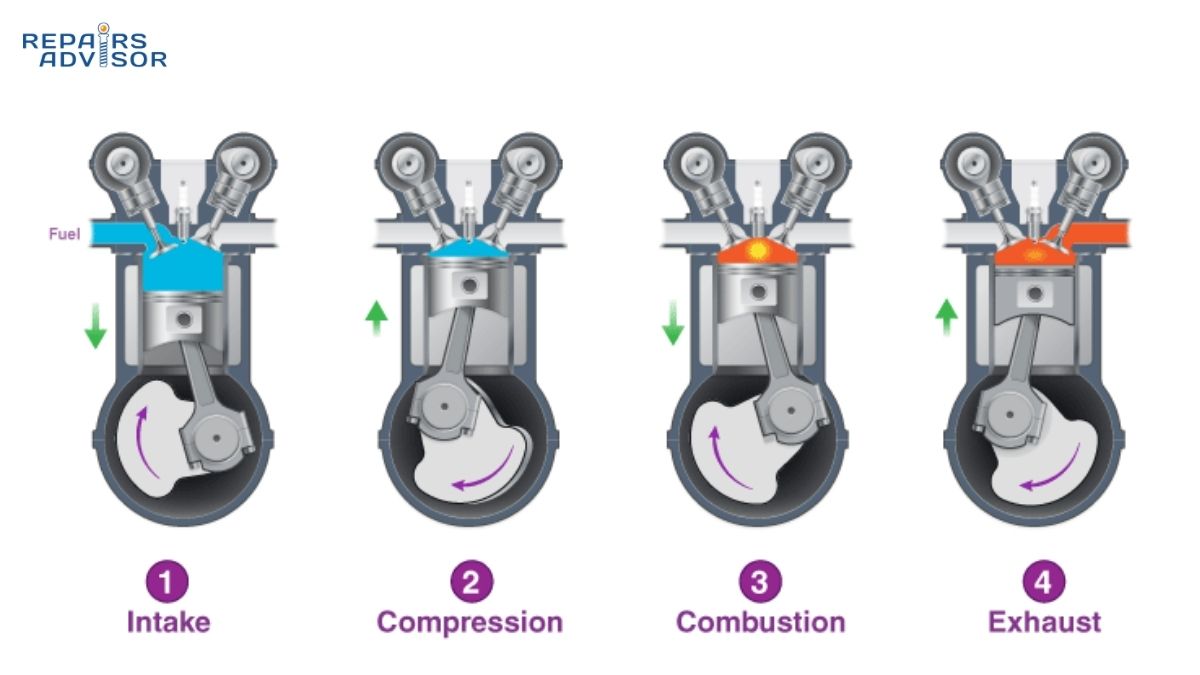

Combustion cycles are the fundamental thermodynamic processes that convert chemical energy in fuel into mechanical energy in your engine. The two primary cycles – Otto (gasoline) and Diesel – operate through distinctly different compression, ignition, and expansion phases that determine engine characteristics, efficiency, and performance. Understanding these cycles reveals why gasoline engines require spark plugs while diesel engines don’t, why compression ratios differ dramatically between engine types, and how ignition timing affects power output and fuel economy.

Quick Facts:

- Function: Convert fuel chemical energy into mechanical work through controlled explosions

- Primary Types: Otto cycle (gasoline), Diesel cycle (compression ignition)

- Process: Four-stroke sequence repeated thousands of times per minute

- Efficiency: Otto cycle 25-35%, Diesel cycle 35-45% thermal efficiency

- Key Difference: Ignition method (spark vs compression) and compression ratios

Safety Note: Combustion cycle analysis involves high-pressure, high-temperature processes with explosive fuel-air mixtures. Always follow manufacturer safety procedures when working on fuel, ignition, or compression systems. Professional consultation is recommended for engine timing modifications or compression ratio changes.

Why Combustion Cycles Are Critical for Engine Performance

Combustion cycles form the foundation of all internal combustion engine operation, determining everything from power output and fuel efficiency to emissions production and operational characteristics. These thermodynamic processes convert the chemical energy stored in fuel into the mechanical energy that moves your vehicle, with cycle efficiency directly impacting performance and economy.

