter driving on snow or ice becomes challenging because any momentary loss of traction at one wheel sends all power to the spinning wheel while the wheel with grip remains stationary. Off-road capability suffers similarly—the moment one wheel lifts or encounters mud, all forward progress stops. Even on-road performance suffers; sports cars with open differentials struggle to put power down when exiting corners because weight transfer unloads the inside wheel.

These characteristics make open differentials ideal for daily commuter vehicles driven primarily on paved roads in moderate climates. They’re perfect for highway cruising, city driving, and any application where aggressive acceleration and low-traction conditions are rare. The vast majority of sedans, minivans, economy cars, and base-model trucks come equipped with open differentials because most drivers never encounter situations that reveal their limitations.

Limited Slip Differential Types and Operation

Limited-slip differentials (LSDs) address the traction limitation of open differentials by adding mechanisms that resist speed differences between the drive wheels. When one wheel begins to slip, the LSD applies resistance that redirects torque toward the wheel with better traction. Multiple designs accomplish this goal through different approaches, each with distinct characteristics.

Clutch-type LSDs add friction plates (similar to clutch discs in manual transmissions) between the differential case and the side gears. Spring preload presses these clutch packs together, creating a base level of resistance to speed differentiation. When one wheel begins to spin faster than the other, the clutch packs slip against each other, creating friction that limits how much speed difference can occur. The harder you accelerate, the more the side gear forces increase, which compresses the clutch packs tighter and increases the locking effect. This progressive characteristic means the differential behaves more like an open diff during gentle cruising but provides increasing lockup as power demands increase.

Clutch LSDs require special friction-modified differential fluid because the clutch plates must slip in a controlled manner. Using regular gear oil causes chattering—a rapid stick-slip action that creates an unpleasant growling noise during slow-speed turns. The friction modifier additives in LSD fluid create a controlled slip characteristic that allows smooth operation. These clutch packs do wear over time, typically lasting 60,000-100,000 miles before the differential begins acting more like an open unit as clutch material wears away. Rebuilding with new clutch packs restores performance.

Torsen (torque-sensing) differentials use helical gears instead of spider gears to create mechanical resistance to speed differentiation. The helical gear angles create wedging forces that bind when torque is applied, effectively biasing torque toward the slower-turning (higher traction) wheel. The beauty of Torsen design is its instant response with no slip required—the moment one wheel begins to spin faster, the helical gears bind proportionally to redirect torque. Torsen differentials typically offer torque bias ratios of 3:1 to 5:1, meaning if one wheel can handle 100 lb-ft of torque, the other wheel can receive up to 300-500 lb-ft depending on the design.

The mechanical nature of Torsen differentials means they require no special additives and produce no clutch wear. They operate silently and smoothly with longevity matching open differentials—150,000+ miles is typical. However, they’re more expensive to manufacture and offer less absolute locking than clutch types. If one wheel has truly zero traction (lifted off the ground or on ice), a Torsen can only multiply that zero traction by its bias ratio, still resulting in zero effective traction. Despite this mathematical limitation, Torsen differentials excel in most real-world conditions because one wheel rarely has absolutely zero traction.

Viscous LSDs use silicone fluid sealed in a chamber between sets of clutch plates. When speed difference occurs between the wheels, the silicone fluid shears between the plates, generating heat and thickening. This progressive engagement provides gentle limiting action proportional to the speed difference. However, viscous LSDs have fallen out of favor in modern vehicles due to several limitations: the silicone fluid can overheat and permanently lose its properties under sustained high loads, the system provides relatively weak locking compared to clutch or Torsen designs, and rebuilding requires specialized equipment. Some all-wheel drive systems still use viscous couplings for their center differentials, but they’re rare in individual axle differentials today.

