Your steering wheel vibrates slightly when you accelerate. There’s a subtle clunking sound over bumps that wasn’t there before. Your car seems to wander on the highway, requiring constant correction. These seemingly minor annoyances often point to a single culprit: worn control arm bushings.

These small rubber or polyurethane components rarely get the attention they deserve, yet they play a critical role in how your vehicle handles, rides, and responds. Control arm bushings are the unsung heroes of your suspension system, quietly absorbing thousands of impacts and vibrations every day. When they fail, the effects ripple through your entire driving experience.

Understanding how control arm bushings work helps you recognize problems early, make informed repair decisions, and choose the right replacement materials for your driving needs. This guide explains the mechanical function of these essential components, compares different bushing materials, identifies failure symptoms, and provides practical guidance on replacement costs and professional consultation.

Whether you’re diagnosing a handling issue, planning suspension maintenance, or simply curious about what’s connecting your control arms to your chassis, you’ll find the answers here. We’ll cover everything from basic bushing design to advanced material selection, with specific attention to when DIY approaches make sense and when professional expertise becomes essential.

What Are Control Arm Bushings?

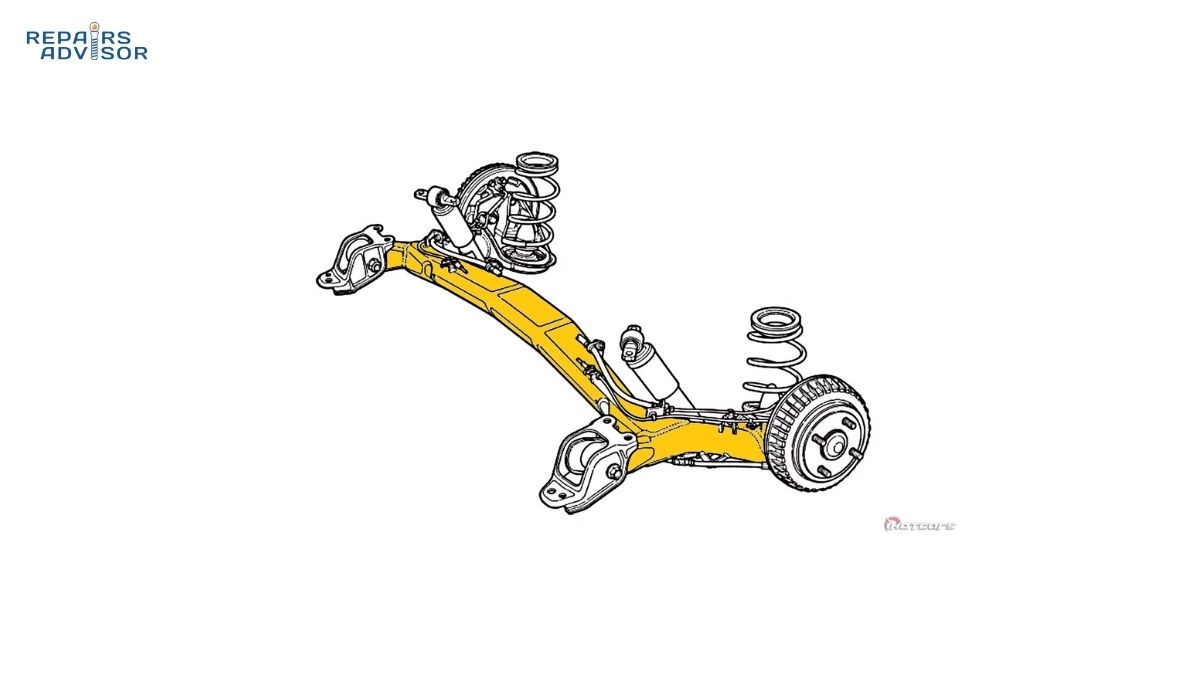

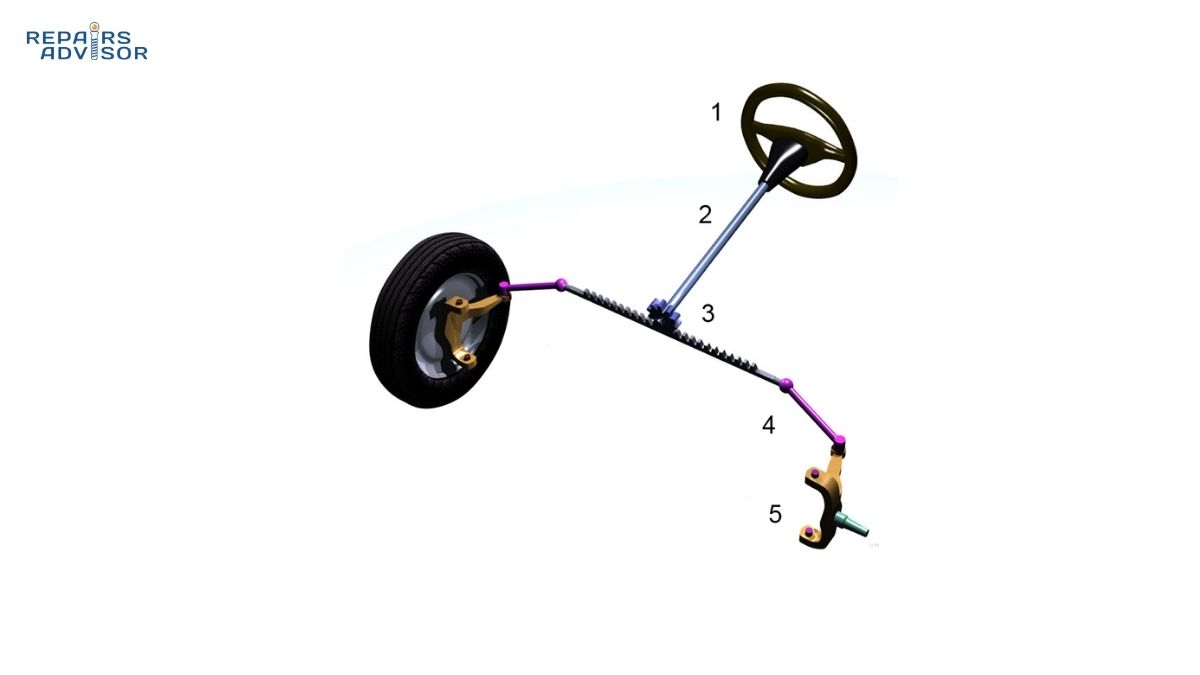

Control arm bushings serve as the pivot points where your control arms attach to the vehicle’s chassis frame. Think of them as highly engineered cushions that allow controlled movement while preventing metal-to-metal contact. Without these components, your suspension system would transmit every road vibration directly into the cabin, creating an uncomfortable and potentially unsafe driving experience.