Performance Impact: The Otto cycle and Diesel cycle each optimize different aspects of combustion for their intended applications. Otto cycle engines achieve higher power density through faster combustion and higher operating speeds (6,000+ RPM), while Diesel cycles produce superior torque through higher compression ratios and more complete fuel utilization. The ignition timing within each cycle precisely controls when maximum pressure occurs relative to piston position, directly affecting power output and efficiency.

System Integration: Combustion cycles coordinate with every major engine system to function properly. The compression ratio determines cylinder pressure and temperature conditions, the ignition system controls combustion initiation in Otto cycles, and the fuel injection system manages mixture preparation and delivery timing. Valve timing must synchronize perfectly with combustion events to optimize cylinder filling and exhaust evacuation.

Consequences of Cycle Disruption: When combustion cycles operate incorrectly, the effects are immediately apparent through reduced power, poor fuel economy, increased emissions, and potential engine damage. Knock detection becomes critical in Otto cycles when compression or timing creates uncontrolled combustion, while Diesel cycles suffer from incomplete combustion when injection timing or compression conditions are suboptimal.

The compression ratio – the relationship between cylinder volume at bottom dead center versus top dead center – fundamentally determines which combustion cycle an engine can use and its performance characteristics.

Combustion Cycles Specs and Construction Explained

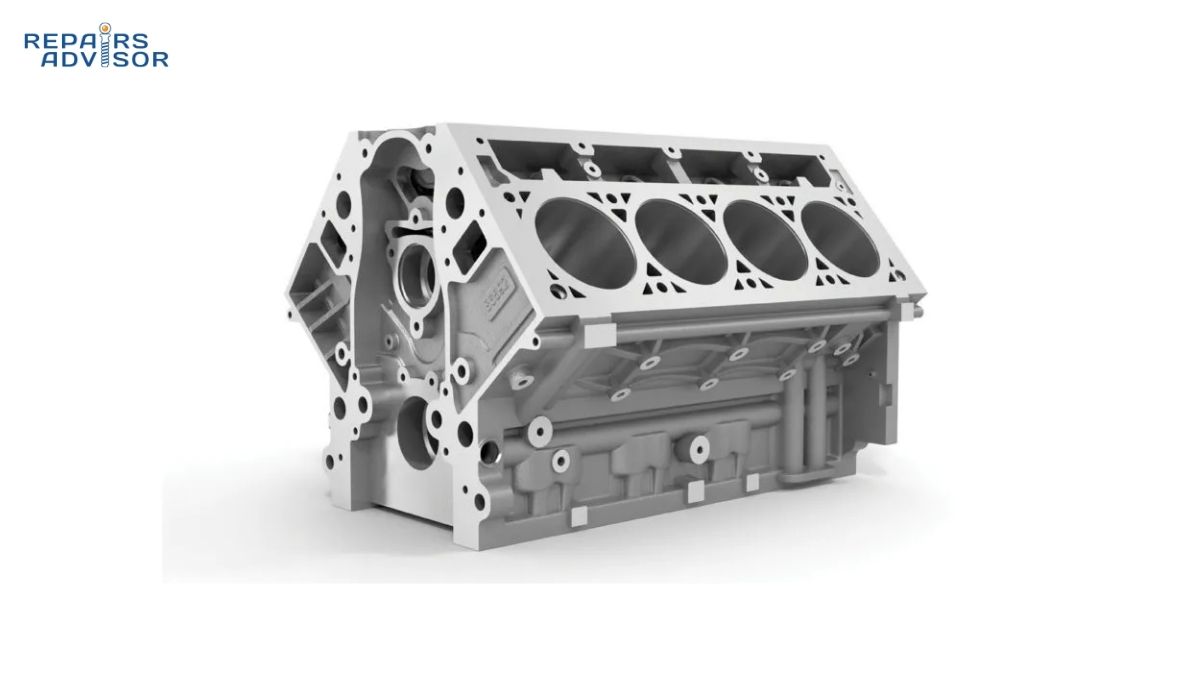

Modern combustion cycles depend on precisely engineered engine components that create and control the thermodynamic processes necessary for efficient energy conversion. The physical construction of these components determines cycle effectiveness, operating limits, and performance characteristics across different engine designs.