Electronic LSDs don’t actually modify the differential itself. Instead, they use the vehicle’s anti-lock braking system to apply individual wheel braking, which simulates limited-slip action. When sensors detect one wheel spinning significantly faster than the other, the system applies brake pressure to the spinning wheel. This artificially creates resistance at that wheel, forcing the open differential to send more torque to the other wheel. Electronic systems integrate with stability control and can provide sophisticated torque vectoring capabilities. The limitation: brake-based systems can overheat the brakes during sustained use and can’t truly multiply torque the way mechanical LSDs can. However, they add virtually no cost or maintenance requirements since they use existing ABS hardware with modified software.

Performance Comparison and Selection

Traction capability varies dramatically between differential types. An open differential on mixed surfaces (one wheel on ice, one on dry pavement) might only deliver 15-20% of the engine’s available power to the ground because the slipping wheel determines the torque limit for both wheels. A clutch LSD in the same situation can typically transfer 60-70% of available torque to the ground, allowing forward motion despite the traction imbalance. A Torsen differential might achieve 50-60% delivery in this scenario. These numbers explain why limited-slip-equipped vehicles feel dramatically more capable in snow, mud, or spirited driving.

Maintenance requirements increase with limited-slip differentials. While open differentials tolerate 50,000-60,000 mile fluid change intervals in normal use, clutch LSDs benefit from more frequent service—every 15,000-30,000 miles for severe service (towing, track use, off-roading) or 30,000-50,000 miles for normal driving. The shorter intervals prevent clutch wear particles from accelerating deterioration and ensure the friction-modified additives remain effective. Torsen differentials follow similar fluid change intervals to open diffs since they generate no additional wear particles. Electronic LSDs require no additional maintenance beyond normal brake system service.

Cost considerations extend beyond initial purchase. A quality aftermarket open differential costs $200-400, while clutch LSDs range from $500-900 and Torsen units typically cost $800-1,200. Installation labor is similar for all types, but clutch LSDs may require more frequent rebuilds during the vehicle’s life, adding to lifetime costs. However, for drivers who regularly encounter the conditions where LSDs excel—winter weather, performance driving, towing, or off-roading—the improved capability easily justifies the additional expense.

How Manual Transmission Works and How Dual-Clutch Transmissions Work explain the clutch friction principles that make clutch-type LSDs possible, showing how similar technology applies throughout the drivetrain.

Differential Maintenance and Fluid Service

Differential maintenance centers almost entirely on fluid service, but the importance of this single maintenance task cannot be overstated. The differential operates in a sealed, harsh environment with extreme pressures, high temperatures, and constant contamination from gear wear. Proper fluid service ensures longevity, quiet operation, and reliable performance.

Differential Fluid Function and Specifications

Differential fluid must accomplish multiple demanding tasks simultaneously. It provides extreme-pressure lubrication for the hypoid gear mesh between the ring and pinion, where tooth contact creates pressures exceeding 100,000 PSI and temperatures hot enough to instantly destroy the gears without proper lubrication. The fluid must maintain a consistent protective film despite these extreme conditions, preventing metal-to-metal contact that would cause immediate failure.

Heat dissipation represents another critical fluid function. As friction generates heat throughout the differential, the fluid absorbs that thermal energy and carries it away from the gear mesh and bearings. The fluid circulates through the differential’s internal passages, transferring heat to the housing where it dissipates. Without adequate fluid level or fluid that’s degraded from age, this cooling capacity diminishes and temperatures climb into the danger zone.

The fluid must also suspend wear particles to prevent them from acting as abrasive contaminants. Every differential generates microscopic metal particles from normal gear wear. Quality differential fluid contains detergent and dispersant additives that keep these particles suspended in the oil, preventing them from settling and being recirculated through the gear mesh where they would accelerate wear. The magnetic drain plug in most differentials captures larger ferrous particles, providing additional protection.

Corrosion protection during vehicle storage is equally important. When the vehicle sits unused, residual moisture in the differential from normal breathing can cause rust on gear surfaces and bearings. Rust inhibitors in the fluid prevent this corrosion, ensuring the differential is ready for service after storage periods. This protection becomes especially critical for seasonal vehicles like RVs, convertibles, or classic cars that may sit for months.

