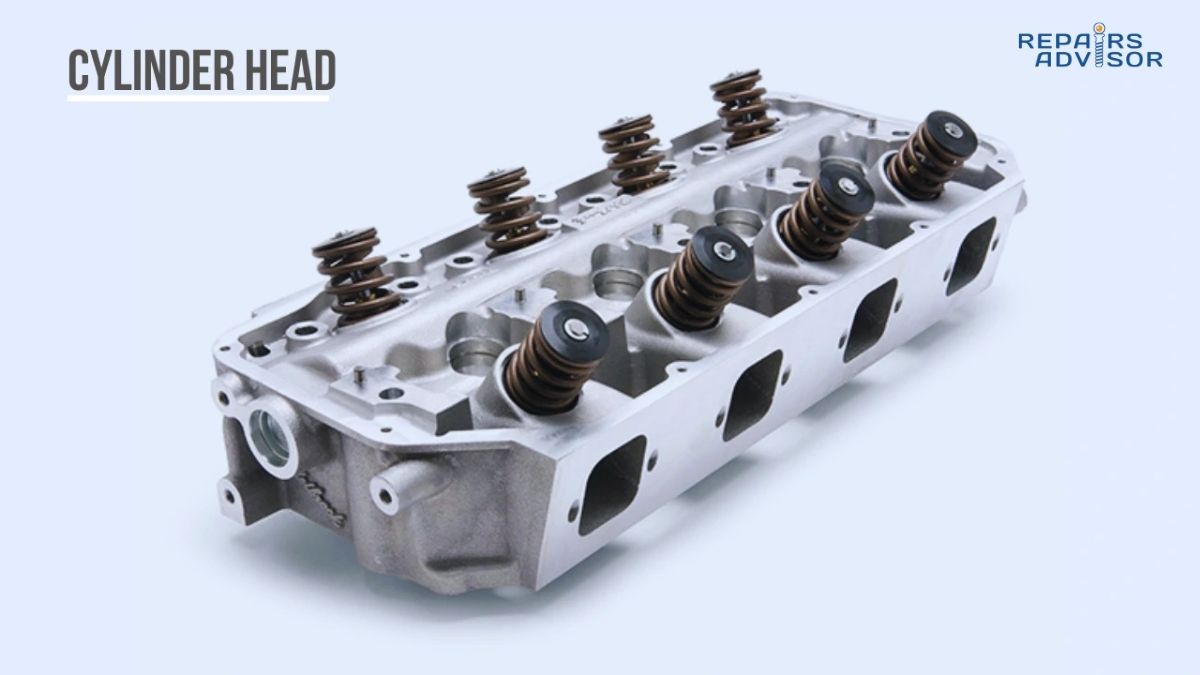

The cylinder head is the critical upper component of your engine that houses the combustion chamber, valves, and valve train components. This precisely engineered casting forms the top of each engine cylinder and plays a vital role in controlling airflow, fuel delivery, and exhaust gas removal. Modern cylinder heads integrate complex port designs, cooling passages, and valve mechanisms that directly impact engine performance, efficiency, and emissions control.

Quick Facts:

- Function: Houses combustion chambers, valves, and valve train components

- Location: Bolted to the top of the engine block

- Materials: Cast iron or aluminum alloy construction

- Service Life: 150,000+ miles with proper maintenance

- Failure Impact: Complete engine shutdown, overheating, or performance loss

Safety Note: Cylinder head repairs involve high-temperature components and pressurized cooling systems. Always allow engines to cool completely and follow manufacturer safety procedures. Professional consultation is recommended for major cylinder head service or replacement.

Why Cylinder Head Is Critical for Engine Performance

The cylinder head serves as the engine’s breathing apparatus and combustion chamber roof, making it absolutely essential for engine performance and reliability. This complex casting must withstand extreme pressures and temperatures while precisely controlling the four-stroke engine cycle through its integrated valve system and combustion chamber design.