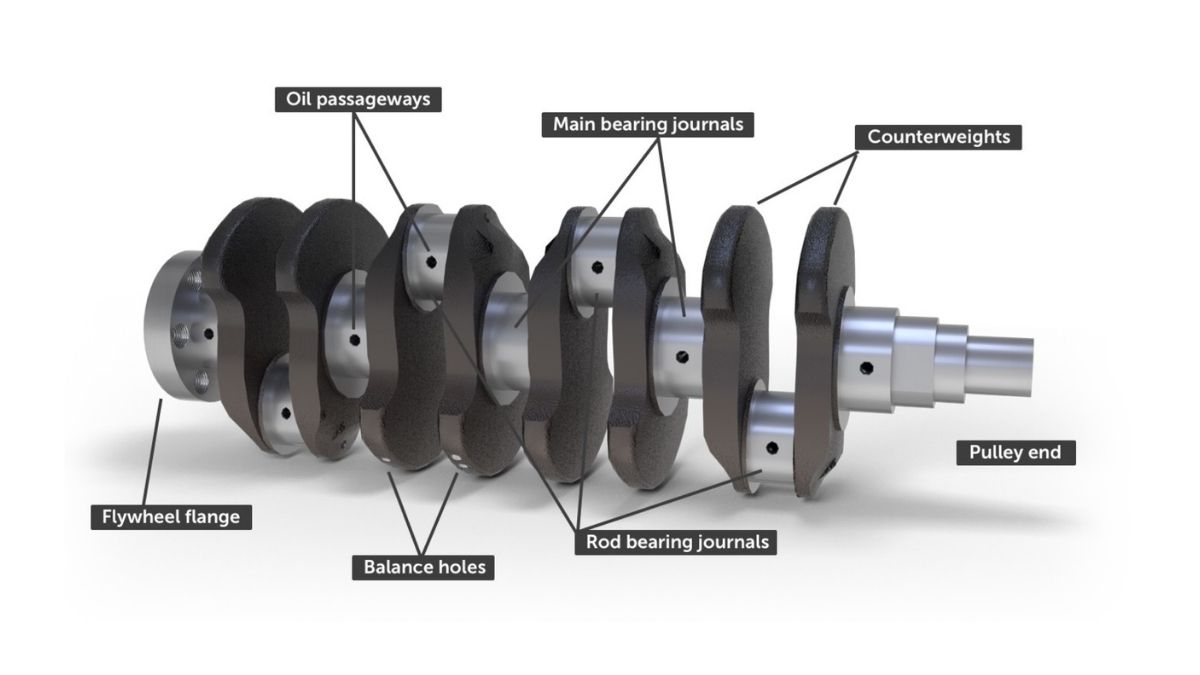

Compression System Components: The compression ratio – typically 8:1 to 12:1 for Otto cycles and 14:1 to 23:1 for Diesel cycles – is created through the relationship between cylinder volume, combustion chamber design, and piston crown configuration. Higher compression ratios require stronger connecting rods, pistons, and crankshafts to handle increased mechanical stress, while combustion chamber designs must prevent knock in Otto cycles or optimize injection patterns in Diesel cycles.

Ignition System Elements: Otto cycle engines require sophisticated ignition systems including spark plugs, ignition coils, and timing control to initiate combustion at precisely the right moment. Spark plug heat range must match combustion chamber temperatures, while ignition timing maps optimize combustion for various engine loads and speeds. Advanced systems include knock sensors and variable timing to prevent destructive combustion irregularities.

Fuel Delivery Architecture: Diesel cycles use high-pressure fuel injection systems (1,500-2,500+ PSI) with precision injectors that create specific spray patterns for optimal air-fuel mixing. Otto cycles traditionally used carburetors or port fuel injection (35-60 PSI), though modern engines increasingly employ direct injection systems (500-2,500 PSI) that inject fuel directly into the combustion chamber during specific cycle phases.

Heat Release Control Systems: Both cycles require sophisticated heat management through cooling systems, exhaust gas recirculation, and thermal barrier coatings. Lambda control systems in Otto cycles maintain stoichiometric air-fuel ratios (14.7:1) for optimal catalytic converter operation, while Diesel cycles operate with excess air and require different emission control approaches.

Knock Detection and Management: Otto cycle engines incorporate knock sensors – typically piezoelectric accelerometers – that detect abnormal combustion frequencies and trigger ignition timing retardation to prevent engine damage. Diesel cycles use different approaches, monitoring injection timing and fuel quality to prevent combustion knock or excessive pressure rise rates.