Conventional gear oils meeting API GL-5 specifications provide adequate protection for most open differentials. These petroleum-based lubricants typically use viscosity grades of 75W-90 or 80W-140 depending on climate and application. Synthetic gear oils offer several advantages: better cold-weather flow for easier starts, superior high-temperature stability, longer service life, and improved fuel economy from reduced friction. Limited-slip differentials require either special LSD fluid or conventional gear oil with a limited-slip additive package. The friction modifiers in these fluids control clutch pack engagement for smooth, quiet operation.

Service Intervals and Procedures

Manufacturer-recommended service intervals vary significantly based on differential type and driving conditions. For open differentials in normal driving, most manufacturers specify fluid changes every 50,000-60,000 miles. Limited-slip differentials typically require more frequent service at 30,000-50,000 mile intervals because the clutch packs generate additional wear particles and friction modifiers degrade over time. Always consult your vehicle’s owner’s manual for specific recommendations, as intervals can range from as little as 15,000 miles for severe service to 100,000 miles or “lifetime fill” for some modern passenger cars.

Severe service driving dramatically accelerates fluid degradation and requires shorter service intervals. Manufacturer definitions of severe service typically include frequent trailer towing or heavy hauling, extensive off-road driving, track or performance use, operation in extremely hot or dusty climates, and frequent short trips where the differential never reaches full operating temperature. These conditions generate more heat, introduce more contaminants, or prevent the fluid from reaching temperatures where condensation evaporates. Under severe service conditions, change differential fluid every 15,000-30,000 miles regardless of differential type.

Many manufacturers recommend an early first fluid change at 12,000-15,000 miles, particularly for limited-slip differentials. This service removes initial break-in particulates—microscopic metal particles generated as new gears and bearings mate and polish their surfaces during the first thousands of miles. These break-in particles are larger and more abrasive than normal wear particles. Removing them early prevents them from accelerating wear during the differential’s most critical break-in period. This first service is especially important because it can significantly extend the differential’s lifespan for minimal cost.

Typical fluid capacities vary by vehicle size and differential design. Passenger car differentials typically hold 1.5-2.5 quarts of fluid. Light truck and SUV rear differentials usually require 2.5-3.5 quarts. All-wheel drive vehicles with front differentials may need 1.0-1.5 quarts for the front unit. Always verify the exact capacity in your vehicle’s service manual, as overfilling or underfilling can cause problems. Overfilling may create excessive pressure, leading to seal leaks, while underfilling leaves insufficient fluid to properly lubricate and cool the gears.

DIY Service Considerations and Professional Requirements

Intermediate DIY mechanics can safely perform basic differential fluid service on most vehicles with accessible differentials. The procedure involves raising and supporting the vehicle safely on jack stands, removing the drain plug to empty old fluid, removing the fill plug to add new fluid, and refilling to the proper level (typically until fluid reaches the bottom of the fill plug hole). Some differentials use a cover with gasket instead of a drain plug; these require removing the cover, cleaning old gasket material, and installing a new cover gasket with proper sealant.

However, several aspects of differential service absolutely require professional expertise and specialized equipment. Bearing adjustment involves precise preload measurements using inch-pound torque wrenches and dial indicators. Gear pattern setup requires special marking compound and expert interpretation to ensure the ring and pinion mesh correctly across the entire tooth face. Pinion depth adjustment demands micrometers and specialized gauges. Limited-slip clutch pack replacement requires proper clutch plate spacing and specific assembly procedures. Any of these internal services, if performed incorrectly, can cause catastrophic failure at highway speeds.