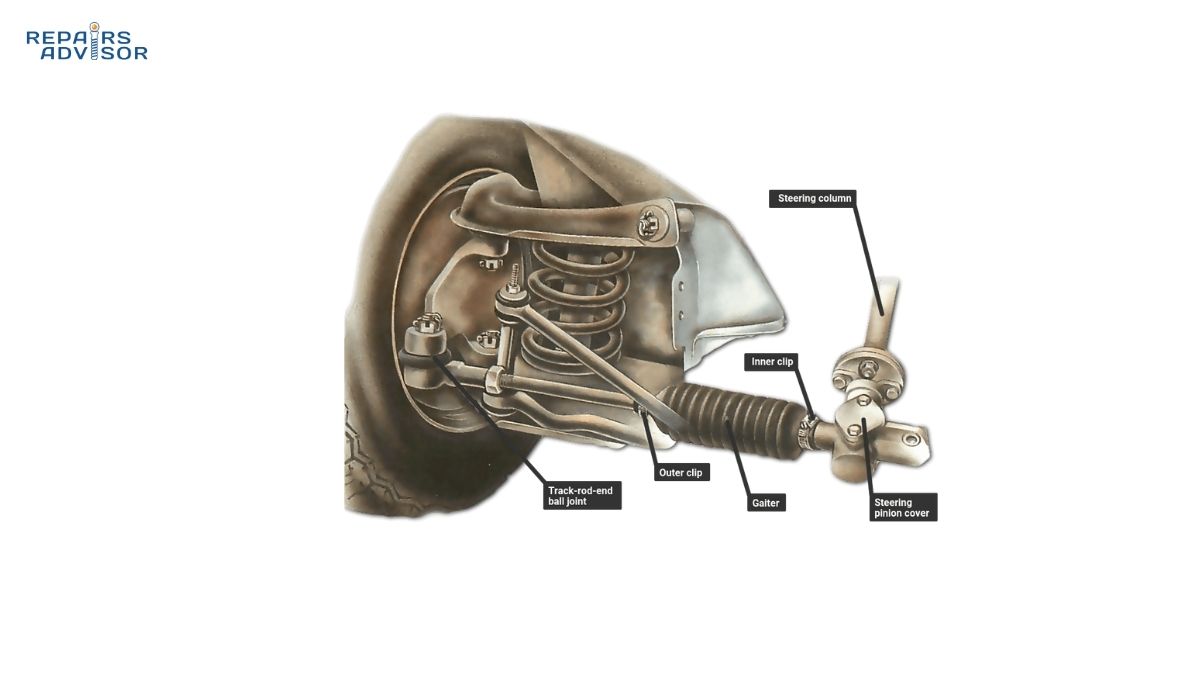

Each control arm typically connects to the chassis through two bushings, one at each mounting point on the chassis side of the arm. The basic construction consists of three layers: an inner metal sleeve that accepts the mounting bolt, an elastomeric (rubber-like) center section that provides compliance and dampening, and an outer metal shell that presses into the control arm housing. This sandwich design allows the bushing to twist and flex under load while maintaining structural integrity.

It’s important to distinguish control arm bushings from ball joints. While both are pivot points in the suspension system, they serve different functions. Ball joints connect the outer end of the control arm to the steering knuckle and allow multi-directional rotation for steering and suspension movement. Control arm bushings, in contrast, connect the inner end of the control arm to the chassis and primarily allow rotational movement around a single axis.

The primary purpose of control arm bushings is vibration absorption and noise isolation, often referred to as NVH (Noise, Vibration, and Harshness) reduction in automotive engineering. As your wheels encounter road imperfections, the suspension components move up and down. The bushings absorb and dampen these movements, preventing harsh impacts from reaching the vehicle’s body structure and, ultimately, the cabin where you sit.

Simultaneously, bushings maintain proper suspension geometry by controlling how much the control arm can move. They’re designed with specific stiffness characteristics that allow necessary suspension articulation while preventing excessive deflection that would alter wheel alignment. This balance between flexibility and rigidity is what makes bushing design so critical to vehicle performance.

For intermediate DIYers, it’s worth noting that bushing failure doesn’t happen all at once. The elastomeric material gradually deteriorates, developing small cracks that grow over time. This progressive wear means you might not notice problems immediately, but the symptoms will worsen as degradation continues. Understanding this gradual failure pattern helps explain why early detection and replacement can prevent more serious suspension damage.

How Control Arm Bushings Work

The mechanical function of control arm bushings centers on managing two competing demands: allowing necessary suspension movement while maintaining precise wheel positioning. When your vehicle travels over a bump, the wheel moves upward, causing the control arm to pivot. The bushing accommodates this rotation by allowing the inner sleeve to twist relative to the outer shell, with the elastomeric center material flexing to permit this motion.

This flexing action simultaneously absorbs energy from the impact. Instead of transmitting the full force of the bump directly to the chassis mounting point, the bushing’s elastic material compresses and rebounds, dampening the impact. The energy gets converted into heat within the bushing material, dissipated harmlessly rather than creating harsh vibrations inside the cabin.