Flame Propagation Architecture: Combustion chamber designs specifically optimize flame propagation characteristics for each cycle type. Otto cycles use compact chambers with centralized spark plugs to minimize flame travel distance, while Diesel cycles employ bowl-in-piston designs that create controlled turbulence for thorough air-fuel mixing during injection.

How Combustion Cycles Work: Step-by-Step Operation

Understanding combustion cycles requires examining both the fundamental four-stroke sequence and the crucial differences between Otto and Diesel thermodynamic processes. Each cycle optimizes different aspects of combustion physics to achieve specific performance and efficiency goals.

Step 1: Intake and Mixture Preparation Phase

Otto Cycle Intake Process: The Otto cycle begins with the intake stroke drawing a homogeneous air-fuel mixture (typically 14.7:1 air-fuel ratio) into the cylinder through the open intake valve. Modern port fuel injection or direct injection systems precisely meter fuel quantity based on airflow measurements from the mass airflow sensor, creating consistent mixture strength across all operating conditions. The intake manifold design and valve timing determine how effectively the cylinder fills, with volumetric efficiency ranging from 80-95% in naturally aspirated engines.

Why Homogeneous Mixing Matters: Otto cycle engines require uniform fuel distribution throughout the combustion chamber because spark ignition can only initiate combustion at a single point. The flame front must propagate outward at 15-40 meters per second to reach all mixture areas before the expansion stroke begins. Inadequate mixing creates lean spots that burn incompletely or rich spots that produce excessive emissions.

Diesel Cycle Air Intake: Diesel cycles intake only air during this stroke, achieving higher volumetric efficiency (90-98%) because air density is greater than air-fuel mixtures. The absence of throttling in most diesel engines (except for emissions control) reduces pumping losses and improves efficiency. Turbocharging is common in diesel engines because the compression ignition process can handle much higher cylinder pressures than spark ignition systems.

Intake Valve Timing Optimization: Advanced engines use variable valve timing to optimize intake events for different operating conditions. Early intake valve opening creates scavenging effects that help remove residual exhaust gases, while late intake valve closing can create effective compression ratio reduction for knock control in Otto cycles or emissions optimization in Diesel cycles.

Visual Reference Needed: [Cross-sectional diagram showing mixture distribution patterns in Otto vs. air-only intake in Diesel cycles]

Step 2: Compression Phase Dynamics

Otto Cycle Compression Characteristics: During compression, the Otto cycle compresses the air-fuel mixture to 8:1 to 12:1 ratios, raising mixture temperature to 800-1000°F and pressure to 150-300 PSI. The compression must occur quickly enough (typically within 180 degrees of crankshaft rotation) to prevent autoignition, while creating sufficient temperature and pressure for rapid flame propagation when spark ignition occurs. Higher compression ratios improve thermal efficiency but increase knock tendency.

Why Compression Ratio Limits Exist: Otto cycle compression ratios are limited by the autoignition temperature of gasoline (approximately 500°F under pressure). Exceeding safe compression limits causes knock – uncontrolled combustion that creates destructive pressure waves and can damage pistons, connecting rods, and bearings. Premium fuel with higher octane ratings allows higher compression ratios by resisting autoignition.

Diesel Cycle High-Compression Process: Diesel cycles compress air-only to 14:1 to 23:1 ratios, creating temperatures of 1000-1200°F and pressures of 400-600 PSI. This high compression is essential because diesel fuel requires these extreme conditions for autoignition – there are no spark plugs in diesel engines. The compressed air temperature must exceed diesel’s autoignition point (approximately 410°F) to ensure reliable ignition when fuel injection begins.

Compression Heating Physics: The compression process follows adiabatic principles, where rapid compression heats the charge according to the relationship T2 = T1 × (compression ratio)^0.4. This explains why diesel engines require much higher compression ratios – they depend entirely on compression heating to reach ignition temperature, while Otto cycles only need sufficient temperature and pressure for efficient combustion after spark ignition.

Variable Compression Technology: Modern engines increasingly employ variable compression ratio systems that adjust compression based on operating conditions. Lower ratios prevent knock during high-load operation, while higher ratios improve efficiency during light-load cruising. These systems typically adjust compression ratios from 8:1 to 14:1 automatically.