Safety cannot be overstated when discussing differential work. An improperly assembled differential can lock solid while driving, causing instant loss of vehicle control. Incorrect bearing preload can cause bearing failure, leading to complete destruction of the ring and pinion gears. Wrong gear mesh patterns create concentrated stress points that accelerate wear and eventually cause tooth breakage. The risk extends beyond the differential itself—sudden drivetrain failure at speed can cause loss of control, endangering vehicle occupants and others on the road.

For these reasons, limit DIY differential work to fluid changes, fluid level checks, and visual leak inspection. Any work involving internal components, bearing service, gear setup, or diagnosis of unusual noises should be performed by a professional technician with differential experience. The modest cost of professional service is insignificant compared to the consequences of improper differential assembly.

How Your Car’s Suspension Works relates to differential operation because suspension geometry affects how weight transfers during acceleration and braking, influencing traction available at each drive wheel.

Differential Problems: Symptoms and Diagnosis

Differential problems rarely occur suddenly without warning. Most differential failures develop gradually over thousands of miles, providing progressive symptoms that allow diagnosis and repair before catastrophic failure. Understanding these warning signs enables timely intervention that can prevent expensive damage and dangerous driving situations.

Common Failure Symptoms and What They Mean

Noise is typically the first indicator of differential problems, and the specific sound characteristics reveal much about the underlying issue. A whining or humming noise that changes pitch with vehicle speed typically indicates bearing wear. The pinion bearings, carrier bearings, or side bearings all generate characteristic whines as their rolling elements develop flat spots or the bearing races develop pitting. This noise often starts quietly and progressively worsens over several thousand miles. The pitch increases with vehicle speed because the bearings rotate faster, creating a direct correlation between speed and noise frequency.

Clunking noises during acceleration, deceleration, or when shifting between drive and reverse suggest damaged ring and pinion teeth or excessive backlash (the clearance between gear teeth when they’re not under load). Worn gear teeth develop flat spots or chips that create impacts as they mesh and unmesh. Excessive backlash allows the gears to slam together when torque direction changes, creating pronounced clunks. These noises are particularly noticeable during low-speed maneuvering in parking lots where the impacts are most audible.

Grinding sounds represent the most serious noise symptom, indicating severely worn gears or complete lack of lubrication. This metal-on-metal contact sound means gear teeth are being rapidly destroyed. If you hear grinding from your differential, stop driving immediately and have the vehicle towed. Continuing to drive with grinding differential noises can cause sudden catastrophic failure, potentially locking the drive wheels and causing loss of control.

Clicking noises specifically during turns often point to worn spider gears or side gears. As the differential allows speed differentiation during cornering, worn gears create rhythmic clicking that corresponds to the speed difference between inner and outer wheels. This clicking is typically more pronounced during slow, tight turns like parking lot maneuvers where the speed difference is greatest.

Howling or roaring sounds frequently indicate ring and pinion gear wear or misalignment. The hypoid gear mesh between ring and pinion creates a distinctive howl when the gear pattern is incorrect or when teeth are worn. This noise may be present during acceleration, deceleration, or both, depending on which side of the gear teeth is affected. Coast-side howl (during deceleration with your foot off the gas) versus drive-side howl (during acceleration) can help technicians diagnose whether the problem is wear or an incorrect gear pattern from previous service.

Performance symptoms accompany many differential problems. Vibration during acceleration, particularly if it intensifies as speed increases, often indicates an out-of-balance driveshaft or a differential with worn components causing irregular rotation. The vehicle pulling to one side during normal driving or braking may indicate uneven brake drag from a seized caliper, but it can also result from a differential problem that’s causing one wheel to receive more torque than the other. Difficulty steering or unusual handling during turns sometimes traces back to differential issues affecting wheel speed control. How Disc Brakes Work helps distinguish between brake-related and differential-related pulling.

Visual symptoms are equally important. Differential fluid leaks appear most commonly at the pinion seal (where the driveshaft enters the differential) or at the differential cover gasket. Fresh leaks show wet, oily residue, while older leaks accumulate dirt and road grime. A burnt smell after driving, particularly after climbing long grades or towing, indicates the differential has overheated. This overheating may result from low fluid level, degraded fluid, or internal damage creating excessive friction.