The load-bearing capacity of bushings is substantial. They support a significant portion of the vehicle’s weight at each mounting point, experiencing both compression forces (pushing down on the bushing) and shear forces (sideways sliding motion). During normal driving, these forces constantly change as weight shifts during acceleration, braking, and cornering. A quality bushing handles these dynamic loads while maintaining its shape and dampening properties.

Temperature cycling adds another layer of complexity to bushing function. As the rubber material heats up from friction and nearby heat sources like the engine and brakes, its properties change. It becomes softer and more pliable at higher temperatures, then firms up again as it cools. This constant expansion and contraction, combined with mechanical stress, gradually breaks down the material’s molecular structure.

Many bushings incorporate void patterns—strategically designed hollow spaces within the elastomeric material. These voids serve two purposes: they reduce the overall stiffness of the bushing in specific directions, allowing easier rotation around the desired axis, and they provide space for the material to deform under load without creating excessive resistance. The sophisticated engineering of these void patterns explains why OEM bushings often perform differently than simpler aftermarket designs.

For those familiar with MacPherson strut or double wishbone suspension systems, the bushing’s role in maintaining suspension geometry becomes even more critical. During cornering, lateral forces try to push the control arm sideways. The bushings resist this motion, preventing unwanted camber and toe changes that would reduce tire contact with the road. However, they must allow enough compliance to let the suspension articulate properly over bumps.

This balance between movement and rigidity directly affects how your vehicle handles. Stiffer bushings provide more precise control, reducing body roll and improving steering response—desirable for performance driving. Softer bushings prioritize comfort, absorbing more vibration but allowing slightly more suspension deflection. Automakers select bushing stiffness based on the vehicle’s intended purpose, whether that’s luxury comfort, sporty handling, or somewhere in between.

The professional technician recognizes that bushings aren’t just simple rubber parts. They’re carefully engineered components with specific durometer ratings (hardness measurements), compression characteristics, and design features tailored to each vehicle’s suspension geometry and performance requirements. This engineering precision is why proper replacement matters—installing bushings with incorrect characteristics can noticeably alter vehicle behavior.

Types of Control Arm Bushings

Understanding the different bushing materials available helps you make informed decisions about replacements that match your driving needs and budget. Each material type offers distinct advantages and trade-offs in performance, longevity, and cost.

Rubber Bushings: The OEM Standard

Natural rubber or synthetic elastomer bushings represent the most common original equipment choice. Automakers favor these materials for their excellent vibration dampening characteristics and ability to provide a comfortable, quiet ride. The soft, compliant nature of rubber effectively isolates road noise and absorbs impact energy before it reaches the cabin.

Under normal driving conditions, quality rubber bushings typically last 50,000 to 100,000 miles. However, this lifespan varies significantly based on environmental factors and driving habits. The rubber material’s main weakness is its vulnerability to degradation from multiple sources: heat from the engine and brake system, oil and grease contamination from leaking components, ozone exposure from the atmosphere, and chemical attack from road salt in winter climates.

Rubber bushings fail in predictable patterns. Small surface cracks appear first, usually developing in areas of highest stress concentration. These cracks gradually deepen and spread until the material begins tearing. Eventually, chunks of rubber may separate entirely, leaving gaps that allow excessive control arm movement. By this point, the symptoms become quite noticeable—significant clunking noises, vibration, and steering issues.

For daily-driven vehicles operating in moderate climates without special performance requirements, OEM-quality rubber bushings remain the best choice. They provide the comfort and noise isolation most drivers prefer, at a reasonable replacement cost.

Polyurethane Bushings: The Performance Upgrade

Polyurethane bushings appeal to enthusiasts seeking improved handling precision and longer service life. This synthetic material offers significantly greater stiffness than rubber, resulting in more direct suspension response and reduced deflection during aggressive cornering or braking. Performance drivers appreciate the sharper, more connected feel polyurethane bushings provide.

Durability represents another key advantage. Polyurethane resists chemical degradation much better than rubber, showing superior resistance to oil, grease, road salt, and environmental exposure. In typical applications, polyurethane bushings can last 75,000 to 120,000 miles or more, often outlasting rubber alternatives by 50% or greater.

However, these benefits come with trade-offs that many daily drivers find objectionable. The increased stiffness that improves handling also transmits more road noise and vibration into the cabin, creating a noticeably harsher ride quality. This characteristic makes polyurethane bushings less suitable for comfort-oriented vehicles or drivers who prioritize a smooth, quiet driving experience.

Polyurethane bushings also require periodic maintenance. The material doesn’t bond to metal surfaces like rubber does, instead rotating against the inner sleeve during suspension movement. This friction surface must be properly lubricated to prevent squeaking and premature wear. Manufacturers recommend regreasing polyurethane bushings every two years or 24,000 miles, using specialized lubricants compatible with the material—never petroleum-based products, which can damage polyurethane.

Professional mechanics recognize that polyurethane bushings work differently than rubber bushings. With rubber, the material flexes and twists to accommodate control arm movement; the rubber stays bonded to both the inner sleeve and outer shell. Polyurethane bushings operate more like bearings, with the bushing material rotating on the metal sleeve. This fundamental difference in operation explains the lubrication requirement and the need for precise fit tolerances.

For track-focused vehicles, heavily modified suspensions, or off-road applications where durability matters more than comfort, polyurethane bushings make excellent sense. For daily drivers, particularly those who value ride quality, they’re usually not the best choice despite their longevity advantages.

Hydraulic Bushings: The Premium Solution

Hydraulic bushings represent advanced engineering found primarily in luxury and premium vehicles. These sophisticated components contain hydraulic fluid in chambers within the bushing structure, allowing the bushing to adapt its dampening characteristics to different driving conditions. At low frequencies (gentle road undulations), the fluid flows easily, providing soft compliance. At higher frequencies (sharp bumps), the fluid flow restricts, creating firmer dampening.