Visual Reference Needed: [Pressure-volume diagram comparing Otto and Diesel compression curves with temperature annotations]

Step 3: Combustion and Power Generation Process

Otto Cycle Spark Ignition: Ignition timing typically occurs 10-35 degrees before top dead center, with spark plugs creating an electric arc that initiates combustion in the compressed air-fuel mixture. The flame kernel grows rapidly, with flame front propagation reaching all areas of the combustion chamber within 15-25 degrees of crankshaft rotation. Peak combustion pressure (800-1500 PSI) occurs 8-15 degrees after top dead center for optimal power transfer to the crankshaft.

Why Ignition Timing Is Critical: Early ignition timing increases thermal efficiency by allowing more complete combustion, but excessive advance causes knock as peak pressure occurs while the piston is still rising. Late ignition timing prevents knock but reduces efficiency as peak pressure occurs too late in the expansion stroke. Modern engines continuously adjust ignition timing based on knock sensor feedback and operating conditions.

Diesel Cycle Compression Ignition: Fuel injection begins near top dead center (0-10 degrees before TDC) with high-pressure injection (1500-2500+ PSI) creating fine fuel droplets that autoignite when contacting the hot compressed air. Unlike Otto cycles, Diesel combustion occurs as a controlled burn rate determined by fuel injection rate and duration. This allows precise control over heat release rate and peak pressure development.

Heat Release Rate Control: Diesel cycles achieve superior efficiency through controlled heat release rates. Pilot injection (small pre-injection) conditions the combustion chamber, main injection provides primary power, and post-injection can reduce emissions. This multi-injection strategy optimizes combustion across different engine speeds and loads while maintaining acceptable noise levels.

Combustion Chamber Design Impact: Otto cycles use compact chambers with minimal surface area to reduce heat losses and promote rapid flame propagation. Diesel cycles employ bowl-in-piston designs that create controlled turbulence, mixing injected fuel with hot compressed air for complete combustion. The different chamber designs reflect each cycle’s fundamental combustion physics requirements.

Knock vs. Diesel Knock: Otto cycle knock involves premature autoignition of end gases creating destructive pressure waves. Diesel knock results from excessive ignition delay followed by rapid heat release, creating harsh combustion noise. While both are undesirable, they require completely different control strategies – ignition timing retard for Otto cycles, injection timing optimization for Diesel cycles.

Visual Reference Needed: [Heat release rate diagrams showing Otto vs. Diesel combustion characteristics over crankshaft degrees]

Step 4: Exhaust and Cycle Completion Process

Expansion and Power Extraction: Both cycles extract work during the expansion stroke as combustion gases push the piston downward. Otto cycles achieve peak pressures early and rely on rapid gas expansion, while Diesel cycles maintain higher working pressures longer due to controlled combustion duration. The expansion ratio (same as compression ratio in four-stroke engines) determines how much work energy can be extracted from the hot gases.

Why Diesel Cycles Extract More Energy: Diesel cycles operate with excess air (lean mixtures) and higher compression ratios, allowing more complete fuel utilization and greater expansion ratios. Otto cycles are limited by stoichiometric air-fuel requirements for catalytic converter operation and knock-limited compression ratios. This fundamental difference explains why diesel engines typically achieve 20-30% better fuel economy than equivalent gasoline engines.

Exhaust Valve Opening Timing: Exhaust valves typically open 40-60 degrees before bottom dead center while cylinder pressure is still 100-200 PSI above atmospheric. This blowdown period allows pressure-driven gas evacuation before the piston begins its exhaust stroke. Early exhaust valve opening reduces pumping work but slightly reduces expansion work – engine designers optimize this timing for best overall efficiency.

Residual Gas Management: Both cycles must manage residual exhaust gases that remain in the combustion chamber and mix with the fresh charge. Otto cycles are more sensitive to residual gas content because it dilutes the air-fuel mixture and reduces combustion speed. Diesel cycles can tolerate higher residual gas levels because they operate with excess air and controlled injection timing.

Exhaust Gas Recirculation (EGR): Modern engines deliberately introduce controlled amounts of exhaust gas back into the intake to reduce combustion temperatures and NOx formation. Otto cycles use EGR primarily for emissions control, while Diesel cycles use EGR for both emissions reduction and combustion noise control. EGR rates typically range from 5-15% in gasoline engines and 15-50% in diesel engines.