Inspecting the differential cover’s magnetic drain plug during fluid service provides valuable diagnostic information. All differentials generate some fine metallic powder from normal gear wear—this is expected. However, large chunks of metal, bearing rollers, or gear teeth fragments indicate serious internal damage. The size, amount, and type of material on the drain plug helps technicians assess the extent of damage and determine whether the differential requires rebuild or replacement.

Excessive tire wear, particularly uneven patterns like severe inside or outside edge wear, can result from differential problems affecting wheel alignment or creating unequal torque distribution. While tire wear has multiple causes, don’t overlook the differential as a contributing factor if other causes have been ruled out. Reduced fuel economy sometimes accompanies differential problems when internal damage creates drag, forcing the engine to work harder to maintain speed.

Diagnosis Process and Common Failure Causes

Professional diagnosis typically follows a systematic approach. The technician begins by identifying when the noise or symptom occurs: during acceleration, deceleration, cornering, or steady cruising? Does it change with speed, load, or turning direction? These characteristics narrow the possible causes significantly. A thorough visual inspection checks for leaks, impact damage to the differential housing, torn CV joint boots, and fluid condition.

A test drive evaluation allows the technician to hear noises under actual driving conditions and note when they occur. Professional technicians can often diagnose specific component failures based solely on noise characteristics, timing, and pitch. Straight-line acceleration noise versus cornering noise, for example, points to different components within the differential.

Fluid analysis during scheduled service or when diagnosing problems provides crucial information. Draining the fluid and inspecting it for metal particles, checking the magnetic drain plug for excessive material, and assessing the fluid’s color and smell all contribute to diagnosis. Dark, burnt-smelling fluid indicates overheating. Milky or grayish fluid suggests water contamination from a failed seal. Fluid with metallic glitter suspended throughout (beyond fine powder) indicates active wear of major components.

Common causes of differential failure fall into several categories. Lack of proper maintenance leads the list—contaminated or degraded fluid, low fluid level from unrepaired leaks, and extended service intervals beyond recommendations all accelerate wear. Even differentials with quality designs cannot withstand the effects of running with insufficient or contaminated lubrication.

Abuse and overload destroy many differentials prematurely. Towing beyond the vehicle’s rated capacity, aggressive launches and burnouts, shock loads from off-road driving, and track use without proper cooling all subject the differential to forces beyond its design parameters. The ring and pinion gears can handle only so much torque; exceed their limits repeatedly, and tooth breakage becomes inevitable.

Normal wear items eventually require attention even with perfect maintenance. The pinion seal, which seals the driveshaft entry point, is the most common leak source. These seals typically last 100,000-150,000 miles before the seal lip wears and allows leakage. Bearings wear over time from millions of rotations. The ring and pinion gears slowly wear from constant meshing under load. These are expected age and mileage-related failures, not true “problems,” but they still require service.

Installation errors from previous differential service cause many premature failures. Incorrect gear pattern setup creates concentrated contact patches that accelerate wear. Wrong pinion depth causes edge loading that quickly destroys gear teeth. Improper bearing preload leads to either excessive friction (too tight) or bearing damage from inadequate support (too loose). Missing, wrong, or improperly installed shims can affect multiple setup parameters. This is why differential work demands professional expertise—the consequences of errors are severe.

When to Seek Professional Help

Certain symptoms demand immediate professional attention. Any grinding or severe clunking noises require immediate inspection before the problem escalates. Stop driving and have the vehicle towed if grinding is present—continuing to drive risks catastrophic failure. Sudden fluid leaks, particularly if the fluid level drops significantly, can cause rapid damage from inadequate lubrication. If the vehicle won’t move properly in one or both directions, the differential has likely suffered major internal damage requiring immediate diagnosis.