This adaptive behavior provides the best of both worlds: comfortable isolation from small vibrations while maintaining control during more aggressive inputs. However, the complex design comes at a price—hydraulic bushings cost significantly more than conventional rubber or polyurethane alternatives. They’re also generally not available as aftermarket upgrades, limiting their use to original equipment applications or direct OEM replacement.

Thermoplastic Elastomer Bushings: The Modern Alternative

A newer category of bushings uses thermoplastic elastomers (TPE), materials that blend characteristics of both rubber and polyurethane. These advanced compounds offer better environmental resistance than traditional rubber while maintaining softer dampening than polyurethane. Service life typically falls in the 75,000 to 120,000-mile range, similar to polyurethane but without the harsh ride quality.

TPE bushings represent a middle-ground solution for drivers who want improved durability without sacrificing comfort. They’re increasingly common in modern vehicles as manufacturers seek to extend service intervals while maintaining ride quality standards.

Choosing the Right Material

Your driving style and vehicle use should guide material selection. Daily drivers operating in typical street conditions benefit most from OEM-quality rubber bushings, which provide the comfort and quiet ride most people prefer. The slightly shorter lifespan is offset by lower replacement costs and superior NVH characteristics.

Performance enthusiasts, autocross competitors, or track day participants should consider polyurethane bushings for their improved precision and durability, accepting the comfort trade-offs as part of the performance package. Remember that polyurethane bushings require periodic lubrication—factor this maintenance into your decision.

Off-road vehicles and trucks operating in harsh environments often benefit from upgraded materials—either polyurethane or thermoplastic elastomers—that resist the accelerated degradation common in challenging conditions. The improved chemical and environmental resistance justifies the higher initial cost and any comfort penalties.

For most drivers, sticking with the material type originally specified by the manufacturer makes the most sense. Automakers spend considerable resources optimizing bushing characteristics for each vehicle model, selecting materials that balance comfort, handling, durability, and cost for the intended use case. Deviating from this specification should be a conscious choice based on specific needs, not just a default upgrade.

Signs of Worn Control Arm Bushings

Recognizing bushing failure symptoms early allows you to address problems before they escalate into more serious suspension damage or create safety concerns. Control arm bushing wear typically produces five primary symptoms, progressing from subtle to severe as degradation advances.

Increased Vibrations

The first symptom most drivers notice is increased vibration transmitted through the steering wheel, floor, or seats. These vibrations become particularly noticeable when accelerating, when load transfer increases forces on the bushings. You might also feel more harshness over rough roads or expansion joints that previously felt smooth.

This happens because worn bushings lose their dampening effectiveness. The elastomeric material that once absorbed vibration energy now transmits it directly through the failed bushing into the chassis structure. As the rubber develops cracks and loses elasticity, its ability to isolate high-frequency vibrations diminishes progressively. What starts as a barely noticeable harshness gradually builds until the ride quality becomes objectively uncomfortable.

Beginner DIYers often dismiss early vibration symptoms as “normal aging” or attribute them to tire problems. However, vibration that intensifies specifically during acceleration, worsens over bumps, and feels most prominent through the steering wheel often indicates bushing issues rather than tire balance or alignment problems.

Clunking or Knocking Noises

As bushing deterioration progresses, you’ll likely hear clunking or knocking sounds from the front suspension area. These noises occur when the control arm moves excessively within the worn bushing, allowing metal-to-metal contact between the control arm and mounting hardware. The sound typically accompanies bumps, potholes, or turning maneuvers—any situation that causes suspension articulation.

The clunking may start quietly, barely audible over road noise, but it intensifies as the bushing degrades further. Eventually, even gentle bumps produce pronounced knocking sounds. Hard braking or sudden stops often trigger particularly loud clunks as weight transfer loads the worn bushings.

Professional technicians can often diagnose bushing failure by reproducing these noises during a test drive or bounce test, where pressing down firmly on one corner of the vehicle compresses the suspension, then releasing it allows the suspension to rebound. Worn bushings produce distinct clunking during this motion that experienced mechanics recognize immediately.

Steering Issues

Worn control arm bushings significantly affect steering feel and precision. You might notice the steering wheel pulling to one side during straight-line driving, requiring constant correction to maintain your lane position. This “steering wander” happens because deteriorated bushings allow the control arm excessive movement, permitting slight changes in wheel alignment as the suspension articulates over road irregularities.

The steering may also feel loose or vague, lacking the precise, connected sensation of a properly functioning suspension. There’s increased play in the system—when you turn the steering wheel, the response feels delayed or mushy rather than immediate and direct. This symptom often develops so gradually that drivers adapt to it unconsciously, not realizing how much steering precision has degraded until they drive a vehicle with proper bushings.

For intermediate mechanics performing diagnostic work, the steering symptoms from bushing wear can mimic other problems like worn tie rod ends or loose steering gear mounts. Comprehensive inspection of all steering and suspension components helps identify the actual source.

Uneven Tire Wear

Failed bushings allow unwanted suspension geometry changes that create uneven tire wear patterns. You might see excessive wear on the inside or outside edges of the tires, diagonal feathering across the tread blocks, or irregular bald spots. These patterns develop because the worn bushings permit camber and toe angles to shift as the suspension moves, changing the tire’s contact patch with the road.

This symptom requires more mechanical knowledge to recognize and diagnose correctly. Many factors can cause uneven tire wear, including improper alignment, worn ball joints, or suspension damage. Professional technicians examine tire wear patterns alongside other symptoms and suspension measurements to determine the root cause.

Importantly, worn bushings can cause alignment problems that persist even after the vehicle is aligned. If bushings allow excessive control arm movement, the alignment settings will shift during normal driving, causing the same wear patterns to return quickly after what should have been a corrective alignment service.

Excessive Vibration During Braking

When control arm bushings wear severely, you may experience increased vibration or shaking when applying the brakes. As the vehicle’s weight transfers forward during braking, forces on the front suspension components increase dramatically. Worn bushings allow more movement than designed, creating a shimmy or shake that radiates through the steering wheel and brake pedal.