Performance Impact: The combustion chamber shape and size directly influence compression ratio, fuel mixing, and flame propagation. Port design affects airflow velocity and turbulence, while valve seat angles and timing control the engine’s ability to breathe efficiently. These factors collectively determine power output, fuel economy, and emission levels.

System Integration: Every cylinder head works in perfect coordination with the engine block, forming the sealed combustion space where fuel and air mix, ignite, and expand. The valve train components housed within the head – including valves, springs, and camshaft systems – must operate with precision timing to ensure proper engine breathing and performance.

Consequences of Failure: A damaged cylinder head can cause coolant leaks, compression loss, valve problems, or complete engine failure. Common symptoms include overheating, white exhaust smoke, coolant consumption, rough idle, and loss of power. These issues require immediate attention to prevent catastrophic engine damage.

The combustion chamber design within the cylinder head is particularly critical, as it determines how efficiently the air-fuel mixture burns and how much heat is generated during combustion.

Cylinder Head Parts and Construction Explained

Modern cylinder heads are precision-engineered castings that integrate multiple critical engine systems into a single, complex component. The basic structure consists of the main casting with machined surfaces, cooling passages, and mounting points, but the internal architecture is where the engineering complexity becomes apparent.

Primary Structure: The main casting forms the combustion chamber walls and houses all internal components. Cast iron heads offer durability and heat resistance, while aluminum heads provide better heat dissipation and weight savings. The deck surface must be perfectly flat and smooth to ensure proper head gasket sealing with the engine block.

Intake Ports: These carefully shaped passages direct the air-fuel mixture from the intake manifold to the combustion chamber. Port design includes runner length, cross-sectional area, and internal surface finish – all optimized for specific engine operating ranges. Straight ports favor high-RPM power, while curved ports enhance low-speed torque through improved air velocity.

Exhaust Ports: These passages channel burnt gases from the combustion chamber to the exhaust manifold. Exhaust ports must handle extreme temperatures while maintaining smooth gas flow. The port design affects exhaust scavenging, which influences engine breathing efficiency and power output.

Coolant Galleries: An intricate network of passages allows coolant to circulate around the combustion chambers and valve seats, removing excess heat. These galleries must be precisely sized to ensure adequate cooling without restricting coolant flow to other engine components.

Valve Seats and Guides: Precision-machined or pressed-in components that control valve sealing and movement. Valve seats provide the sealing surface for intake and exhaust valves, while guides control valve stem movement and prevent oil consumption.

Quench Areas: The flat surfaces around the combustion chamber that come close to the piston at top dead center. These areas help control combustion knock by rapidly cooling the end gases and promoting efficient flame propagation across the combustion chamber.