Visual Reference Needed: [Complete four-stroke cycle comparison showing Otto vs. Diesel pressure curves and valve timing events]

Step 5: Cycle Efficiency and Optimization Factors

Thermal Efficiency Fundamentals: Otto cycle theoretical (ideal) efficiency depends only on compression ratio: η = 1 – (1/r)^(γ-1), where r is compression ratio and γ is the specific heat ratio. Real Otto cycle efficiency ranges from 25-35% due to heat losses, incomplete combustion, and pumping losses. Diesel cycle efficiency is higher (35-45%) because of higher compression ratios and lean operation that reduces heat losses.

Why Diesel Cycles Are More Efficient: Multiple factors contribute to superior Diesel cycle efficiency: higher compression ratios extract more work per cycle, lean operation reduces heat losses to combustion chamber walls, no throttling reduces pumping losses, and higher energy density of diesel fuel provides more energy per unit volume. The controlled combustion process also allows optimal heat release timing across operating conditions.

Real-World Efficiency Factors: Actual engine efficiency depends on factors beyond basic thermodynamic cycles: friction losses (typically 10-15% of indicated power), pumping losses during gas exchange (5-12% depending on throttling), heat losses to cooling system (25-30% of fuel energy), and incomplete combustion losses (2-8% depending on operating conditions and mixture quality).

Advanced Cycle Modifications: Modern engines employ various techniques to improve basic cycle efficiency: variable valve timing optimizes gas exchange, direct injection improves mixture control, turbocharging increases power density, and exhaust gas recirculation reduces heat losses. These modifications can improve efficiency by 10-20% compared to basic naturally aspirated engines.

Operating Condition Impact: Both cycles perform optimally under different conditions. Otto cycles achieve peak efficiency at moderate loads with minimal throttling, while Diesel cycles maintain high efficiency across a broader load range due to quality (lean) mixture control rather than quantity (throttle) control. This explains why diesel engines excel in steady-state applications like highway cruising and commercial vehicles.

Visual Reference Needed: [Efficiency map comparison showing Otto vs. Diesel brake specific fuel consumption across speed and load ranges]

Combustion Cycles Location and Access Guide

Combustion cycles occur within the engine’s cylinders, but understanding and servicing these systems requires access to multiple engine components including the combustion chambers, fuel delivery systems, ignition systems, and emission control equipment.