This symptom sometimes gets misdiagnosed as warped brake rotors, which can produce similar vibration during braking. However, rotor warpage typically creates a pulsing sensation that corresponds to wheel rotation speed, while bushing-related vibration tends to be more random and may include clunking sounds as the control arm shifts position under braking loads.

Visual Inspection Indicators

For those comfortable performing under-vehicle inspection, worn bushings often show visible damage. With the vehicle safely raised and supported on jack stands, you can examine the bushings for:

- Visible cracks in the rubber material, especially around stress concentration points

- Tearing or splitting where the rubber separates from metal surfaces

- Oil or grease saturation, which accelerates rubber degradation

- Deformed appearance—the bushing looks compressed, sagging, or misshapen

- Missing rubber chunks where material has separated completely

- Excessive play when you manually move the control arm

The visual inspection works best when you can compare the suspect bushing to a known-good example or reference images. Bushings naturally compress somewhat under vehicle weight, so distinguishing normal compression from problematic deformation requires experience.

If you’re experiencing any combination of these symptoms, particularly vibration combined with clunking noises or steering issues, have your suspension system inspected by a qualified technician. While you can perform preliminary visual checks yourself, proper diagnosis often requires lifting the vehicle, measuring suspension geometry, and comparing findings to manufacturer specifications—tasks best left to professionals with proper equipment.

Causes of Bushing Failure

Understanding what causes control arm bushings to fail helps you anticipate problems and potentially extend service life through preventive maintenance. Bushing degradation results from a combination of environmental factors, driving conditions, and inherent material limitations.

Environmental Factors

Age and mileage represent the primary drivers of bushing wear. Even vehicles driven gently on smooth roads will eventually experience bushing failure simply due to time. The elastomeric materials in bushings undergo molecular changes as they age, gradually losing their elastic properties. UV exposure from sunlight, ozone in the atmosphere, and temperature cycling all contribute to this chemical breakdown at the molecular level.

Heat exposure accelerates degradation significantly. Bushings near the engine or brake components experience elevated temperatures during operation. This heat softens the rubber material, making it more susceptible to deformation and cracking. Each heating and cooling cycle stresses the material, eventually causing permanent changes in its properties.

Road salt and chemical exposure present particular challenges in regions with harsh winters. The chemicals used for de-icing roads attack rubber compounds, causing surface deterioration that progresses inward. Coastal environments expose bushings to salt spray with similar effects. Regular undercarriage washing can help mitigate these environmental factors, though it won’t eliminate them entirely.

Oil and grease contamination dramatically shortens bushing life. When engine oil, power steering fluid, or grease from nearby components contacts rubber bushings, it causes the material to swell and soften. The contaminated rubber loses strength and develops cracks much faster than clean material. Addressing oil leaks promptly helps protect bushings and other suspension components from this accelerated degradation.

Driving Conditions

Your driving environment and habits significantly influence bushing longevity. Vehicles operated primarily on smooth highways typically experience longer bushing life than those navigating rough city streets with numerous potholes and speed bumps. Each impact over a bump loads the bushings, flexing the material and generating heat from internal friction.

Pothole strikes and curb impacts create sudden, severe loads that can damage bushings instantly. While these components handle normal suspension articulation well, the extreme forces from a sharp impact can tear the material or separate the bonding between rubber and metal surfaces. Even a single severe impact can compromise bushing integrity, leading to accelerated wear afterward.

Off-road driving subjects bushings to particularly harsh conditions—larger impacts, greater suspension articulation, and exposure to mud and water that can contaminate or degrade the rubber. Enthusiasts who regularly take their vehicles off-road should expect shorter bushing service life and consider upgraded materials designed for these demanding conditions.

Overloading your vehicle beyond its rated capacity increases stress on all suspension components, including bushings. The extra weight compresses bushings more than designed, creating higher internal temperatures and greater material deformation. Regularly carrying heavy loads or towing near or at the vehicle’s maximum capacity will reduce bushing lifespan.

Plus-sized tires—wheels with larger diameters and lower-profile tires—transfer more road vibration through the suspension because the shorter sidewalls provide less cushioning. This increased vibration transmission subjects bushings to more high-frequency cycling, accelerating wear. While the effect is modest, it’s worth considering if you’re installing non-standard tire sizes.

Design and Material Limitations

Even the best bushings have inherent limitations related to the engineering compromises manufacturers must make. Automakers balance cost against performance when selecting bushing materials and designs. A premium luxury vehicle might use more expensive materials with longer service life, while an economy car uses cost-optimized components designed to last through the warranty period but perhaps not much longer.

The durometer rating—essentially the hardness measurement—of bushing material represents one such compromise. Softer durometer materials provide better vibration isolation but wear faster and allow more deflection under load. Harder materials last longer and maintain geometry better but transmit more noise and harshness. Manufacturers select durometer ratings that balance these competing priorities for each vehicle’s intended use.

Bonding failure between the elastomeric material and metal components can occur even in quality bushings. The adhesives and bonding processes used to join rubber to metal have their own limitations. Temperature cycling, chemical exposure, and mechanical stress can weaken these bonds over time, allowing the rubber to separate from the metal surfaces it should be attached to.

Understanding these failure mechanisms reinforces the importance of regular inspection. While you can’t prevent natural aging or eliminate environmental factors, recognizing early symptoms allows timely replacement before minor bushing wear creates more serious suspension damage or safety issues.

Replacement Considerations

When your control arm bushings fail, you face several important decisions about the replacement approach, parts selection, and whether to attempt the repair yourself or hire a professional. Understanding your options helps you make choices that balance cost, convenience, and long-term results.

DIY vs. Professional Replacement

Replacing control arm bushings falls into the intermediate-to-advanced category of DIY repairs. The job requires specialized tools, particularly a hydraulic press capable of removing old bushings and installing new ones. While some vehicles use bolt-in bushing designs that simplify replacement, most bushings are press-fit into the control arm, requiring substantial force to remove and install.