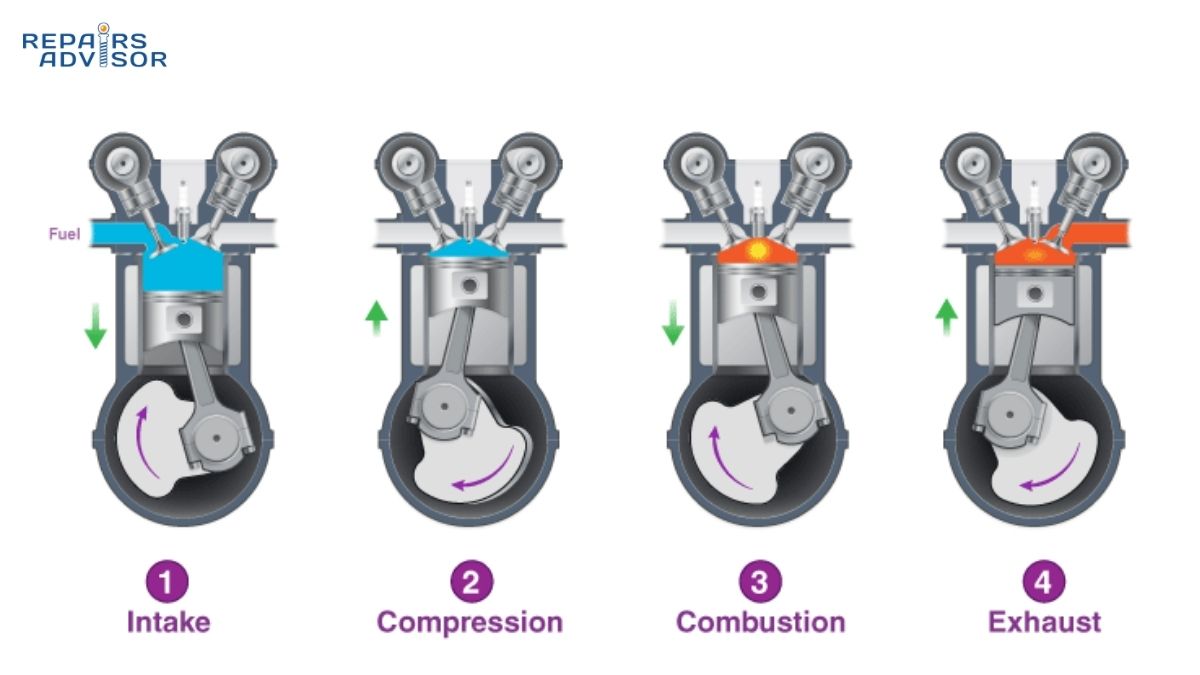

How Cylinder Head Works: Step-by-Step Operation

The cylinder head orchestrates the complex four-stroke engine cycle through precise coordination of its valve system, combustion chamber design, and cooling network. Understanding this operation reveals how this single component enables engine power production while managing extreme thermal and mechanical stresses.

Step 1: Intake Stroke Operation

During the intake stroke, the intake valves open while the piston moves downward. The combustion chamber shape and intake port design create specific airflow patterns as the air-fuel mixture enters. Port design determines flow velocity and turbulence, while the combustion chamber geometry begins conditioning the mixture for optimal burning. The valve seats must seal perfectly when closed to maintain compression, while the valve guides ensure precise valve movement throughout the cycle.

Step 2: Compression and Combustion Control

As the piston rises during compression, the cylinder head’s combustion chamber shape becomes critical. Quench areas around the chamber perimeter cool the end gases to prevent knock, while swirl chambers may induce air motion for better fuel mixing. The compression ratio – determined by combustion chamber volume – directly affects power output and efficiency. When ignition occurs, the chamber design influences flame propagation speed and combustion completeness.

Step 3: Exhaust Stroke Management

During the exhaust stroke, exhaust valves open to allow burnt gases to escape through the exhaust ports. Port design affects scavenging efficiency – the ability to remove exhaust gases completely while potentially drawing in fresh mixture. The timing and duration of valve events, controlled by the camshaft system housed in or operated by the cylinder head, determines how effectively the engine breathes.

Step 4: Thermal and Pressure Management

Throughout all four strokes, the cylinder head must manage extreme conditions. Coolant galleries remove heat from critical areas like valve seats and combustion chamber walls. Oil passages lubricate valve train components and provide additional cooling. The head gasket sealing surface must maintain perfect sealing despite thermal expansion and combustion pressures exceeding 1,000 psi.

Real-Time Integration: Modern cylinder heads incorporate variable valve timing systems, integrated exhaust manifolds, and sophisticated cooling circuits. Electronic controls may adjust valve timing based on engine load and speed, while thermal management systems maintain optimal operating temperatures across varying conditions.