Other symptoms warrant planned professional service rather than emergency response. Bearing noise (whining or humming) that develops gradually can typically be driven cautiously until convenient to schedule service, though delaying too long risks the bearing disintegrating and causing collateral damage. Small fluid leaks at the pinion seal or cover gasket don’t require immediate emergency service, but they should be repaired soon to prevent fluid level from dropping to dangerous levels. Limited-slip differentials that begin chattering during turns need service to replace worn clutch packs or update to proper friction-modified fluid.

DIY-appropriate tasks remain limited to basic maintenance and inspection. Intermediate mechanics can handle fluid level checks, routine fluid changes on accessible differentials, and visual inspection for leaks or damage. However, any work beyond fluid service requires professional expertise. Internal differential work, bearing replacement, gear setup, seal replacement (which affects bearing preload), and any diagnosis of unusual noises should be performed only by qualified technicians with differential experience and proper equipment.

How Wheel Bearing Systems Work and How Ball Joints Work cover other drivetrain components that can produce symptoms similar to differential problems, making professional diagnosis important for correct repairs.

Conclusion

The differential stands as one of automotive engineering’s most elegant solutions to a complex problem. By allowing drive wheels to rotate at different speeds while maintaining equal torque distribution, differentials enable smooth cornering, predictable handling, and proper tire wear. Whether your vehicle has a simple open differential or a sophisticated limited-slip design, understanding how these components work helps you maintain them properly and recognize when problems develop.

Key Maintenance Takeaways:

- Follow manufacturer service intervals for fluid changes—typically 30,000-60,000 miles for open differentials, 15,000-30,000 miles for limited-slip designs under severe service

- Use the correct fluid type and additives, particularly friction modifiers for limited-slip differentials

- Address leaks promptly to prevent low fluid levels that can cause rapid damage

- Consider early first service at 12,000-15,000 miles to remove break-in particles

- Inspect the magnetic drain plug during fluid changes for excessive metal particles

Recognizing Problems Early: Differential problems rarely occur without warning. Listen for unusual noises like whining (bearings), clunking (gear damage), or grinding (severe wear). Watch for fluid leaks at the pinion seal or cover gasket. Notice any pulling, vibration, or handling changes. These early warning signs allow diagnosis and repair before catastrophic failure occurs. The cost of catching problems early—often just bearing or seal replacement—is insignificant compared to the expense of rebuilding or replacing an entire differential after complete failure.

Professional Consultation Guidelines: While intermediate DIY mechanics can safely perform fluid service and basic inspection, differential work demands strict boundaries between DIY-appropriate and professional-only tasks. Fluid changes, level checks, and visual leak inspection fall within DIY capabilities for those with proper tools and mechanical aptitude. However, any internal differential work, bearing service, gear setup, seal replacement affecting bearing preload, or diagnosis of unusual noises requires professional expertise. The specialized knowledge, precise measurements, and specific tools needed for proper differential assembly are beyond typical DIY capabilities.

Final Safety Note: Differential failures can occur suddenly while driving, causing immediate loss of vehicle control. A differential that locks solid at highway speeds can instantly lock the drive wheels, creating a situation similar to emergency braking with locked wheels. Never ignore warning signs like unusual noises, vibrations, leaks, or handling changes. Have your differential inspected by a qualified technician at the first indication of problems. The inconvenience and cost of early diagnosis and repair is trivial compared to the potential consequences of catastrophic failure while driving.

Your differential works constantly, every time you turn your steering wheel. With proper maintenance and attention to warning signs, these robust components typically provide reliable service for 150,000 miles or more. Understanding how they work and what they need empowers you to maintain them properly and ensure they continue performing their crucial role in your vehicle’s drivetrain.

Related Systems: How Rack and Pinion Steering Works explains the steering control that determines when your differential must accommodate wheel speed differences during turns. How Control Arms Work covers the suspension components that maintain proper wheel position and allow the differential to effectively transfer power to the road surface.