The basic procedure involves safely lifting and supporting the vehicle, removing the wheel, disconnecting the control arm from the chassis and ball joint, pressing out the old bushings, pressing in new ones, reinstalling the control arm, and having the suspension aligned. Time investment typically runs 2-4 hours per side for someone with mechanical experience and proper tools.

However, several factors complicate DIY bushing replacement. First, safely lifting and supporting the vehicle requires proper jack stands rated for the vehicle’s weight—using a floor jack alone creates serious injury risk. Second, separating ball joints often requires specialized tools like pickle forks or ball joint separators that can damage the boot if not used carefully. Third, pressing bushings demands not just a hydraulic press but also the correct adapters sized to your specific bushings—using incorrect adapters can damage new bushings during installation.

Perhaps most importantly, any control arm removal requires a professional wheel alignment afterward. Removing and reinstalling the control arm changes suspension geometry, making proper alignment essential for safe handling and to prevent rapid tire wear. Even if you successfully replace the bushings yourself, you’ll need to transport the vehicle to an alignment shop for this final step.

Professional replacement eliminates these challenges. Experienced technicians have the proper tools, work on lifted vehicles for easy access, complete the job efficiently, and can perform the alignment in-house. The warranty on professional labor also provides recourse if problems arise after the repair. For most vehicle owners, professional replacement makes the most practical sense despite the higher cost.

Replacement Options and Costs

You have three primary approaches to bushing replacement, each with different cost implications and practical considerations.

Bushing-Only Replacement

Replacing just the bushings—pressing out the old ones and installing new ones in your existing control arms—represents the most economical parts cost. Quality replacement bushings typically cost $5-$15 per bushing, so replacing both bushings in one control arm might cost $10-$30 in parts.

However, labor costs for this approach run higher because of the pressing requirement. Shops typically charge $100-$300 per side for bushing replacement labor, as the process requires control arm removal, pressing, and reinstallation. Total cost usually falls in the $105-$450 range per side, including parts and labor but excluding alignment.

This approach makes the most sense when your control arms are in good condition—no bends, cracks, or corrosion—and you’re working with a vehicle where bushing replacement is relatively straightforward. Some vehicles, however, have bushings that are extremely difficult to press out, making this option impractical even though it’s theoretically less expensive.

Complete Control Arm Replacement

Many mechanics recommend replacing the entire control arm assembly rather than just the bushings. Complete control arms come with bushings already pressed into place and typically include a new ball joint as well. Parts cost ranges from $80 for economy vehicle arms to $400+ for premium or performance vehicle components.

Labor costs decrease with this approach because no pressing is required—the mechanic simply removes the old control arm and bolts in the new one. Labor typically runs $150-$200 per side, making total costs $220-$600+ per side for parts and labor combined.

The complete arm replacement offers several advantages beyond easier installation. You get a new ball joint included, eliminating concern about that component failing soon after you replace the bushings. The arm structure is new, with no fatigue cracks or corrosion that might be present in an older arm. Installation is faster, reducing labor time and shop hours.

For most modern vehicles, complete control arm replacement has become the standard approach. The parts cost difference versus bushing-only replacement has narrowed as control arm manufacturing has improved, while the labor savings make total costs comparable or even lower. Unless you’re working with a classic vehicle where original arms have value, or a specialty application where bushings alone make sense, complete arm replacement typically provides better overall value.

Both Sides Simultaneously

Regardless of whether you replace bushings only or complete control arms, addressing both sides at the same time makes practical and economic sense. Control arms on both sides experience similar wear patterns—if one side’s bushings have failed, the other side is likely close behind. Replacing only one side means you’ll face another repair bill soon when the other side fails.

More importantly, replacing both sides reduces total alignment costs. You’ll need an alignment whether you replace one side or both, so addressing both sides during a single visit saves the cost of a second alignment service a few months later. The combined labor for doing both sides simultaneously also typically costs less than scheduling two separate repairs.

Post-Replacement Requirements

Professional wheel alignment is mandatory after any control arm or bushing replacement. This isn’t an optional service or a way for shops to increase the bill—it’s an essential final step that ensures your vehicle handles safely and prevents rapid tire wear.

When you remove and reinstall control arms, you change the suspension geometry that determines wheel alignment angles. Even if you’re extremely careful during installation, those angles will shift from their proper specifications. A four-wheel alignment service typically costs $100-$150 and measures all suspension angles (camber, caster, and toe) on both axles, adjusting them to manufacturer specifications.

Driving without proper alignment after bushing replacement creates several problems. The tires will wear unevenly and prematurely, potentially requiring replacement after just a few thousand miles. The vehicle may pull to one side, requiring constant steering correction. Handling will be compromised, with reduced stability and unpredictable responses in emergency maneuvers.

Budget for alignment costs when planning your repair—it’s not optional. Any shop that replaces control arms or bushings without recommending a follow-up alignment is doing you a disservice, as the repair isn’t truly complete without this final step.

Many shops offer alignment packages that combine the parts and labor for bushing or control arm replacement with the alignment service in a single quote. This bundled pricing often provides modest savings compared to paying for services separately and ensures all necessary work gets completed during one visit.

Related suspension components often warrant attention during control arm work. If your shock absorbers are original or showing signs of wear, replacing them at the same time makes sense since the vehicle is already lifted and partially disassembled. Similarly, if ball joints show wear but haven’t completely failed, addressing them during control arm replacement prevents another repair visit soon afterward. Discuss these considerations with your mechanic to develop a comprehensive suspension refresh plan that addresses current and emerging problems efficiently.

Maintenance and Prevention

While you can’t prevent control arm bushings from eventually wearing out, proactive maintenance and smart driving habits can extend their service life and help you catch problems early before they escalate.

Regular Inspection Schedule

The most effective preventive measure is regular visual inspection of your bushings during routine service. Every 15,000 miles or during oil changes, take a few minutes to examine your control arm bushings for early signs of wear. Many shops include suspension inspection in their multipoint inspection service, but you can also check yourself if you’re comfortable working under a safely supported vehicle.