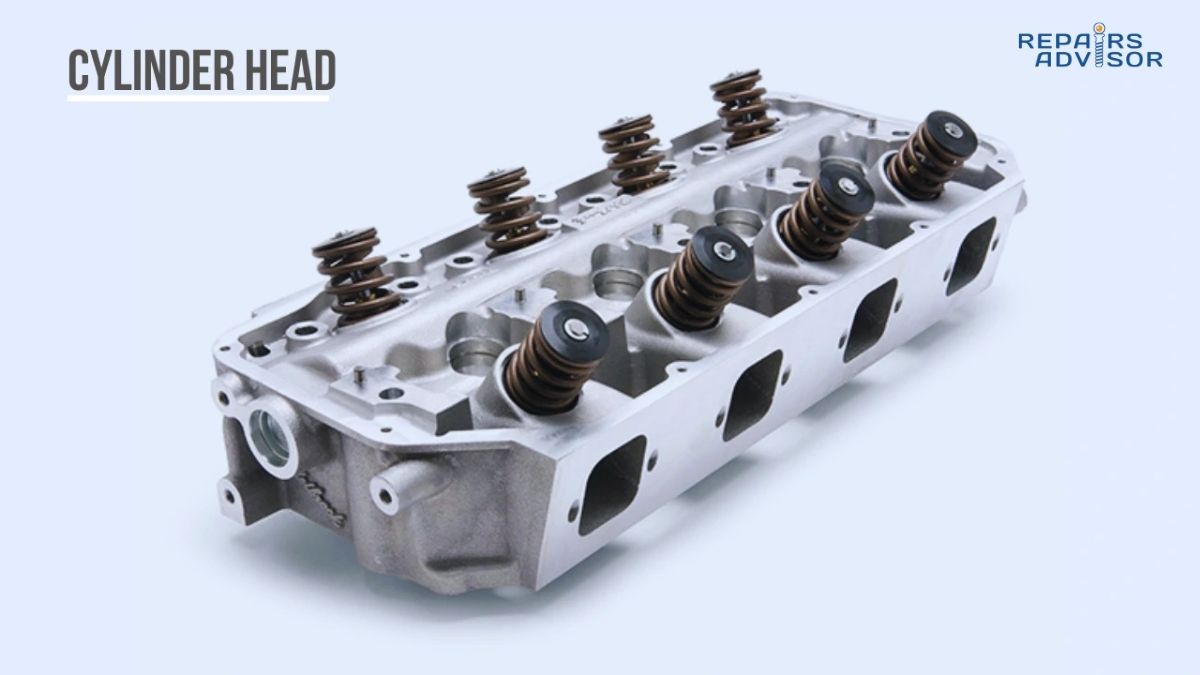

Primary Location: Combustion cycles take place in the space above each piston when it reaches top dead center, formed by the cylinder bore, piston crown, and combustion chamber in the cylinder head. This space varies from 40-80cc in modern engines, with the exact volume determining compression ratio when combined with total cylinder displacement.

Visual Identification of Cycle Type: You can identify engine cycle type through several visual cues: Otto cycle engines have spark plugs threaded into the cylinder head, while Diesel engines have fuel injectors and often glow plugs for cold starting. Diesel engines typically have much more robust construction with heavier engine blocks, larger crankshafts, and more substantial fuel injection systems due to higher operating pressures.

Access Requirements for Cycle Analysis: Combustion cycle diagnosis requires specialized equipment including compression gauges, cylinder leakdown testers, pressure transducers for combustion analysis, and oscilloscopes for ignition system analysis. Basic cycle health can be assessed through compression testing (requiring spark plug or glow plug removal), while detailed analysis needs professional equipment and training.

Component Access Considerations: Otto cycle service requires access to ignition components (spark plugs, ignition coils, timing systems) typically located on top of or alongside the engine. Diesel cycle service focuses on fuel injection systems often requiring special tools for high-pressure components. Both systems require access to intake and exhaust systems for complete cycle optimization.

Vehicle Configuration Impact: Transverse-mounted engines in front-wheel-drive vehicles often complicate access to rear cylinders for compression testing or spark plug service. Longitudinally-mounted engines typically provide better access but may require removal of intake manifolds or other components. V-configuration engines require separate access to each bank’s combustion components.

Safety Considerations: Combustion cycle service involves multiple hazards including residual pressure in fuel rails (especially high-pressure diesel systems), stored energy in ignition systems, and hot exhaust components. Always relieve fuel system pressure, disconnect battery power, and allow complete engine cooling before beginning service. Diesel fuel injection systems can inject fuel through skin – never check injection with hands or body parts.

Professional Service Requirements: Advanced combustion cycle analysis requires specialized diagnostic equipment including combustion analyzers, fuel injection testing equipment, and emission measurement tools. Fuel system service on modern high-pressure systems often exceeds DIY capabilities due to safety requirements and special tools. Ignition timing adjustment and compression ratio modifications require professional expertise and equipment.

Related Articles

For complete combustion cycle understanding, explore these related components and systems:

Direct Component Articles:

- How Your Car’s Engine Block Works – The foundation housing combustion cycles

- How Cylinder Heads Work – Upper combustion chamber architecture

- How Engine Pistons and Connecting Rods Work – Components creating compression ratios

- How Ignition Systems Work – Otto cycle spark ignition control

System Integration Articles:

- How Fuel Injection Systems Work – Precise fuel delivery for both cycles

- How Engine Management Systems Work – Electronic control of combustion parameters

- How Turbochargers Work – Forced induction for both cycle types

- How Variable Valve Timing Works – Cycle optimization technology

Fuel System Articles:

- How Diesel Fuel Systems Work – High-pressure Diesel cycle fuel delivery

- How Direct Injection Systems Work – Modern Otto cycle fuel delivery

- How Fuel Pumps Work – Fuel delivery system fundamentals

Troubleshooting Support:

- Have not received my order – Download assistance for engine repair manuals

- How can I search for specific information in the manual – Finding combustion system specifications

Equipment Categories:

- Car Manuals – Automotive combustion system documentation

- Engine Manuals – Specific engine type repair guides

- Truck Manuals – Heavy-duty diesel cycle systems

Disclaimer: This information is provided for educational purposes only. Combustion cycle analysis and modification involve complex procedures that may require specialized tools, equipment, and expertise. Always consult qualified professionals for fuel system service, ignition timing modifications, or compression ratio changes. Repairs Advisor provides technical documentation and manuals but does not perform direct repair services.