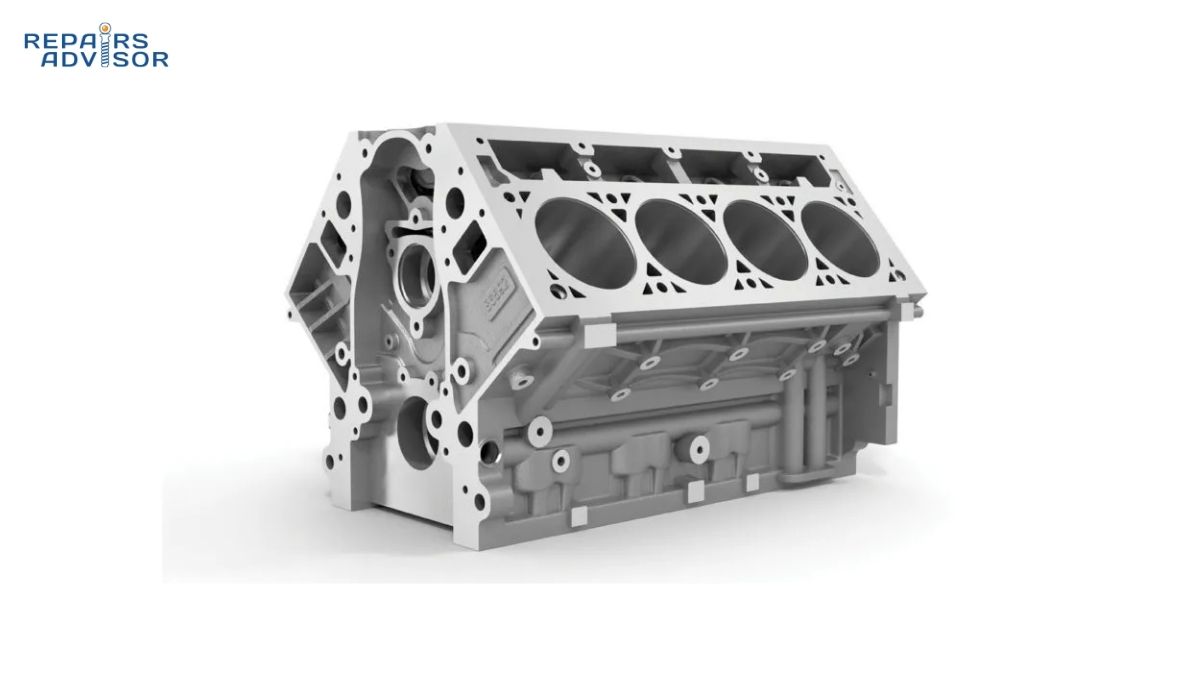

Cylinder Head Location and Access Guide

The cylinder head sits prominently at the top of the engine, making it one of the most visible major engine components. However, accessing internal components for service requires understanding the complex assembly of parts that must be removed in proper sequence.

Primary Location: Cylinder heads bolt directly to the top of the engine block, forming the upper boundary of each cylinder. On inline engines, you’ll find a single head covering all cylinders, while V-configuration engines have separate heads for each bank. The heads are secured with head bolts that must be torqued in specific sequences to prevent warping.

Visual Identification: Look for the largest casting at the top of the engine, typically featuring the valve covers on top, intake manifold on one side, and exhaust manifold on the other. Spark plugs thread directly into the cylinder head, and coolant hoses connect to various points. The casting usually displays manufacturer logos, part numbers, and sometimes displacement markings.

Access Requirements: Basic inspection requires only the removal of the valve cover and some peripheral components. However, cylinder head removal is a major service requiring engine support, timing component removal, and disconnection of all attached systems. Special tools include head bolt sockets, torque wrenches, and often specialized pullers for press-fit components.

Vehicle Variations: Front-wheel-drive engines often require more complex access due to transverse mounting and space constraints. Rear-wheel-drive vehicles typically provide better access from above. All-wheel-drive systems may require additional component removal for clearance. Hybrid vehicles add electrical safety considerations with high-voltage systems near the engine bay.

Safety Considerations: Cylinder heads operate at extreme temperatures – allow complete cooling before service. Cooling system pressure must be released safely to prevent injury from hot coolant. The cylinder head is heavy (50-100+ pounds) and requires proper lifting techniques or equipment. Always support the engine when removing heads to prevent damage to engine mounts.

Professional Service Requirements: Cylinder head service often requires precision measuring equipment, surface grinding capabilities, and specialized assembly techniques. Valve seat cutting, pressure testing, and head bolt replacement typically exceed DIY capabilities and require professional machine shop services.