Look for surface cracks in the rubber, which appear as fine lines on the bushing surface. Early-stage cracks don’t necessarily require immediate replacement, but they indicate the aging process has begun and the bushing is entering the latter part of its service life. Monitor cracks during subsequent inspections—if they deepen or multiply, plan for replacement soon.

Check for oil or grease saturation, which appears as dark discoloration or a glossy, wet appearance on the rubber. If you find contaminated bushings, identify and fix the leak source before it causes more damage. Even if the bushings haven’t failed yet, contamination accelerates wear significantly, so plan for replacement in the near future.

After any pothole strike, curb impact, or other suspension trauma, inspect bushings for damage even if you don’t notice immediate symptoms. Hard impacts can cause internal tearing that won’t be visible externally but will lead to accelerated failure. If you see fresh cracks or separation after an impact, have the suspension professionally inspected to assess damage extent.

Prevention Strategies

While normal aging is inevitable, certain practices help maximize bushing lifespan. Avoid potholes and road hazards when safely possible—even though your suspension is designed to absorb impacts, each severe hit stresses the bushings and contributes to fatigue damage. When you can’t avoid a pothole, slow down before hitting it to reduce impact severity.

Don’t overload your vehicle beyond its rated capacity. Check the payload rating on the door jamb sticker and respect these limits. Regularly carrying heavy loads or maximum towing capacity stresses all suspension components, including bushings. If you frequently haul heavy loads, consider a vehicle rated for those capacities or plan for more frequent suspension maintenance.

Address any fluid leaks promptly. Power steering leaks, engine oil leaks, and grease from torn CV boot covers can all contaminate suspension bushings. While fixing leaks primarily prevents major component damage, it also protects your bushings from chemical attack that would shorten their life.

Use quality replacement parts when bushings do need replacement. Cheap aftermarket bushings made from inferior materials won’t last as long as OEM-quality parts or premium aftermarket options from reputable manufacturers. The modest savings on cheap parts rarely justify the shorter service life and need for earlier replacement.

In areas with harsh winters, consider regular undercarriage washing to remove road salt accumulation. Many car washes offer underbody spray options, and some touchless automatic washes include this service. While it won’t eliminate salt exposure entirely, regular washing reduces the concentration of corrosive chemicals in contact with rubber components.

Polyurethane Bushing Maintenance

If you’ve chosen polyurethane bushings for their performance and durability advantages, remember that they require periodic lubrication to maintain proper function and prevent squeaking. Manufacturers typically recommend lubrication every two years or 24,000 miles, though frequent performance driving or harsh conditions may warrant more frequent service.

Use only lubricants specifically designed for polyurethane bushings. These specialized greases are formulated to be compatible with the material and provide lasting lubrication at the metal-to-polyurethane interface. Never use petroleum-based lubricants, including most standard greases, as they can damage polyurethane and cause premature failure.

If your polyurethane bushings develop squeaking noises, that’s a clear indicator they need lubrication. Don’t ignore squeaking—it indicates the bushings are operating with inadequate lubrication, leading to accelerated wear. Proper regreasing typically eliminates the noise and prevents damage.

For vehicles equipped with polyurethane bushings, keep track of when they were last serviced and schedule periodic lubrication as part of your maintenance routine. This simple preventive measure ensures you get the full benefit of the material’s superior durability without experiencing the noise and wear issues that plague neglected polyurethane components.

Understanding these maintenance requirements and following through with regular inspections and preventive care helps you maximize the return on your bushing investment while maintaining safe, predictable handling characteristics.

Safety Warnings and Professional Consultation

While understanding control arm bushings empowers you to maintain your vehicle more effectively, it’s crucial to recognize when professional expertise becomes essential for safety and proper repair outcomes.

When to Consult a Professional

Certain symptoms require immediate professional attention rather than a wait-and-see approach. Severe steering wander that makes the vehicle difficult to control, particularly if it worsens quickly over days or weeks, indicates suspension problems that could become dangerous. Similarly, loud clunking that intensifies rapidly suggests progressive component failure that might lead to complete detachment if not addressed.

If you observe visible damage to the control arm structure itself—bends, cracks, or severe rust perforation—professional inspection is mandatory. While bushing failure is common and expected, structural damage to the control arm assembly indicates more serious problems, potentially from an accident or severe impact that may have damaged other components as well.

Uncertainty about diagnosis also warrants professional consultation. If you’re experiencing symptoms that might be bushing-related but could also indicate other problems like worn ball joints, damaged struts, or steering system issues, don’t guess. Modern vehicles have complex suspension systems where multiple problems can produce similar symptoms. Proper diagnosis requires experience, specialized tools, and systematic testing that professional technicians provide.

Professional Services Recommended For

Even experienced DIY mechanics should consider professional service for certain aspects of control arm bushing replacement. Bushing pressing requires a hydraulic press with appropriate adapters—not typical homeowner equipment. While you might theoretically rent or borrow this equipment, incorrect technique or improper adapters can damage new bushings during installation, wasting the parts cost and your time.

Wheel alignment demands specialized equipment that measures suspension angles with high precision and allows controlled adjustments to bring them within specification. Modern alignment machines use computer-controlled systems and laser or camera-based measurement that simply isn’t available outside professional shops. This isn’t a service you can DIY with measuring tapes and string methods—proper computerized alignment is essential for modern vehicles.

If ball joints need replacement simultaneously with bushings, professional service becomes even more advisable. Ball joint separation requires specific tools and techniques to avoid damaging related components. The pressing equipment needed for ball joints is even more specialized than bushing presses, and incorrect installation can create dangerous failure points.

Comprehensive suspension system inspection provides value beyond bushing diagnosis. When checking control arm bushings, experienced technicians also examine ball joints, tie rod ends, struts or shocks, anti-roll bar links, and suspension springs for wear or damage. This holistic assessment identifies all current and emerging problems, allowing you to plan maintenance strategically rather than addressing failures reactively as they occur.

DIY Limitations to Recognize

The safety implications of improper lifting cannot be overstated. Using a floor jack alone to support a vehicle while you work underneath creates deadly risk. If the jack fails or the vehicle shifts, the weight can cause fatal crushing injuries. Proper procedure requires floor jacks only for lifting, with heavy-duty jack stands rated for the vehicle’s weight positioned at approved jacking points to support the vehicle during any work underneath.

Incorrect bushing installation creates handling and safety issues that might not be immediately apparent. If bushings aren’t fully seated in their housings, if wrong-sized bushings create loose fits, or if mounting bolts aren’t properly torqued to specification, the suspension won’t function as designed. In worst cases, improperly installed components can separate during driving, creating loss of control.

Skipping professional alignment after control arm work causes rapid tire wear and compromised handling. Modern tires can cost $150-$300 each—a full set represents significant investment. Destroying that investment through poor alignment in an attempt to save $100-$150 on alignment service is false economy. Beyond tire costs, poor alignment creates unpredictable handling that could contribute to accidents.

Using incorrect tools risks component damage and personal injury. Trying to press bushings without proper press tools, attempting to separate ball joints with hammers or pry bars, or using impact guns without proper technique can damage expensive parts and create dangerous situations. If you don’t have the right tools for the job, either acquire them or hire someone who has them.

Critical Safety Considerations

Control arm bushings directly affect your vehicle’s ability to maintain proper wheel alignment and respond predictably to steering inputs. These aren’t cosmetic components—they’re safety-critical parts that influence vehicle control in all driving situations, from gentle highway cruising to emergency avoidance maneuvers.

Worn bushings compromise your ability to control the vehicle, particularly during emergency situations when you need maximum handling capability. The slight wandering or minor vibration you experience during normal driving becomes more severe when you need to swerve suddenly or brake hard while turning. In these critical moments, worn bushings allow excessive suspension deflection that can reduce tire contact with the road or create unpredictable steering response.

Don’t delay repairs when you identify bushing problems. While it might be tempting to continue driving with early symptoms like mild vibration or occasional clunking, bushing deterioration is progressive. What seems like a minor annoyance will worsen, potentially creating unsafe handling characteristics. Moreover, worn bushings allow excessive control arm movement that can damage other suspension components, turning a relatively simple bushing replacement into a more extensive and expensive repair.

Always prioritize professional assessment if you’re uncertain about diagnosis or repair capability. The modest cost of professional inspection provides expert evaluation and peace of mind that problems are correctly identified and properly addressed. Your safety and that of other road users depends on properly functioning suspension components—it’s not an area for shortcuts or guesswork.

Understanding your limitations and recognizing when professional expertise is necessary represents mature judgment, not mechanical inadequacy. Even experienced mechanics sometimes choose professional service for jobs where specialized equipment, manufacturer technical data, or warranty protection justify the cost. Make informed decisions based on your actual capabilities, available tools, and the safety criticality of the work involved.

Conclusion

Control arm bushings exemplify how small, inexpensive components create outsized impact on vehicle performance and safety. These seemingly simple rubber or polyurethane parts connect your control arms to the chassis, absorbing thousands of impacts daily while maintaining the precise geometry that keeps your wheels properly aligned and your steering responsive.

Understanding the different material types—rubber for comfort, polyurethane for performance, hydraulic for adaptive premium comfort—helps you make informed decisions when replacements become necessary. Each material offers distinct advantages in service life, vibration isolation, and handling precision, allowing you to match bushing characteristics to your driving needs and priorities.

Recognition of failure symptoms enables early intervention before minor bushing wear creates more serious problems. Increased vibration, clunking noises, steering issues, uneven tire wear, and braking vibrations all indicate bushing deterioration that warrants inspection. Acting on these early warnings prevents the accelerated suspension component wear that occurs when bushings fail completely, saving repair costs and maintaining safety margins.

Service life expectations provide realistic planning guidance: 50,000-100,000 miles for rubber bushings under normal conditions, 75,000-120,000+ miles for polyurethane or thermoplastic alternatives. Environmental factors, driving conditions, and maintenance practices all influence actual longevity, but understanding typical ranges helps you anticipate when replacement might become necessary.

Replacement costs vary significantly based on your approach and parts selection. Bushing-only replacement runs $105-$450 per side when the control arm structure remains serviceable. Complete control arm replacement—increasingly the standard approach—costs $220-$600+ per side but includes new ball joints and eliminates difficult pressing operations. Remember to budget for mandatory wheel alignment ($100-$150) regardless of which replacement method you choose, as proper alignment is essential for safe handling and preventing rapid tire wear.

Professional consultation provides value at multiple points in the bushing lifecycle. Expert diagnosis distinguishes bushing problems from similar symptoms caused by other suspension issues, avoiding unnecessary parts replacement or overlooked actual problems. Professional installation ensures proper technique, correct torque specifications, and appropriate alignment—critical factors for safety and longevity. Even experienced DIYers often choose professional service for bushing work because the specialized equipment requirements and alignment necessity make self-service impractical for many vehicle owners.

Your suspension system works as an integrated whole, with control arm bushings playing a crucial supporting role alongside struts or shocks, springs, anti-roll bars, and other components. Maintaining these bushings in good condition preserves the performance and safety characteristics your vehicle’s engineers designed into the complete suspension system.

Don’t ignore the subtle symptoms of bushing wear. That slight vibration, occasional clunk, or minor steering wander represents your vehicle communicating that maintenance attention is needed. Early diagnosis and timely replacement prevent the escalating problems and safety compromises that develop when worn bushings finally fail completely. Your comfort, your vehicle’s handling capability, and ultimately your safety depend on these critical components functioning as designed.

For comprehensive guidance on maintaining your vehicle’s steering and suspension systems, explore our complete library of technical resources covering all aspects of vehicle dynamics and control.